How Can Worn Mining Conveyor Rollers Be Repaired With Short Downtime?

Chris Lu

Leveraging over a decade of hands-on experience in the machine tool industry, particularly with CNC machines, I'm here to help. Whether you have questions sparked by this post, need guidance on selecting the right equipment (CNC or conventional), are exploring custom machine solutions, or are ready to discuss a purchase, don't hesitate to CONTACT Me. Let's find the perfect machine tool for your needs.

Chris Lu

Leveraging over a decade of hands-on experience in the machine tool industry, particularly with CNC machines, I'm here to help. Whether you have questions sparked by this post, need guidance on selecting the right equipment (CNC or conventional), are exploring custom machine solutions, or are ready to discuss a purchase, don't hesitate to CONTACT Me. Let's find the perfect machine tool for your needs

A conveyor roller goes down, and your entire production line grinds to a halt. Every minute of downtime costs you money. On-site repair is the only way forward.

Repair worn mining rollers on-site using a portable shaft lathe. This machine clamps directly onto the roller’s shaft, allowing you to re-turn worn journals and surfaces to specification. This process avoids removal and transport, cutting repair time from weeks to just hours or days.

The old way was a logistical nightmare. You’d dismantle the massive roller, crane it onto a truck, and send it to a machine shop. The whole process could take days, even weeks. I’ve seen operations paralyzed by a single worn-out roller. But the game changed with portable machining. It reduces safety risks from heavy lifting and gets you back running in a fraction of the time. Let’s explore how this technology works.

What Is a Portable Shaft Lathe?

You need to repair a huge shaft. Dismantling it is a nightmare and costs a fortune. There has to be an easier way to machine it right where it is.

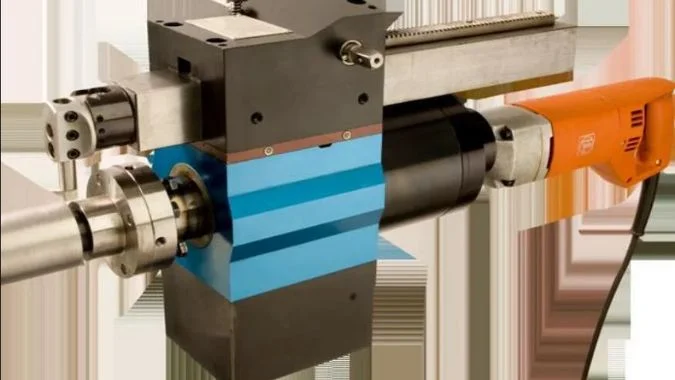

A portable shaft lathe is a compact, rugged machine tool designed for on-site turning. It mounts directly to a shaft with bolts or clamps, using rotating cutting tools to perform repairs without removing the component. It’s a complete machine shop that comes to you.

It’s modular, so we can set it up horizontally or vertically, and it often needs only a few inches of radial clearance to fit. These machines can be powered electrically, hydraulically, or pneumatically, making them versatile for any site condition. We just fix it in place, add a balance weight for smooth rotation, and start cutting. Inside, it has heavy-duty, zero-clearance spindle bearings1 to ensure stable, vibration-free operation—the key to a good finish. With adjustable tool heads and variable speed feeds, it’s a rigid, powerful, and precise machine that you can set up almost anywhere in under an hour.

What Types of Damage Can a Portable Shaft Lathe Repair?

A worn journal or a damaged seal groove can shut you down. Repairing these specific damages seems complex. But it doesn’t have to be with the right tool.

A portable shaft lathe excels at repairing common shaft damage on-site. It can fix wear and abrasion on journals, recut damaged threads and keyways, repair bearing seats, and machine new seal grooves or chamfers. It is not, however, suitable for severe structural cracks or failures.

Their versatility is their biggest strength. The most common job is fixing a worn journal by turning the surface smooth and true again. But they can do much more.

Common On-Site Repairs:

- Wear and Abrasion2: Turning down surfaces damaged by friction or contaminants to restore a uniform diameter.

- Bearing and Seal Seats: Resurfacing worn seats to ensure a proper fit for new components.

- Damaged Threads and Keyways: Precisely recutting stripped threads or damaged keyways.

- Surface Damage3: Removing scoring, pitting, and corrosion from a shaft’s surface.

- Weld Buildup: Machining down welded areas after a structural repair to bring the shaft back to its original dimensions.

The power behind these units is impressive. With constant torque, we can take a cutting depth of up to 3mm during roughing, which really speeds up the job. It’s the perfect tool for surface and feature restoration.

What Kind of Accuracy Can Be Achieved by Using a Portable Shaft Lathe?

You worry that an on-site repair won’t be as precise as a job done in a machine shop. This doubt can make you hesitate. But portable machines can deliver incredible accuracy.

Modern portable shaft lathes deliver workshop-level precision, achieving tolerances as tight as 0.001 inches (0.0254 mm) and a surface roughness up to Ra3.2. This ensures the repaired component meets or exceeds original equipment specifications for reliable operation.

I used to be skeptical too. The answer is in the engineering. These lathes are built with high-precision actuators4 and rigid mounting systems. Advanced features, like balanced feed mechanisms on some units, ensure smooth and accurate tool travel. The vibration-free spindle bearings5 are also key to achieving a fine finish. This combination allows for highly controlled cuts. A surface finish of Ra3.2 is very smooth and perfectly suitable for critical bearing journals and sealing surfaces. Whether we are correcting a deformed shaft end or machining a bearing seat, the accuracy we get from these portable machines is more than enough for even the most demanding applications.

What Industries Need a Portable Shaft Lathe For On-site Machining?

Your industry relies on massive, non-movable machinery. When a critical shaft fails, the costs are enormous. You need a repair solution that understands these unique challenges.

Many heavy industries rely on portable shaft lathes, including mining, power generation, oil and gas, shipbuilding, and heavy manufacturing. Any industry with large, hard-to-move rotating equipment can drastically reduce downtime and repair costs with on-site machining.

The applications for this technology are incredibly broad. I’ve seen them used in almost every heavy industry sector6 because the core problem is always the same: the equipment is too big, too critical, or too expensive to move. Bringing the machine tool to the job site is the only logical solution.

Here’s a quick table of where they are used:

| Industry | Common Application |

|---|---|

| Mining & Material Handling | Conveyor rollers, crushers, gearboxes, haul truck axles |

| Power Generation | Turbine and generator shafts (hydro, fossil, nuclear) |

| Oil & Gas | Pump shafts, pipeline components, drilling equipment |

| Shipbuilding & Marine | Propeller shafts, rudder posts, crane shafts |

| Heavy Manufacturing | Large motor shafts, press rollers, spindles |

| Construction & Infrastructure | On-site structural machining, heavy equipment repair |

| Paper & Pulp | Rollers in paper mills |

Conclusion

A portable shaft lathe is the best solution for repairing worn conveyor rollers and other large shafts on-site. It minimizes downtime, cuts costs, and delivers high-precision results right where you need them.

-

This resource will explain the significance of zero-clearance spindle bearings in achieving precision and stability in machinery. ↩

-

Exploring this resource will provide you with advanced techniques to effectively address wear and abrasion issues. ↩

-

This link will guide you through effective methods to repair surface damage, ensuring your machinery runs smoothly. ↩

-

Explore this link to understand how high-precision actuators enhance engineering processes and improve machine performance. ↩

-

Discover the importance of vibration-free spindle bearings in achieving superior machining accuracy and surface finishes. ↩

-

Explore this link to understand how technology is transforming heavy industries and improving efficiency. ↩