How Do Spindle & Structure Impact CNC Drill Performance & Lifespan?

Ever wonder why some CNC drills hum along for years while others struggle? The spindle and machine structure are key. Get these wrong, and performance suffers, and breakdowns become common. It’s a costly lesson.

A CNC drill’s performance and lifespan heavily depend on a well-matched spindle for power and torque, combined with a rigid machine structure that minimizes vibration and maintains accuracy under cutting forces.

It’s not just about the flashy features you see on a brochure. I’ve learned the hard way that the real workhorses in a CNC drilling machine are the spindle – the part that actually does the cutting – and the machine’s overall frame or structure. If the spindle isn’t powerful or robust enough for your jobs, you’ll constantly fight with slow cycle times and worn tools. Insufficient power can even cause stalling. And if the machine frame isn’t rigid, you’ll chase accuracy problems and deal with vibrations that can shorten the life of the whole machine, not to mention your tools. Think of it like a high-performance athlete: they need both a strong heart (the spindle) and a solid skeleton (the machine structure) to perform at their best and stay healthy. So, let’s look at how these core elements really make or break your drilling operations and what you should be looking for.

What Spindle Power is Needed for Your Materials & Hole Sizes?

Are you struggling to drill certain materials, or finding your machine bogs down on larger holes? This often points to insufficient spindle power for the task at hand. It’s a common frustration.

The required spindle power for your CNC drilling machine is directly determined by the hardness, toughness, and thermal properties of the materials you process, as well as the diameter and cutting volume of the holes you intend to drill.

Spindle power isn’t a one-size-fits-all deal; it has to match the work. Using too much power on soft materials like wood can cause splintering, while too little on steel means poor performance.

Material Characteristics Demanding Power

The material you’re cutting plays a massive role.

- Hardness and Strength: If you’re drilling into high-hardness materials like stainless steel or strong titanium alloys, the cutting forces are much higher. So, you need more spindle power to overcome this resistance. Softer materials like basic aluminum or plastics require far less.

- Toughness: Some materials, like certain alloy steels, are very tough. They generate a lot of heat and sticky chips during drilling. This increases the load on the spindle, so more power is needed to keep things running smoothly.

- Thermal Conductivity: Materials that don’t conduct heat well, such as titanium alloys, cause the cutting zone to get very hot. This can increase tool wear and cutting resistance, again demanding more power from the spindle to maintain efficiency.

Hole Diameter’s Direct Link to Power Needs

The size of the hole you’re drilling is the other big piece of the puzzle.

- Diameter Size: It’s pretty logical – a larger hole diameter means a larger drill bit. This, in turn, means a larger cutting area and, therefore, increased cutting forces. The spindle power must be adequate for the largest drill bit you plan to use.

- Cutting Volume: When you drill larger holes, you’re often also using greater feed rates and cutting depths to be efficient. This directly increases the amount of material being removed per unit of time, which puts a heavier load on the spindle. So, your power requirement goes up accordingly.

Here’s a general idea of how material and hole size can influence power needs. Remember, these are just examples, and you should always check specific machine guidelines.

General Spindle Power Guidelines for CNC Drilling (Examples):

| Material Category | Typical Drill Diameter (mm) | Suggested Spindle Power (kW) | Common RPM Range |

|---|---|---|---|

| Softer Materials | Up to 5 | 0.8 – 1.0 | Up to 24,000 |

| (e.g., Wood, Plastics, Aluminum) | Up to 8 | 1.0 – 2.0 | Up to 24,000 |

| Up to 12 | 2.0 – 3.5 | Up to 24,000 | |

| Up to 16 | 3.5 – 6.0 | Up to 24,000 | |

| Harder Materials | Up to 10 | 3.0 – 4.0 | Around 15,000-18,000 |

| (e.g., Steel, Hard Alloys) | Up to 12 | 4.0 – 6.0 | Around 15,000-18,000 |

| Up to 16 | 6.0 – 7.5 | Around 15,000-18,000 | |

| Up to 20 | 7.5 – 10+ | Around 15,000-18,000 |

Thinking about these factors helps ensure you choose a machine that won’t let you down.

How Does Spindle Torque Affect Drilling Large or Tough Materials?

Ever had a drill bit stall or chatter when trying to make a big hole in hard metal? That’s often a sign of insufficient spindle torque, which is the twisting force the spindle can deliver.

Sufficient spindle torque is crucial for drilling large diameter holes or tough materials, as it provides the necessary rotational force to overcome high cutting resistance, ensuring stable cutting, preventing stalls, and minimizing tool wear.

I’ve definitely been there, trying to push a machine beyond its torque capabilities, especially at lower RPMs. The sound is awful, and the results are even worse – broken tools, bad surface finish, and sometimes a stalled spindle. Torque1 is like the muscle behind the speed. It’s especially important to remember that a spindle rated for high power at high RPMs might deliver much less actual power and torque at lower RPMs if it’s not designed for it. I once saw a powerful spindle struggle with a large Forstner bit in wood at low speed because its torque just wasn’t there in that range.

Key Factors Influencing Required Torque

Several things determine how much torque you need and what affects the spindle’s ability to deliver it:

- Material Cutting Force Coefficient2: Different materials resist cutting differently. Harder, tougher materials have a higher cutting force coefficient, meaning they require more torque to drill effectively.

- Hole and Drill Bit Diameter: Just like with power, a larger hole and a correspondingly larger drill bit will demand significantly more torque to rotate the tool through the material.

- Spindle Speed and Torque Curve3: It’s not just about peak power; you need adequate torque at the specific RPM you’ll be using for a given job. Some VFD-controlled spindles are better at maintaining torque at low RPMs, which is vital for certain large-diameter drilling tasks.

- Use of Cutting Fluid: Good lubrication is your friend! Using the right cutting fluid reduces friction between the drill bit and the workpiece. Less friction means the spindle needs less torque to do the same job.

Why Sufficient Torque is Non-Negotiable

Having enough spindle torque isn’t just a nice-to-have; it’s critical:

- Processing Quality: Plenty of torque ensures the drilling process is stable. This reduces vibration and noise, leading to better hole accuracy and a smoother surface finish.

- Equipment Stability and Safety: If the spindle doesn’t have enough torque and stalls or chatters violently, it can shake the machine, cause excessive noise, and in bad cases, even lead to equipment damage or failure.

- Reduced Drill Bit Wear: When the spindle can deliver consistent torque, the drill bit cuts more smoothly and efficiently. This reduces stress on the cutting edges, so your drill bits last longer.

For me, ensuring a machine has the torque for my toughest jobs, especially at the RPMs I’ll be using, is a top priority.

Why is Machine Frame Design Critical for Rigidity and Vibration?

Have you ever seen a CNC machine that seems to shake or where you struggle to hold tight tolerances? A lot of that comes down to the design of the machine’s frame. It’s the very foundation.

A CNC drilling machine’s frame design is critical because it dictates the machine’s overall rigidity, which is essential for resisting cutting forces and maintaining accuracy, and its ability to dampen or prevent harmful vibrations that degrade performance and tool life.

A strong, well-designed frame isn’t just about looking sturdy; it’s fundamental to the machine’s performance. Insufficient rigidity4 leads to poor tool life, inaccurate parts, and a bad surface finish.

The Foundation: Rigidity’s Role in Precision

Rigidity is all about how well the machine resists bending or deforming when it’s under the stress of cutting.

- Accuracy and Stability: A machine with high rigidity will hold its shape. This means the drill bit goes exactly where it’s told, even when cutting tough materials. This ensures you get accurate hole sizes and positions.

- Preventing Deformation: If the frame isn’t rigid enough, it will actually deform slightly under cutting forces. This directly affects the dimensional and shape accuracy of your workpiece. Even thermal changes can affect rigidity if not considered in the design.

Battling the Buzz: Understanding and Mitigating Vibration

Vibration is a big enemy in machining.

- Negative Impacts: Vibration can ruin the surface finish of your workpiece, cause your tools to wear out much faster, and even shorten the life of the machine tool itself. It often leads to chatter, a self-excited vibration5 that is particularly damaging.

- Design for Stability: Good frame design aims to reduce vibration. This involves using materials with good damping properties. Cast iron is often preferred for its excellent damping and stiffness. Steel frames, while stiff, sometimes need enhancement, like being filled with an epoxy granite composite, to improve their damping capabilities. The machine should also be dynamically balanced, have support points in the right places, and incorporate effective damping measures.

- External Factors: Even the floor matters! Setting up a CNC machine on a solid, crack-free concrete floor helps minimize external vibrations that could otherwise affect performance.

- Static vs. Dynamic Rigidity: Static rigidity handles steady loads. Dynamic rigidity resists vibrations. Both are crucial.

A well-designed frame isn’t just heavy; it’s engineered to be a stable, vibration-resistant platform.

How Do Key Components Ensure Drill Machine Rigidity?

We know a rigid frame is vital, but what specific parts of a CNC drill actually contribute to that all-important stiffness? It’s really a team effort involving several key components, all working together.

Key components like a heavy machine bed, a sturdy column, a robust spindle assembly, precise guideways, and proper assembly techniques work together to ensure a CNC drill machine’s rigidity, enabling it to absorb cutting forces, resist deflection, and maintain accuracy.

When I look at a new CNC drilling machine, I’m not just looking at the overall size. I’m mentally breaking it down, looking at how the main parts are built and how they connect. Each one has a role to play in keeping the machine stable and accurate. The choice of materials and how these parts are assembled are critical.

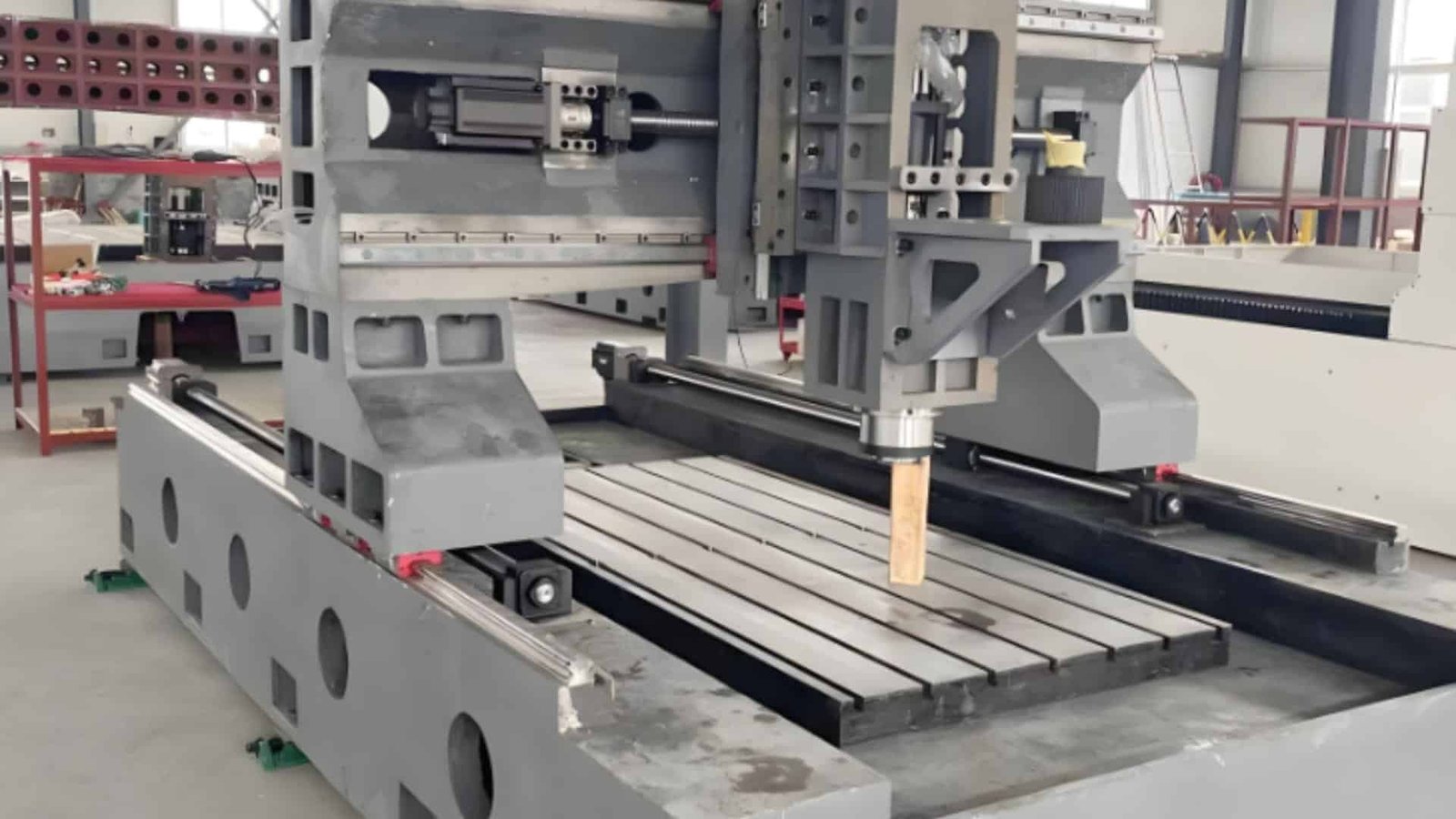

The Solid Bedrock: Machine Bed/Base

This is the foundation.

- Role: The bed supports everything else and absorbs vibrations.

- How it Adds Rigidity: Made from heavy materials like cast iron6 (known for good damping) or properly engineered welded steel structures7, often with large cross-sections and internal ribs. Some designs use steel weldments filled with materials like epoxy granite to further enhance damping and stiffness.

The Upright Pillar: Column and Frame

Supports the spindle head.

- Role: Must transfer drilling forces without flexing.

- How it Adds Rigidity: Often a box-shaped design or with internal bracing for maximum stiffness. High-quality construction is key to avoid weak points.

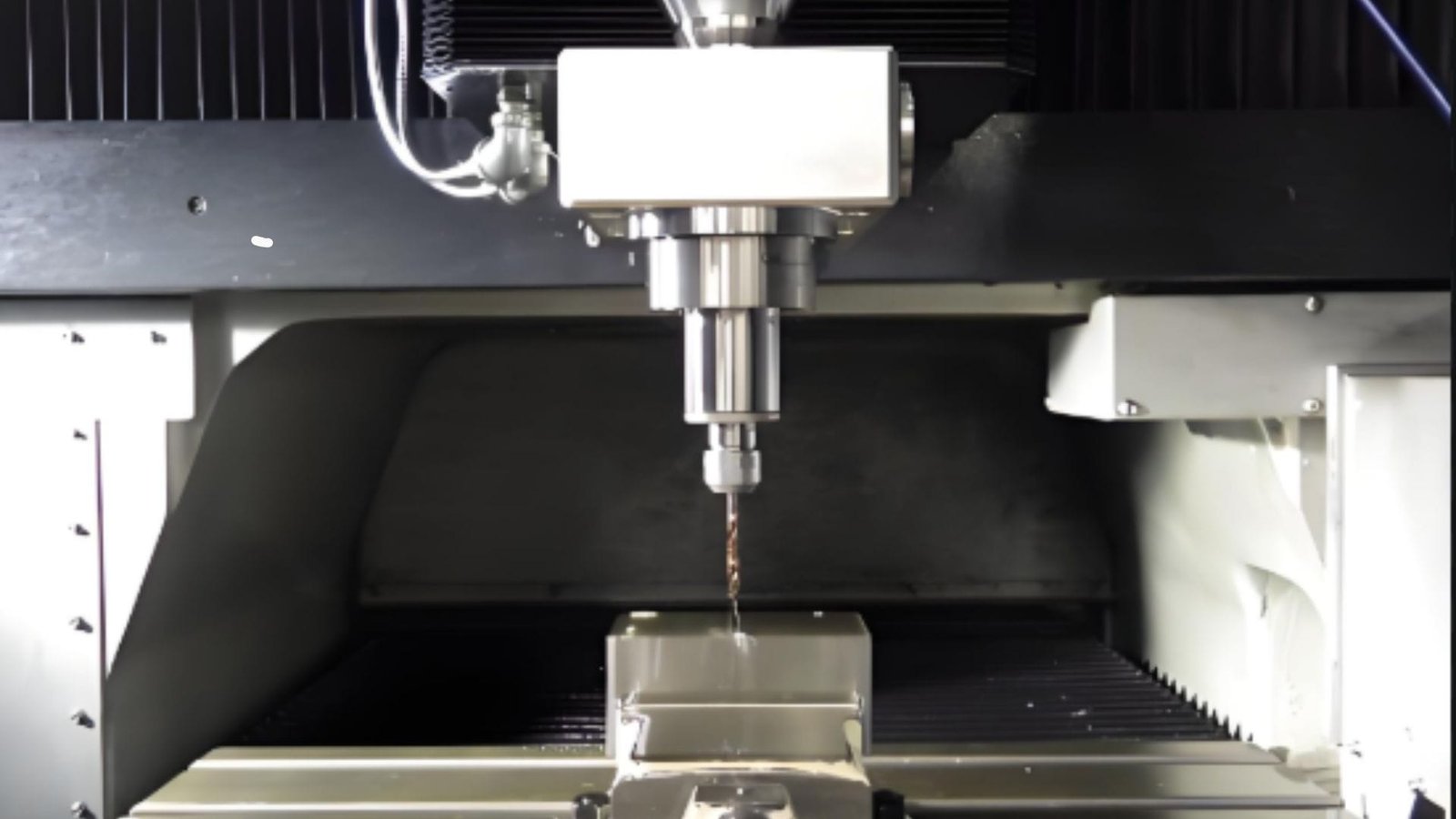

The Heart of Precision: Spindle and Spindle Housing

Delivers power and maintains alignment.

- Role: The spindle rotates the drill; its housing holds it precisely and rigidly.

- How it Adds Rigidity: A robust spindle shaft with high-precision bearings minimizes runout. The housing, usually integrated into the column and made of cast iron, provides a stiff enclosure.

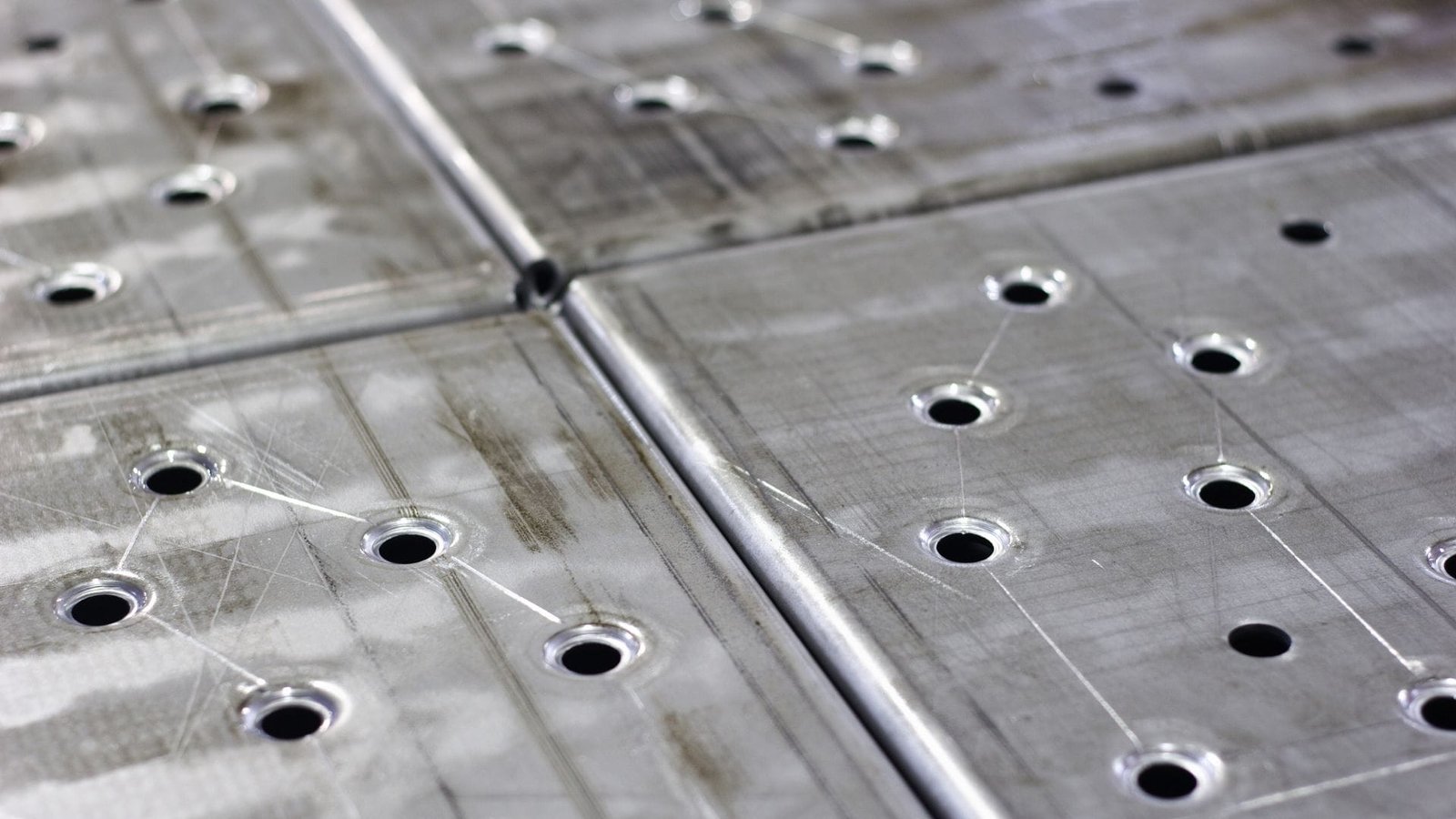

Guiding the Way: Linear Motion Systems

The rails and guides for movement.

- Role: Control precise movement along X, Y, or Z axes.

- How it Adds Rigidity: High-rigidity linear guideways or traditional box ways, made from hardened steel, provide smooth motion while resisting deformation. Large contact surfaces distribute forces. Proper preloading of these components is essential to reduce any play and enhance stability.

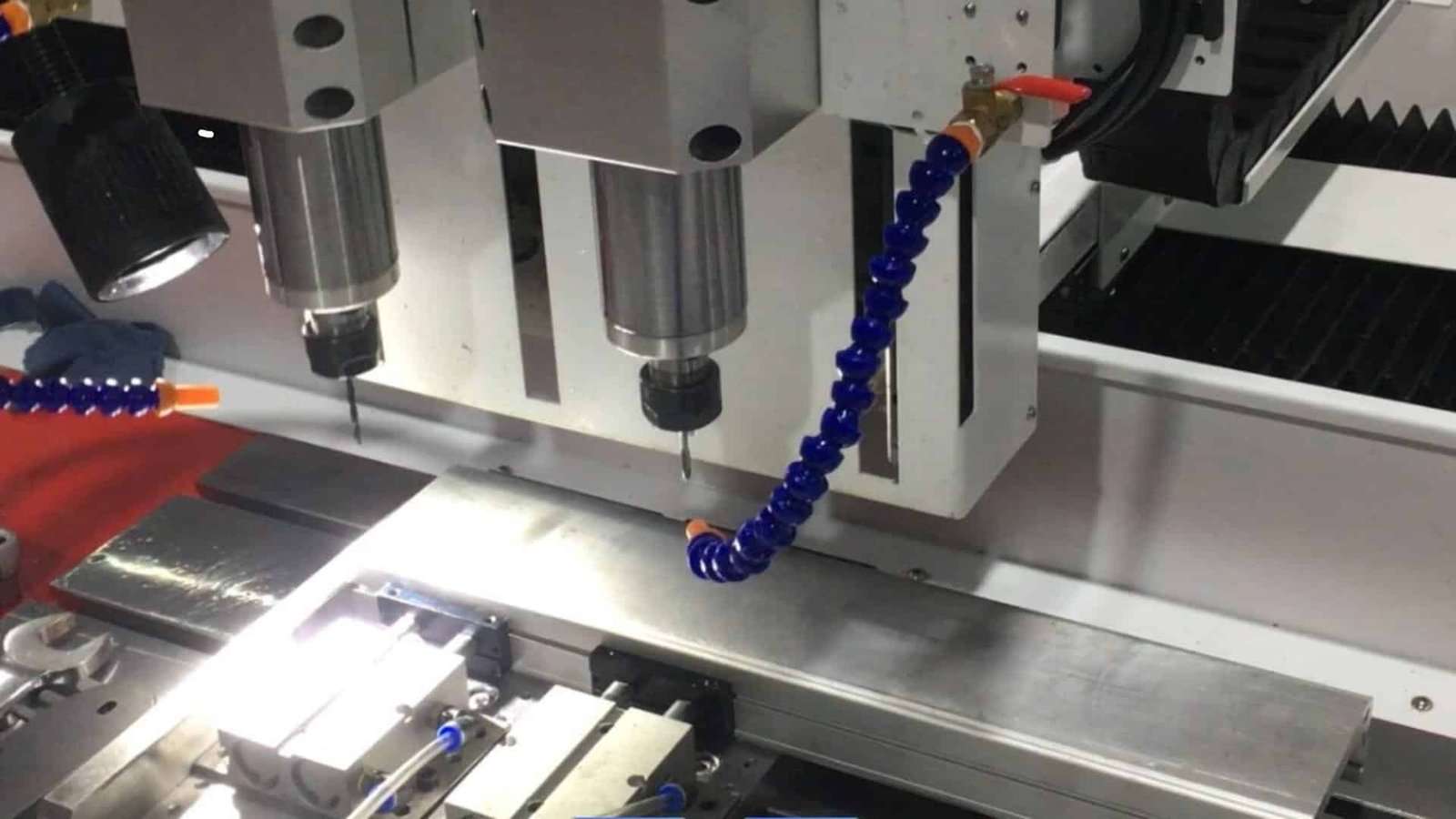

Assembly and Other Factors

- Proper Assembly: Even the best components won’t perform well if not assembled correctly. Preloading bearings and guideways reduces backlash and improves stiffness.

- Coolant Systems: While not a structural component, features like coolant-through drilling can improve stability during the cut by clearing chips efficiently, reducing forces and vibration.

All these parts, from the worktable securing the part to the drive system providing controlled motion, must be robust. If one link in this chain is weak, overall rigidity suffers.

Conclusion

In the end, your CNC drill’s spindle capabilities and structural integrity are not just features; they are the core of its performance. Getting these right means better parts, longer tool life, and a more reliable machine.

-

Understanding torque is essential for optimizing machining processes and ensuring equipment longevity. Explore this link to deepen your knowledge. ↩

-

Discover how the cutting force coefficient affects torque requirements and machining performance, crucial for effective drilling. ↩

-

Learn how spindle speed influences torque delivery to enhance your machining efficiency and quality. This resource will provide valuable insights. ↩

-

Understanding rigidity is crucial for enhancing machine performance and ensuring precision in machining processes. ↩

-

Exploring the effects of vibration can help you mitigate its negative impacts on machining quality and tool life. ↩

-

Discover the advantages of cast iron in machine components, particularly its damping properties and strength, essential for stability. ↩

-

Learn how properly engineered welded steel structures contribute to the overall rigidity and durability of machinery, ensuring long-term performance. ↩

Chris Lu

Leveraging over a decade of hands-on experience in the machine tool industry, particularly with CNC machines, I'm here to help. Whether you have questions sparked by this post, need guidance on selecting the right equipment (CNC or conventional), are exploring custom machine solutions, or are ready to discuss a purchase, don't hesitate to CONTACT Me. Let's find the perfect machine tool for your needs.