How to Choose Between VDI and BMT Turret for a CNC Lathe?

You’re buying a new turn-mill center, but the spec sheet offers two options: VDI or BMT. They seem similar, but choosing the wrong one could mean constant chatter, limited power, or slow setups.

Choose a VDI turret for high-mix, quick-changeover environments where setup speed is critical. Select a BMT turret for heavy-duty cutting, tough materials, and applications that demand the absolute highest rigidity, especially for milling operations.

This is one of the most important decisions you can make when specifying a new lathe. It’s not just a tool holder; it’s the entire foundation for your machine’s performance. For years, I saw shops default to VDI because it was common and fast. But then they’d wonder why they couldn’t push their live tools hard in stainless steel. The choice between VDI and BMT comes down to a simple trade-off: do you need speed and flexibility, or do you need raw power and stability? Getting this right from the start will save you a lot of headaches later.

What is the Core Mechanical Difference in How VDI and BMT Holders Mount to a Turret?

You see these two systems, and they look vaguely similar, but you know the mounting method is the key. You’re trying to understand why one is considered more rigid than the other.

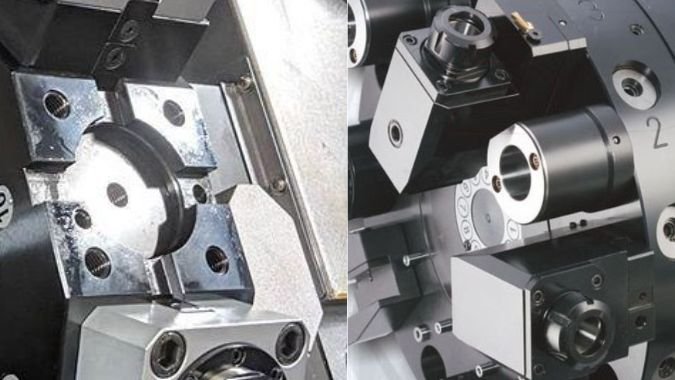

A VDI holder uses a serrated shaft that slides into a hole and is secured by a single clamping mechanism. A BMT holder is bolted directly to the flat face of the turret with four screws and locating keys.

Think of it this way. A VDI holder1 is like putting a peg in a hole. A serrated shaft gives it a positive lock so it can’t twist, and a single bolt or wedge tightens it in place. It’s fast. A BMT holder is like bolting a solid block of steel directly onto another solid block of steel. The holder has keys that align it perfectly, and then four heavy-duty bolts pull it tight against the turret face. This fundamental difference in mounting is the source of all the performance variations. One is designed for speed and convenience; the other is designed for maximum strength.

The Critical Alignment Difference

The way these holders align is a huge practical difference. With a VDI holder, because it’s a single shaft in a bore, you often have to "indicate" it with a dial indicator to make sure it’s perfectly straight before you tighten it down. This adds a step to the setup process. The BMT system2 is different. It uses solid locating keys or dowels that fit into precision slots on the turret. When you bolt it down, it’s straight every time—no indicating needed. This inherent accuracy and solid, face-to-face contact create a much more rigid and reliable connection, which is where BMT gets its strength.

| Feature | VDI | BMT |

|---|---|---|

| Fixing Method | Single serrated shaft, clamped by a wedge. | Four bolts, mounted flat against the turret face. |

| Alignment | Requires manual "indicating" for precision. | Precision keys/dowels ensure automatic alignment. |

| Contact Area | Smaller, concentrated around the shaft. | Large, distributed across the face of the holder. |

| Mounting Position | Can be axial (face) or radial (side). | Axial (face) mounting only. |

Why is a BMT Turret Superior for Heavy-Duty Cutting and Interrupted Cuts?

Your jobs involve tough materials or heavy roughing on large forgings. You’ve experienced chatter and tool failure, and you need a system that can handle the extreme forces without flinching.

A BMT turret is superior because its face-mounted, four-bolt system creates a single, solid unit with the turret. This massive rigidity prevents tool vibration and deflection under the intense impact of heavy or interrupted cuts.

I’ll never forget a job we had turning a large cast part with sections missing. Every time the tool hit the material after cutting air, it was like a hammer blow. With VDI system, we were breaking inserts and fighting chatter constantly. We moved the job to a machine with a BMT turret3, and the difference was night and day. The cut was smoother, quieter, and we could increase our feed rate. The BMT’s solid connection absorbs those impacts instead of letting the tool vibrate. This superior rigidity directly translates into better part quality, longer tool life, and the ability to machine tougher materials more efficiently.

Handling Extreme Forces

The BMT’s design is purpose-built for high-stress scenarios. Its stability comes from the large contact area and the clamping force of four bolts, which minimizes any chance of the tool holder shifting or flexing. This is crucial for maintaining precision during heavy roughing or when working with difficult alloys like Inconel4 or hardened steel. The efficient transfer of power and torque from the spindle through the turret to the tool means less energy is wasted as vibration and heat. This not only protects the tool and workpiece but also the machine’s spindle and bearings over the long term. For applications in aerospace, medical, or any field that demands both power and precision, BMT is the safer, more productive choice.

When Does the Quick-Change Capability of VDI Make it the Smarter Choice for a Workshop?

Your shop handles a wide variety of jobs with small batch sizes. Your biggest enemy isn’t cutting force, it’s the time the machine sits idle during setup and tool changes.

VDI is the smarter choice when setup speed and machine utilization are more important than maximum rigidity. Its single-clamp design allows operators to change and set tools in seconds, drastically reducing downtime between jobs.

I once worked with a shop that specialized in prototypes and small runs of 10-20 pieces. They were changing tools constantly. On BMT lathe, that would mean unbolting four screws for every holder. With VDI lathes, the operator could pop a tool out, drop a new one in, tighten one wedge, and be ready to go in under 30 seconds. For them, saving several minutes per tool change, multiple times a day, translated into hours of extra production time each week. This speed can increase machine utilization by 20-30% in a dynamic environment. VDI shines when agility is more profitable than brute strength.

Optimizing for Uptime

The VDI system5 was engineered for efficiency in automated and multi-tasking environments. Its design makes tool changes6 incredibly fast and repeatable. For complex jobs that require many different tools or long-overhang boring bars, the ability to swap them quickly is critical. VDI holders can be preset offline, and their modularity allows for both axial (on the face) and radial (on the side) mounting, which adds a layer of flexibility in tight setups. For a job shop that thrives on variety and quick turnarounds, the agility of the VDI system is a massive competitive advantage. It keeps the spindle turning and the parts moving, which is the key to profitability in a high-mix, low-volume world.

What Are the Differences in the Cost and Availability of VDI and BMT Tool Holders?

You’re trying to budget for a new machine and the tooling that goes with it. You need to know if one system is significantly more expensive or harder to find than the other.

VDI tool holders are generally less expensive and more widely available due to their simpler design. BMT holders are more costly to manufacture, reflecting their higher performance, precision, and rigidity.

From a purchasing standpoint, the difference is clear. VDI has been a dominant standard for a long time, so there is a huge variety of holders available from many manufacturers. This competition keeps prices down, sometimes making the initial investment 20-50% lower than for BMT. BMT is a more modern, premium system. The holders require more precise manufacturing to ensure the face is perfectly flat and the keyways are accurate, which increases the cost. I always tell my clients to think about the total cost. While BMT holders cost more upfront, their rigidity might save you money in the long run through better tool life and higher productivity on tough jobs.

Market Trends and Your Supply Chain

Availability can also be a factor depending on your location and industry. The VDI system, as an older German standard, is extremely popular and remains dominant in many parts of the world. You will have no trouble finding a wide range of standard and specialized VDI holders from many suppliers. The BMT system has seen strong adoption in markets that prioritize high-performance and heavy-duty machining. While all major tooling distributors stock both systems, you might find that VDI is more common and cost-effective in general manufacturing, while BMT is the standard for premium, specialized applications. It is always a good idea to check with your preferred tooling provider to see what their stock and support looks like for each system before making a final decision.

Conclusion

Choose VDI for speed, flexibility, and lower costs in general-purpose turning. Choose BMT for the power, rigidity, and stability needed for heavy milling, interrupted cuts, and demanding materials.

-

Explore this link to understand why VDI holders offer speed and convenience in tool mounting, ideal for quick setups. ↩

-

Learn how the BMT system provides superior strength and precision through its unique bolted and keyed mounting design. ↩

-

Explore the benefits of BMT turrets for improved machining efficiency and precision. ↩

-

Learn about the unique challenges of machining Inconel and how to overcome them for better results. ↩

-

Explore this link to understand how the VDI system enhances efficiency and flexibility in manufacturing processes. ↩

-

Discover insights on the significance of tool changes and their effect on overall production efficiency in manufacturing. ↩

Chris Lu

Leveraging over a decade of hands-on experience in the machine tool industry, particularly with CNC machines, I'm here to help. Whether you have questions sparked by this post, need guidance on selecting the right equipment (CNC or conventional), are exploring custom machine solutions, or are ready to discuss a purchase, don't hesitate to CONTACT Me. Let's find the perfect machine tool for your needs.