How Do You Repair a Damaged Turbine Casing in Short Down-Time?

Your turbine is down, and every second costs a fortune. The pressure is immense; you need a fast, precise repair without a six-week workshop visit. How is that even possible?

The fastest way to repair a damaged turbine casing is with on-site portable line boring. This method allows you to re-machine damaged bores using other undamaged bores as a reference, restoring perfect alignment without moving the entire casing.

Chemical corrosion had chewed up a critical bearing housing surface on their main turbine. The problem wasn’t just the one damaged bore. A turbine rotor is supported by multiple bearings, and their centerlines must form a perfectly straight line for the rotor to spin smoothly. If even one is out, the whole system is compromised. Taking that massive casing to a workshop would mean weeks, maybe months, of downtime. The solution was to take the workshop to the turbine. This is where line boring becomes an absolute game-changer, and it’s the only method that can solve this problem on-site.

What Exactly Is a Line Boring Machine?

You hear the term "line boring," but what is it really? It sounds complex, but the core idea is surprisingly straightforward and incredibly powerful for on-site repairs.

A portable line boring machine is a specialized, transportable tool designed to precisely repair and restore cylindrical bores in heavy machinery right where it stands, eliminating the need for costly disassembly and transport.

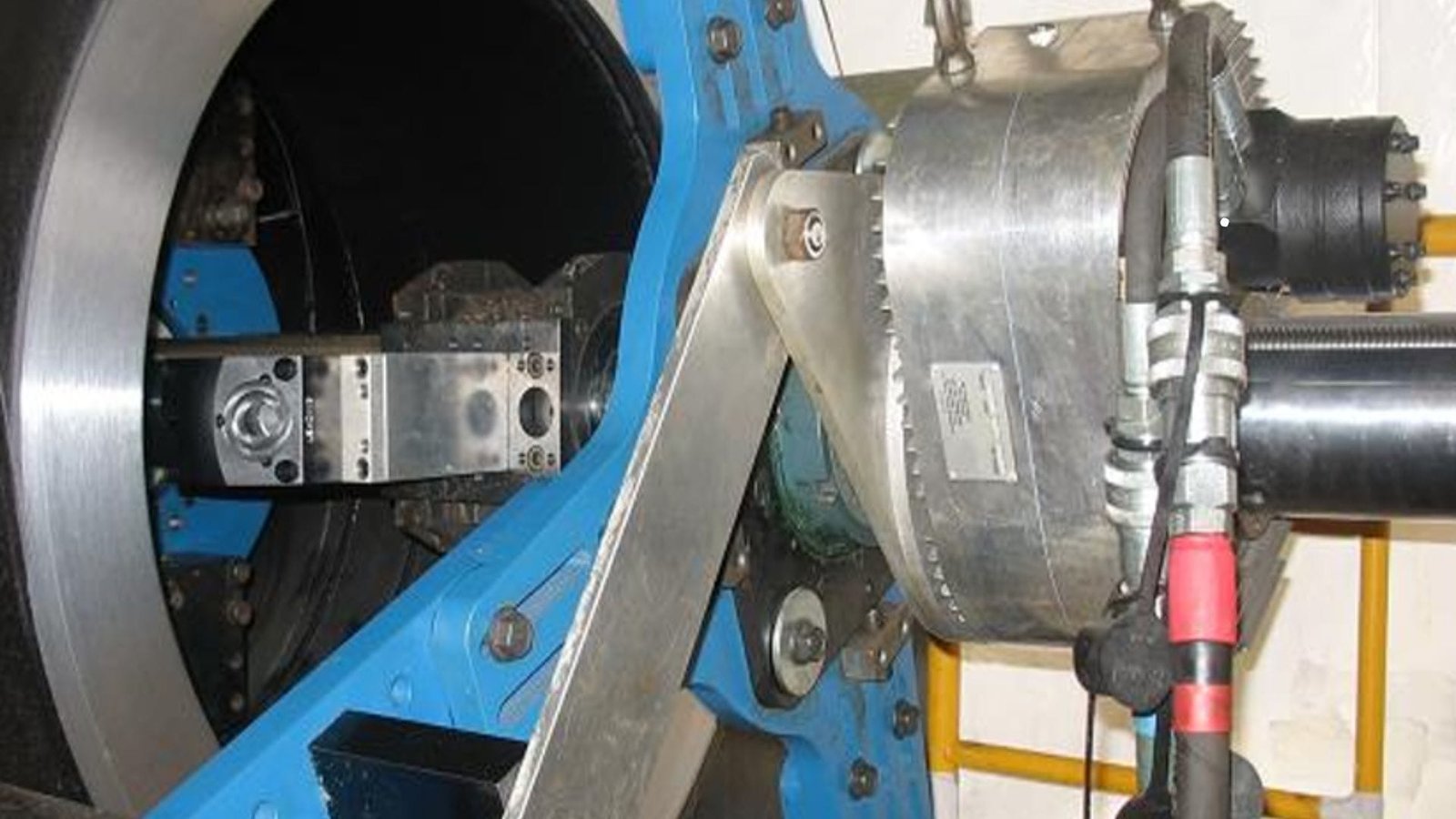

At its heart, a portable line boring machine1 is designed to do one thing with extreme precision: restore the internal dimensions and alignment of a worn or damaged cylindrical hole, or "bore." The process starts by mounting a rigid boring bar so that it passes through the bore—or a series of bores—that need repair. This bar is meticulously aligned, often using laser tools to verify its position relative to the OEM specifications. Once locked in place, a cutting tool2 is attached to the bar. As the bar rotates, the cutting tool is fed along its length, precisely shaving away material from the inner surface of the bore. This process is so accurate it can achieve tolerances as tight as a fraction of a thousandth of an inch, which is absolutely critical for preventing vibrations or steam leaks in high-performance machinery.

Many modern line boring machines also feature an automated welding system3. If a bore is excessively worn, the automated welder can be used to add layers of new material inside the bore first. Once built up, the line boring process begins, machining it back down to its original design dimensions. This two-step process is fundamental to true on-site restoration.

What Are the Advantages of Portable Line Boring for On-Site Repairs?

Heavy equipment breaks down, that’s a fact. But the real nightmare is the logistics of transporting it to a workshop for repair. There’s a much better way.

The main advantages are drastically reduced downtime, massive cost savings by avoiding transport and disassembly, and maintaining high precision. It allows repairs in remote locations, getting critical machinery back online faster.

The benefits of bringing the machine tool to the job are immense, and they go far beyond simple convenience. I’ve seen these advantages save projects time and time again.

Drastic Reduction in Downtime

This is the single biggest advantage. The traditional repair process—dismantle, transport, wait, repair, transport back, reassemble—can take weeks or months. With portable line boring4, the repair happens in situ. This reduces a timeline of weeks to just days, or even hours.

Significant Cost Savings5

When you eliminate transportation and disassembly, you eliminate a huge chunk of the cost. You’re no longer paying for heavy haulage, crane rentals, workshop fees, or the extensive labor hours for teardown and reassembly. The cost of an on-site repair is often a fraction of a traditional workshop repair.

High Precision Where It Counts6

Performing the repair on-site often results in a more accurate outcome. For machinery with multiple co-linear bores, like a turbine, using the machine’s own undamaged bores as reference points ensures perfect alignment. You are machining the component relative to its own true centerline, which can be more accurate than trying to recreate that alignment in a workshop.

Quick Setup and Versatility

These machines are designed for rapid response. In the hands of an experienced operator, a portable line boring machine can often be set up in well under an hour. Their modular design means they can be configured to work in tight, awkward spaces where other tools simply couldn’t fit.

What Are the Typical Use Cases for Large and Small Line Boring Machines?

Not all boring jobs are created equal. Using a massive machine for a small, precision job is inefficient, and a small machine can’t handle a huge construction frame.

Large line boring machines tackle big, on-site jobs like turbine casings and ship components. Small machines are for high-precision work on smaller parts like engine bearing pockets and gearbox housings.

The choice between a large or small line boring machine depends entirely on the job’s scale, location, and precision requirements. The difference is stark, both in capability and application.

Large Line Boring Machines

These are the heavy hitters, designed for components with huge diameters, sometimes up to 80 inches or more. Their modular design allows them to be set up in confined spaces, but their real strength is high torque and power, enabling them to make deep, aggressive cuts on massive workpieces.

- Typical Applications: Repairing steam and hydro turbine casings, machining marine stern tubes, aligning coupling holes, and re-boring large diesel engine bedplates.

Small Line Boring Machines

These machines are built for precision and flexibility, with boring diameters starting as small as 1.5 inches. They are lightweight and ideal for finer operations where achieving a perfect surface finish and tight tolerances on smaller components is the primary goal.

- Typical Applications: Repairing engine bearing pockets, re-boring valve bodies, and general maintenance on smaller machinery components like gearbox housings, hinge pins, and A-frame supports.

| Feature | Large Line Boring Machine | Small Line Boring Machine |

|---|---|---|

| Typical Diameter | 10 inches to 80+ inches | 1.5 inches to 10 inches |

| Processing Focus | High torque, deep cuts on massive components | High precision, fine finish on smaller parts |

| Primary Use Cases | Power generation turbines, marine propulsion, large engines | General maintenance, automotive, construction equipment pins/supports |

What Other Industries Commonly Utilize Line Boring Machines?

You might think this technology is only for power plants or massive ships. In reality, you’d be surprised how many essential heavy industries rely on this critical repair capability.

Besides power generation, line boring is crucial in Construction and Mining for equipment repair, Automotive for engine manufacturing, Marine and Shipbuilding for propulsion systems, and Oil and Gas for critical rig maintenance.

The ability to perform precise on-site repairs7 makes line boring an indispensable tool across a wide range of sectors.

-

Power Generation: This is a primary user for repairing turbine casings, nozzle chambers, and other critical components in steam, gas, and hydro power plants to maintain efficiency and prevent catastrophic failure.

-

Marine and Shipbuilding: In a saltwater environment, wear is relentless. Line boring is vital for machining stern tubes, rudder pintles, driveshaft housings, and A-frame supports, both during new construction and for in-service vessel repairs.

-

Heavy Equipment: This is a huge user. For construction and mining equipment like excavators and bulldozers, line boring is used on-site to repair bucket pins, hydraulic cylinder mounts, and articulation points, keeping machines working and projects on schedule.

-

Automotive: While mostly for larger engines, such as those in industrial or marine applications, line boring is essential for precision repairs on engine blocks and bearing housings to ensure performance and longevity.

-

Oil and Gas: In this industry, downtime is unacceptable. Line boring is used for on-site repairs of machinery on offshore rigs and in refineries, where large components like turbine casings and engine bedplates require maintenance to ensure operational continuity.

-

General Manufacturing: The technology is also used for precision machining8 of industrial components like gearboxes, press frames, and driveshaft housings, ensuring high-quality production and maintenance.

Conclusion

On-site line boring brings precision repair directly to heavy machinery. This crucial capability saves enormous time and money by drastically reducing downtime across many essential industries.

-

Explore this link to understand the mechanics and applications of portable line boring machines in precision engineering. ↩

-

Discover the various cutting tools used in line boring to enhance your knowledge of precision machining techniques. ↩

-

Learn about the integration of automated welding systems in line boring for improved efficiency and restoration quality. ↩

-

Explore the benefits of portable line boring, which can drastically reduce downtime and costs while improving precision in repairs. ↩

-

Learn how on-site repairs can save you money by eliminating transportation and disassembly costs, making maintenance more efficient. ↩

-

Discover the importance of high precision in repairs, ensuring better alignment and accuracy for machinery performance. ↩

-

Discover the advantages of on-site repairs and how they enhance efficiency and reduce downtime in industries. ↩

-

Learn about precision machining and its critical role in ensuring high-quality production in various manufacturing sectors. ↩

Chris Lu

Leveraging over a decade of hands-on experience in the machine tool industry, particularly with CNC machines, I'm here to help. Whether you have questions sparked by this post, need guidance on selecting the right equipment (CNC or conventional), are exploring custom machine solutions, or are ready to discuss a purchase, don't hesitate to CONTACT Me. Let's find the perfect machine tool for your needs

Chris Lu

Leveraging over a decade of hands-on experience in the machine tool industry, particularly with CNC machines, I'm here to help. Whether you have questions sparked by this post, need guidance on selecting the right equipment (CNC or conventional), are exploring custom machine solutions, or are ready to discuss a purchase, don't hesitate to CONTACT Me. Let's find the perfect machine tool for your needs