What Are the Environmental Requirements for the Use of MS-WEDM?

You invest in high-precision MS-WEDM equipment, but the parts keep coming out with errors. You blame the machine or the operator, but the real culprit is often the room itself.

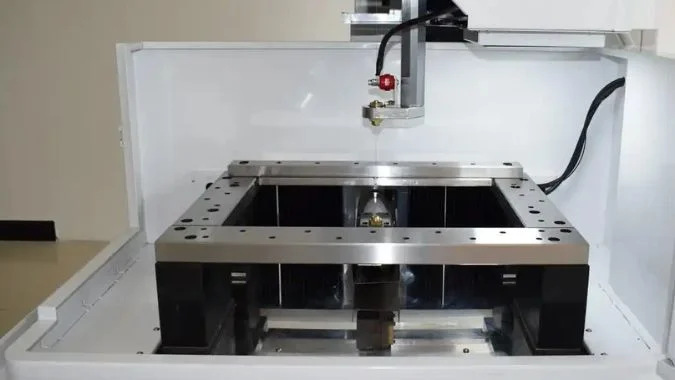

To maximize the performance of MS-WEDM, you must maintain a stable temperature around 20°C to prevent thermal expansion. The environment must be dust-free to protect lead screws, isolated from external vibrations to ensure uninterrupted wire tension, and well-ventilated to remove hazardous oil mist and control humidity between 40-60%.

I visited some of factories where expensive machines are placed next to open windows or heavy stamping presses. This destroys accuracy. If you want your WEDM to last for as long as possible, you need to treat the workshop environment as part of the machine system.

How Does Strict Temperature Control Help Maintain the Accuracy of MS-WEDM?

Metal expands and contracts with heat, which is the silent killer of precision machining. If your workshop temperature fluctuates wildly, your cutting accuracy will drift throughout the day.

MS-WEDM machines rely on maintaining tight tolerances. To do this, the room temperature should be strictly controlled, ideally around 20°C with fluctuations less than ±1°C. This prevents uneven thermal expansion in the lead screws, the workpiece, and even the wire itself, which ensures consistent calibration and prevents dimensional distortion.

A machine tool is like a living thing; it reacts to its environment. When a machine works, it creates its own heat. If the room is also hot or the temperature changes rapidly, the machine metal expands.

The 20-Degree Standard

Many top enterprises build their factories with special insulation materials. Their goal is to keep the room temperature locked at 20 degrees Celsius1. Why? Because even a small shift can change the distance between the wire and the workpiece. If the sun hits the machine through a window in the morning, one side of the machine warms up while the other stays cool. This twists the frame.

Impact on Wire and Fluid

It is not just the heavy iron that moves. Thermal variations cause the workpiece to warp slightly. More importantly, heat affects the electrode wire, causing it to sag or stretch. This changes the spark gap—which is usually extremely small, around 0.01 to 0.05 mm. If that gap changes, you get tapered cuts. Furthermore, temperature affects the viscosity and conductivity of the dielectric fluid. If the fluid gets too hot, the sparking becomes unstable, leading to a rougher surface finish. To get the fine finish that MS-WEDM is famous for, you need that temperature stability to be absolute.

What Makes a Dust-Free Environment Essential for Protecting the Precision Lead Screws and Guide Rails?

Dust is not just dirty; it is abrasive sandpaper that grinds down your machine’s most expensive parts. Ignoring cleanliness will destroy your positioning accuracy in a matter of months.

A dust-free environment is essential because dust, metal chips, and oil mix to form an abrasive paste on precision ball screws and guide rails. This contamination can reduce guide rail life by 40% to 60% and worsen positioning errors from ±0.01mm to over ±0.03mm, causing jamming and premature failure.

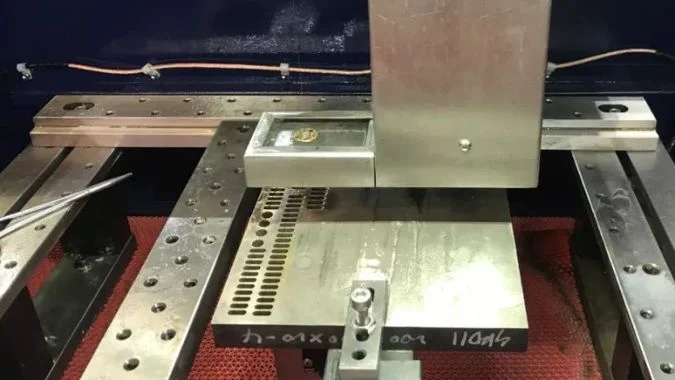

The MS-WEDM is a high-density, high-precision machine. The core of its accuracy lies in the ball screws and linear guide rails. These parts have mirror-like finishes. They are designed to glide perfectly.

The "Grinding Paste2" Effect

When dust enters the air, it does not just sit on the floor. It lands on the greased rails. It mixes with the oil. This creates a grinding paste. Every time the machine moves, it is grinding itself down. Our data shows that in a dusty shop, the life of a guide rail drops by half. This abrasive wear scratches the surfaces, leading to backlash or binding.

Accuracy Loss and Corrosion3

The wear is not just about broken parts; it is about losing precision. A new machine might hold ±0.01mm. After running in dust, the resistance increases. The wear creates gaps. Suddenly, your error is over ±0.03mm. You cannot hold tight tolerances anymore. Also, in humid conditions, this dust promotes corrosion on the metal parts. It causes uneven torque on the lead screws.

Overheating Risks

Dust also acts as a blanket. It covers the heat sinks and electrical components. The heat generated by the machine cannot escape. Over time, this causes motors and boards to burn out. While we use wipers and covers, they cannot stop everything if the air is dirty.

| Contaminant Impact | Clean Environment | Dusty Environment |

|---|---|---|

| Guide Rail Life | 100% (Normal) | Reduced by 40-60% |

| Positioning Error | ±0.01mm | > ±0.03mm |

| Running Resistance | Low | High (Jamming risk) |

| Maintenance Cost | Low | High (Frequent replacement) |

How Can External Vibrations From Nearby Compromise the EDM Surface Finish?

You see strange ripple marks on your cut surface and assume the wire tension is wrong. Often, the problem is the heavy forklift driving past your machine.

The precision of MS-WEDM relies on a stable, non-contact spark gap. External vibrations from heavy machinery or traffic cause the wire to oscillate, widening the spark gap inconsistently. This prevents proper debris flushing and leads to "chatter marks," pits, and a degraded surface finish.

Reliability is everything. You cannot produce precise parts if the ground beneath you is shaking.

Wire Instability4

MS-WEDM cuts with a wire that is thinner than a human hair. It uses electrical sparks. It never touches the metal. If the machine shakes, the wire vibrates. This oscillation widens the spark gap unpredictably. Instead of a smooth, continuous erosion, you get erratic discharges. We call these "chatter marks." I advise my customers never to place an EDM machine near a punch press or a shearing machine.

Debris and Surface Quality4

Vibration does more than just shake the wire; it stops the machine from cleaning the cut. The shaking hinders the flushing of molten material and debris from the kerf (the cut slot). If that debris stays there, it creates "recast layers"—thick, rough surfaces with microcracks.

Structural Damage

It is not just about the cut quality today. Continuous vibration loosens screws. It causes stress on the casting. Over years, this "stress relaxation" warps the machine. You must ensure the machine is far away from vibration sources. If that is impossible, you need to dig a separate foundation or use high-quality vibration-damping feet.

Why Is Proper Ventilation and Mist Extraction Necessary for MS-WEDM Workshop?

A foggy, oily workshop is a health hazard for your staff and a death sentence for your electronics. You cannot ignore the air quality inside the production zone.

Proper ventilation and oil mist extraction are necessary to remove hazardous metal fumes and ozone, protecting operator health. It also prevents oily residue from coating circuit boards, which leads to overheating. Furthermore, humidity must be controlled between 40-60% to prevent corrosion and moisture damage to sensitive electronics.

We need to look at air quality from three angles: health, machine safety, and moisture control.

Health and Safety

The working fluid in MS-WEDM creates oil mist5 and metal fumes under high heat. These particles are tiny, less than 5 microns. If employees breathe this for years, it can cause chronic lung issues. Also, the oil settles on the floor. I have seen operators slip and fall. It is a major liability. An electrostatic adsorption system can drop mist levels to safe limits (0.5mg/m³).

Protecting the Electronics

Oil mist is sticky. It gets inside the electrical cabinet. It lands on the circuit boards. This blocks heat dissipation. Even worse, if the oil is conductive or acidic, it eats the solder and causes short circuits.

Moisture and Humidity Control

We aim for a relative humidity of 40-60%. If it is too dry, static electricity builds up. If it is too wet, you get rust. High humidity is dangerous, especially in the "plum rain season." We recommend sealing electrical cabinets and using desiccants (like color-changing silica gel). For machines that sit idle, we apply acrylic protective films to the circuit boards. Ventilation systems with heat recovery help keep the humidity stable, preventing the "sweating" that shorts out motors and wires.

Checklist for Air Quality

- Install oil mist collectors at the source to capture metal fumes.

- Seal electrical cabinets with dust-proof sponges.

- Use desiccants inside cabinets during humid months.

- Monitor humidity levels to keep them between 40-60%.

Conclusion

To ensure your MS-WEDM lasts and performs, you must control the temperature around 20°C, eliminate dust, isolate vibrations, and manage air quality. A good environment pays for itself in reduced maintenance and higher precision.

-

Understanding the importance of 20 degrees Celsius can help optimize machine performance and ensure precision in manufacturing. ↩

-

Understanding the grinding paste effect is crucial for maintaining machine precision and longevity, ensuring optimal performance. ↩

-

Exploring this topic reveals the hidden dangers of dust in machinery, helping you prevent costly repairs and maintain accuracy. ↩

-

Understanding Wire Instability is crucial for maintaining precision in EDM machining. Explore this link to learn more about its impact. ↩ ↩

-

Understanding the effects of oil mist is crucial for ensuring worker safety and machine longevity. ↩

Chris Lu

Leveraging over a decade of hands-on experience in the machine tool industry, particularly with CNC machines, I'm here to help. Whether you have questions sparked by this post, need guidance on selecting the right equipment (CNC or conventional), are exploring custom machine solutions, or are ready to discuss a purchase, don't hesitate to CONTACT Me. Let's find the perfect machine tool for your needs.