Can an Aluminum Profile Machining Center Also Machine Steel?

You have a machine designed for aluminum, but a client asks you to cut a steel part. You worry that the harder material will damage your equipment or produce bad results.

Yes, an aluminum profile machining center can machine steels like die steel and #45 steel. There is no fundamental difference in the milling process. The success lies in adjusting your cutting parameters and changing your tools. You must prioritize tool life and rigidity over speed.

I have seen many shop owners turn down steel jobs because they thought their machines were "aluminum only." This is a mistake. With over 12 years of experience in machine tool industries, I know that the machine is capable if you treat it right. You just have to change how you think about the cut.

How Do Feed Rates and Spindle Speeds Differ When Switching Between Aluminum and Steel?

If you try to run steel at the same speed you run aluminum, you will burn your tool in seconds. The physics of the materials are completely different.

Aluminum machining focuses on high efficiency, using high spindle speeds (often 3-4 times faster than steel) to maximize material removal. Steel machining is limited by rigidity and tool load. You must set parameters conservatively, lowering both speed and feed to prevent excessive heat and protect the machine.

When we machine aluminum1, the goal is speed and efficiency. Aluminum is soft and dissipates heat well. It wants to stick to the tool. So, we spin the spindle fast—often in the range of thousands of RPM—and feed it fast. We want to rip the material out as quickly as the machine allows. The chips fly everywhere, and the heat leaves with the chips.

Steel is different. It is harder and generates significantly more resistance. If you run high speeds on steel, you generate too much friction. This creates massive heat that the material cannot release quickly. Because an aluminum profile machining center is not as heavy as a dedicated machining center, it lacks the same rigidity. High loads make it vibrate.

So, when I switch to steel, I slow everything down. I reduce the spindle speed significantly compared to aluminum. This keeps the heat down. I also lower the feed rate. This reduces the "chip load" or the amount of material the tooth cuts per rotation. This conservative approach protects the machine. It prevents the spindle from stalling and stops the frame from flexing. You trade time for capability. It takes longer to cut the steel part2, but the part comes out correct.

| Material | Goal | Speed (RPM) | Feed Rate | Limiting Factor |

|---|---|---|---|---|

| Aluminum | High Efficiency | High | High | Chip Evacuation |

| Steel | Tool Survival | Low | Low | Machine Rigidity |

What Adjustments in Tooling are Required if You Machine Steel on an Aluminum Center?

Using an aluminum end mill on steel is like trying to cut a steak with a plastic spoon. The geometry is wrong, and it will break eventually.

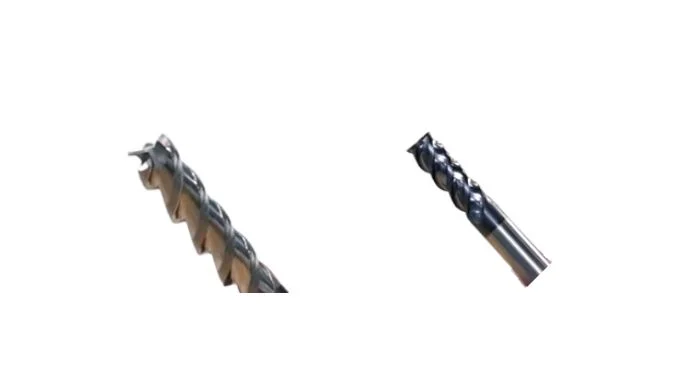

Aluminum tools use large rake angles and large chip flutes (1 or 3 flutes) to prevent sticking. Steel tools require smaller rake angles for strength and multi-flute designs (4 or more) to withstand high cutting forces. You need coated tools that resist high heat and abrasion.

The tool does the work. You must choose the right one. We always check the tool bin before a job. For aluminum, we use tools that look "sharp" and "open." They usually have one flute or three flutes. The "valleys" (flutes) between the blades are deep and wide. This is because aluminum chips are big and sticky. They need room to escape. If they get stuck, they weld to the tool.

For steel, we need a tool that is "strong3." We switch to tools with four, five, or six flutes. Why? Because steel puts a heavy load on the cutting edge. A tool with large flutes has a thin core. It is weak. It will snap under the pressure of steel. A tool with many flutes has a thick core. It is rigid.

Also, look at the coating. Aluminum tools are often uncoated or polished. Steel tools need coatings like TiAlN (Titanium Aluminum Nitride)4. These coatings act like a heat shield. They allow the tool to survive the high temperatures generated by cutting hard metal. We also change the angle. We use a smaller rake angle. This makes the cutting edge less sharp but much stronger. It pushes the steel rather than slicing it like a razor.

Why is Flood Coolant Often Necessary for Steel Machining but Not Always for Aluminum Profiles?

You might cut aluminum dry and just sweep up the chips later. If you try that with steel, you will ruin the part and the tool.

Aluminum dissipates heat rapidly, so air blowing is often enough to clear chips. Steel has low thermal conductivity, meaning heat builds up in the cut. You must use flood coolant to lubricate the tool, reduce friction, and prevent thermal deformation of the workpiece.

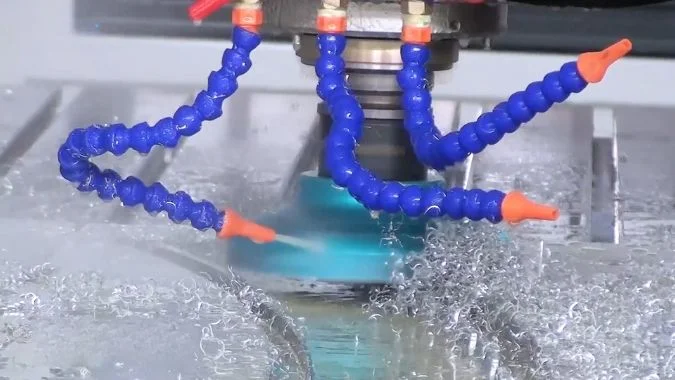

Heat is the enemy of precision. When I machine aluminum, I mostly worry about chips. I use an air blast or mist. The air blows the chips out of the hole. Because aluminum conducts heat so well, the heat leaves with the chip. The workpiece usually stays cool enough.

Steel holds onto heat. Its thermal conductivity is low. When you mill steel, the friction is intense. The tool gets hot. The workpiece gets hot. If the workpiece gets hot, it expands. You might cut the part to the perfect size, but when it cools down, it shrinks. Now your dimensions are wrong. This is "thermal deformation5."

To stop this, we use flood coolant6. We use a lot coolant. This does two things:

- Cooling: It keeps the temperature stable. The part stays the same size. The tool does not soften from overheating.

- Lubrication: It makes the surface slippery. This reduces the friction between the tool and the steel. Lower friction means less force is needed to cut. Since an aluminum profile center is not as rigid as a machining center, anything that reduces cutting force helps the machine cut smoothly without shaking.

What Changes Are Required Due to Rigidity Limitations of Aluminum Profile Machining Centers?

Your machine is built for speed, not brute force. If you push it too hard against steel, it will complain by vibrating.

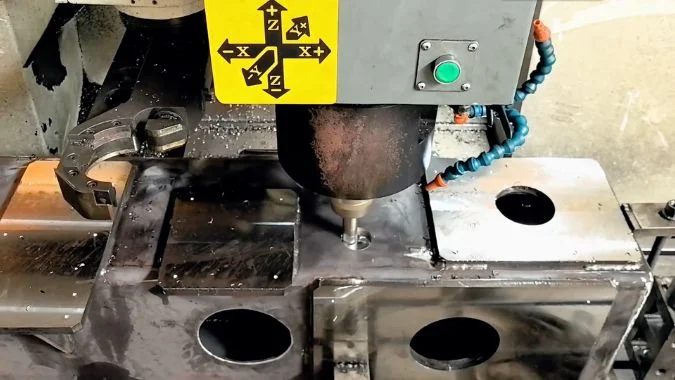

Machine rigidity is relative; you can machine harder materials if you modify your approach. Aluminum centers are lighter. To handle steel, you must minimize vibration by taking lighter cuts (smaller depth of cut) and increasing the number of passes. This reduces the load on the machine frame.

Rigidity is just a measure of how much the machine bends under load. A heavy-duty machining center is like a tank. It does not bend. An aluminum profile center is lighter. It is designed for fast movements. When you cut steel, the resistance creates a "push back" force. If this force is too high, the machine structure flexes slightly. This causes "chatter" or deflection. You hear a loud noise, and the surface of the steel looks like a record player disk.

Does this mean you cannot cut steel? No. It means you must lower the force. We do this by changing the "Depth of Cut7" (Ap) and "Width of Cut8" (Ae). Instead of trying to cut 5mm deep in one pass, I cut 1mm deep. I take five passes instead of one.

This reduces the load on the spindle and the frame. The force becomes small enough that the machine acts rigid again. It takes more time. You cannot compete with a heavy machining center on speed. But you can compete on quality. By respecting the limits of the machine and taking lighter bites, I can produce steel parts that are just as precise as those from a heavier machine.

Conclusion

An aluminum profile center can machine steel if you adapt. You must use stronger multi-flute tools, flood coolant, and conservative parameters to respect the machine’s rigidity limitations.

-

Explore this link to learn effective techniques and tips for machining aluminum efficiently. ↩

-

Discover expert advice on cutting steel parts to ensure precision and quality in your machining projects. ↩

-

Understanding the significance of strength in cutting tools can enhance your machining efficiency and tool longevity. ↩

-

Exploring TiAlN coatings can provide insights into improving tool performance and durability in high-temperature applications. ↩

-

Understanding thermal deformation is crucial for precision machining, as it affects the final dimensions of your workpiece. ↩

-

Exploring flood coolant can enhance your machining process by maintaining temperature and reducing friction, leading to better results. ↩

-

Understanding the Depth of Cut is crucial for optimizing machining processes and achieving high-quality results. ↩

-

Exploring the Width of Cut can help you enhance machining efficiency and improve the quality of your finished products. ↩

Chris Lu

Leveraging over a decade of hands-on experience in the machine tool industry, particularly with CNC machines, I'm here to help. Whether you have questions sparked by this post, need guidance on selecting the right equipment (CNC or conventional), are exploring custom machine solutions, or are ready to discuss a purchase, don't hesitate to CONTACT Me. Let's find the perfect machine tool for your needs.