Choosing the right CNC lathe can significantly impact manufacturing efficiency and product quality. CNC slant bed and flat bed lathes each have unique features that cater to different machining needs. While flat bed lathes dominate the market, slant bed lathes offer compelling advantages, especially in precision and automation. This blog explores the key differences and advantages between these two lathe types to help you make an informed decision for your production needs.

CNC slant bed and flat bed lathes differ in design, performance, and applications. Slant bed lathes excel in precision and automation, while flat bed lathes offer simplicity and cost-effectiveness. Dive in as we compare these machines in detail to highlight their strengths and best use cases.

This blog will answer key questions about the structural differences between slant and flat bed lathes, their efficiency for high-precision machining, their suitability for different operations, and how they compare in maintenance, cost, and durability.

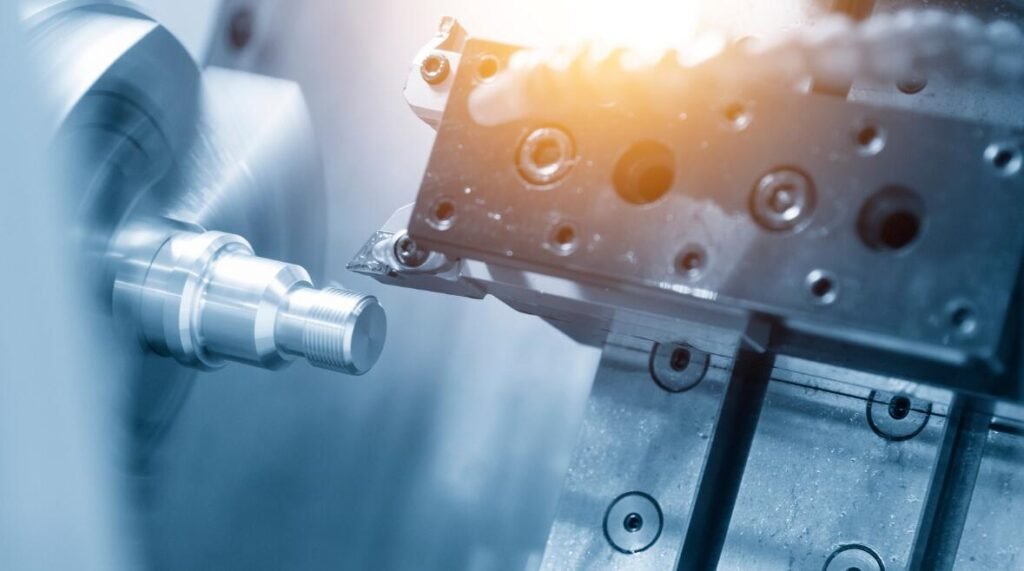

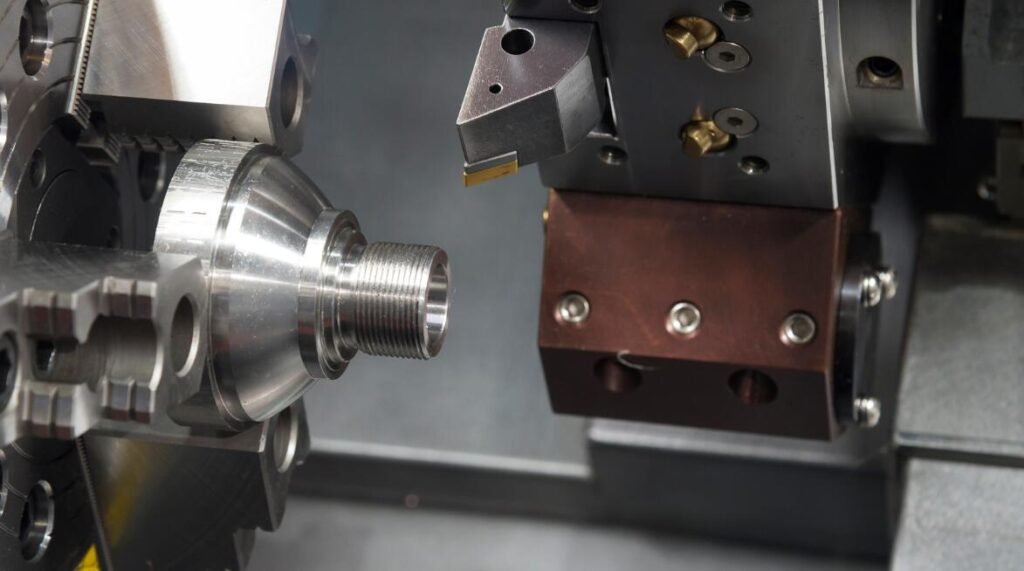

How Does the Design of a Slant Bed Lathe Differ From a Flat Bed Lathe, and What Impact Does It Have on Performance?

The primary distinction between CNC slant bed and flat bed lathes lies in the orientation of their guide rails. The design directly influences their performance in machining operations, including precision, stability, and tool arrangement.

Slant bed lathes feature inclined guide rails, offering better rigidity, reduced vibration, and enhanced tool positioning. Flat bed lathes, with their parallel-to-ground guide rails, are simpler but less optimized for high-precision tasks.

In slant bed lathes, the guide rails are set at angles of 30° to 75°, forming a triangular bed structure. This design increases the bed’s cross-sectional area, enhancing its resistance to bending and torsion. The downward cutting motion aligns with the gravity of the workpiece, reducing vibration and ensuring smoother operations. In contrast, flat bed lathes have a rectangular bed structure, and the cutting forces act perpendicular to the gravity of the workpiece, increasing the likelihood of vibrations. Additionally, the inclined layout of slant beds allows for more tool positions, making them more versatile for complex machining tasks.

Why Are CNC Slant Bed Lathes Often Considered More Efficient for High-Precision Machining?

Precision machining requires stability, minimal tool vibration, and accurate positioning. CNC slant bed lathes, by design, address these needs more effectively than flat bed lathes.

The inherent precision of slant bed lathes stems from their ability to reduce reverse gaps in ball screws, optimize chip removal, and enhance tool stability. These factors make them ideal for high-precision applications.

In slant bed lathes, the gravity-aligned cutting force minimizes spindle vibrations, ensuring a smoother finish and higher dimensional accuracy. The inclined guide rails also reduce the reverse gap in ball screws, a common issue in flat bed lathes where gravity does not assist in gap elimination. Furthermore, slant bed lathes feature efficient chip removal systems, including automatic conveyors, which prevent chip accumulation and tool entanglement. These features not only improve precision but also streamline machining operations, making slant bed lathes the preferred choice for industries like aerospace and automotive.

What Types of Machining Operations Are Best Suited for Flat Bed Lathes Compared to Slant Bed Lathes?

Both flat bed and slant bed lathes have their strengths and are suited for specific machining operations. Understanding these distinctions can help manufacturers choose the right tool for their needs.

Flat bed lathes are ideal for simple, large-scale machining tasks that do not require high precision, while slant bed lathes are better suited for complex, high-precision operations and automated workflows.

Flat bed lathes are commonly used for basic turning operations in industries where cost-efficiency and ease of use are priorities. They excel in machining larger workpieces that do not require intricate detailing. On the other hand, slant bed lathes are designed for high-precision applications, such as intricate component production in the medical and aerospace sectors. Their ability to accommodate more tools and support automated processes makes them more versatile and efficient for complex machining tasks.

How Do CNC Slant Bed and Flat Bed Lathes Compare in Terms of Maintenance, Cost, and Long-Term Durability?

When investing in CNC lathes, considerations like maintenance, cost, and durability play a crucial role. Both slant bed and flat bed lathes offer distinct advantages and trade-offs in these aspects.

While flat bed lathes are easier to manufacture and maintain, slant bed lathes provide better durability and cost-efficiency in automated, high-precision setups.

Flat bed lathes have simpler structures, making them easier and cheaper to produce, which translates to lower upfront costs. They also require less maintenance due to their straightforward design. However, slant bed lathes, with their robust triangular bed structure, offer better long-term durability, especially under high-stress machining conditions. Their advanced features, such as automatic chip conveyors and tool changers, reduce manual intervention and downtime, leading to lower operational costs over time. While slant bed lathes require a higher initial investment, their efficiency and durability make them a cost-effective choice for precision-driven industries.

Conclusion

CNC slant bed and flat bed lathes serve distinct purposes in the machining world. While flat bed lathes are simple, cost-effective solutions for basic machining needs, slant bed lathes shine in high-precision, automated production environments. Their advanced design minimizes vibration, improves precision, and supports complex machining tasks. Choosing the right lathe depends on your production requirements, budget, and long-term goals. For manufacturers prioritizing precision and efficiency, CNC slant bed lathes are a clear winner, offering exceptional performance and versatility.

Chris Lu

Leveraging over a decade of hands-on experience in the machine tool industry, particularly with CNC machines, I'm here to help. Whether you have questions sparked by this post, need guidance on selecting the right equipment (CNC or conventional), are exploring custom machine solutions, or are ready to discuss a purchase, don't hesitate to CONTACT Me. Let's find the perfect machine tool for your needs

Chris Lu

Leveraging over a decade of hands-on experience in the machine tool industry, particularly with CNC machines, I'm here to help. Whether you have questions sparked by this post, need guidance on selecting the right equipment (CNC or conventional), are exploring custom machine solutions, or are ready to discuss a purchase, don't hesitate to CONTACT Me. Let's find the perfect machine tool for your needs