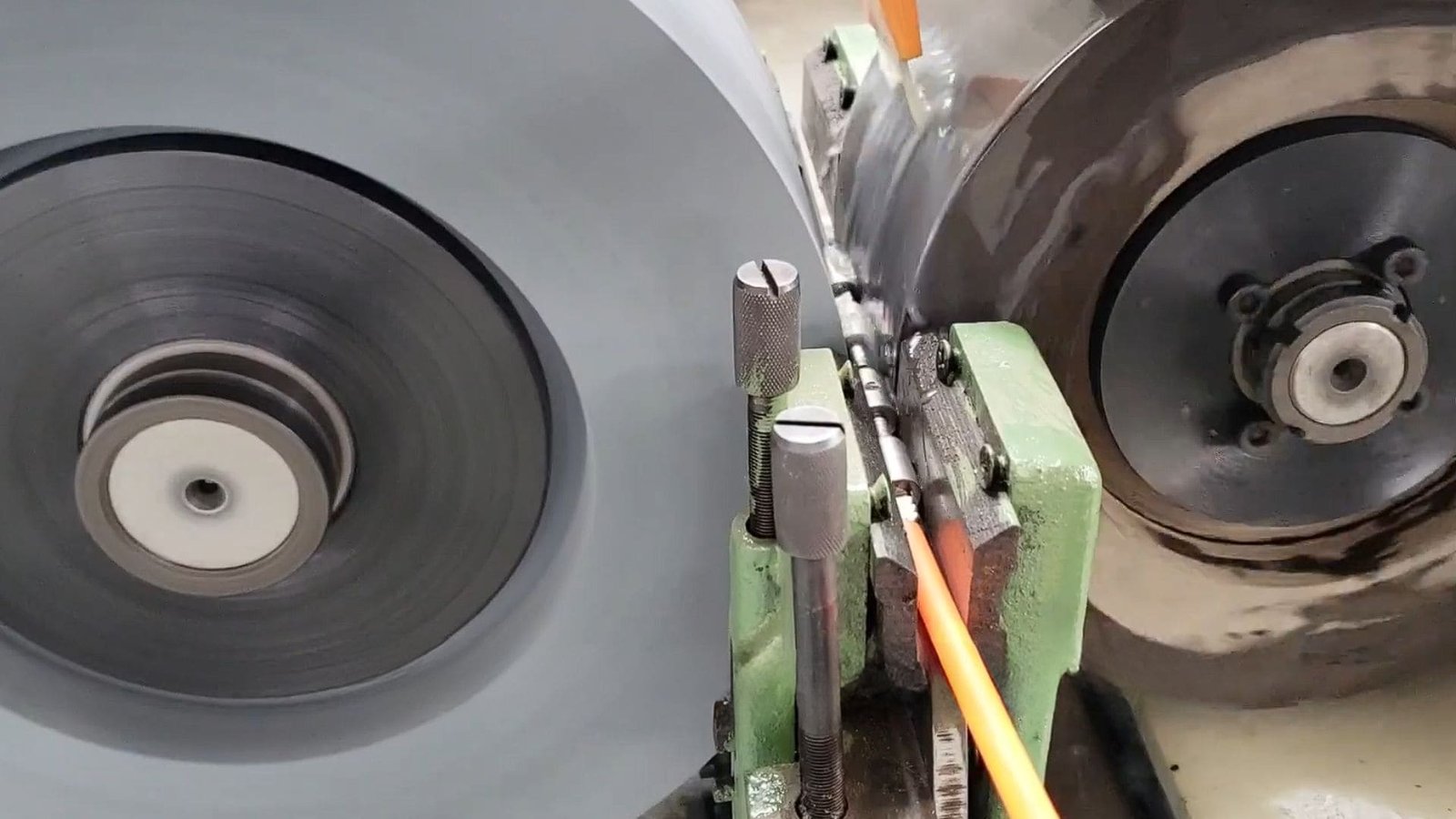

What Causes Out-of-Roundness in Centerless Grinding Operations?

Are your centerless ground parts failing inspection because they aren’t perfectly round? Achieving tight tolerances is impossible when underlying issues create inconsistent diameters, leading to scrap and frustration.

Out-of-roundness often stems from an improperly dressed regulating wheel, insufficient grinding passes for the initial stock condition, a dull or glazed grinding wheel, or overly aggressive material removal rates (heavy cuts or fast traverse speeds).

Fixing basic out-of-roundness is the first step. However, sometimes the problem manifests in specific geometric errors, like lobing or polygon shapes, which require understanding slightly different causes and solutions.

How Can Lobing or Polygonal Shapes Be Prevented During Centerless Grinding?

Do your "round" parts look more like subtle triangles or pentagons under inspection? This lobing effect is a frustrating geometric error that ruins precision fits and indicates setup problems.

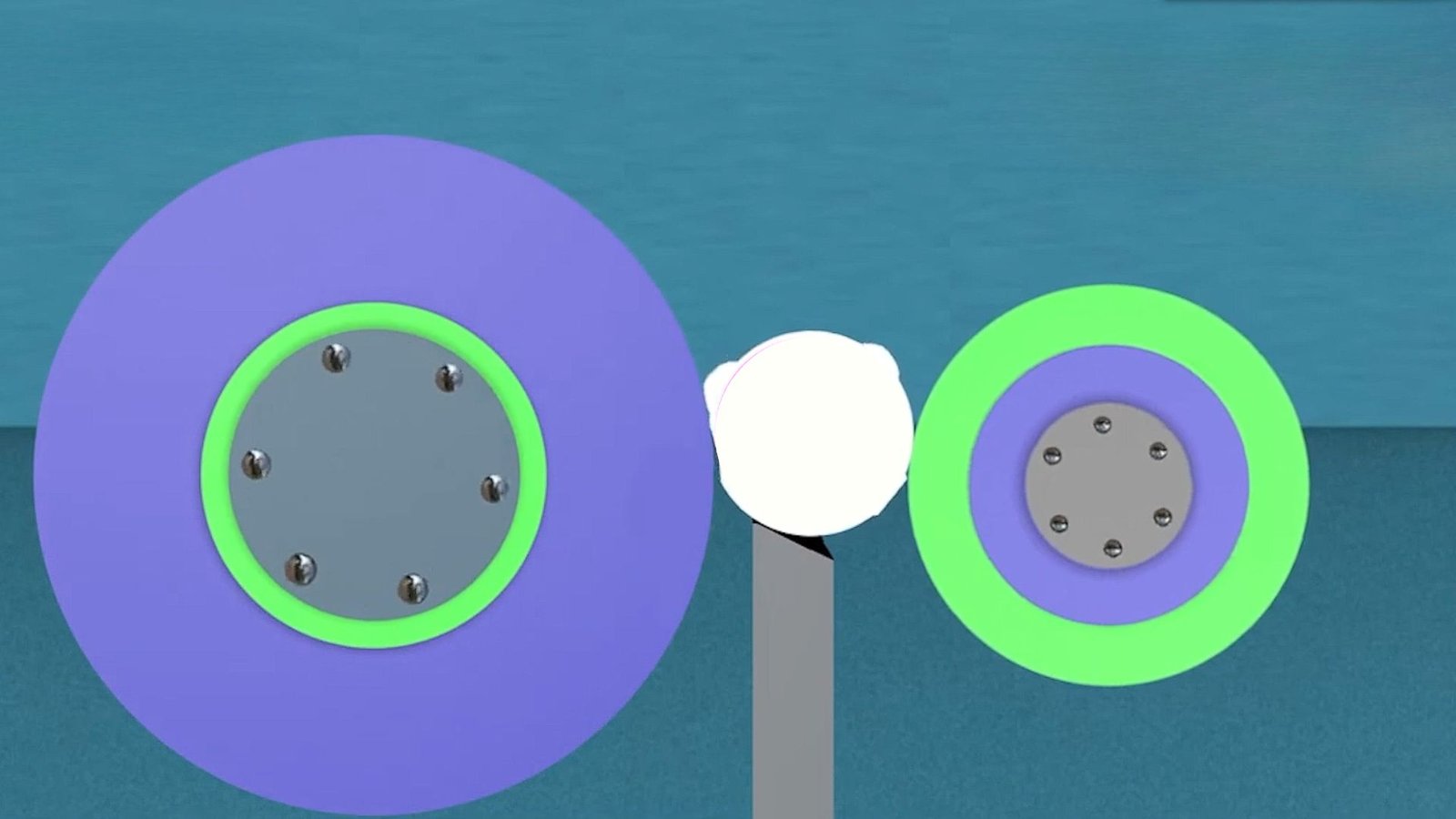

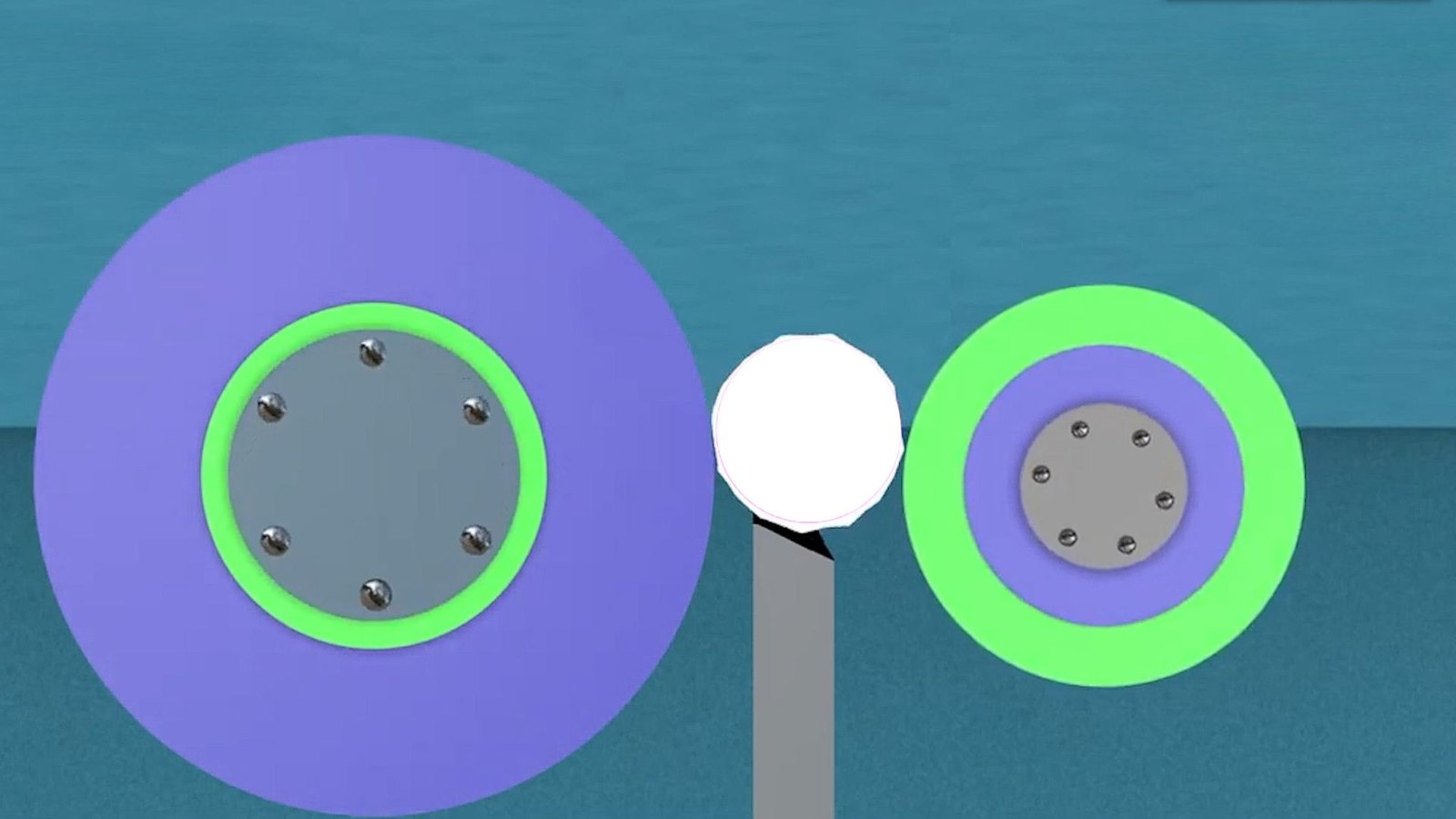

Lobing (polygon error) is typically prevented by ensuring the correct workpiece center height relative to the wheels, minimizing excessive axial thrust against end stops, and making sure the grinding wheel is properly balanced.

At J&M Machine Tools, we see lobing arise from incorrect geometry in the grinding setup. Your insights point to key causes and fixes:

- Incorrect Center Height1: This is a primary culprit. The relationship between the workpiece centerline and the centerlines of the grinding and regulating wheels dictates the rounding action. If the part center is too high, it can lead to the generation of lobes (often odd-numbered like 3, 5, 7 lobes). Conversely, while lowering the center height often helps, setting it too low can also cause issues. Precise adjustment is critical.

- Excessive Axial Thrust (Infeed)2: If the workpiece is pushed too hard against its end stop (common in infeed grinding), it might not rotate uniformly against the regulating wheel, leading to uneven grinding and lobing. Reducing the regulating wheel’s inclination angle (e.g., to 0.5° or even 0.25°) can lessen this thrust. If the problem persists, checking that the workrest blade support is perfectly level and aligned is crucial.

- Grinding Wheel Imbalance3: An unbalanced grinding wheel creates vibration throughout the machine, disrupting the smooth contact needed for perfect rounding and potentially inducing lobing patterns. Careful balancing is essential.

- Solution Summary: Carefully adjust the workpiece center height (often slightly above the wheel centerlines, but follow machine guidelines). For infeed, reduce reg wheel tilt if axial thrust is suspected and check blade support alignment. Always ensure the grinding wheel is well-balanced.

What Causes Surface Chatter Marks During Centerless Grinding?

Are you seeing ugly, evenly spaced ripples or waves on the surface of your ground parts? These chatter marks ruin the finish and often indicate vibration or instability in the grinding process.

Chatter marks are usually caused by grinding wheel imbalance creating vibration, incorrect part center height causing instability (bouncing), a dull/glazed grinding wheel that rubs instead of cutting, or running the regulating wheel too fast.

Chatter is essentially a vibration signature etched onto the workpiece. Finding the source of that vibration is key. Your insights help pinpoint common causes:

- Grinding Wheel Imbalance: Just like with lobing, an unbalanced wheel is a major source of system vibration, which translates directly into chatter marks on the part’s surface. Meticulous balancing is non-negotiable.

- Improper Part Center Height4: If the workpiece isn’t positioned correctly relative to the wheel centerlines (often too high), it can become unstable and tend to bounce or jump during grinding. This inconsistent contact creates chatter. Appropriately lowering the center height (within optimal limits) usually improves stability.

- Dull or Glazed Grinding Wheel5: When the grinding wheel’s abrasive grains become dull or the wheel face gets loaded with material (glazed), it stops cutting efficiently and starts rubbing or skipping. This irregular action generates vibration and chatter. Proper dressing is needed to expose sharp grains and break the glaze. Over-dressing, making the wheel too smooth, can sometimes also lead to rubbing instead of cutting.

- Regulating Wheel Speed Too Fast: If the workpiece is rotating too quickly, it might not allow the grinding wheel enough time to effectively cut the material smoothly, potentially leading to instability and chatter. Reducing the regulating wheel speed can often calm the process down.

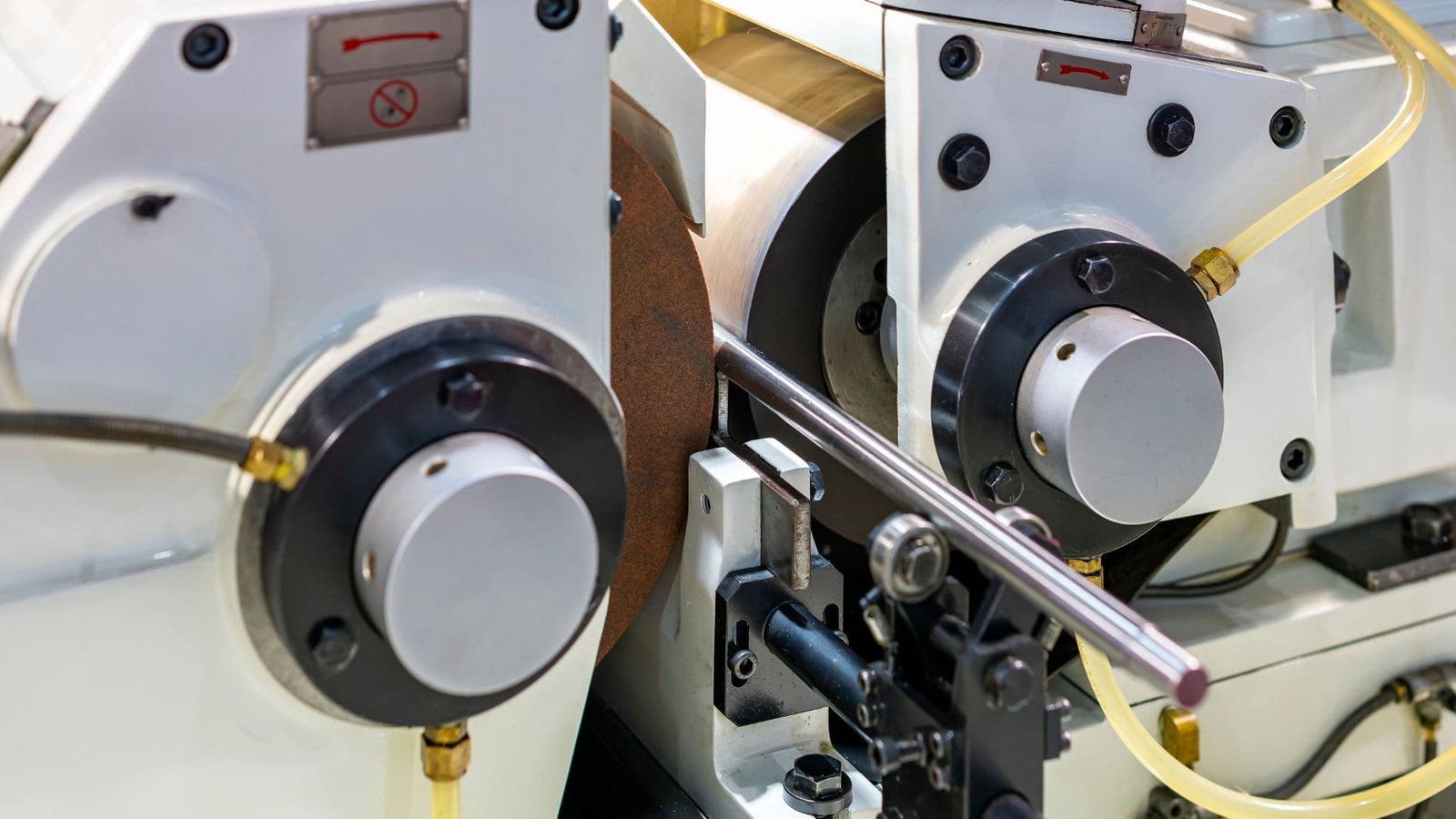

How Can a Centerless Grinder Be Set Up to Prevent Part Taper?

Are your parts consistently measuring smaller on one end than the other after grinding? Taper is a common issue that prevents parts from meeting print specifications, often pointing to alignment problems.

Preventing taper involves ensuring the workpiece guide plates (infeed/outfeed) are perfectly parallel to the regulating wheel’s line of contact or axis, and verifying the grinding wheel is dressed straight without any inherent taper.

Achieving perfect cylindricity requires precise alignment throughout the grinding zone. Your notes highlight the critical areas:

- Guide Plate Alignment6: This is crucial, especially in thrufeed grinding. The front guide plate (entry side) and rear guide plate (exit side) must guide the workpiece perfectly parallel to the regulating wheel’s axis or line of contact.

- If the front guide is angled away from the grinding wheel (relative to the regulating wheel), the front end of the part might get ground slightly smaller.

- If the rear guide is angled away from the grinding wheel, the rear end might get ground smaller.

- Careful adjustment using indicators to ensure these guides are perfectly parallel is essential.

- Incorrect Wheel Dressing7: If the diamond dresser path isn’t perfectly parallel to the regulating wheel axis during grinding wheel dressing, it will create a taper on the grinding wheel itself. This wheel taper will be directly transferred to the workpiece. The dressing setup must be checked and adjusted based on which direction the part taper is occurring.

- Uneven Wheel Wear8: Significant or uneven wear on either the grinding or regulating wheel face can also induce taper over time. Monitoring wear patterns and re-dressing or replacing wheels as needed is important.

How Can Convex (Barrel-Shaped) Parts Be Fixed After Centerless Grinding?

Are your parts coming out thicker in the middle and thinner at the ends, like a barrel? This convex shape is another frustrating geometric error that usually points to specific setup mistakes.

Barrel shaping (convex parts) is typically caused by both front and rear guide plates being tilted towards the grinding wheel side, or by the grinding wheel itself being dressed into a concave (hollow) shape.

This "center high" condition is the opposite of taper, but often related to guide or wheel shape issues. Your insights explain the causes:

- Guide Plates Angled Inwards: If both the front and rear guide plates are slightly angled towards the grinding wheel (pinching the path in the middle relative to the ends), the ends of the workpiece will receive slightly more grinding pressure9 or time, causing them to become smaller relative to the center. The solution is to readjust the guides, ensuring they are perfectly parallel to the intended workpiece path/regulating wheel axis.

- Concave Grinding Wheel Dress10: If the dressing operation accidentally creates a concave ("waist drum" or hollow) shape on the face of the grinding wheel, this shape will be imparted to the workpiece. The high points of the concave wheel will grind the ends of the part more than the center, resulting in a convex part. The dressing procedure needs to be adjusted to ensure a perfectly straight or appropriately crowned (if needed for other reasons) wheel face, avoiding a concave profile.

Conclusion

Achieving true roundness and consistent size in centerless grinding means addressing potential issues like regulating wheel condition, center height, guide alignment, wheel balance, and proper dressing to avoid common defects.

-

Understanding the impact of incorrect center height can help improve grinding accuracy and prevent defects like lobing. ↩

-

Exploring this topic can provide insights into optimizing grinding techniques and achieving better results. ↩

-

Learning about grinding wheel imbalance can enhance machine performance and product quality, reducing defects. ↩

-

Explore the importance of correct part positioning to enhance stability and reduce chatter in grinding operations. ↩

-

Learn how to maintain your grinding wheels for optimal performance and prevent chatter during machining. ↩

-

Understanding Guide Plate Alignment is essential for achieving precision in grinding, ensuring optimal performance and quality in your workpieces. ↩

-

Exploring the effects of Incorrect Wheel Dressing can help you avoid common pitfalls and improve your grinding efficiency and product quality. ↩

-

Learning about Uneven Wheel Wear is crucial for maintaining grinding equipment and ensuring consistent results in your machining processes. ↩

-

Explore the significance of grinding pressure in machining to enhance your understanding of workpiece quality and performance. ↩

-

Learn how concave wheel dressing can alter workpiece dimensions and discover best practices for achieving optimal results. ↩

Chris Lu

Leveraging over a decade of hands-on experience in the machine tool industry, particularly with CNC machines, I'm here to help. Whether you have questions sparked by this post, need guidance on selecting the right equipment (CNC or conventional), are exploring custom machine solutions, or are ready to discuss a purchase, don't hesitate to CONTACT Me. Let's find the perfect machine tool for your needs

Chris Lu

Leveraging over a decade of hands-on experience in the machine tool industry, particularly with CNC machines, I'm here to help. Whether you have questions sparked by this post, need guidance on selecting the right equipment (CNC or conventional), are exploring custom machine solutions, or are ready to discuss a purchase, don't hesitate to CONTACT Me. Let's find the perfect machine tool for your needs