Blog

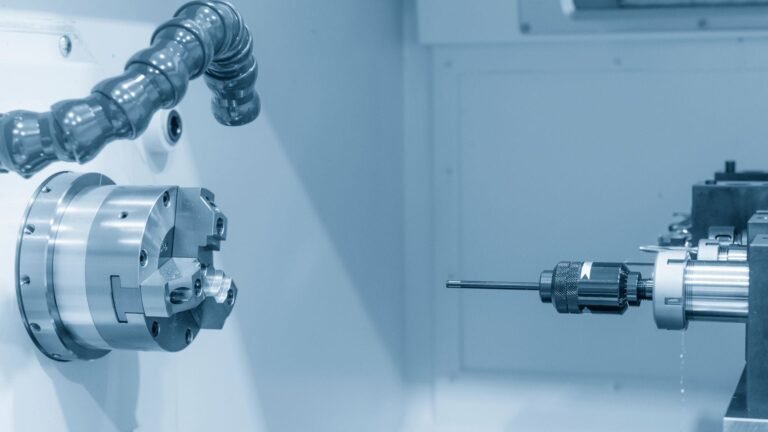

What Workpiece Features Affect CNC Lathe Selection?

Choosing the wrong CNC lathe can be a costly mistake. It leads to inefficiencies, an inability to process your parts, and ultimately, lost profits. Understanding key workpiece features is your...

What is a CNC Internal Grinding Machine?

Struggling with precise internal bore finishing? Manual methods are slow, inconsistent, and often lead to frustrating rework. CNC internal grinding offers the automated precision your workshop needs for superior quality....

Why is EDM Machining More Precise than Ordinary CNC Machining?

Manufacturing precision parts with conventional CNC machines often means battling tool deflection, material hardness limitations, and heat-induced distortion. Even with the best equipment, achieving extreme precision remains challenging, costing time...

How to Improve Chip Removal Performance on CNC Drilling Machines?

Poor chip evacuation in CNC drilling can ruin workpieces, break expensive tools, and halt production. Yet many machinists overlook this critical aspect, focusing only on speeds and feeds while chip...

Why Is Staged Infeed Often Used on CNC Lathes?

Turning parts in one big cut seems fast. But this can quickly damage your tools, your machine, and the part itself. Staged infeed, sometimes called incremental infeed, offers a much...

Why are Chatter Marks Appearing on The Surface of CNC-Turning Workpieces?

Are you tired of those ugly, wavy chatter marks ruining your carefully planned CNC-turned parts? This all-too-common issue wastes good material, adds extra time for rework, and ultimately chips away...

How Can You Repair Worn Pin Holes on Excavators with Minimal Downtime?

Your excavator’s pin holes are badly worn, causing sloppy movements and risking serious damage. The usual workshop repair means huge transport costs and weeks of the machine sitting idle. You...

What Heavy-Duty Machining Operations are Better Suited to a GMC Than an HMC?

You’re dealing with truly massive workpieces – think huge molds, aerospace spars stretching several meters, or giant machine beds. An HMC is a powerhouse, but sometimes even its capacity is...

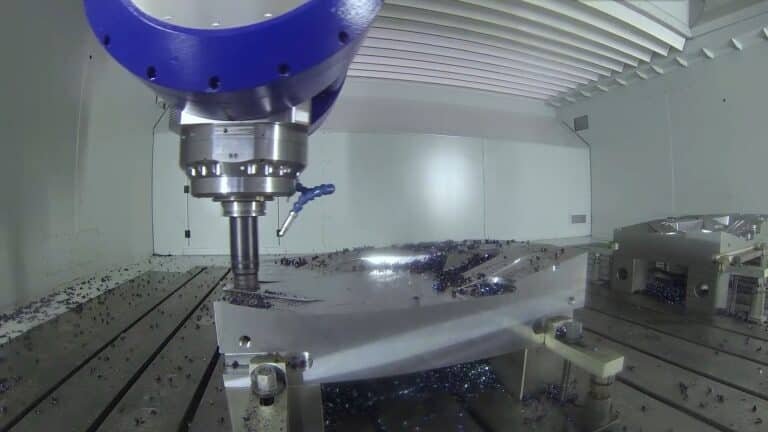

Why Is a Horizontal Machining Center More Suitable for Heavy-Duty Machining?

You need to machine large, heavy parts, and you’re wondering which CNC machine is up to the task. A Vertical Machining Center (VMC) seems versatile, but heavy-duty jobs make you...