How to Choose Between Dead Center and Live Center for Lathe?

Machining a shaft requires the right support, or you risk oval parts and chatter marks. Choosing the wrong center is the fastest way to ruin your surface finish or destroy your tailstock bearings.

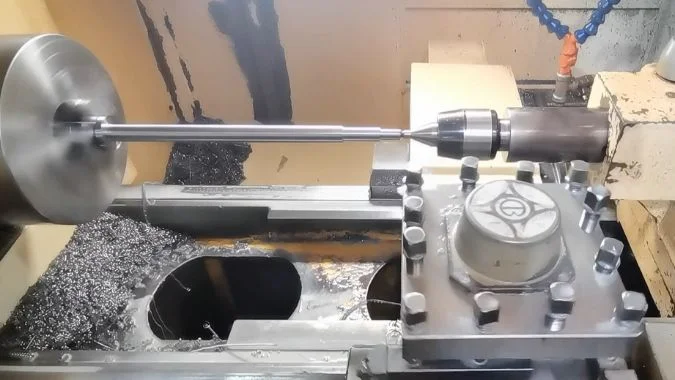

You must choose a Live Center for general CNC turning to handle high RPMs and reduce friction. You should choose a Dead Center for grinding or high-precision turning where you need zero runout. Your choice depends on whether you prioritize production speed (Live) or absolute geometric accuracy (Dead).

In my experience, many operators try to force a dead center to work at 2,000 RPM. This always ends in failure. You need to understand the mechanics to make the right call.

What are the Primary Functional Differences Between a Dead Center and a Live Center?

You can tell them apart by looking at them, but the real difference happens inside the housing.

The primary functional difference is rotation. A live center uses internal bearings to rotate its tip synchronously with the workpiece, eliminating friction. A dead center is a solid, stationary piece of steel that the workpiece spins against, offering higher rigidity but generating significant heat due to metal-on-metal contact.

The difference is not just about moving parts; it is about how the tool interacts with your workpiece.

A Live Center1 is built for motion. It houses a complex assembly of ball or roller bearings. When your lathe chuck spins the part, the tip of the live center spins with it. Because they move together, there is no rubbing action. This is crucial for modern manufacturing. However, bearings have internal clearance. This means even a high-quality live center might have a runout of 0.003mm to 0.005mm. For most turning jobs, this is acceptable.

A Dead Center2 is built for stability. It is one solid piece of hardened steel or carbide. It creates a "static" support point. Since there are no bearings, there is zero mechanical play. If your headstock is perfect, your part will be perfect. The downside is friction. Your part is spinning, but the dead center is not. This creates heat and drag.

Here is a simple breakdown of the technical differences to help you decide:

| Aspect | Dead Center | Live Center |

|---|---|---|

| Rotation | Stationary; workpiece rotates against it | Rotates with the workpiece via bearings |

| Friction/Heat | High; requires lubrication | Low; bearings reduce friction |

| Precision | Excellent for concentricity | Good, but potential runout from bearings |

| Speed Suitability | Low to medium RPMs | High RPMs |

| Typical Use | High-accuracy, short runs | Long runs, CNC, heavy loads |

What are the Risks of Thermal Expansion and Friction When Using a Dead Center?

Friction creates heat, and heat changes the size of your metal parts. This is the hidden danger of using a dead center.

The risk is that friction generates heat, causing the workpiece to expand lengthwise (thermal expansion). Since the tailstock is locked, this expansion forces the part against the dead center with immense pressure. This can warp the shaft, damage the machine bearings, or weld the center tip to the part.

When you use a dead center3, you are essentially creating a brake. You are rubbing metal on metal under load.

The Physics of Failure

Let’s say you are turning a long steel shaft. As it spins against the fixed dead center, the friction heats the tip. The heat travels into the shaft. Steel expands when it gets hot. A 1-meter shaft can easily grow by 0.5mm during a heavy cut.

What Happens Next?

The tailstock does not move back to accommodate this growth. The shaft is now longer, but the space between centers is the same. The shaft begins to bow in the middle. This destroys your straightness. If the pressure gets too high, the lubrication film breaks down. The dead center will literally fuse (gall) to the workpiece.

How We Fix It

If you must use a dead center for precision, you cannot run it dry.

- Lubrication: We use high-pressure grease4 like Moly D (molybdenum disulfide). Standard oil spins off instantly.

- Speed Limits: You must run slowly.

- Adjustments: On long jobs, we sometimes stop the machine, back off the tailstock slightly to relieve the pressure from expansion, and then finish the cut.

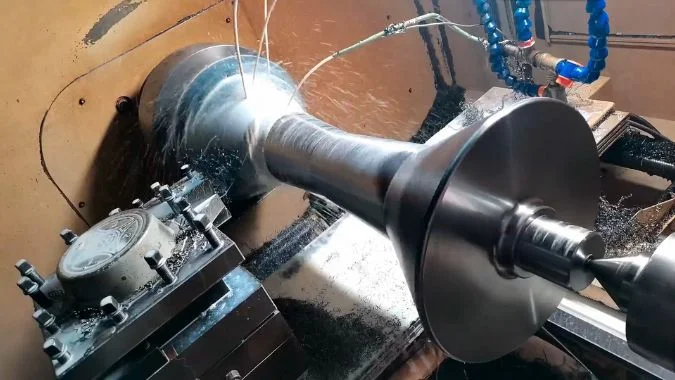

Why Choose Live Center Over Dead Center On CNC Lathe?

CNC machines are designed for speed and efficiency. Dead centers simply cannot keep up with the pace of modern automation.

You choose a live center for CNC lathes to enable high-speed machining without burning the tool. Live centers prevent frictional heat, protect the center hole from wear during repetitive operations, and allow the use of modern coated inserts that require high surface speeds to function correctly.

Using a dead center on a high-speed CNC lathe is usually a mistake. Here is the breakdown of why live centers5 are the superior choice for this application.

1. Matching Insert Speeds

Modern carbide inserts are designed to cut fast. If you run them too slow, they chip. To get the right Surface Feet Per Minute (SFM), you often need 2000+ RPM. A dead center will burn up at that speed in seconds. A live center handles high RPMs effortlessly because the bearings take the load.

2. Protecting the Center Hole

In production environments, we often move parts from a lathe to a mill or a grinder. The center hole is our reference point. If you use a dead center, the friction can score or ovalize the center hole. A live center has rolling contact. It preserves the geometry of the center hole, ensuring the part is still accurate when it moves to the next machine.

3. Vibration Damping

CNC turning can be aggressive. A live center actually helps absorb some vibration. The oil film in the bearings acts as a small shock absorber. This helps prevent chatter on long, slender parts, which is a common issue we see with our automotive supply chain clients.

What is the Impact of Workpiece Weight on the Lifespan of Live Center Bearings?

Every live center has a limit. Ignoring the weight of your workpiece is the most common cause of bearing seizure.

Workpiece weight directly reduces bearing life if it exceeds the radial load rating. Heavy parts push the internal rollers into the races, causing "brinelling" (denting) and overheating. Overloading a live center causes it to seize mid-cut, which will gouge the workpiece and break your cutting tools.

The weight of the part changes how we select tools. A standard Morse Taper 4 live center might be rated for 2,000 RPM, but it might only support 500kg.

Radial vs. Axial Load

Most people think about the tailstock pushing in (Axial Load). But gravity pulls down (Radial Load6). Standard live centers are great at taking axial pressure but weak against radial weight. When you put a heavy roller on a small center, the bearings are crushed.

The Consequence of Overload

When a bearing is overloaded, it generates excess heat. The grease cooks inside the housing. Eventually, the bearing seizes. On a manual lathe, you might hear the squeal and stop. On a CNC lathe, the machine keeps pushing. The center stops spinning, but the chuck keeps turning. The live center tip acts like a boring bar and destroys the end of your shaft.

The Solution

For heavy parts, we recommend "Bull Nose" centers or heavy-duty models with extra rows of bearings. We always tell our clients: calculate the weight of your raw stock. If you are near the limit of the live center’s rating, buy a bigger one. It is cheaper than scrapping a 2-ton workpiece.

Conclusion

Live centers are essential for high-speed, efficient CNC production. Dead centers are the only choice for high-precision grinding where runout is unacceptable. Match the tool to your speed and accuracy needs.

-

Explore this link to understand how a Live Center enhances precision and efficiency in machining processes. ↩

-

Discover the advantages of using a Dead Center for stability and precision in your machining projects. ↩

-

Understanding dead centers is crucial for precision machining, ensuring you avoid common pitfalls and improve your work quality. ↩

-

Exploring high-pressure grease options can enhance your machining processes, ensuring better lubrication and performance. ↩

-

Explore this link to understand the advantages of live centers over dead centers in CNC machining, enhancing your production efficiency. ↩

-

Understanding Radial Load is crucial for selecting the right tools and preventing equipment failure. ↩

Chris Lu

Leveraging over a decade of hands-on experience in the machine tool industry, particularly with CNC machines, I'm here to help. Whether you have questions sparked by this post, need guidance on selecting the right equipment (CNC or conventional), are exploring custom machine solutions, or are ready to discuss a purchase, don't hesitate to CONTACT Me. Let's find the perfect machine tool for your needs.