How to Choose Between a True and an Interpolated Y-axis on a Turn-Mill Center?

Chris Lu

Leveraging over a decade of hands-on experience in the machine tool industry, particularly with CNC machines, I'm here to help. Whether you have questions sparked by this post, need guidance on selecting the right equipment (CNC or conventional), are exploring custom machine solutions, or are ready to discuss a purchase, don't hesitate to CONTACT Me. Let's find the perfect machine tool for your needs.

Chris Lu

Leveraging over a decade of hands-on experience in the machine tool industry, particularly with CNC machines, I'm here to help. Whether you have questions sparked by this post, need guidance on selecting the right equipment (CNC or conventional), are exploring custom machine solutions, or are ready to discuss a purchase, don't hesitate to CONTACT Me. Let's find the perfect machine tool for your needs

You need Y-axis capability for your new turn-mill center, but the choice is confusing. You’re afraid of spending the extra 30% on a true Y-axis you don’t need, or worse, buying an interpolated machine that isn’t rigid enough for your jobs.

Choose a true Y-axis for milling-heavy work, complex side features, and applications needing maximum rigidity. Opt for an interpolated Y-axis for primarily turned parts with simpler milling on the face, like flats or keyways, where cost is a major factor.

Once a client that bought an interpolated Y-axis machine for low budget. It worked great for drilling off-center holes on the part face. But six months later, a new job came in that required milling a deep pocket on the side of a shaft. They discovered their machine couldn’t handle it. The walls tapered and the finish was terrible. This is a critical decision that comes down to honestly evaluating not just the parts you make today, but the parts you might want to make tomorrow.

What is the Core Mechanical Difference Between a True Y-axis and an Interpolated Y-axis?

You hear the terms "true" and "interpolated" but they sound like software jargon. You’re trying to understand the physical difference in the iron, not just the code in the control.

A true Y-axis is a physical, independent slide with its own guides and ballscrew, moving perpendicular to the X-axis. An interpolated Y-axis is a virtual axis created by coordinating the motion of the X-axis and the C-axis to move the tool.

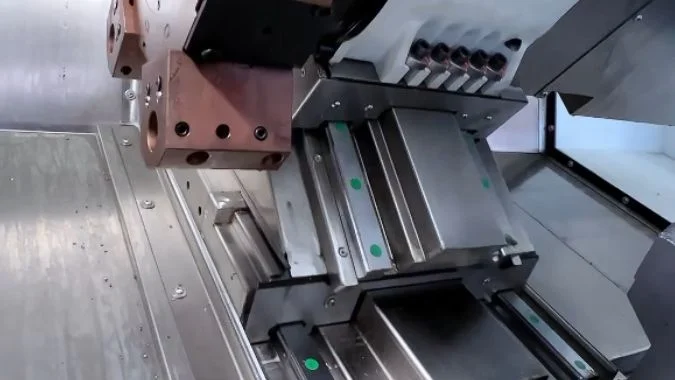

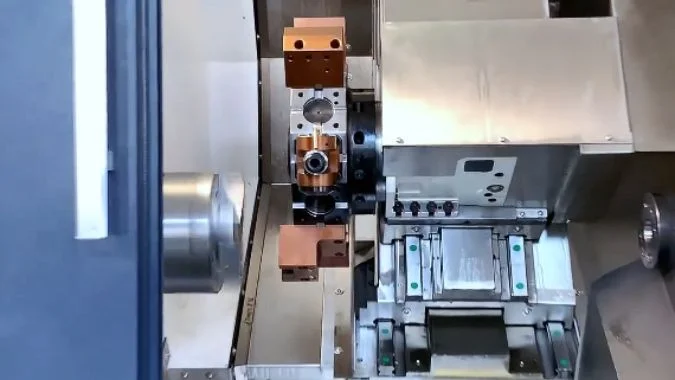

A true Y-axis1 is a real piece of hardware. The machine has a dedicated, servo-driven slide, usually with a travel of ±2 to ±4 inches, that moves the tool turret up and down. It forms a standard, orthogonal XYZ coordinate system. Programming is simple: you command a Y-move, and the Y-axis slide moves.

An interpolated Y-axis is a clever trick, sometimes called polar coordinate interpolation2. There is no physical up-and-down slide. To move the tool to a Y position, the control simultaneously moves the X-axis (linear motion) and rotates the C-axis (rotary motion). By perfectly synchronizing these movements, it places the tool at the desired Y coordinate. It’s a virtual axis that exists only in the software, created by the motion of other physical axes. This makes the machine mechanically simpler but geometrically limited.

How Does a True Y-axis Affect the Rigidity and Heavy-Cutting Capability of a Turn-Mill Center?

You need to do some serious milling on your lathe, not just light engraving. You’re worried an interpolated Y-axis won’t be rigid enough and will lead to chatter and poor tool life.

A true Y-axis significantly increases rigidity. Its independent ways and guides provide direct support for cutting forces, allowing the machine to function more like a small machining center. This is far superior for heavy milling.

When you mill on the side of a part, the forces are pushing sideways against the tool. In a true Y-axis machine3, this force is directly opposed by a massive, dedicated Y-axis slide. The structure is designed to absorb these forces in a straight line, which provides incredible rigidity. This allows you to take deeper cuts and machine tougher materials without vibration.

Contrast this with an interpolated Y-axis4. The side-loading force is resisted by the combined effort of the X-axis slide and the C-axis spindle brake. This system is simply not as direct or robust. Under a heavy cut, it is more prone to deflection. This is why you’ll see issues like tapered walls in milled pockets—the system isn’t rigid enough to hold a perfectly perpendicular line under load. For any aggressive milling, a true Y-axis is the only way to go.

What Machining Tasks Can Be Effectively Completed Using Interpolated Y-axis Instead of True Y-axis?

You see that true Y-axis machines cost a lot more. You’re wondering if you can get away with an interpolated Y-axis for your parts, which are mostly turned but have some milled features.

An interpolated Y-axis is perfect for parts that are primarily turned but need secondary milling operations on the part face. It excels at features like off-center holes, flats, keyways, and simple face profiles.

An interpolated Y-axis is a fantastic, cost-effective solution5 for "done-in-one" machining when turning is the main event. Think about milling a hexagon or a square on the end of a shaft, engraving text, or drilling a pattern of off-center holes. These are not heavy roughing operations. The cutting forces are low, and the interpolated motion can handle them with excellent precision. The goal is to eliminate a second operation on a mill, which saves setup time and improves accuracy by avoiding re-clamping.

However, it has clear limitations. It is not ideal for milling features on the side of a part or holding extremely tight tolerances (e.g., ±0.0005 inches can be a challenge due to thermal growth). It is a specialized tool for face-work, not a substitute for a true third axis. If your work is confined to the face of the part, it’s a great way to save a significant amount of money on the machine purchase.

What are the Differences in Maintenance and Reliability Between These Two Y-axis Designs?

You’re thinking about the long-term. A new machine is a 10-year investment, and you’re worried that a complex interpolated system will be a maintenance headache down the road.

A true Y-axis is mechanically more complex but more reliable for holding accuracy long-term. An interpolated Y-axis is mechanically simpler but its accuracy is highly dependent on software and the condition of other axes.

From a maintenance view, a true Y-axis6 adds more physical components: another ballscrew, linear guides, and a servo that all need lubrication and alignment checks. However, its accuracy is independent. If the X-axis develops a small amount of wear, the Y-axis is unaffected.

An interpolated Y-axis has fewer parts to break, but its reliability is a different challenge. Its accuracy depends on the perfect health and synchronization of the X-axis and C-axis. Any wear or backlash in those systems will directly cause an error in your "Y" position. It’s also very sensitive to thermal drift. It’s not uncommon for the X-axis to shift by 0.001 inches in the first hour of running, which throws off your interpolated position. This makes it less dependable for ultra-precise or unattended "lights-out" operations. It requires more frequent calibration to maintain its accuracy over time, whereas the true Y-axis is more robust and stable.

Conclusion

A true Y-axis is for rigidity, heavy milling, and long-term accuracy on complex parts. An interpolated Y-axis is a cost-effective choice for turning-focused parts that need simpler milling features on the face.

-

Understanding the Y-axis is crucial for mastering machining techniques and improving precision in your projects. ↩

-

Exploring polar coordinate interpolation can enhance your machining skills and help you utilize advanced techniques effectively. ↩

-

Understanding true Y-axis machines can enhance your milling efficiency and precision, making it essential for serious machinists. ↩

-

Exploring the drawbacks of interpolated Y-axis systems can help you make informed decisions about your milling setup. ↩

-

Exploring cost-effective solutions can help you optimize your machining processes and save money without compromising quality. ↩

-

Explore the benefits of a true Y-axis, including its robustness and independence from X-axis wear, crucial for precision engineering. ↩