What are the Differences Between a Swiss Lathe and a Turn-mill Center?

Choosing between a Swiss lathe and a turn-mill center is confusing. They both combine turning and milling, but making the wrong choice means wasting a huge investment on a machine that’s either overkill or simply can’t do your job efficiently.

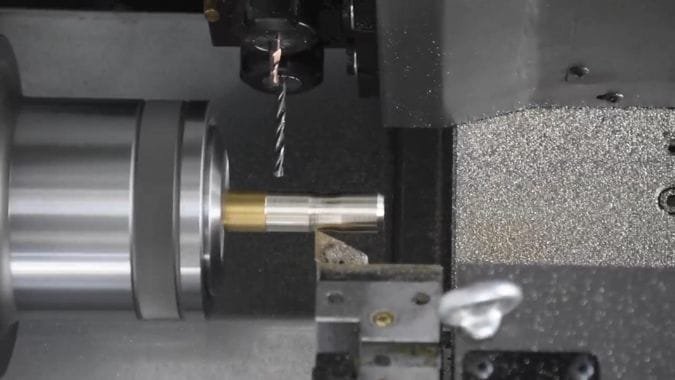

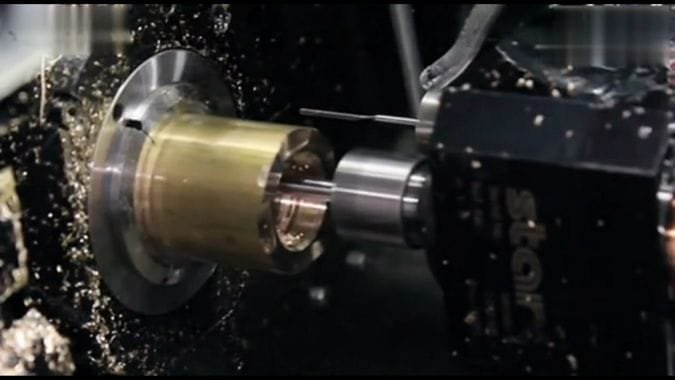

A Swiss lathe uses a sliding headstock and a guide bushing to support and machine long, slender parts with extreme precision. In contrast, a turn-mill center is a more robust, versatile machine with a multi-axis B-axis milling spindle, designed to produce complex, often larger parts in a single setup.

The core difference isn’t just about features; it’s about the entire philosophy of how the machine approaches the part. A Swiss lathe is a specialist, built for one primary purpose: controlling vibration on long, skinny workpieces. A turn-mill is a generalist, designed to bring a massive amount of multi-axis capability to bear on a complex, often chunkier part. Understanding this fundamental difference is the key to choosing the right tool.

What is the Key Difference Between a Guide Bushing and a B-axis Spindle?

You hear the terms "guide bushing" and "B-axis spindle," but what do they really mean for your day-to-day machining? Confusing them leads to a fundamental misunderstanding of what each machine is truly designed to do, and where its strengths lie.

A guide bushing is a workpiece support mechanism that rigidly holds slender material near the cutting tool to prevent it from bending. A B-axis spindle is a powerful, articulating milling head that approaches the workpiece from any angle for complex 5-axis machining. It’s support versus versatility.

I once had a client who wanted to make long, thin medical shafts. He was looking at a massive turn-mill because of its impressive B-axis. I had to explain that for his parts, the B-axis was irrelevant. What he needed was the simple, rigid support of a guide bushing. They are two tools designed for completely different jobs. The guide bushing’s entire purpose is stability. It rotates in sync with the main spindle, gripping the raw material to prevent it from vibrating or deflecting under cutting pressure. The B-axis spindle’s purpose is flexibility. It turns the machine into a full 5-axis machining center, capable of creating complex curves and angled features that are impossible on a standard lathe.

Design Philosophy at a Glance

| Feature | Guide Bushing1 (Swiss Lathe) | B-axis Spindle2 (Turn-mill) |

|---|---|---|

| Primary Function | Workpiece Support | Multi-axis Machining |

| Core Purpose | To create stability for slender parts. | To provide flexibility for complex geometries. |

| Mechanical Design | A collet that rotates with the spindle to guide material. | An independent, articulating milling head. |

| Main Benefit | Eliminates deflection and vibration. | Enables "done-in-one" machining of complex parts. |

Why is a Swiss Lathe Ideal for Long, Slender Parts with High Length-to-Diameter Ratios?

Trying to turn a long, skinny part on a conventional lathe is a recipe for disaster. The part bends, chatters, and comes out with terrible tolerances and a poor surface finish. This scrap is costly and incredibly frustrating for any machinist.

A Swiss lathe is ideal for these parts because its guide bushing provides rigid support mere millimeters from the cutting tool. As the material feeds out, the tool is always working on a short, well-supported section, which completely eliminates deflection and vibration, even on parts with a 20:1 length-to-diameter ratio.

This is the absolute magic of a Swiss machine. On a normal lathe, any part with a length-to-diameter ratio over 3:1 will start to bend under cutting pressure. A Swiss lathe3 solves this completely. The guide bushing supports the material so firmly that the tools are always cutting just a millimeter or two away from that support point. It doesn’t matter if the part is 200mm long; the unsupported length is always tiny. This is combined with the fact that the headstock moves the material through the guide bushing, rather than the tools moving along the part. This ensures the cutting forces are always applied to a rigidly held section of the bar, guaranteeing incredible accuracy for parts like medical implants, aerospace pins, and electronic components.

What Programming and Operator Skills Differ Between Swiss Machines and Multi-axis Turn-mills?

You might think a good machinist can run any machine. But the programming logic and setup process for a Swiss lathe and a 9-axis turn-mill center are worlds apart. Putting the wrong operator on the machine can lead to crashes, scrap, and inefficient cycle times.

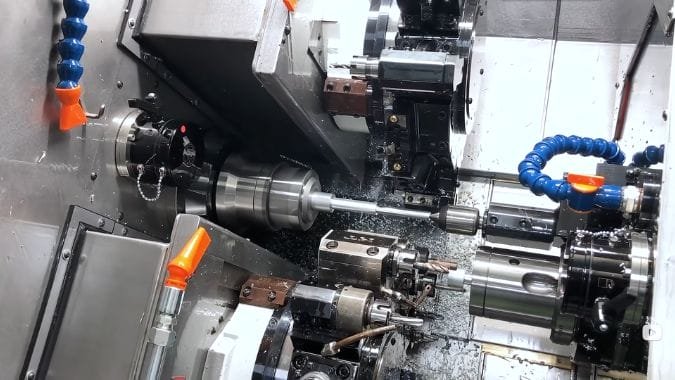

Swiss lathe programming uses a "divide and conquer" strategy, synchronizing multiple tools cutting simultaneously. Turn-mill programming requires managing complex 5-axis simultaneous motion. Operationally, a Swiss operator masters the guide bushing, while a turn-mill operator masters complex fixturing.

While both machines demand a high level of skill, the focus is different. When I train operators, the Swiss machine training is all about process synchronization4. You’re thinking about how to get the main spindle, sub-spindle, and multiple tool gangs working in perfect harmony. The operator’s key physical skill is mastering the guide bushing setup—adjusting its pressure perfectly for the material to prevent slippage or scratching. For a turn-mill, the training is heavily focused on 3D spatial thinking5. You are programming a B-axis to move in coordination with C, X, Y, and Z axes. The operator’s main skill is fixturing complex parts and managing a large tool library for diverse jobs.

Skillset Comparison

| Skill Area | Swiss Lathe Operator | Turn-mill Operator |

|---|---|---|

| Programming | Focus on process synchronization ("divide and conquer"). | Focus on multi-axis simultaneous motion and 3D toolpaths. |

| Core Challenge | Managing multiple simultaneous operations and guide bush constraints. | Managing complex kinematics and collision avoidance. |

| Key Physical Skill | Precise setup and pressure adjustment of the guide bushing. | Workpiece fixturing and managing a large tool changer. |

| Machine Setup | Optimized for high-speed, continuous bar feeding. | Optimized for lower-volume, diverse job changeovers. |

How Should Part Geometry, Size, and Volume Guide Your Choice Between a Swiss Lathe and a Turn-mill?

You have a part to make, but which machine is the right fit? Choosing a massive turn-mill for a simple, high-volume pin is wasteful, but trying to make a complex aerospace valve body on a basic Swiss machine is impossible.

Choose a Swiss lathe for high-volume production of small (typically ≤38mm diameter), long, and slender parts. Choose a turn-mill center for lower-volume, high-complexity parts that are often larger and require true 5-axis simultaneous machining.

The final decision comes down to three factors: the shape of your part, its size, and how many you need to make. I guide my clients through this logic every day. If the part is long and thin, and you need to make thousands of them, the Swiss lathe is the only answer. Its automatic bar feeder and unmatched speed for this geometry will give you the lowest possible cost per part. If your part is complex, with angled holes, 3D surfaces, or non-cylindrical features, and you’re making them in smaller batches, the turn-mill is the correct choice. Its flexibility and multi-axis power allow it to finish the part in one go, avoiding costly secondary operations.

Decision Matrix

| Swiss Lathe | Turn-mill Center | |

|---|---|---|

| Part Geometry | Simple to complex, but long and slender (high L:D ratio). | Highly complex with multi-faceted features, angled holes, 3D contoured surfaces. |

| Typical Diameter | Small, typically under 38mm. | Can handle both small and very large diameter parts. |

| Production Volume | Ideal for high volume and mass production (thousands to millions). | Ideal for low to medium volume, prototypes, and R&D. |

| Key Advantage | Unmatched stability and efficiency for long, thin parts. | Ultimate flexibility for complex, "done-in-one" machining. |

| Cost | Lower initial investment ($70k-$150k). | Higher initial investment (over $150k). |

Conclusion

The Swiss lathe and turn-mill center are powerful specialists. The Swiss lathe is a production powerhouse for small, long, slender parts, offering speed and precision. The turn-mill is a versatile solution for complex, multi-sided components, offering ultimate machining flexibility.

-

Understanding the role of a Guide Bushing can enhance your machining knowledge, especially for stability in slender parts. ↩

-

Exploring the B-axis Spindle’s benefits can reveal how it transforms machining processes, enabling complex geometries. ↩

-

Discover how Swiss lathes enhance precision and efficiency in manufacturing, especially for complex parts. ↩

-

Understanding process synchronization is crucial for optimizing machine operations and enhancing productivity. ↩

-

Exploring 3D spatial thinking can improve your programming skills and efficiency in complex machining tasks. ↩

Chris Lu

Leveraging over a decade of hands-on experience in the machine tool industry, particularly with CNC machines, I'm here to help. Whether you have questions sparked by this post, need guidance on selecting the right equipment (CNC or conventional), are exploring custom machine solutions, or are ready to discuss a purchase, don't hesitate to CONTACT Me. Let's find the perfect machine tool for your needs.