How to Choose Between HS-WEDM and MS-WEDM?

Chris Lu

Leveraging over a decade of hands-on experience in the machine tool industry, particularly with CNC machines, I'm here to help. Whether you have questions sparked by this post, need guidance on selecting the right equipment (CNC or conventional), are exploring custom machine solutions, or are ready to discuss a purchase, don't hesitate to CONTACT Me. Let's find the perfect machine tool for your needs.

Chris Lu

Leveraging over a decade of hands-on experience in the machine tool industry, particularly with CNC machines, I'm here to help. Whether you have questions sparked by this post, need guidance on selecting the right equipment (CNC or conventional), are exploring custom machine solutions, or are ready to discuss a purchase, don't hesitate to CONTACT Me. Let's find the perfect machine tool for your needs

Choosing the wrong Wire EDM machine can trap your shop with poor part quality or high costs. This decision between High-Speed and Medium-Speed machines is confusing, leaving many with an inefficient process.

Choose a High-Speed Wire EDM (HS-WEDM) for fast, low-cost roughing where tolerances are looser (±0.01 mm). Select a Medium-Speed Wire EDM (MS-WEDM) for molds and precision parts that demand a superior surface finish and tighter accuracy (±0.005 mm).

The medium-speed machine was born directly from the limitations of the high-speed process. HS-WEDM machines are workhorses that use a reciprocating molybdenum wire to cut quickly and cheaply. But the recycled wire and aggressive cut always left a rough finish. MS-WEDM evolved by borrowing the multi-pass cutting strategy from high-end machines, using the same type of wire to achieve a drastically better surface. Your choice depends entirely on what you make and who you make it for.

Why is Surface Finish a Deciding Factor When Choosing Between These Two Machine Types?

Your parts have a rough, unacceptable surface finish that requires secondary operations. This wastes time and money, and you’re wondering if a different machine could solve the problem directly.

Surface finish is the primary difference. A HS-WEDM uses one fast, high-energy cut that produces a rough finish (Ra ~3.0). A MS-WEDM uses multiple, lower-energy trim cuts to produce a much finer finish (Ra ~1.0 or better) directly off the machine.

The entire reason MS-WEDM machines exist is to solve the finish problem of HS-WEDM machines. A high-speed machine blasts through material with a single pass, using a molybdenum wire that runs back and forth at high speed (8-12 m/s). This wire is recycled continuously, but this leads to erosion and vibration, which directly causes a rougher surface. A medium-speed machine, in contrast, makes a first roughing cut and then comes back for second or third "trim" passes. Each trim pass uses progressively less electrical energy. These gentle passes skim the surface, removing the rough recast layer from the previous cut. This multi-cut strategy is what lets a MS-WEDM achieve a smooth, almost polished surface right from the machine, saving hours of manual labor.

Surface Finish1 vs. Cutting Strategy2

| Feature | High-Speed WEDM (HS-WEDM) | Medium-Speed WEDM (MS-WEDM) |

|---|---|---|

| Cutting Method | Single high-energy cut with recycled wire. | One roughing cut plus multiple low-energy trim cuts. |

| Key Limiting Factor | Wire vibration and erosion from high-speed reuse. | Slower cycle times due to multiple passes. |

| Typical Finish (Ra) | 2.5 – 3.2 μm (Rough) | 0.8 – 1.2 μm (Smooth) |

| Result | Often requires secondary polishing or grinding. | Often eliminates the need for secondary finishing. |

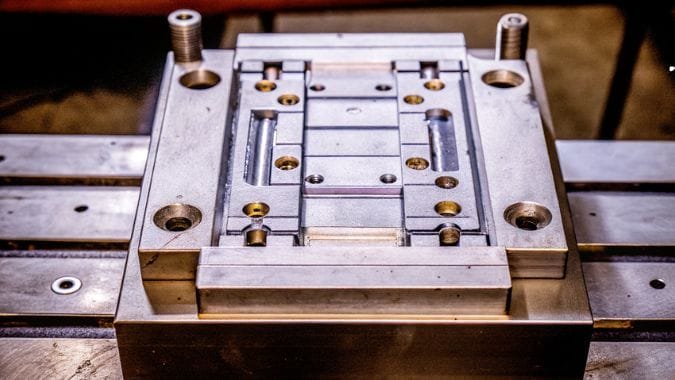

Why is a MS-WEDM Often the Minimum Requirement For Mold Making and Precision Parts?

You’re trying to break into the mold making industry, but your parts are rejected. Customers complain about poor finish and inaccurate dimensions, even though you are hitting your numbers.

Molds demand tight tolerances (often ±0.005 mm) and a flawless surface to ensure proper part ejection and dimensional stability. A MS-WEDM’s multi-pass cutting delivers the necessary smoothness and accuracy that a HS-WEDM struggles to achieve reliably.

For molds, dies, and precision aerospace or medical parts, the quality of the cut is everything. It’s not just about looks; a smooth surface is critical for easy part release from a mold. More importantly, the gentle trim passes of a MS-WEDM3 minimize the heat-affected zone and recast layer. This reduces stress in the hardened tool steel, preventing distortion and ensuring the mold holds its precise dimensions over its lifespan. A HS-WEDM’s single aggressive cut is simply too rough and introduces too much stress for this level of work.

Why Precision Demands a Better Process

- Surface Transfer: In molding, the machined surface is the final product surface. A rough mold creates a rough part.

- Dimensional Integrity4: MS-WEDM’s gentle trim passes allow for tighter tolerances and reduce heat-induced stress in hardened materials.

- Reduced Labor: The smooth finish from a MS-WEDM drastically cuts down on the hours of expensive and difficult manual polishing.

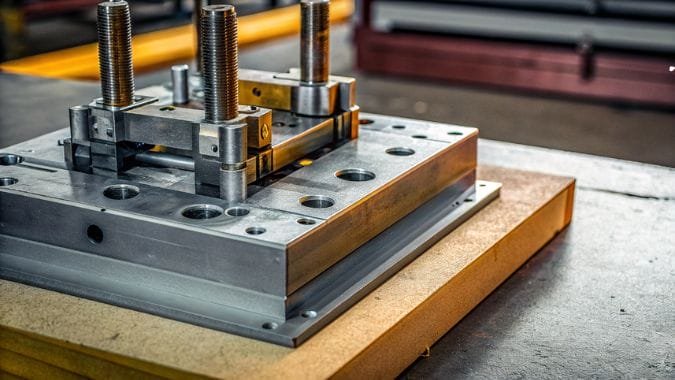

What Specific Applications are Best Suited for a Cost-Effective HS-WEDM?

Your shop gets a lot of requests for one-off jobs and simple parts. You need a versatile cutting tool, but the high cost and slower speed of a precision machine don’t make financial sense.

A HS-WEDM is perfect for general fabrication, roughing out large blocks of material, prototyping, and producing parts where speed and low cost are more important than a perfect surface finish.

Don’t think of a HS-WEDM5 as a "bad" machine. It is an incredible workhorse when used for the right jobs. Its strengths are its speed, simplicity, and low operating cost due to the reusable wire. It excels in applications where you need to remove a lot of material quickly. For example, you can use a HS-WEDM to rough out the basic shape of a die or mold, efficiently cutting away the bulk of the material before moving it to a different machine for the final precision finishing. It’s also ideal for creating prototypes in hardened alloys, making jigs and fixtures, or even for cutting advanced materials like thin-walled carbon fiber composites where its non-contact cutting prevents delamination. It’s the go-to choice when function, speed, and cost trump aesthetic perfection.

The HS-WEDM Sweet Spot

- Die and Mold Roughing6: Quickly removing large amounts of material before a finishing process.

- General Fabrication & Prototyping: Making functional parts, jigs, and test pieces where finish is not critical.

- High-Volume, Simple Profiles: Cutting simple shapes in conductive materials where speed is the main priority.

- Specialty Materials: Cutting thin-walled components or composites where cutting force is a concern.

What is the Final Checklist to Determine if a HS-WEDM or MS-WEDM is the Right Investment for Your Workshop?

You have the technical details, but you’re stuck on the final decision. You need a clear, business-focused way to compare the options and justify the investment for your specific workshop.

Evaluate your choice based on five key factors: the precision your customers demand, the surface finish required, your production speed needs, your budget, and your future growth plans.

Making the right investment comes down to a simple analysis of your business. Forget the machine specs for a minute and focus on the work. Who are your customers, and what are they paying for? A MS-WEDM is an investment in quality that opens doors to the mold, die, and aerospace industries. A HS-WEDM is an investment in speed and efficiency for a different class of work. Being honest about your goals is the key to making a decision you won’t regret. Use this checklist to guide your final choice.

Your Investment Decision Checklist

| Factor | Key Considerations | HS-WEDM is a Good Fit | MS-WEDM is a Good Fit |

|---|---|---|---|

| Precision & Tolerance | What accuracy do your parts need (e.g., ±0.01 mm vs. ±0.005 mm)? | Suitable for looser tolerances where perfect fit-up is not critical. | Essential for tighter tolerances needed in molds, dies, and precision parts. |

| Surface Finish | Is a smooth finish required, or will parts be post-processed? | Best for rougher finishes (Ra > 2.5 μm) or when polishing is planned. | Ideal for smooth finishes (Ra < 1.2 μm) to reduce or eliminate manual labor. |

| Production Speed | Is overall throughput or single-part quality more important? | Excellent for high-speed roughing and high-volume, simple parts. | Slower overall due to multiple passes, but efficient for high-quality work. |

| Budget & Costs | What is your initial investment budget and operating cost sensitivity? | Lower upfront machine cost and low consumable cost due to reusable wire. | Higher initial investment but can lower total costs by reducing rework. |

| Future Growth | Are you targeting your current market or aiming for higher-value work? | Best for staying competitive in cost-sensitive fabrication and roughing. | A strategic step to enter or expand into the precision machining market. |

Conclusion

Choose the machine that fits your work. A HS-WEDM is the fast, cost-effective choice for general fabrication and roughing. A MS-WEDM is the right investment for the superior finish and accuracy demanded by mold and precision parts industries.

-

Understanding surface finish is crucial for quality control in machining, ensuring optimal performance and longevity of parts. ↩

-

Exploring cutting strategies can enhance your knowledge of machining efficiency, leading to better production outcomes. ↩

-

Explore this link to understand how MS-WEDM enhances precision in machining, ensuring high-quality molds and parts. ↩

-

Learn about the significance of dimensional integrity in manufacturing processes and how it affects product quality. ↩

-

Explore the benefits of HS-WEDM to understand how it can enhance your manufacturing processes and reduce costs. ↩

-

Learn about Die and Mold Roughing techniques to optimize your production workflow and achieve better results. ↩