How to Fix Deck Machinery Mounting Holes On-site Instead of Sending it to the Workshop?

Worn mounting holes on your deck machinery mean trouble. The thought of dismantling a huge winch, crane, or capstan and shipping it to a workshop is a logistical nightmare, costing you weeks of downtime and a fortune in transport and labor.

You can fix deck machinery mounting holes on-site using a portable boring machine. This portable machine tool mounts directly to the equipment base, allowing you to accurately weld, re-bore, and face the worn holes to original specifications without removing the machinery from the deck.

I’ve seen this exact problem cripple operations for weeks. A client once had a massive mooring winch with oval-shaped mounting holes, making it unsafe to use. The cost to remove it and send it for repair was astronomical. The solution, however, was much simpler and cheaper than they ever imagined. It involved bringing the machine shop directly to the job site. Let’s walk through how this powerful technology gets the job done right where the equipment sits.

What is a Portable Boring Machine?

You’re facing a critical repair on a huge, immovable part. Taking it apart seems impossible and would shut down your entire operation for far too long. There has to be a better way to fix it in place.

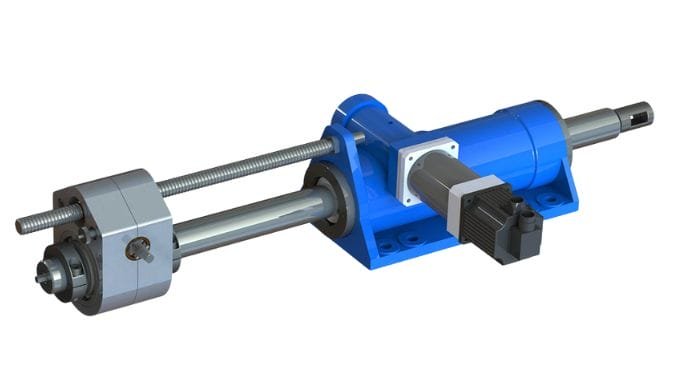

A portable boring machine, or line borer, is a powerful tool that clamps directly onto a large workpiece. It uses a rotating boring bar with cutting tools to accurately machine or repair holes on-site, bringing workshop-level precision to the field.

This machine is a true problem-solver. It’s designed in modular sections to be lightweight enough for one or two people to set up, but powerful enough to make heavy cuts. The core idea is simple: instead of moving the mountain, you move the machine tool. Its design is a marvel of efficiency, built around key systems that allow it to work in almost any situation. A sealed lubrication system lets you mount it horizontally, vertically, or even upside down. Heavy-duty, zero-clearance spindle bearings are critical, ensuring the operation is smooth and free from the vibration that would ruin a precise finish.

Key Features and Capabilities

| Feature | Description |

|---|---|

| Boring Range | Typically handles diameters from Φ30mm up to Φ300mm and beyond. |

| Power System | Can be electric, hydraulic, or pneumatic with constant torque for control. |

| Modular Design1 | Lightweight components allow for easy transport and setup in confined spaces. |

| Cutting Force2 | Powerful enough for a single-side feed rate of over 3mm per pass. |

| Versatility | Can be equipped with a facing head to machine hole end faces or even weld. |

| Portability | Lightweight and compact for easy transport and setup on-site. |

What Are the Advantages of a Portable Boring Machine for On-Site Repairs?

Downtime is killing your budget and your project schedule. Moving heavy equipment is expensive, risky, and incredibly time-consuming. You need a faster, cheaper, and more efficient repair solution that gets you back up and running.

The primary advantages are drastically reduced downtime and cost. By avoiding disassembly and transport, you can cut repair times by up to 90% and save massively on labor, logistics, and crane services.

I always tell my clients to think about the total cost of a repair, not just the workshop bill. You have to account for disassembling the equipment, hiring a crane, paying for transport, and then doing it all again in reverse. Most importantly, you have to calculate the cost of the downtime itself. When a key piece of machinery is out of service, the whole operation can grind to a halt. A portable boring machine cuts through all these secondary costs. I’ve seen projects where a two-week repair timeline was condensed into a single day. That’s not just a saving; it’s a competitive advantage.

The Main Advantages in Detail

- Minimized Downtime3: This is the biggest win. A repair that might take weeks using the traditional workshop method can often be completed in hours or a couple of days on-site. Less downtime means your assets get back to work faster, generating revenue instead of sitting idle.

- Massive Cost Savings4: You eliminate a huge portion of the repair budget. There are no heavy transport fees, no need for large crane rentals, and you reduce the labor hours required for disassembly and reassembly. The repair is focused, fast, and financially smart.

- Increased Flexibility and Safety: You bring the solution to the problem, wherever it is—on a ship at sea, deep in a mine, or on a remote construction site. It also reduces the risks associated with lifting and transporting massive, heavy components.

What Level of Accuracy and Surface Finish Can Be Expected from a Portable Boring Machine?

You’re worried that an on-site repair won’t be as good as a proper workshop job. If the accuracy isn’t perfect, the repair might fail, wasting time and money and putting your valuable equipment at risk.

A high-quality portable boring machine can achieve exceptional results, rivaling stationary equipment. You can expect tolerances meeting H7 class fits and a surface finish better than Ra 1.6, suitable for bearings and critical mounts.

This is a concern I hear all the time. People assume "portable" means "less precise." But that’s simply not true anymore. These machines are engineered for precision. The key is in the rigid setup and the machine’s construction. After securely mounting the machine frame by bolting or welding it to the workpiece, the operator uses dial indicators or laser alignment tools to center the boring bar perfectly, often within a hundredth of a millimeter. When the machine starts cutting, its heavy-duty bearings and constant torque drive ensure a smooth, chatter-free cut. The result is a hole that meets original manufacturer specifications. An "H7" tolerance is a standard for a perfect press-fit for bearings, and a surface roughness of Ra 1.65 or better is more than smooth enough for any critical mounting application.

What Industries Rely on a Portable Boring Machine for On-site Machining?

You might think this is just a niche tool for ships. But wear and tear on large, immovable equipment is a universal problem. Many industries face the exact same challenge: repairing critical holes without a complete shutdown.

This technology is essential in construction, mining, shipping, power generation, and heavy manufacturing. Any industry that uses large, hard-working machinery relies on portable boring machines to minimize downtime and repair costs.

Once I started working with these machines, I saw them everywhere. The applications are incredibly diverse because the core problem they solve is so common. From the massive pinholes on an excavator’s arm to the turbine casings in a power plant, the need for precise, in-place repairs6 is constant. These machines are the unseen heroes that keep some of our most critical industries running smoothly and efficiently.

Key Industrial Applications

- Construction & Mining: This is the most common use. The pivot pin holes on excavator arms, loader buckets, and bulldozer frames wear into an oval shape over time. A portable boring machine7, often paired with a portable bore welder to add material first, re-bores these holes to perfect roundness right in the field.

- Shipbuilding & Maritime: From the deck machinery mounts we started with to rudder systems and stern tubes below the waterline, portable boring is essential for ship maintenance. It allows for critical repairs during brief dry-docking periods to save precious time.

- Power Generation: Turbines and generators in power plants are massive and delicate. A portable boring machine can repair bolt holes on a turbine casing or bearing seats on a wind turbine gearbox without the need for a costly and time-consuming disassembly.

- Petrochemical & Steel: In factories with continuous production lines, a shutdown is a financial disaster. These machines are used to repair things like rolling mill housings and large compressor cylinders in tight spaces during brief maintenance windows.

Conclusion

A portable boring machine is a game-changing technology. It brings workshop accuracy directly to the job site, drastically cutting repair times and costs for huge, immovable equipment across countless industries.

-

Explore this link to understand how modular design enhances efficiency and portability in machinery, making setups easier. ↩

-

Learn about the significance of cutting force in machining to ensure precision and effectiveness in your projects. ↩

-

Understanding minimized downtime can help you appreciate its impact on productivity and revenue generation. ↩

-

Exploring cost-saving strategies can provide insights into optimizing your repair budget and improving financial efficiency. ↩

-

Exploring Ra 1.6 surface roughness helps in grasping the quality standards necessary for critical mounting applications. ↩

-

Discover the significance of precise, in-place repairs in maintaining critical machinery and preventing costly shutdowns in industries. ↩

-

Explore this link to understand how portable boring machines revolutionize repairs across various industries, enhancing efficiency and reducing downtime. ↩

Chris Lu

Leveraging over a decade of hands-on experience in the machine tool industry, particularly with CNC machines, I'm here to help. Whether you have questions sparked by this post, need guidance on selecting the right equipment (CNC or conventional), are exploring custom machine solutions, or are ready to discuss a purchase, don't hesitate to CONTACT Me. Let's find the perfect machine tool for your needs.