How to Choose Between a Dead Center and a Live Center for Lathe?

Chris Lu

Leveraging over a decade of hands-on experience in the machine tool industry, particularly with CNC machines, I'm here to help. Whether you have questions sparked by this post, need guidance on selecting the right equipment (CNC or conventional), are exploring custom machine solutions, or are ready to discuss a purchase, don't hesitate to CONTACT Me. Let's find the perfect machine tool for your needs.

Chris Lu

Leveraging over a decade of hands-on experience in the machine tool industry, particularly with CNC machines, I'm here to help. Whether you have questions sparked by this post, need guidance on selecting the right equipment (CNC or conventional), are exploring custom machine solutions, or are ready to discuss a purchase, don't hesitate to CONTACT Me. Let's find the perfect machine tool for your needs

You have a shaft to turn. You know you need tailstock support. But grabbing the wrong center will ruin your finish or burn your part. You must choose the right tool for the specific job.

You should choose a Live Center for general CNC turning and high-speed operations to prevent friction and heat buildup. You must choose a Dead Center for grinding or low-speed, high-precision turning where runout must be near zero. The choice depends entirely on your need for speed versus your need for extreme accuracy.

Many operators destroy dead centers by running them at high RPMs. Others ruin precision jobs by using a cheap live center with loose bearings. I want to help you avoid these costly mistakes.

What are the Primary Functional Differences Between a Dead Center and a Live Center?

You got both of them in hands. One spins, one is solid. But do you understand how this mechanical difference changes your machining process?

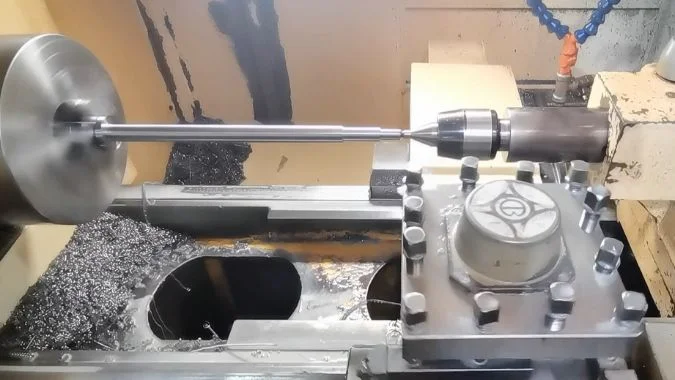

A live center has internal bearings and the tip rotates with your workpiece. A dead center is a solid, single piece of steel that remains stationary while the workpiece spins against it. This structural difference dictates their friction levels, speed capabilities, and potential accuracy.

The core difference lies in the structure and the motion.

A Live Center1 is a complex assembly. It has a front cone that contacts your part. Inside the housing, it has rolling bearings. These bearings allow the front cone to rotate synchronously with your workpiece. Because the tip spins with the part, there is almost no sliding friction between the center and the center hole. This design is perfect for high-speed cutting conditions. However, bearings are not perfect. They have tiny clearances. This introduces a small amount of radial runout. This means the tip might wobble slightly, affecting rotational accuracy. We typically use these for roughing or semi-finishing where speed matters more than micron-level perfection.

A Dead Center2 is simple. It is a solid, integrated rigid structure. It does not move. It stays fixed in the tailstock. Your workpiece spins, but the center does not. This provides a "static contact." Because there are no moving parts, there is no bearing wobble. The rigidity is incredibly high. It offers the best possible positioning accuracy. However, metal spinning on metal creates friction. This requires lubrication.

Here is a simple breakdown of the differences:

| Aspect | Dead Center | Live Center |

|---|---|---|

| Rotation | Stationary; workpiece rotates against it | Rotates with the workpiece via bearings |

| Friction/Heat | High; requires lubrication | Low; bearings reduce friction |

| Precision | Excellent for concentricity | Good, but potential runout from bearings |

| Speed Suitability | Low to medium RPMs | High RPMs |

| Typical Use | High-accuracy, short runs | Long runs, CNC, heavy loads |

What are the Risks of Thermal Expansion and Friction When Using a Dead Center?

A dead center is rigid, but it creates heat. Ignoring this heat will destroy your workpiece very quickly.

The primary risk is thermal expansion caused by friction. As the workpiece spins against the fixed dead center, heat builds up, potentially expanding the part by 0.4-0.6 mm. This expansion forces the part against the center, which can warp the shaft or damage the machine bearings.

When you use a dead center, you are essentially rubbing two pieces of metal together under pressure. Even with lubricant, friction is inevitable. This creates a dangerous cycle for your part.

The Cycle of Failure

First, the part rotates against the stationary tip. Friction generates heat. Metal expands when hot. On a long shaft, this thermal expansion3 can be significant, sometimes exceeding 0.5mm. Since the tailstock is locked, the growing part has nowhere to go. It pushes harder against the dead center. This increased pressure creates more friction and more heat.

Consequences of Heat

If you do not manage this, the results are bad.

- Galling: The tip will weld itself to the workpiece.

- Distortion: The slender shaft will bow or bend because it is being squeezed.

- Safety Hazards: In severe cases, the tool pressure combined with expansion can pop the part out of the machine.

How to Manage It

You must use a high-pressure lubricant4 like molybdenum disulfide grease. Regular oil spins off too fast. Also, you must keep speeds low. You cannot run a dead center at 3000 RPM. For cylindrical grinding, this is less of a problem because coolant flows constantly. But on a lathe, you might need to stop the machine, back off the tailstock pressure slightly, and re-lubricate to handle the expansion.

Why Choose Live Center Over Dead Center on CNC Lathe?

CNC machines run fast. A solid center simply cannot keep up with modern production speeds without causing damage.

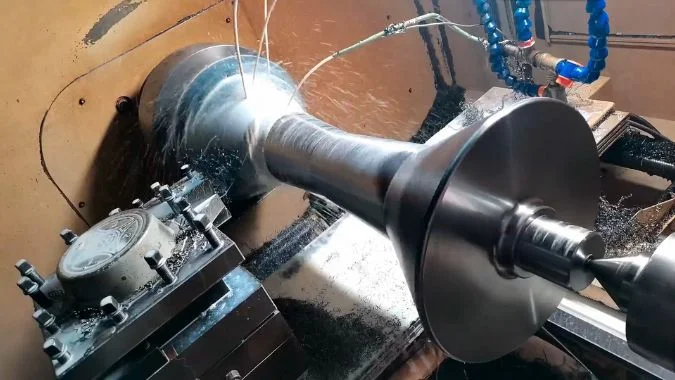

You choose a live center for CNC lathes to handle high-speed cutting without overheating. The rotating bearings eliminate the friction that burns out dead centers, allowing for efficient production, longer tool life, and consistent dimensional stability during long runs.

There are four specific reasons why the industry prefers them for CNC work.

-

Reducing Friction and Thermal Deformation5

CNC lathes often run for hours without stopping. A live center rotates with the workpiece. This effectively stops friction buildup. It prevents the workpiece from heating up and growing lengthwise. This ensures that your shoulder lengths stay consistent from the first part to the last part of the batch. -

Adapting to High RPM

Modern CNC turning uses coated carbide inserts. These tools perform best at high surface speeds. A dead center limits your RPM. A live center lets you run at the optimal speed for the insert. If you run a dead center at high speeds, you will destroy the tip in minutes. The live center rotates freely, reducing wear and ablation. -

Extending Center Hole Life6

We often move parts between machines. We might turn it on a lathe, then move it to a grinder. We need the center hole to stay perfect. A live center uses rolling contact. It does not rub. It does not ovalize or score the center hole. This ensures that the center hole remains accurate for secondary operations. -

Reducing Vibration and Improving Stability

For slender shaft workpieces, the bearing structure of the live center absorbs some cutting vibrations. It acts as a dampener. This improves the stability of the machining process and reduces workpiece runout, leading to a better surface finish.

What is the Impact of Workpiece Weight on the Lifespan of Live Center Bearings?

Live centers rely on bearings. Like any bearing, they have a load limit. Overloading them leads to catastrophic failure.

Workpiece weight directly shortens bearing life if it exceeds the center’s radial load rating. Heavy parts exert massive pressure on the races, causing premature fatigue, overheating, and eventual seizure of the live center, which can ruin the workpiece.

I deal with clients ranging from small workshops to massive steel mills. The "weight" conversation is one we have often. You cannot use a standard live center to hold a heavy roller.

Understanding Load Ratings7

A live center handles two forces.

- Axial Load: The force of the tailstock pushing into the part.

- Radial Load: The weight of the workpiece pushing down.

Standard live centers are designed for axial load. They are good at being pushed in. They are less good at holding heavy weights up.

Bearing Failure Modes8

If you put a heavy shaft on a small live center, the internal bearings suffer. The balls or rollers press into the races. This is called brinelling. It creates a bumpy, grinding feel when you spin it by hand. Additionally, uneven or cantilevered loads amplify this stress. The bearings will heat up and seize. If the bearing seizes while the lathe is spinning at 1000 RPM, the center tip stops, but the part keeps moving. This instantly gouges the part and breaks your cutting tool.

Calculating Lifespan

Engineers use the L10 life factor to predict bearing failure. This calculation includes weight and RPM. If you double the load, you do not just cut the life in half; you reduce it significantly more. For our heavy-duty clients, we recommend centers with extra rows of bearings or "Bull Nose" styles. Always check the manufacturer’s maximum weight rating. It is cheaper to buy a heavy-duty center than to scrap a 2-ton shaft.

Conclusion

Live centers are the standard for high-speed, efficient CNC turning. Dead centers remain the king of accuracy for grinding and low-speed work. Choose based on your need for speed versus precision.

-

Understanding Live Centers is crucial for optimizing high-speed cutting processes and achieving better results. ↩

-

Exploring Dead Centers can enhance your knowledge of precision machining and improve your workpiece accuracy. ↩

-

Exploring thermal expansion will provide insights into how heat affects metal parts, crucial for preventing machining failures. ↩

-

Understanding high-pressure lubricants can help you choose the right product for reducing friction and heat in machining processes. ↩

-

Explore this link to understand how reducing friction can enhance CNC machining efficiency and part quality. ↩

-

Learn about the importance of center hole life in CNC machining and how it affects accuracy and productivity. ↩

-

Understanding load ratings is crucial for selecting the right live center, ensuring optimal performance and longevity. ↩

-

Exploring bearing failure modes helps prevent costly mistakes and ensures the right equipment is used for heavy loads. ↩