How Do CNC Internal and External Grinders Differ in Spindle and Application?

Choosing between internal and external grinders1? They look similar but do very different jobs. Using the wrong one for the task leads to costly errors and project delays.

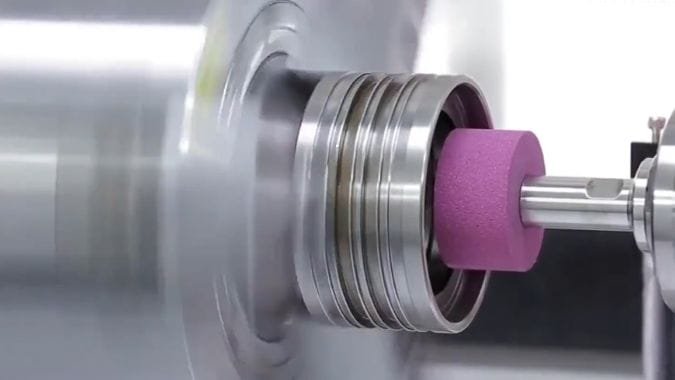

External grinders use rigid, low-speed spindles to machine the outside of shafts. In contrast, internal grinders use smaller, high-speed electric spindles designed to fit inside parts and precisely finish complex internal surfaces like cylinder walls.

I’ve seen people try to make one machine do the job of another, and it never ends well. The differences are fundamental, starting with how the machine is built from the ground up. An external grinder is built for rigidity with tapered bearings to handle long, heavy shafts. An internal grinder is built for agility, with a high-speed spindle2 that has to work in a tight, enclosed space, facing challenges like heat dissipation. It’s also important to distinguish them from another machine that works on holes.

What are the Difference Between CNC Internal Grinding and CNC Boring Machines?

Need to finish a precise internal hole? Boring and grinding might seem like two ways to do the same thing, but choosing wrong will ruin your part’s accuracy and finish.

Internal grinding uses a spinning abrasive wheel to achieve a fine, polished finish with sub-micron accuracy. Boring uses a single cutting tool to remove larger amounts of material, ideal for bigger holes but with less precision.

This is a question I get a lot from people new to precision machining3. It’s simple when you think about the tool itself. A boring machine uses a sharp tool to "carve" material away, much like a lathe but on the inside of a hole. An internal grinder uses a spinning wheel made of tiny, hard particles to "polish" the surface.

The Machining Method and Accuracy

A boring machine is for roughing out or enlarging existing holes, especially large ones in big parts like machine tool bases. It’s a cutting process, and its final accuracy is heavily dependent on the precision of the machine tool itself. Grinding is a finishing process. It removes only a tiny amount of material to bring a hole to its exact final dimension and create a perfectly smooth surface. I’ve used grinders to get a part to sub-micron accuracy4, a level of precision that boring just can’t touch.

Where We Use Them

We use boring machines5 on heavy machinery parts where the main goal is creating a large, functional hole in a box-type part. We use internal grinders6 for high-tech, precision components. For example, the planetary roller screw components in advanced robots7 need a perfect internal surface to work correctly, and that’s a job only a grinder can do.

| Feature | CNC Internal Grinder | CNC Boring Machine |

|---|---|---|

| Method | Abrasive wheel polishes surface | Single tool cuts material |

| Accuracy | Sub-micron level (Extremely High) | Medium precision (machine-dependent) |

| Application | Precision parts (robotics, bearings) | Large parts (heavy machinery frames) |

| Goal | Perfect surface finish and size | Creating or enlarging a hole |

Which Internal Geometries Require CNC Internal Grinding Machines?

Do you need to finish a complex shape inside a part? A standard drill or reamer can only make straight holes, leaving you stuck when the job calls for more.

CNC internal grinders are required for finishing high-precision cylindrical holes, tapered holes, and even complex internal profiles like curves or grooves inside parts like gears and bearing races, which other processes cannot achieve.

You might think an internal grinder just makes simple, straight holes, but that’s just scratching the surface of what these machines can do. The real power comes from the CNC control, which allows us to finish a variety of complex internal shapes8 that are impossible to create otherwise.

Standard Cylindrical and Tapered Holes

The most common job is grinding a perfectly straight cylindrical hole. Modern machines can handle an impressive diameter range, from as small as 2mm all the way up to 360mm. By swiveling the machine’s head, we can also grind perfect conical or tapered holes9 with a cone angle up to 60°. This is critical for parts that need a perfect seal or fit, like in a valve body.

Complex Internal Shapes and Multi-Tasking

This is where these machines really shine. With specialized fixtures and grinding tools, we can program the grinder to follow complex paths, creating curved surfaces or internal grooves. This is essential for the internal surfaces of gears or the races inside high-performance bearings. Some of our more advanced machines are compound grinders. They have a second external grinding head that can also finish the external diameter and face of the part in the same setup. This saves a huge amount of time and guarantees perfect concentricity between the inner and outer surfaces.

When Is CNC Internal Grinding the Most Cost-Effective for Precision Internal Diameter Work?

Worried that CNC grinding is too expensive for your project? The high price tag can be intimidating, but for certain jobs, it actually saves you a lot of money in the long run.

Internal grinding is most cost-effective in two key situations: when sub-micron precision is absolutely required, and when a complex part needs multiple internal features machined, which combines operations and reduces setup time.

A machine’s price is one thing, but the total cost to produce a perfect part is what really matters. Internal grinding becomes the cheapest option when the alternatives lead to failure or inefficiency.

When Precision is Non-Negotiable

If you’re making parts where the tolerance is extreme, like an optical glass mold, there is no other choice. When a part needs a roundness of ≤0.2μm or a surface finish (Ra) of ≤0.015μm, trying to use a cheaper process will just lead to a high scrap rate. The cost of one rejected high-value part is often more than the extra cost of grinding it correctly. Technologies like hydrostatic guideways, closed-loop control, and thermal compensation systems10 ensure a level of stability and nanometer-level precision that other processes can’t match.

When One Part Needs Multiple Operations

Think about a complex automotive or aerospace part that needs a cylinder, a taper, and an internal groove. You could set that part up on three different machines, but each setup costs time and introduces the risk of error. A CNC internal grinder with a modular design can do all of this in a single clamping. This multi-process integration11 dramatically shortens the production cycle and reduces overall labor costs. The initial investment pays for itself through massive gains in efficiency.

What Materials Are Commonly Machined with CNC Internal Grinders?

Are you trying to machine an extremely hard or brittle material? Standard cutting tools will wear out instantly or shatter the part, costing you time and money.

CNC internal grinders are used for very hard materials like hardened steel, carbide, and cast iron. They also excel at machining brittle non-metals like glass and granite, which cannot be machined with traditional cutting tools.

An internal grinder is a specialist’s tool designed for the toughest materials out there. If you can’t cut it, you can probably grind it. The key is that we must carefully adjust the grinding parameters—like the wheel speed and feed rate—for each specific material to ensure we get the accuracy and stability we need.

Metal Materials

The most common use is for hardened steel12s, like you find in bearing rings and gears. After heat treatment, these parts are too hard to cut. We also regularly grind various types of cast iron and extremely hard carbide for cutting tools and other precision mechanical parts.

Non-Metal Materials

This is where grinding truly stands apart. It’s the perfect method for brittle materials13 like glass and granite, which would shatter with any other machining process. We also use it for special applications involving softer materials like unhardened steel or non-ferrous metals when the surface finish requirements14 are exceptionally high.

| Material Type | Examples | Common Applications |

|---|---|---|

| Hardened Metals | Hardened Steel, Carbide, Cast Iron | Bearing rings, gears, cutting tools |

| Brittle Non-Metals | Glass, Granite, Ceramics | Optical components, metrology equipment |

| Special Metals | Unhardened Steel, Non-ferrous Metals | High-finish applications, specialty parts |

Conclusion

Internal and external grinders are highly specialized tools. Internal grinding is essential for achieving superior precision and fine finishes inside parts made from hard, demanding materials, securing its vital role in modern manufacturing.

-

Learn about the unique benefits of external grinders for machining the outside of shafts. ↩

-

Learn how high-speed spindles contribute to the efficiency of internal grinding processes. ↩

-

Delve into the world of precision machining and its importance in producing high-quality parts. ↩

-

Understand the significance of sub-micron accuracy in high-precision manufacturing. ↩

-

Find out how boring machines differ from internal grinders in terms of functionality and application. ↩

-

Explore how internal grinders enhance precision and efficiency in machining complex internal surfaces. ↩

-

Learn how internal grinding is essential for the functionality of advanced robotic systems. ↩

-

Discover the methods for machining complex internal shapes using advanced grinding techniques. ↩

-

Explore the techniques used to create tapered holes with CNC internal grinding. ↩

-

Explore how thermal compensation systems enhance precision in CNC machining. ↩

-

Understand how multi-process integration can streamline production and reduce costs. ↩

-

Learn about the difficulties in machining hardened steel and how internal grinders address them. ↩

-

Find out how CNC internal grinders effectively machine brittle materials like glass and granite. ↩

-

Explore the importance of surface finish requirements in achieving high-quality machined parts. ↩

Chris Lu

Leveraging over a decade of hands-on experience in the machine tool industry, particularly with CNC machines, I'm here to help. Whether you have questions sparked by this post, need guidance on selecting the right equipment (CNC or conventional), are exploring custom machine solutions, or are ready to discuss a purchase, don't hesitate to CONTACT Me. Let's find the perfect machine tool for your needs.