How to Choose Between a Single and Rotary Tool Post for a CNC Lathe?

Choosing the wrong tool post on a CNC lathe can bottleneck your entire production. You’re either wasting time with constant manual tool changes or you’ve overpaid for a complex system you don’t need.

For simple, single-operation jobs on small parts, a single tool holder is enough. For any job needing multiple tools or processes, a rotary tool holder like a turret or a gang tool system is essential to improve efficiency and enable automation.

Many manufacturers struggle with this choice. They buy a simple lathe to save money, then spend hours a day stopping the machine to swap tools by hand. On the other hand, some buy a massive turn-mill center when all they make are simple pins. The tooling system is the heart of a CNC lathe’s productivity. It defines what kind of work you can do, and how fast you can do it. The decision isn’t just about holding one tool or many; it’s about matching the machine’s capability directly to the parts you need to produce.

What Tool Post Can You Choose When More Tools Are Required?

Your jobs are getting more complex, and a single tool is no longer enough. You’re tired of stopping the machine for every single operation, and you know there has to be a more efficient way.

When you need more tools, you can choose from a rotary turret, a gang tool slide, or a power turret. Each system holds multiple tools and is designed for different levels of complexity, speed, and production volume.

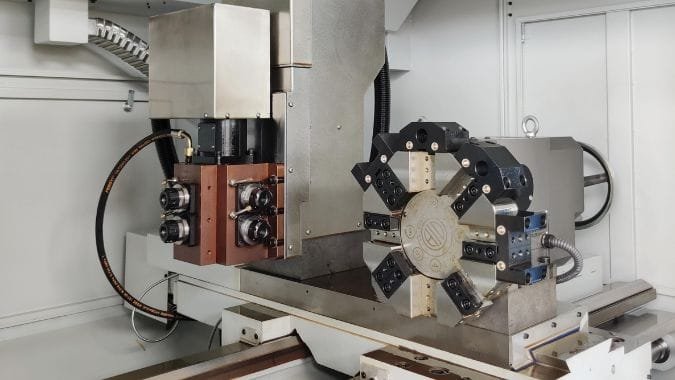

Today, the options are much more advanced, and each solves a different problem. You’re moving beyond the "one tool at a time" world. The next step is choosing the right multi-tool system1. A gang tool slide lines up tools for lightning-fast changes on small parts. A standard rotary turret is the versatile workhorse, holding 8-12 tools for a variety of jobs. A power turret2 is the ultimate problem-solver, turning your lathe into a multi-function machine. Your choice here will define your shop’s capabilities.

Comparing Multi-Tool Systems

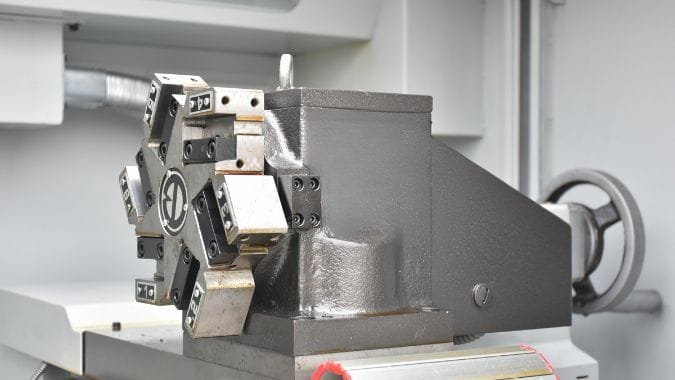

The three main options for holding more tools each have a clear purpose. A gang tool system arranges 4-8 tools in a line on the cross slide. It’s incredibly fast because it just moves the X and Z axes to change tools—no indexing time. This makes it perfect for high-volume production of small, simple parts. A standard rotary turret is the most common choice. It holds 8-12 tools and indexes them into position. It’s more flexible and can handle longer work that needs a tailstock. For even more capability, some shops mount gang plates onto turret stations, creating a hybrid system. The power turret, or live tool turret, looks similar to a standard turret but adds a motor to drive rotating tools. This lets you mill, drill, and tap on the face or side of a part, combining multiple operations into one setup.

| Tooling System | Typical Tool Count | Best For… | Key Feature |

|---|---|---|---|

| Gang Tooling | 4 – 8 | Small parts, high volume, speed-critical jobs. | Fastest tool changes (linear motion). |

| Rotary Turret | 8 – 12 | General purpose, medium complexity, varied jobs. | Versatility and good tool capacity. |

| Power Turret | 8 – 12+ | Complex parts needing milling, drilling, and turning. | Combines operations (turn-mill capability). |

When Should You Choose Gang Tooling Over a Rotary Turret?

You’re focused on making thousands of small parts as fast as possible. You’ve heard gang tooling is quick, but you’re not sure if giving up the flexibility of a turret is the right move.

Choose gang tooling when your top priority is the absolute shortest cycle time on small-diameter, short parts. Its instant, linear tool changes are much faster than a turret’s indexing motion, making it ideal for high-volume production.

The beauty of gang tooling3 is its simplicity and speed. A customer who was making thousands of small aluminum spacers came before. Their turret lathe4 was spending almost as much time indexing as it was cutting. We switched them to a gang tool lathe, and their cycle time dropped by nearly 40%. Because the tools are just lined up on the slide, a tool change is just a quick X-Z axis move. There’s no turret to unlock, rotate, and lock. This makes it unbeatable for simple, high-volume work. The trade-off is that you have a limited number of tools, and the setup can interfere with a tailstock, so it’s not good for long, slender parts. A turret is the more versatile, "do-anything" choice, but for pure speed on the right part, nothing beats gang tooling.

The Speed vs. Flexibility Trade-off

The decision between gang tooling and a rotary turret is a classic battle of specialization versus generalization. Gang tooling is a specialist. It is designed for one thing: producing a specific small part as fast as humanly possible. By eliminating the rotational indexing time, you can shave critical seconds off your cycle time. Over a run of 100,000 parts, those seconds add up to huge cost savings. It is also very rigid for its size, as the tools are mounted directly to the cross slide. However, it’s inflexible. The number of tools is limited by the physical length of the slide, and it’s poorly suited for parts that require many different operations or support from a tailstock. A rotary turret is a generalist. It’s slower to change tools, but it can hold more of them and can be configured for a massive variety of jobs, both short and long. It’s the safe, flexible choice for a job shop with unknown future work.

Which Tooling System Offers the Best Rigidity for Heavy Cutting and Tight Tolerances?

You’re taking on jobs that require heavy roughing cuts in tough materials. You need to hold tight tolerances, but you’re getting chatter and vibration, and you suspect your tool holder is the weak link.

For the highest precision and rigidity on small parts, gang tooling is often superior due to its simple, direct design. For heavy roughing on larger, more complex parts, a robust rotary turret system offers the necessary mass and stability.

Rigidity is everything when you’re pushing a machine hard. The answer to which system is more rigid depends on the job. For tight tolerance work on smaller parts, gang tooling is king. Because it has fewer moving parts, no indexing mechanism, and shorter tool overhangs, there’s less opportunity for backlash or vibration to creep in. The structure is simple and solid. However, when you need to hog off a lot of material on a larger part, the sheer mass of a large rotary turret5 and the robust machine it’s attached to provides better stability. The large, heavy casting of the turret absorbs vibration from heavy cuts in a way that a smaller gang-tool system cannot. It’s about matching the right kind of rigidity to the right kind of work.

Understanding the Sources of Rigidity

Rigidity in a tooling system comes from minimizing the number of interfaces and maximizing the mass and clamping force. A simple tool post on a compound slide has many potential points of flex. Gang tooling improves on this by mounting tools directly to the cross slide, creating a very short, stiff load path. This is why it excels at precision. A rotary turret, on the other hand, has more components—the turret disc, the coupling, the drive mechanism—which can introduce tolerance stack-up. But on a large lathe designed for heavy cutting, the entire system is oversized to compensate. The massive turret disc and heavy-duty machine frame work together to dampen vibration, making it the better choice for high material removal rates on big, tough jobs.

How Does the Choice of Tooling System Influence the CNC Lathe’s Overall Size and Work Envelope?

You’re planning your shop layout and need to choose a new lathe. You’re realizing that the tooling system doesn’t just affect performance; it dictates the entire size and shape of the machine.

The tooling system fundamentally defines the machine’s footprint. Gang tool lathes are typically compact with a smaller work envelope, while turret lathes are larger to provide clearance for the turret and a potential tailstock.

When you buy a tooling system, you are also buying a machine architecture. Once a client who wanted to set up a cell for small medical screws. We chose a series of small gang tool lathes6. Their compact design meant we could fit three machines in the space where one traditional turret lathe would have gone. A gang tool machine doesn’t need the extra depth and height to accommodate a large rotating turret. The whole machine can be smaller. A turret lathe, by its nature, needs more space. The turret is a large component, and the machine bed must be long enough to allow the turret to travel without interfering with the chuck or a tailstock. This makes it a bigger, more general-purpose machine. The choice of tooling directly impacts your floor space utilization and workflow.

The Architecture of the Machine

The tooling system and the machine base are designed together. A slant bed design, for example, is often used with both systems because it provides excellent rigidity and allows chips to fall away. On a gang tool lathe, the slant bed provides a solid foundation for the compact linear cross slide, and the work envelope is focused on small, short parts. In contrast, a turret lathe needs more room to breathe. The design must account for the turret’s full rotation, ensuring it can clear the chuck, the workpiece, and the tailstock at its maximum travel. This often results in a larger headstock, a longer bed, and a deeper enclosure, leading to a significantly larger overall machine footprint. Choosing a power turret adds even more complexity, as the design must now include space for the drive motor and gearing within the turret housing.

Conclusion

Choose gang tooling for speed on small parts, a standard turret for versatility, and a power turret for complex, multi-operation work. Matching the tooling system to your parts is the key to a profitable and efficient CNC lathe operation.

-

Explore this link to understand the advantages and functionalities of multi-tool systems in machining. ↩

-

Learn about power turrets to see how they enhance machining capabilities and efficiency. ↩

-

Explore the benefits of gang tooling to understand how it can enhance production efficiency and reduce cycle times. ↩

-

Learn about turret lathes and their versatility in manufacturing, especially for complex jobs requiring multiple operations. ↩

-

Discover the benefits of rotary turrets for heavy cutting, including stability and vibration dampening, essential for large part machining. ↩

-

Explore the benefits of gang tool lathes, including space efficiency and precision, to enhance your machining operations. ↩

Chris Lu

Leveraging over a decade of hands-on experience in the machine tool industry, particularly with CNC machines, I'm here to help. Whether you have questions sparked by this post, need guidance on selecting the right equipment (CNC or conventional), are exploring custom machine solutions, or are ready to discuss a purchase, don't hesitate to CONTACT Me. Let's find the perfect machine tool for your needs.