What are the Advantages of a Swiss Type Lathe?

Wasting expensive material and struggling with complex parts? The hidden costs of scrap, long setup times, and secondary operations are eating into your profits and slowing down production.

The main advantages of a Swiss-type lathe are incredible material savings, flawless concentricity, and perfect perpendicularity. They achieve higher accuracy and efficiency than traditional lathes, which saves money and speeds up production for complex parts.

I often get asked about the specific hows and whys behind these claims. It’s not magic; it’s just really smart engineering that solves some of the biggest challenges in precision machining. The benefits go far beyond just making small parts. Let’s break down some of the biggest advantages one by one.

How do Swiss-type Lathes Reduce Waste and Improve Bar Stock Utilization?

Every inch of wasted bar stock is money thrown away. Long remnants and material needed for multiple clampings on traditional machines can make a job unprofitable before it even starts.

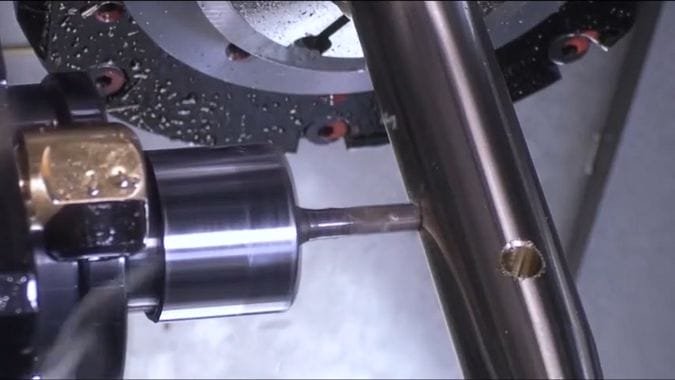

By using a sliding headstock and guide bushing, they machine parts completely from the bar stock with a very small remnant. This single-setup process avoids the waste from multiple clampings.

When you are machining with expensive materials like titanium or medical-grade stainless steel, waste is your biggest enemy. This is where a Swiss-type lathe1 really shines. It’s designed from the ground up to be incredibly efficient with material.

Deeper Cuts and Fewer Passes

Because the guide bushing provides such rigid support right at the cutting point, we can take deeper, more aggressive cuts in a single pass. On a traditional lathe, you’d have to take multiple shallow passes to avoid causing the part to bend, which is slow and less efficient. This single-pass capability means less wasted motion and faster cycle times.

One-and-Done Machining

The machine’s ability to perform turning, milling, and drilling in a single cycle is a huge factor. With its sub-spindle, it machines the front and back of the part in one continuous process. This eliminates the need for extra material for re-clamping, pushing our raw material utilization up to 98% and achieving overall material savings2 of up to 30% compared to traditional methods.

| Waste Reduction Method | Impact on Utilization |

|---|---|

| Single-Setup Machining | Eliminates waste from multiple clampings. |

| Deeper, Single-Pass Cuts | More efficient material removal with less scrap. |

| Sub-Spindle Back-working | Uses the entire bar, leaving a tiny remnant. |

What Mechanism Ensures Concentricity in Swiss-type Lathe Machining?

Misaligned features on a shaft cause vibration, poor performance, and part failure. A tiny error in concentricity can lead to a whole batch of returned parts and a damaged reputation.

Concentricity is ensured by the high-precision spindle and the guide bushing providing rigid support. For complex parts, a sub-spindle grabs the workpiece to guarantee perfect alignment between features machined on both ends.

Achieving this is critical, and a Swiss-type lathe has several mechanisms built in to guarantee it.

The foundation is the high-precision main spindle3. It’s built to spin perfectly true. This is paired with the guide bushing, which prevents any "runout" or wobble by supporting the workpiece right where the tools are cutting. This constant support is the first line of defense. But the real magic for complex parts is the sub-spindle4. After the front of the part is machined, the sub-spindle—perfectly aligned with the main spindle—travels forward and clamps onto the part before it’s cut off. It then pulls the part away for back-working. Because the workpiece is transferred while still held in alignment, the features on both ends are perfectly concentric.

How do Swiss-type Lathes Maintain Perpendicularity During Machining?

Drilling a perfectly straight hole, especially a small one, is incredibly difficult. A drill bit can easily "walk" or wander off-center, resulting in a crooked hole and a useless part.

Perpendicularity is maintained using live tooling like high-frequency milling heads for drilling, precisely controlling the feed rate, and selecting the optimal cutting tool for the job. This prevents the drill from wandering.

When you drill a cross-hole, you want it to be perfectly perpendicular to the main axis of the part. Swiss-type lathes are excellent at this because of their live tooling capabilities and overall stability.

Using the Right Tools for the Job

Instead of just a simple drill, we can use high-frequency milling heads5. These are essentially miniature, high-speed milling spindles that replace a standard tool. They spin at very high RPMs, which allows them to drill clean, precise holes without deviation. We also carefully select high-quality drills with the right shape and cutting angle for the specific material.

Controlling the Process

The machine’s rigid structure and the close support from the guide bushing prevent the workpiece itself from moving under the force of the drill. We then precisely control the feed rate6—how fast the drill moves into the material. Pushing too fast or too slow can cause the drill to deflect. By finding the sweet spot, we ensure the drill enters straight and stays straight.

How does a Swiss-type Lathe Improve Accuracy and Efficiency over Traditional Lathes?

Traditional lathes can be slow and may struggle to hold tight tolerances on complex parts. This means longer lead times, more manual checks, and lower overall quality for demanding applications.

They improve accuracy with their rigid design, achieving tolerances down to 0.001mm. Efficiency is boosted by a dual-axis tool arrangement and up to 13 axes, allowing multiple operations at once and slashing idle time.

When you get down to it, a machine shop makes money by producing accurate parts as quickly as possible. A Swiss-type lathe beats a traditional lathe on both counts, especially for complex production runs.

A Higher Level of Accuracy

The accuracy of these machines is incredible. We can consistently hold tolerances down to 0.001mm. This is possible because the guide bushing supports the workpiece right where the cutting happens, eliminating the vibration that causes errors. For industries making things like spinal implants or aerospace sensors, this level of precision isn’t just nice to have—it’s absolutely mandatory.

Built for Maximum Efficiency

The efficiency gains are huge. With anywhere from 7 to 13 axes compared to a traditional lathe’s 2 to 5, we can have multiple tools cutting at the same time. While a turning tool shapes the outside, a live tool can drill a cross-hole. This overlapping of operations, planned with smart CAM software, drastically shortens the cycle time. Add in an automatic bar feeder, and the machine can run unattended for hours, making it perfect for high-volume production.

Conclusion

Swiss-type lathes offer huge advantages in waste reduction, concentricity, and perpendicularity. They boost accuracy and efficiency, making them the best choice for producing complex, high-precision parts profitably.

-

Explore the advantages of Swiss-type lathes for efficient machining, especially with costly materials like titanium. ↩

-

Learn how advanced machining techniques can significantly reduce material waste and improve efficiency. ↩

-

Understanding the role of a high-precision main spindle can enhance your machining accuracy and efficiency. ↩

-

Exploring the function of a sub-spindle can provide insights into improving part concentricity and machining processes. ↩

-

Explore this link to understand how high-frequency milling heads enhance precision and efficiency in drilling operations. ↩

-

Learn about the importance of feed rate in drilling to ensure optimal performance and prevent tool deflection. ↩

Chris Lu

Leveraging over a decade of hands-on experience in the machine tool industry, particularly with CNC machines, I'm here to help. Whether you have questions sparked by this post, need guidance on selecting the right equipment (CNC or conventional), are exploring custom machine solutions, or are ready to discuss a purchase, don't hesitate to CONTACT Me. Let's find the perfect machine tool for your needs

Chris Lu

Leveraging over a decade of hands-on experience in the machine tool industry, particularly with CNC machines, I'm here to help. Whether you have questions sparked by this post, need guidance on selecting the right equipment (CNC or conventional), are exploring custom machine solutions, or are ready to discuss a purchase, don't hesitate to CONTACT Me. Let's find the perfect machine tool for your needs