How to Repair Damaged Flange Sealing Surface?

Are flange leaks giving you headaches and causing unexpected shutdowns? Damaged sealing surfaces are often the culprit, leading to costly downtime, safety risks, and production losses. You need a fast, effective repair solution right where the problem is.

For flange face damage like scratches, dents, erosion, or corrosion deeper than 0.3mm, on-site machining using a portable flange facer is often the best solution. This specialized tool restores the surface finish and flatness without removing the flange from the system.

Dealing with damaged flanges is a common challenge across many industries. Sending flanges to a workshop involves major disassembly, transport, and delays. That’s why understanding on-site repair methods, particularly using portable flange facers, is crucial for efficient maintenance. Let’s explore what these machines are and how they keep critical systems sealed and operational.

What is a Flange Facer?

You’ve found a damaged flange, but removing it seems like a nightmare? Taking apart large pipes, vessels, or valves is a massive undertaking. Surely, there’s a tool designed to fix flanges right in place?

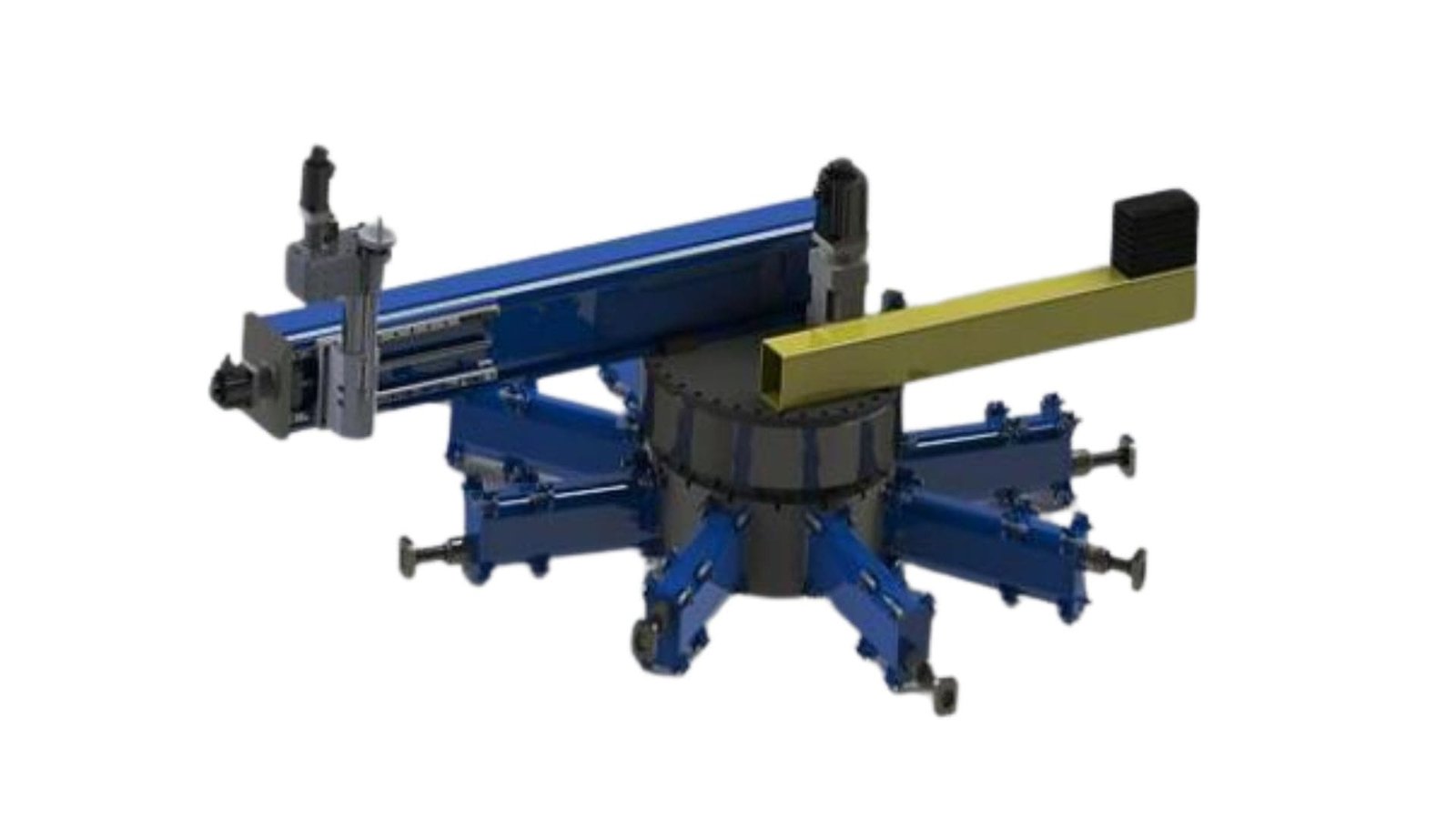

A flange facer is a portable machine tool designed to mount directly onto a flange. It uses cutting tools, much like a lathe or mill, to precisely re-machine the flange face, restoring its flatness and required surface finish on-site.

Let’s look closer at how these clever devices work. I’ve relied on them many times for urgent repairs, and they bring machine shop accuracy directly to the field, saving enormous amounts of time.

Principle of Operation

Think of a flange facer as a compact, specialized lathe designed specifically for flange surfaces. Here’s the basic concept:

- Mounting: The machine needs a stable base on the flange itself. Common methods include:

- Internal Mount (ID Mount): Clamping mechanisms expand inside the flange bore, centering and securing the machine. This is very common.

- External Mount (OD Mount): Clamps grip the outside diameter of the flange. Useful when the bore needs to stay clear or for very large flanges.

- Rotating Tool Head: Once mounted securely and centered, the machine has a rotating arm or assembly holding one or more cutting tool bits.

- Cutting Action: As the tool head rotates, the cutting tool sweeps across the flange face, removing the damaged material. This is usually done with specialized insert bits suitable for various flange materials like carbon steel, stainless steel, or aluminum alloys.

- Feed Mechanism: To create the required surface finish (like a specific spiral groove pattern for gasket sealing or a smooth finish), the tool bit must move across the face precisely. This feed can be:

- Radial: Moving the tool inwards or outwards.

- Axial: Moving the tool perpendicular to the face (for grooves or hubs).

- The feed is carefully controlled, often manually or via powered systems (pneumatic, hydraulic), to achieve consistent results and meet surface finish specifications1 (e.g., Ra values). Low feed rates are often used for fine finishes.

- Precision: Despite being portable, these machines are built for accuracy. Rigid construction, precision bearings, and calibrated feed systems allow them to achieve tight tolerances for flatness and surface finish, often meeting standards like ASME B16.5, critical for ensuring a reliable, leak-free seal. After machining, thorough cleaning removes all debris.

The goal is always to remove the minimum material necessary to restore a perfect sealing surface.

What Kinds of Machining Tasks Can A Flange Facer Handle On-Site?

So, a flange facer can smooth out a flat surface, but what about more complex damage? Flanges often have special grooves or need preparation for welding. What else can these machines actually do out in the field?

Beyond standard resurfacing, flange facers can machine RTJ grooves, O-ring grooves, lens ring seats, repair tube sheets, resurface pump bases, create weld prep bevels, spot face bolt holes, and even perform some drilling or milling tasks.

These tools are surprisingly versatile. We regularly use them for a variety of critical repair jobs beyond just simple flat facing. Let’s break down their capabilities.

Common On-Site Machining Operations

A portable flange facer brings significant machining capability directly to the workpiece:

- Flat / Raised Face Resurfacing2: The most frequent task. Removing damage (scratches, corrosion, tool marks, erosion) to restore the primary sealing area to specified flatness and finish (e.g., stock finish, smooth finish).

- Groove Machining & Repair:

- Ring Type Joint (RTJ) Grooves: Precisely re-cutting or creating grooves for metal ring gaskets according to standards.

- O-Ring Grooves: Machining grooves for O-ring seals.

- Lens Ring Seats: Machining specialized profiles for high-pressure lens ring seals.

- Other Grooves: Handling various proprietary or standard groove profiles for specific sealing needs.

- Weld Preparation3: Creating accurate edge preparations (bevels, counterbores) on flanges or pipe ends before welding. This ensures strong, reliable welds.

- Heat Exchanger Repair4: Re-machining gasket seals on tube sheets and divider bars within heat exchangers.

- Pump Base / Housing Resurfacing: Ensuring flat mounting surfaces for pumps or other equipment.

- Bearing Surface Repair: Re-machining bearing surfaces on components like rotary cranes.

- Spot Facing: Creating flat, perpendicular surfaces around bolt holes to ensure even clamping pressure from nuts and bolt heads.

- Specialized Applications: Depending on the machine setup, tasks like facing ship thruster mounts or hatch sealing surfaces, or even limited drilling and milling, might be possible.

This versatility comes from interchangeable mounting systems, adjustable tool heads using various cutting bit geometries, and precise feed controls, making them indispensable for comprehensive on-site flange maintenance.

What Industries Are Flange Facers Most Commonly Used?

Is this technology niche, or is it widely used? Understanding where flange facers are essential highlights their importance in maintaining the safety and efficiency of critical industrial infrastructure.

Flange facers are vital in Oil & Gas (upstream, downstream, pipelines), Power Generation (all types), Petrochemical & Chemical plants, Shipbuilding & Repair, Pharmaceutical production, Food Processing, Mining, Heavy Construction, and Pulp & Paper industries.

Essentially, we see these machines wherever pressurized systems with flanged connections are critical, and leaks pose significant risks to safety, the environment, or production.

Key Industrial Applications

The need for dependable, leak-free flange joints5 is universal in heavy industry:

- Oil & Gas: From offshore platforms and refineries to cross-country pipelines, countless flanges handle high pressures and corrosive fluids. On-site facing is routine for maintaining valves, vessels, heat exchangers, and pipeline connections.

- Power Generation: Fossil fuel, nuclear, and renewable power plants rely on complex piping for steam, water, and fuel. Turbine casings, boiler connections, valves, and condensers all require reliable flange seals. Downtime is extremely costly.

- Petrochemical & Chemical: Continuous processes often involve aggressive chemicals, high temperatures, and pressures. Maintaining reactors, columns, tanks, and piping integrity is paramount for safety and preventing product loss.

- Pharmaceutical & Food Processing: Sterile or hygienic processes demand perfectly sealed systems. Flange facers help maintain sanitary connections required for product quality and safety.

- Shipbuilding & Repair: Extensive piping systems on vessels require maintenance, often in confined spaces during dry-docking. Portable facers allow efficient repairs without major component removal.

- Pipelines: Maintaining flanges along extensive pipeline networks requires portable solutions for remote locations.

- Mining & Heavy Construction: Processing plants and infrastructure projects involve significant pipework where on-site repair capability is essential.

In all these sectors, the common drivers are the high cost of failure (leaks, downtime), the difficulty of removing large components, regulatory compliance, and the absolute need for precision repairs.

What Makes Portable Flange Facers Ideal for On-Site Machining?

Why haul a machine tool to the flange? Isn’t a workshop repair better? While workshops offer controlled environments, the specific advantages of portable flange facing often make it the only practical and economical choice.

Portability eliminates massive costs and delays from disassembly, transport, and workshop time. These machines are compact, easy to set up quickly, versatile, highly accurate, and bring essential repair capability directly to the problem location.

Having managed both workshop and field repairs, the benefits of on-site machining are undeniable, especially for integrated or large-scale equipment.

Advantages of Portability

Bringing the machining capability to the flange offers huge advantages:

- Massive Downtime Reduction6: This is the primary benefit. Disassembling large systems, transporting heavy components, waiting for workshop queues, and reassembly can take days or weeks. On-site facing can often be done within a single shift, minimizing lost production. I recall jobs where we repaired critical flanges during brief planned outages, saving the client millions.

- Significant Cost Savings: Avoids costs associated with cranes, heavy transport, workshop labor fees, and extended plant shutdown. The investment in portable machining (service or equipment purchase) often pays back very quickly.

- Logistical Simplicity: Eliminates the complex planning and safety risks associated with moving large, heavy parts. Machines are designed for transport and setup by technicians, even in confined or remote areas (like offshore platforms or pipelines). Some models are even self-contained, requiring no external power lines.

- Rapid Response: Enables quick reaction to unexpected leaks or damage found during inspections, preventing escalation.

- On-the-Spot Precision7: Modern portable facers deliver workshop-level accuracy. They are designed to meet stringent industry standards for flatness and surface finish right in the field, ensuring a reliable, long-lasting seal.

- Versatility: One machine can often tackle various flange sizes (from under an inch to many feet in diameter) and perform multiple tasks (facing, grooving, beveling), making it a flexible maintenance tool.

- Enhanced Safety: Reduces risks associated with lifting and moving large components.

Portable flange facers essentially decentralize precision machining, offering a faster, safer, more economical, and highly effective way to maintain the integrity of critical flanged connections.

Conclusion

Effectively repairing damaged flange sealing surfaces prevents dangerous leaks and costly operational delays. Portable flange facers deliver precise, on-site machining, tackling diverse tasks across vital industries, dramatically saving time and money compared to traditional workshop repairs.

-

Discover the importance of surface finish specifications in ensuring leak-free seals and optimal performance. ↩

-

Explore this link to understand the importance of resurfacing in maintaining sealing integrity and preventing leaks. ↩

-

Learn about the critical role of weld preparation in ensuring strong and reliable welds, enhancing overall structural integrity. ↩

-

Discover effective techniques for heat exchanger repair to maintain efficiency and prolong equipment lifespan. ↩

-

Understanding dependable, leak-free flange joints is crucial for industries to prevent costly failures and ensure safety. Explore this resource for in-depth insights. ↩

-

Explore how reducing downtime can significantly enhance productivity and save costs in manufacturing processes. ↩

-

Discover the importance of on-the-spot precision in machining and how it ensures quality and efficiency in repairs. ↩

Chris Lu

Leveraging over a decade of hands-on experience in the machine tool industry, particularly with CNC machines, I'm here to help. Whether you have questions sparked by this post, need guidance on selecting the right equipment (CNC or conventional), are exploring custom machine solutions, or are ready to discuss a purchase, don't hesitate to CONTACT Me. Let's find the perfect machine tool for your needs

Chris Lu

Leveraging over a decade of hands-on experience in the machine tool industry, particularly with CNC machines, I'm here to help. Whether you have questions sparked by this post, need guidance on selecting the right equipment (CNC or conventional), are exploring custom machine solutions, or are ready to discuss a purchase, don't hesitate to CONTACT Me. Let's find the perfect machine tool for your needs