Choosing the right CNC lathe for your production needs is crucial for ensuring efficiency, precision, and long-term value in your business. With the variety of CNC lathes available, identifying the best fit depends on understanding key factors such as machining requirements, material compatibility, and specific features tailored to your work. Let’s dive into the main considerations to help you make an informed choice.

Buying a CNC lathe involves careful analysis of your machining goals, material specifications, precision needs, and whether you prefer a new or used machine. Discover the essential factors in selecting a lathe that will align perfectly with your production needs.

When it comes to CNC lathes, understanding your machining needs and the machine’s capabilities is paramount. Let’s explore each factor in detail to guide you through this decision process.

What Types of Materials Will You Be Machining with a CNC Lathe, and How Do They Affect the Lathe Selection?

The type of materials you plan to machine greatly impacts the selection of a CNC lathe. From metals to plastics, each material has distinct requirements for machine power, speed, and tooling.

Choosing a CNC lathe that matches your material needs is essential for efficient, high-quality production. High-torque, heavy-duty lathes may be necessary for tough metals, while lighter models may suffice for plastics or softer materials.

For hard metals like stainless steel or titanium, consider a CNC lathe with high spindle power and torque to handle the resistance of these materials without straining the machine. If your projects involve plastics or softer metals, a lathe with lower power can still offer precision without over-investing in heavy-duty features. Additionally, check for lathes with specific spindle or coolant systems tailored to your material type, as these can significantly improve performance and longevity.

Why Is It Important to Understand the Spindle Speed and Power Capabilities of a CNC Lathe?

The spindle speed and power capabilities of a CNC lathe directly impact its efficiency, productivity, and the quality of parts produced. Understanding these capabilities is essential to match the machine with your production needs.

Spindle speed and power determine a CNC lathe’s ability to handle different materials and achieve required machining precision. Balancing these factors with your production requirements ensures optimal performance.

High spindle speeds are ideal for small, precise parts, while lower speeds and higher torque are often necessary for heavy, tough materials. Ensure that the lathe’s speed range matches your material demands and production volume. A spindle with built-in cooling or vibration dampening features can be beneficial for extended precision and reduced wear on the machine over time.

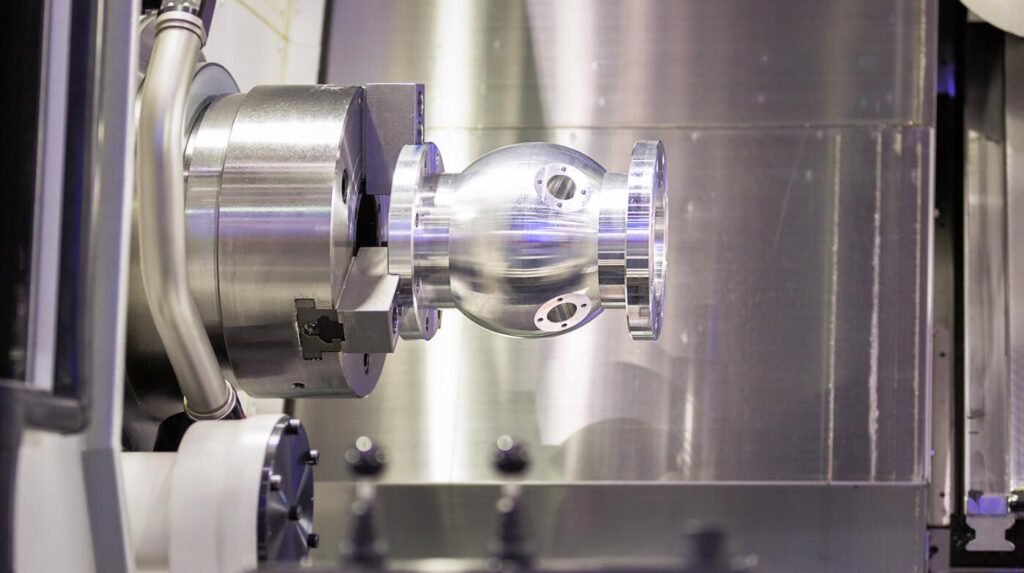

How Does the Size and Type of Parts You Need to Produce Impact the Choice of CNC Lathe?

The size and type of parts you plan to manufacture will determine the size, bed length, and spindle bore of the CNC lathe needed. The machine’s capacity to accommodate these specifications is crucial for optimal performance.

Selecting a CNC lathe that matches the dimensions of your workpieces ensures smooth production flow and prevents costly errors or machine downtime.

For larger workpieces, ensure the lathe has a wide enough spindle bore and sufficient bed length. Heavy-duty lathes are better suited for bulky parts and offer increased stability. For smaller, more intricate parts, a high-precision lathe with a compact bed may be ideal. Tailstock features are also valuable when working with longer materials, providing essential support for stable, accurate machining.

What Level of Automation and Tooling Options Should You Look for in a CNC Lathe for Efficiency?

Automation and tooling options significantly affect productivity and operational ease. Advanced automation features can streamline repetitive processes, saving time and reducing human error.

Opt for CNC lathes with automated tool changers, user-friendly control panels, and adequate support for advanced software integration to maximize efficiency.

Look for CNC lathes that offer multi-station turrets for fast tool changes, reducing idle time between machining steps. Some lathes come with automated chucks and advanced controllers compatible with CAD/CAM software, allowing seamless transitions from design to machining. Prioritize machines that offer high repeatability in their turrets and easy-to-learn control panels for improved productivity and reduced setup times.

Conclusion

In summary, choosing the best CNC lathe requires understanding your machining needs, materials, production requirements, and budget constraints. Here’s a quick recap of our tips for selecting the right CNC lathe:

1.Material Compatibility – Ensure the lathe’s spindle speed and power match your material requirements.

2.Precision & Capacity – Match the lathe’s size and specifications to your part dimensions and precision needs.

3.Automation & Tooling – Look for machines with automated features that support efficient, high-quality production.

By considering these factors, you can confidently select a CNC lathe that aligns with your business goals. For expert guidance in selecting a CNC lathe machine that best fits your requirements, reach out to a trusted provider for additional support and insights.

Chris Lu

Leveraging over a decade of hands-on experience in the machine tool industry, particularly with CNC machines, I'm here to help. Whether you have questions sparked by this post, need guidance on selecting the right equipment (CNC or conventional), are exploring custom machine solutions, or are ready to discuss a purchase, don't hesitate to CONTACT Me. Let's find the perfect machine tool for your needs.