How to Choose Between Hard or Soft Jaw Chuck for a CNC Lathe?

Chris Lu

Leveraging over a decade of hands-on experience in the machine tool industry, particularly with CNC machines, I'm here to help. Whether you have questions sparked by this post, need guidance on selecting the right equipment (CNC or conventional), are exploring custom machine solutions, or are ready to discuss a purchase, don't hesitate to CONTACT Me. Let's find the perfect machine tool for your needs.

Chris Lu

Leveraging over a decade of hands-on experience in the machine tool industry, particularly with CNC machines, I'm here to help. Whether you have questions sparked by this post, need guidance on selecting the right equipment (CNC or conventional), are exploring custom machine solutions, or are ready to discuss a purchase, don't hesitate to CONTACT Me. Let's find the perfect machine tool for your needs

Choosing the wrong chuck jaw can scrap your part. This mistake costs you time and money. Knowing the difference between hard and soft jaws is the solution.

Use hard jaws for roughing raw stock with high clamping force. They are durable for high-volume work. Use soft jaws for finishing, delicate parts, or irregular shapes to prevent marring. Soft jaws are customizable but require more setup time and wear faster.

That’s the basic rule of thumb. But the real difference is in the details, from the material they’re made of to how they grip your part.Let’s dive deeper into what makes them so different, so you can make the right choice for every single job that comes through your shop.

What Materials are Soft Jaw Chucks and Hard Jaw Chucks Made of?

Ever wondered why one jaw is tough and the other is gentle? The material is the secret. Using the wrong one can lead to unexpected wear or damaged parts.

Hard jaws are made from high-strength, through-hardened steel alloys with a Rockwell hardness over 48. Soft jaws are typically unhardened, machinable materials like mild steel (e.g., 45# steel), aluminum, or sometimes brass, making them easy to customize for specific jobs.

The choice of material directly impacts how a jaw performs. It’s not just about being "hard" or "soft"; it’s about having the right properties for the job. I remember one time a junior machinist used hard jaws on a finished aluminum part. The result was predictable: deep marks on a part that was supposed to be perfect. This taught us a valuable lesson about material choice.

Hard Jaw Materials1

Hard jaws need to be incredibly tough and wear-resistant. They are usually made from high-strength alloy or carbon tool steel. This material is then heat-treated—often through-hardened—to achieve a very high hardness, often exceeding 50 or even 60 on the Rockwell C scale (HRC). This extreme hardness allows them to bite into raw material without deforming or wearing out quickly, even after thousands of cycles.

Soft Jaw Materials2

Soft jaws, on the other hand, prioritize machinability and gentleness. The most common material I see is 45# steel, a medium-carbon steel. In its unhardened state, it’s easy to machine. For even more delicate parts, we use aluminum, copper, or brass jaws. These materials are much softer than most workpieces, ensuring they won’t leave a single scratch.

Here is a simple comparison:

| Feature | Hard Jaws | Soft Jaws |

|---|---|---|

| Material | Hardened Alloy/Tool Steel | Unhardened Steel, Aluminum, Copper, Brass |

| Hardness (HRC) | > 48 HRC (often 55-62 HRC) | < 47 HRC |

| Primary Use | High-force roughing, high-volume production | Finishing, delicate parts, custom shapes |

| Machinability | Very low | High |

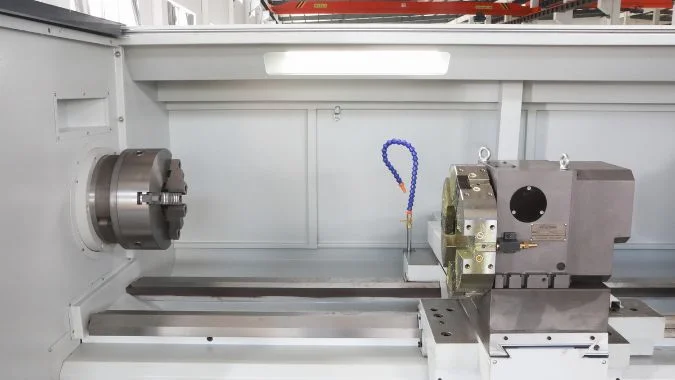

Why Are Hard Jaws the Default Choice for First-Operation Roughing of Raw Stock?

Starting a job with raw material? You need a powerful, unyielding grip. A weak hold can cause the part to slip, ruining the cut and maybe even damaging the machine.

Hard jaws are perfect for roughing because their serrated teeth bite deep into raw stock. Their hardened steel construction can withstand the aggressive forces and uneven surfaces of unprocessed material, allowing for heavy cuts without the risk of the workpiece moving or the jaws wearing out.

When you’re taking the first cut on a piece of raw bar stock, precision is secondary to aggressive material removal. This is where hard jaws3 truly shine. They are built for abuse. I’ve seen workpieces fly out of a chuck because the grip wasn’t strong enough for a heavy cut. That’s a dangerous situation you can avoid by using the right jaws for the job. Their design is perfect for this initial, brutal stage of machining for a few key reasons.

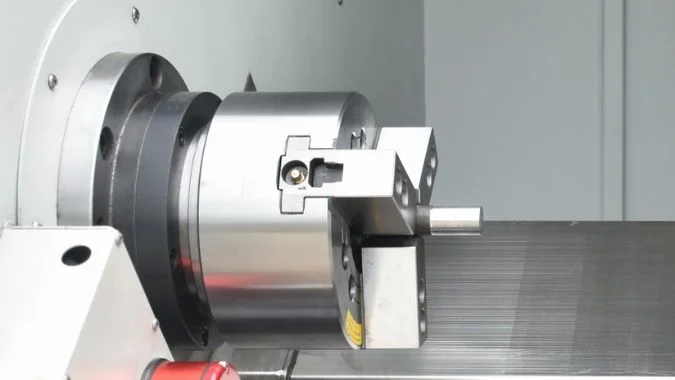

Maximum Clamping Force and Torque

The serrated or toothed clamping surface is the most important feature of hard jaws. These teeth are designed to dig into the rough, often uneven surface of raw material. This creates a powerful mechanical lock, allowing you to transmit a massive amount of torque from the spindle to the part. You can then use high cutting forces and deep cuts without fear of the part slipping. They are designed for brute force, not finesse.

Durability and Cost-Effectiveness

Rough machining is demanding. The high clamping pressures and vibrations can destroy equipment. Hard jaws are made of hardened steel specifically to resist this wear. They can handle countless clamping cycles on rough, scaly material without deforming themselves. This makes them cost-effective for high-volume production, as they don’t need frequent replacement. They are standardized and ready to use right out of the box, saving valuable setup time.

What Jaw Type Offers More Versatility for Gripping Irregularly Shaped or Cast Parts?

Have you ever tried to hold a weirdly shaped part in a standard chuck? It’s frustrating and often impossible. Forcing it can lead to poor concentricity or a failed setup.

Soft jaws offer far more versatility for irregular shapes. Because they are made of machinable steel or aluminum, you can easily cut them to perfectly match the unique profile of any workpiece, including castings, forgings, or other non-cylindrical parts. This ensures a secure, full-contact grip.

While hard jaws are great for round or hex bar stock, they are almost useless for anything else. If you have a casting, a forged part, or a piece that is asymmetric, you need a custom solution. That solution is almost always a set of custom-cut soft jaws4. I’ve relied on them for countless jobs that would have been impossible otherwise.

Custom Machining for a Perfect Fit

The magic of soft jaws is that you can mount a blank set in the chuck and machine them in place. You can bore them to a specific diameter, mill a pocket, or cut a complex profile that perfectly cradles your part. This process, often called "boring the jaws5," creates a clamping surface that is perfectly true to the machine’s spindle centerline. This gives you the highest possible concentricity for second operations and provides full surface contact with the part. This maximizes grip and stability, which is essential for holding parts that aren’t perfectly round. This adaptability makes them superior for any non-standard workpiece.

Why Can You Prevent Surface Marring and Part Deformation by Using Soft Jaws?

You’ve spent hours getting a perfect finish on a part. Now you need to flip it for the second operation. Using the wrong jaws now could leave ugly marks, ruining all your hard work.

Soft jaws prevent damage because they are made from materials softer than the workpiece. They can also be machined for full surface contact, which distributes clamping force evenly and avoids stress points that cause deformation, especially on thin-walled or delicate parts.

Protecting the workpiece is critical, especially in the final stages of machining. This is where soft jaws6 become an essential tool in any machine shop. I tell my team to think of them as insurance for their finished surfaces. Their ability to grip securely without causing damage comes from two key principles working together: soft materials and distributed pressure.

Material Softer Than the Part

The first line of defense against marring is the material itself. When you use aluminum or mild steel soft jaws to hold a hardened steel part, the jaws are much softer. Even under pressure, the jaws will conform to the workpiece, not the other way around. This means no jaw marks, scratches, or indentations are left on your beautifully finished surface.

Even Distribution of Clamping Force

The second reason is even pressure distribution. When we bore soft jaws to the exact profile of the part, the jaws make full contact. This spreads the clamping force over a very large surface area. Instead of three small points of high pressure like with hard jaws, you have three large areas of low pressure. This is crucial for thin-walled parts. Best of all, because the grip is so efficient, you can often use lower overall clamping force without compromising security. This dramatically reduces the risk of deforming or crushing the part.

Conclusion

Choosing between hard and soft jaws is simple. Use hard jaws for powerful roughing on raw stock. Use soft jaws for precision, finishing, and holding delicate or irregular parts.

-

Explore this link to understand the best materials for hard jaws, ensuring optimal performance and durability in your machining projects. ↩

-

Discover the ideal materials for soft jaws to prevent damage to delicate parts, enhancing your machining accuracy and quality. ↩

-

Explore this link to understand how hard jaws enhance machining efficiency and safety, especially during aggressive cuts. ↩

-

Explore this link to understand how custom-cut soft jaws can enhance your machining projects and improve part stability. ↩

-

Learn about the boring process to see how it ensures precision and concentricity in custom jaw setups. ↩

-

Explore this link to understand the importance of soft jaws in machining and how they protect workpieces during the process. ↩