What Are the Differences Between Belt-Driven and Gearbox Spindles in a CNC Lathe?

Choosing the wrong spindle type for a CNC lathe can lead to poor performance, stalled cuts, and high long-term costs. The decision between a belt drive and a gearbox directly impacts a machine’s capability, precision, and operational budget.

Belt-driven spindles are ideal for high-speed, precision finishing work, offering quiet operation and low maintenance. Gearbox spindles provide superior torque for heavy-duty cutting on hard materials, enabling higher material removal rates at the cost of increased noise, heat, and maintenance complexity.

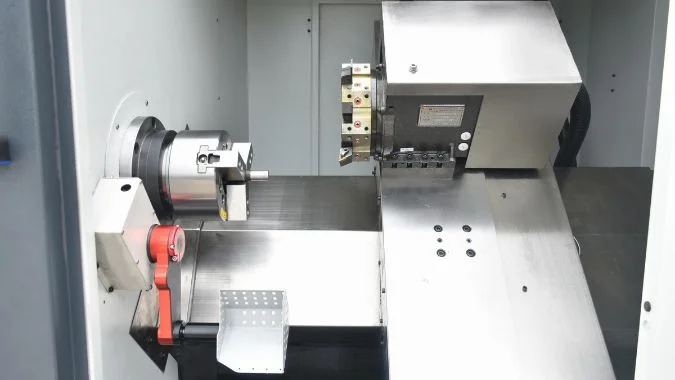

The spindle is the heart of any CNC lathe, determining its power, speed, and cutting performance. While both belt-driven and gearbox systems transfer power from a motor to the workpiece, their internal mechanisms are fundamentally different. This difference dictates which applications each is best suited for, from rapid machining of aluminum to heavy roughing of hardened steel. Understanding these core distinctions is essential for selecting a machine that aligns perfectly with your production requirements and delivers the best return on investment.

How Do the Power Transmission Mechanisms Differ Between Belt-Driven and Gearbox Spindles?

A motor spins, but how does that rotational energy get to the spindle? The method of power transmission defines the spindle’s core characteristics of rigidity, smoothness, and efficiency.

A belt-driven spindle uses a high-tension belt and pulleys for smooth, friction-based power transfer. A gearbox uses a complex system of intermeshing gears to provide rigid, direct-drive power with mechanical advantage.

A belt-driven system is elegant in its simplicity. The motor connects to the spindle via a pulley system and a modern high-tension belt, such as a poly-V or synchronous timing belt1. This design has very few moving parts. Power is transmitted smoothly and quietly, as the belt naturally absorbs vibrations from the motor. While modern designs minimize slip, the inherent elasticity of the belt makes the connection slightly less rigid than a solid gear train.

In contrast, a gearbox spindle, also known as a geared-head2, is a much more complex mechanical assembly. Power flows into an enclosed headstock filled with multiple sets of precisely machined helical or spur gears. By engaging different gear combinations, typically in two to four distinct speed ranges, the machine achieves a significant mechanical advantage. Power is transferred through the direct, positive meshing of gear teeth. This creates an incredibly rigid connection but introduces more friction and a slight efficiency loss, typically around 5–10%, from gear contact and oil churning.

What Spindle Type Delivers Superior Torque for Heavy-Duty Cutting on Hard Metals?

When facing a large-diameter billet of tough alloy steel or Inconel, the machine needs immense rotational force, or torque, to avoid stalling and maintain a consistent cut.

A gearbox spindle delivers vastly superior torque for heavy-duty cutting. Its gear reduction system acts as a torque multiplier, making it the only choice for aggressive roughing and machining hard materials at low RPMs.

A gearbox’s primary advantage is its ability to multiply torque3. By shifting into a low-speed gear range4, the spindle sacrifices speed for raw power, often generating two to four times more torque than a belt-driven system at speeds below 1000 RPM. This allows the machine to perform deep cuts, turn large diameters, and achieve high material removal rates without placing excessive load on the motor. This capability is essential in industries like oil & gas and aerospace, where machining large forgings from difficult materials is common.

A belt-driven spindle’s torque output is directly tied to the motor’s power and the fixed pulley ratio. While suitable for many applications, its torque significantly drops off at the low RPMs required for cutting hard metals. Under the extreme pressure of a heavy cut, the belt can slip, reducing effective power at the tool. While a larger motor can compensate to some degree, it cannot replicate the pure mechanical advantage that a gearbox provides for true heavy-duty applications.

How Do Belt-Driven and Gearbox Spindles Compare in Terms of Noise, Heat, and Vibration?

The operational environment of a machine shop is a key concern. Noise affects operator comfort, while heat and vibration can directly impact machining precision and surface finish.

Belt-driven spindles operate much more quietly and generate less heat and vibration. Gearboxes are inherently louder and produce more heat due to the friction and impact of their internal moving parts.

The operational differences are stark. A belt drive5 is known for its smooth and quiet performance, as the belt itself dampens motor vibrations. This results in a better working environment and can contribute to a finer surface finish on the workpiece. Because there is less friction, the headstock generates less heat, promoting better thermal stability and accuracy during long machining cycles.

A gearbox6 is a complex mechanical system that generates noise through the constant meshing of gears, especially under heavy load. The friction from gear contact and the churning of lubricating oil also produce significant heat within the headstock, often requiring an oil cooler to maintain thermal stability.

| Aspect | Belt-Driven Spindle | Gearbox (Geared-Head) Spindle |

|---|---|---|

| Noise Level | Significantly quieter (often < 70 dB); belts dampen sound. | Louder (can exceed 80-90 dB); caused by gear meshing. |

| Vibration | Lower; the belt acts as a natural shock absorber. | Higher; gear meshing transmits vibration to the machine frame. |

| Heat Generation | Lower; less internal friction and motor heat is isolated. | Higher; friction and oil shear create heat in the headstock. |

What are the Long-Term Maintenance Requirements and Costs Associated with Each Spindle Type?

A machine tool is a long-term investment, and the total cost of ownership includes not just the initial purchase price but also ongoing maintenance, repairs, and potential downtime.

Belt-driven spindles have significantly lower long-term maintenance costs and simpler requirements. Gearboxes demand more complex, regular service and can be extremely expensive to repair if a failure occurs.

The lifetime ownership costs for a belt-driven spindle are very manageable. Routine maintenance is typically limited to checking, tensioning, and eventually replacing the drive belt, a task that is quick, inexpensive, and can often be performed in-house. Furthermore, the belt often acts as a mechanical "fuse" in a crash, slipping or breaking to protect the far more expensive motor and spindle bearings from catastrophic damage.

Gearbox maintenance7 is a more demanding and costly process. It requires regular oil changes and periodic inspections of gear wear and backlash by a skilled technician. A failure within the gearbox, such as a worn gear or failed bearing, can lead to a major rebuild, resulting in significant downtime and repair costs that can run into the thousands of dollars.

| Aspect | Belt-Driven Spindle8 | Gearbox (Geared-Head) Spindle |

|---|---|---|

| Routine Maintenance | Simple belt check/tension/replacement (every 2,000-5,000 hrs). | Complex oil changes (every 6-12 months); gear/clutch inspection. |

| Common Failures | Belt wear or breakage; an inexpensive and quick fix ($50 – $300). | Gear tooth wear, bearing failure; a costly and time-consuming rebuild. |

| Crash Protection | Excellent; belt slips or breaks, protecting the drive train. | Poor; rigid connection transmits full impact force to gears. |

| Long-Term Cost | Lower; fewer complex parts and simpler repairs. | Higher; precision components and specialized labor increase costs. |

Conclusion

Choose a belt-drive for speed, precision, and low operational costs on standard parts. For applications demanding extreme torque for heavy-duty cutting of tough materials, the power of a gearbox is indispensable.

-

Explore this link to understand how poly-V and synchronous timing belts enhance smooth, quiet power transmission with minimal slip and vibration absorption. ↩

-

Learn about the mechanical complexity and rigidity of geared-head spindles, including their gear combinations and efficiency trade-offs. ↩

-

Understanding how gearboxes multiply torque can enhance your knowledge of mechanical systems and their applications. ↩

-

Exploring the impact of low-speed gear ranges can provide insights into optimizing machinery for heavy-duty tasks. ↩

-

Exploring this link will provide insights into the benefits of belt drives, including their smooth operation and reduced noise. ↩

-

This resource will help you understand the complexities of gearboxes and their impact on noise and heat generation in machinery. ↩

-

Learn effective Gearbox maintenance techniques to prevent costly repairs and ensure the longevity of your machinery. ↩

-

Explore the advantages of Belt-Driven Spindles, including cost-effectiveness and ease of maintenance, to enhance your machinery knowledge. ↩

Chris Lu

Leveraging over a decade of hands-on experience in the machine tool industry, particularly with CNC machines, I'm here to help. Whether you have questions sparked by this post, need guidance on selecting the right equipment (CNC or conventional), are exploring custom machine solutions, or are ready to discuss a purchase, don't hesitate to CONTACT Me. Let's find the perfect machine tool for your needs.