Blog

What Cause Your CNC Drilled Holes Failing Quality Inspections?

You finish a large production run, but the quality inspector rejects the batch. The holes are oval, rough, or slightly misplaced. You lose valuable time and money trying to guess...

Why is Through-Spindle Coolant Critical for CNC Deep Hole Drilling?

Drilling deep holes destroys tools when heat builds up and chips get stuck. If you rely on external nozzles, you will ruin your expensive workpieces and waste production time. Through-spindle...

What are the Differences Between Hydraulic and Servo Motor Feed in a CNC Drilling Machine?

You struggle to choose the right feed system for your drilling machine. A wrong choice leads to slow cycles, broken tools, and lost revenue. I will explain the real differences...

What is a Deep Hole Drilling Machine?

Drilling a truly deep, straight hole with a standard drill bit is often a recipe for disaster. The drill wanders off-center, chips clog the flutes causing the tool to jam...

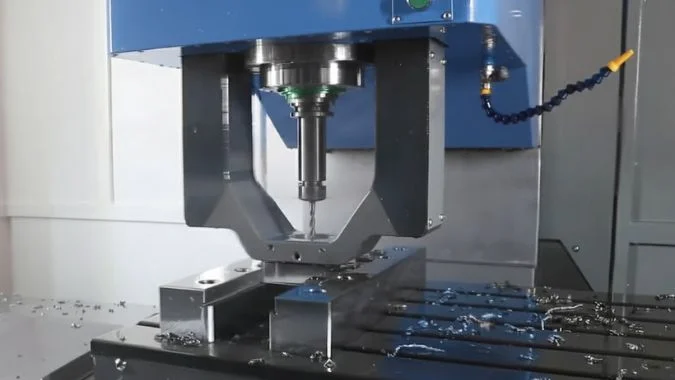

How Do Spindle & Structure Impact CNC Drill Performance & Lifespan?

Ever wonder why some CNC drills hum along for years while others struggle? The spindle and machine structure are key. Get these wrong, and performance suffers, and breakdowns become common....

What Workpiece Dimensions and Weight Must Your Ideal CNC Drilling Machine Accommodate?

Choosing a CNC drilling machine feels like a big step. If you pick one that’s too small or not sturdy enough for your parts, you’ll face constant problems. Getting this...

How to Improve Chip Removal Performance on CNC Drilling Machines?

Poor chip evacuation in CNC drilling can ruin workpieces, break expensive tools, and halt production. Yet many machinists overlook this critical aspect, focusing only on speeds and feeds while chip...

What Features Does a CNC Drilling Machine Need for Tapping?

Need to create internal threads after drilling holes on your CNC drilling machine? You might be wondering if your drilling machine is actually capable of tapping, or if you need...

What's the Real Difference between CNC Drilling Machine and CNC Machining Center on Drilling?

Need to drill lots of precise holes, maybe achieving tolerances as tight as ±0.005 inches? You might wonder if a dedicated CNC drilling machine, specialized for this task, is the...