How Does Grinding Wheel Selection Impact Centerless Grinding Performance?

Chris Lu

Leveraging over a decade of hands-on experience in the machine tool industry, particularly with CNC machines, I'm here to help. Whether you have questions sparked by this post, need guidance on selecting the right equipment (CNC or conventional), are exploring custom machine solutions, or are ready to discuss a purchase, don't hesitate to CONTACT Me. Let's find the perfect machine tool for your needs.

Chris Lu

Leveraging over a decade of hands-on experience in the machine tool industry, particularly with CNC machines, I'm here to help. Whether you have questions sparked by this post, need guidance on selecting the right equipment (CNC or conventional), are exploring custom machine solutions, or are ready to discuss a purchase, don't hesitate to CONTACT Me. Let's find the perfect machine tool for your needs

Getting inconsistent finishes, slow material removal, or burning through expensive wheels on your centerless grinder? Choosing the wrong grinding wheel wastes time, material, and money, turning a precise process into a frustrating bottleneck.

Grinding wheel selection is critical; factors like abrasive type (e.g., conventional vs. superabrasives like CBN/Diamond), grain size, bond, and hardness directly dictate material removal rate, surface finish, wheel life, and suitability for specific workpiece materials.

Picking the right wheel characteristics is fundamental for top performance. Superabrasives, for instance, offer longer life and maintain sharpness on hard metals but come at a higher cost. But even the best wheel needs the correct machine setup to shine. Many parameters demand careful attention before you even start grinding.

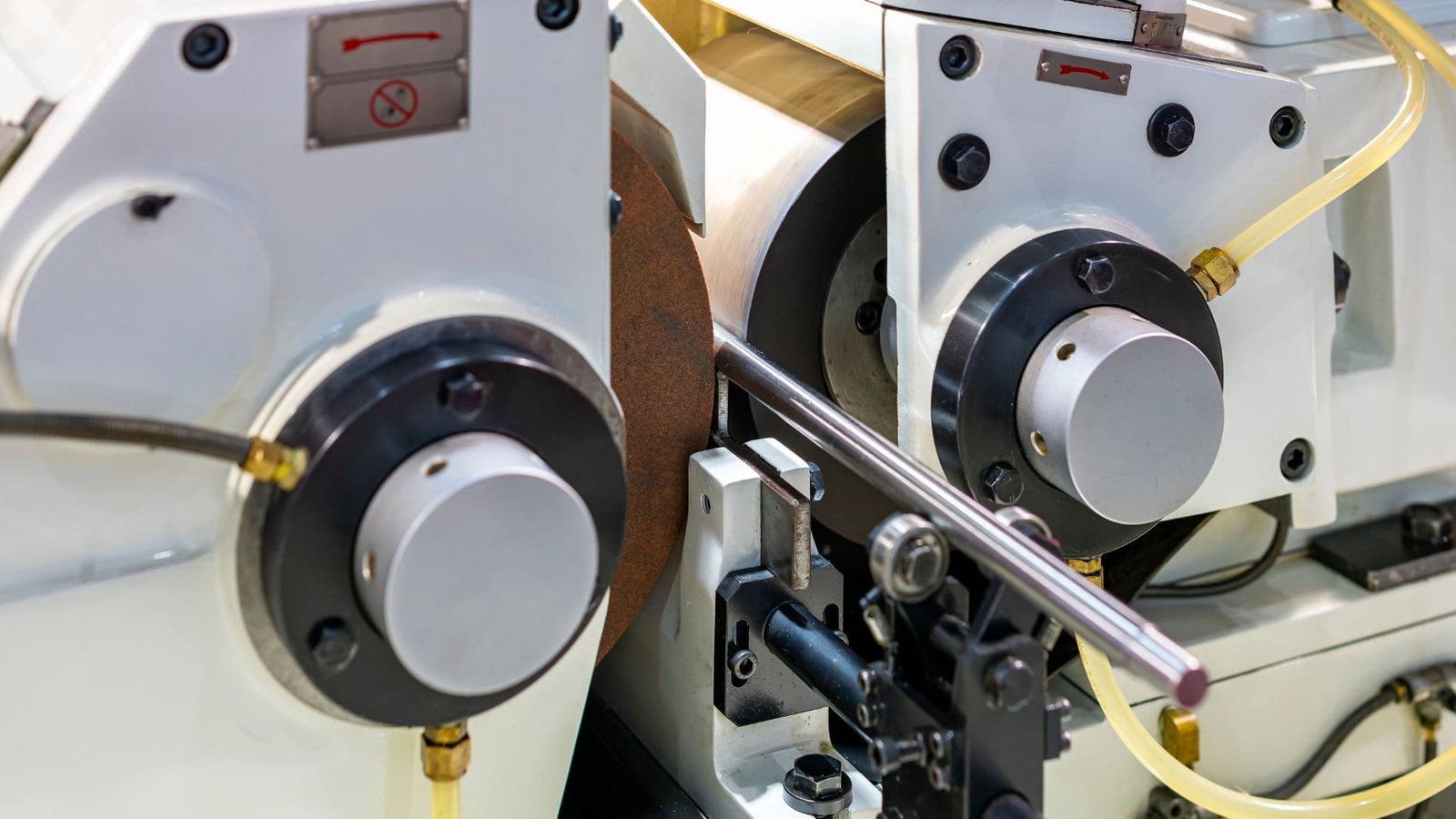

What Key Parameters Must Be Considered When Setting Up a Centerless Grinding Operation?

Struggling with chatter, out-of-roundness, or inconsistent sizes coming off your centerless grinder? Chasing setup variables costs valuable time and results in scrap. Nailing the initial parameters is the foundation for any successful grinding operation.

Key setup parameters include selecting appropriate grinding and regulating wheels, setting the work rest blade angle and height correctly, choosing optimal wheel speeds, managing coolant effectively, and deciding between thrufeed or infeed methods based on the part.

At J&M Machine Tools, we know that overlooking these fundamentals is where many issues begin. Your research reinforces a comprehensive checklist:

- Grinding & Regulating Wheels: Select the right abrasive type (e.g., Aluminum Oxide, Silicon Carbide, or superabrasives like CBN/Diamond for hard materials), grain size (coarser for roughing, finer for finishing), bond type (e.g., vitrified, resinoid), and hardness for both wheels based on the workpiece material and finish requirements. The regulating wheel controls workpiece rotation and feed.

- Work Rest Blade: Crucial for support. Its material, height, and especially its angle (more on this next) must be set correctly.

- Wheel Speeds: The grinding wheel needs sufficient surface speed for cutting, while the regulating wheel speed controls the workpiece’s rotation speed. These must be balanced.

- Work Height: The height of the workpiece centerline relative to the wheel centerlines affects stability and roundness. Incorrect height can cause chatter or lobing.

- Coolant1: Proper type, flow rate, and pressure are non-negotiable for cooling, flushing swarf, and lubrication. Insufficient coolant leads to thermal damage and poor finish.

- Grinding Method2: Choose thrufeed for simple cylinders or infeed (plunge) for parts with heads, tapers, or multiple diameters.

- Machine Alignment & Dressing: Ensure the machine guides are aligned, and both grinding and regulating wheels are properly dressed (trued) for the correct shape and sharpness. Modern CNC controls can help maintain precision.

- Operator Experience3: While modern machines help, an experienced operator’s ability to fine-tune these parameters remains invaluable.

What is the Function of the Work Rest Blade and How Does its Angle Affect Centerless Grinding Quality?

Are your ground parts consistently out-of-round, tapered, or showing chatter marks despite good wheels and setup? Don’t overlook the work rest blade – its condition and angle critically influence grinding outcomes.

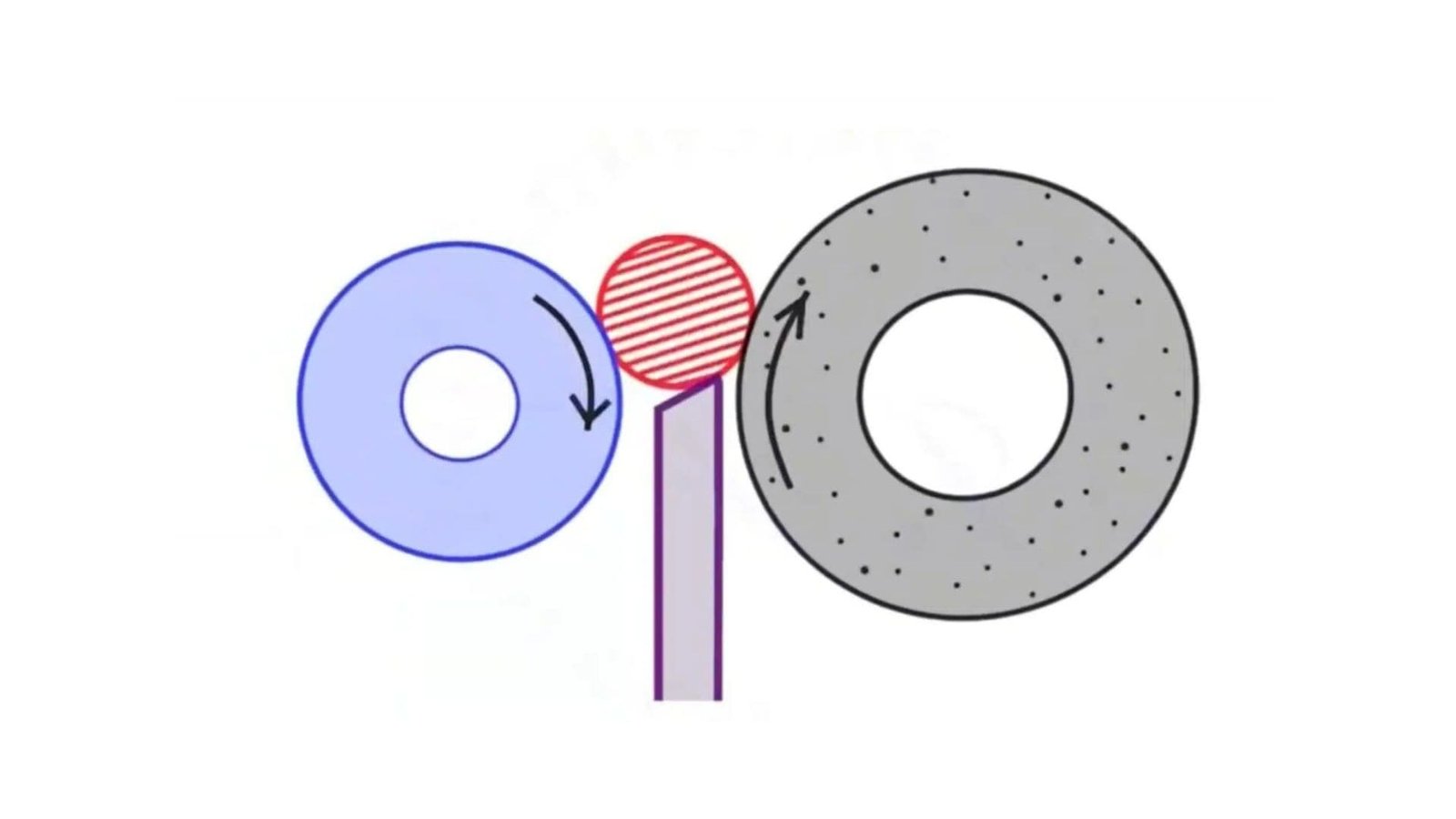

The work rest blade supports the workpiece between the grinding and regulating wheels, ensuring stability. Its angle significantly impacts workpiece stability, roundness, and surface finish by controlling the pressure against the regulating wheel.

Think of the work rest blade as the critical third point of contact. Your insights confirm its importance beyond just holding the part up. Its primary function is stable support4. The angle of the blade’s top surface5 plays a key role:

- Steeper Angle (e.g., 30°): Often recommended for narrower wheels (like 4" / 101.6mm) or smaller diameter workpieces. This increases the pressure pushing the workpiece against the regulating wheel, giving better rotational speed control and potentially improving the rounding effect. However, too steep an angle or excessive pressure can introduce vibration and chatter.

- Flatter Angle (e.g., 20°-25°): Typically used for wider wheels (like 6" / 152.4mm or 8" / 203.2mm) or larger workpieces. This reduces the downward pressure component, helping to minimize vibration and chatter6, leading to better stability and potentially improved roundness and surface finish on larger parts.

The optimal angle depends on the wheel width, workpiece diameter, and material. Incorrect angle or a worn/damaged blade leads directly to geometric errors (poor roundness, cylindricity) and surface finish defects. Regular inspection and precise adjustment are vital.

What Are the Differences Between Infeed and Thrufeed Centerless Grinding?

Unsure whether infeed or thrufeed grinding is right for your parts? Using the wrong method leads to inefficiency, poor quality, or makes the job impossible. Understanding the distinction is key to process selection.

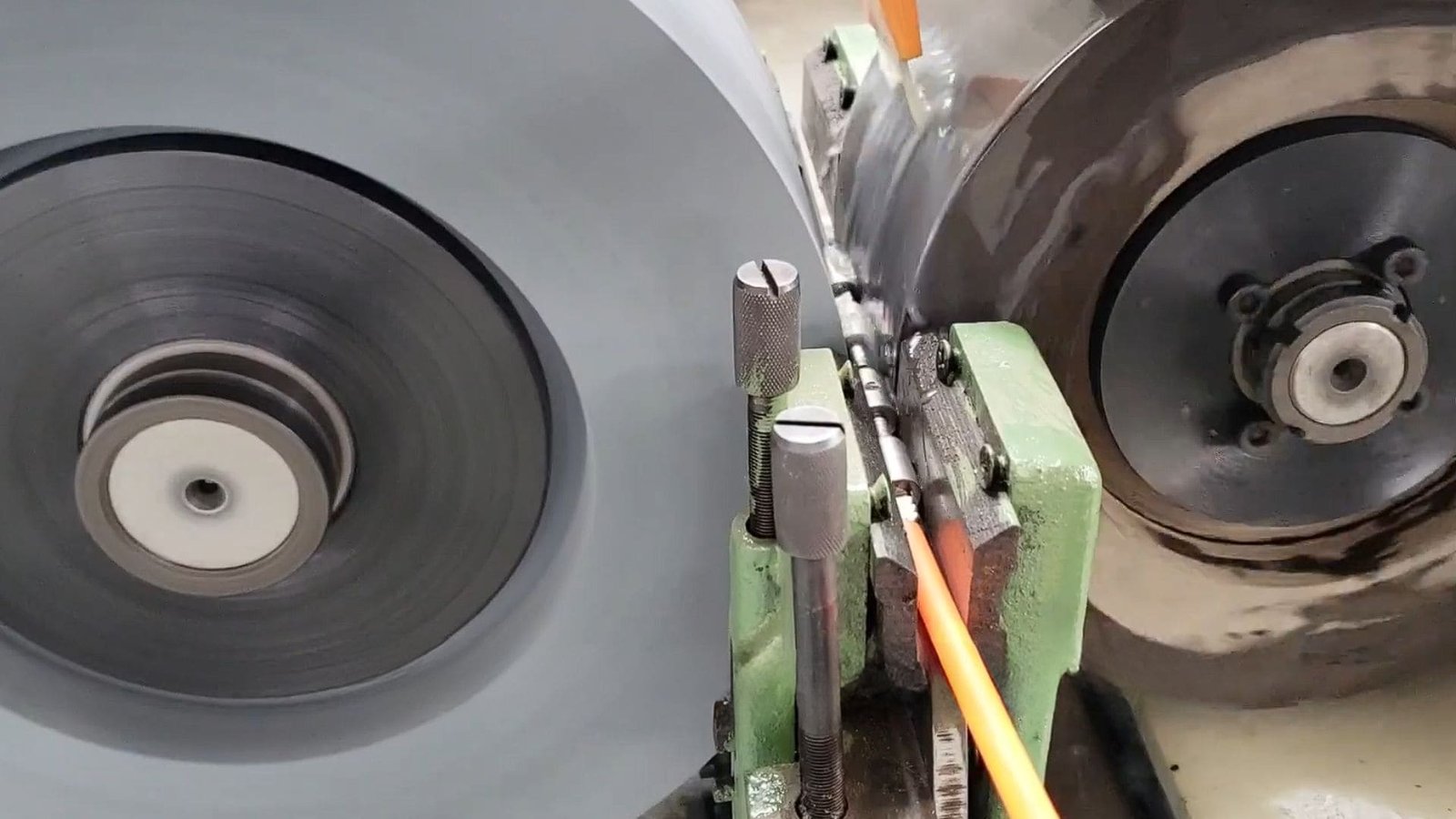

Infeed (or Plunge) grinding is for parts with shoulders, tapers, or complex shapes, where the part is placed, ground by the wheel feeding in, and then removed. Thrufeed grinding feeds straight cylindrical parts continuously through the wheels.

These two methods serve different purposes, as your research details:

- Infeed (Plunge) Centerless Grinding7:

- Process: The workpiece is placed on the work rest blade against the regulating wheel. The grinding wheel then moves in (plunges) to grind the required feature(s). There’s no axial feeding during the grind. End stops often position the workpiece axially.

- Workpiece Type: Ideal for parts that are not simple cylinders – think headed bolts (grinding the shank), parts with multiple diameters ground simultaneously by a formed wheel, tapered parts, or other complex geometries (like hourglass shapes).

- Characteristics: Offers precision for these intricate shapes. Cycle time per piece can be quick for formed features.

- Thrufeed Centerless Grinding8:

- Process: Straight cylindrical workpieces are fed axially between the grinding and regulating wheels. The regulating wheel is slightly tilted, providing the force to pull the workpiece through the grinding zone continuously.

- Workpiece Type: Best suited for simple, straight cylindrical parts like pins, rods, shafts, or rollers where the entire length needs grinding.

- Characteristics: Highly efficient for high-volume production of cylindrical parts. Doesn’t require complex feed mechanisms beyond guides. Generally provides excellent size control and roundness along the length.

| Feature | Infeed (Plunge) Grinding | Thrufeed Grinding |

|---|---|---|

| Workpiece Type | Complex, headed, tapered, formed | Simple straight cylinders, rods, pins |

| Workpiece Motion | Held axially, wheel plunges in | Fed continuously through wheels |

| Primary Use | Grinding specific features/forms | Grinding entire length uniformly |

| Efficiency | Good for formed parts per cycle | High volume for cylindrical parts |

| Complexity | Can handle complex geometry | Best for simple geometry |

Choosing correctly depends entirely on the part’s shape and production volume needs.

What are the Essential Maintenance Procedures for Ensuring Centerless Grinder Longevity and Accuracy?

Is your previously reliable centerless grinder starting to drift on tolerances or experiencing unexpected downtime? Skipping routine maintenance is a fast track to costly repairs, production delays, and inaccurate parts. Consistent care is crucial.

Essential maintenance involves daily checks, regular lubrication, hydraulic system upkeep, spindle monitoring, truing/dressing tool care, electrical/mechanical inspections, and planned component replacements to ensure long-term accuracy and prevent breakdowns.

A centerless grinder requires consistent, detailed attention to maintain its precision. Based on your comprehensive research, a robust maintenance schedule should include:

- Daily Tasks:

- Check for any obvious damage or misplaced components.

- Clean the immediate work area to prevent debris ingress.

- Check coolant levels and condition.

- Regular Checks (Weekly/Monthly):

- Lubrication: Verify automatic lubrication systems are working, check oil levels (spindle, hydraulics, gearbox), inspect lubrication blocks and lines for leaks or blockages. Manually lubricate points as required by the manufacturer.

- Hydraulic System: Check hydraulic oil level, temperature, and filters. Inspect hoses for wear, cracking, or leaks. Listen for unusual pump noise.

- Spindles (Grinding & Regulating): Monitor bearing temperatures and listen for noise/vibration. Check spindle bearing clearance if applicable. Inspect seals for leaks. Ensure proper oil flow/pressure if applicable.

- Truing/Dressing Units: Inspect ways and way covers for damage/debris. Adjust gibs for proper slide movement. Check anti-backlash mechanisms. Ensure dressers move smoothly and diamonds are sharp.

- Mechanical Components: Check handwheels, handles, lead screws, and nuts for smooth operation and excessive wear. Inspect bearings for roughness or play.

- Electrical: Clean motor fans and electrical cabinet filters. Check connections for tightness (power off!).

- Annual/Periodic Tasks:

- Perform a full lubrication system flush and refill if recommended.

- Replace filters (hydraulic, coolant, air).

- Consider replacing known wear items proactively based on usage and manufacturer recommendations.

- Perform a full machine geometry check and calibration.

- Continuous Monitoring: Always be alert for increased vibration, unusual noises, declining surface finish, or difficulty holding size – these often indicate developing problems needing immediate attention.

This diligent approach, combining daily awareness with scheduled deep checks, is key to keeping your centerless grinder running accurately and reliably for years.

Conclusion

Mastering centerless grinding requires careful wheel selection, precise setup of key parameters, meticulous attention to the work rest blade, choosing the right grinding method (infeed/thrufeed), and executing a rigorous maintenance plan for sustained accuracy.

-

Exploring the role of coolant can help you prevent thermal damage and achieve a better finish in your grinding operations. ↩

-

Understanding various grinding methods like thrufeed and infeed can enhance your machining efficiency and precision. ↩

-

Learning about the impact of operator experience can help you appreciate the value of skilled labor in achieving optimal machining results. ↩

-

Understanding stable support is crucial for achieving precision in machining, ensuring better quality and efficiency in production. ↩

-

Exploring this topic can provide insights into optimizing machining techniques for better results and reduced errors. ↩

-

Learning about vibration and chatter can help improve machining stability and surface finish, enhancing overall product quality. ↩

-

Explore this link to understand the unique applications and benefits of Infeed Centerless Grinding for complex geometries. ↩

-

Discover the efficiency and advantages of Thrufeed Centerless Grinding for high-volume production of cylindrical parts. ↩