What Does a Tailstock on a CNC Lathe Do in Machining?

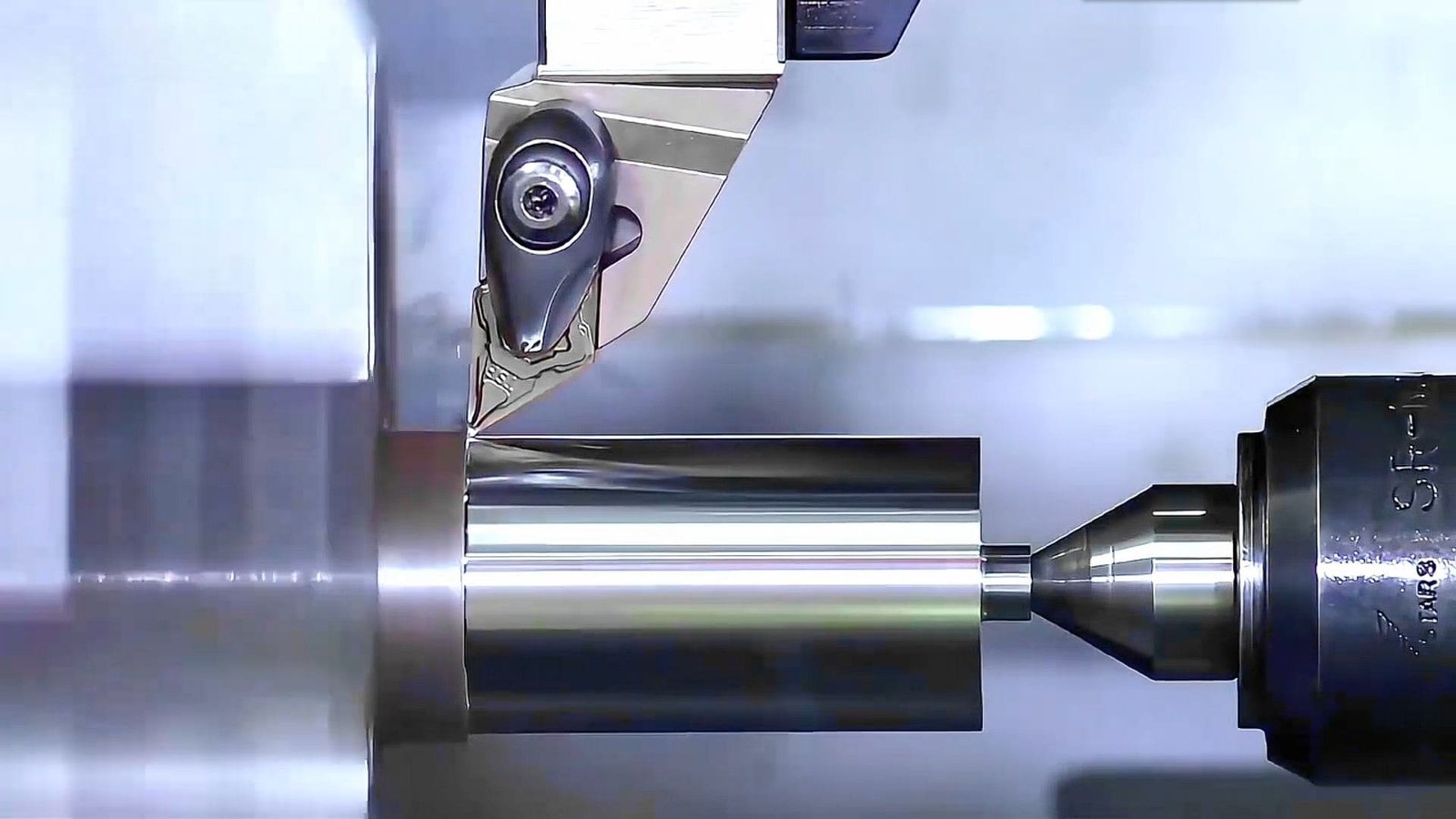

Trying to turn long, thin shafts like axles or even rifle barrels accurately on your CNC lathe? Without proper support, these parts can easily wobble, bend under cutting forces, or vibrate, leading to poor surface finish and inaccurate dimensions.

The tailstock primarily supports the free end of longer workpieces held in the main spindle chuck, preventing deflection and vibration. It ensures stability, allows accurate machining along the part’s length, and can sometimes hold tools for centering operations.

This support is fundamental for many turning operations, especially when the workpiece length is significantly greater than its diameter. But just knowing its basic role isn’t enough. How does using it actually impact the quality of the parts we make, and what are the critical factors like center type, alignment, and pressure?

Can Using the Tailstock Improve the Accuracy and Surface Finish of Machined Parts?

Struggling with taper, chatter marks, or poor roundness on longer turned parts, especially those with high length-to-diameter ratios? These issues often stem from the workpiece flexing or vibrating during the cut, ruining tolerances and the final look.

Yes, using the tailstock significantly improves accuracy and surface finish by providing rigid support that minimizes workpiece deflection and vibration. This directly leads to better dimensional accuracy (less taper, better roundness) and a smoother finish.

At J&M Machine Tools, we know that when a cutting tool pushes against a long workpiece, it wants to bend. Without that crucial end support, you get inconsistencies. Your research confirms the benefits:

- Stability & Reduced Deflection1: The tailstock acts as a solid anchor, keeping the workpiece stable between the spindle and the tailstock center. This counteracts cutting forces, preventing the part from bending away from the tool, which is essential for avoiding taper, especially on parts with length-to-diameter ratios over 2:1 or 3:1.

- Minimized Vibration (Chatter): A securely supported workpiece is far less prone to vibrating during the cut. Less vibration means a significantly smoother surface finish (lower roughness value) and improved roundness, critical for high-precision components like those in aerospace.

- Improved Alignment & Concentricity2: It helps ensure the workpiece rotates true to the lathe’s central axis, maintaining concentricity along its length. This is vital for achieving accurate diameters and shapes consistently. The tailstock effectively combats the axial errors and roundness problems that arise from poor support.

What is the Difference Between Using a Live Center and a Dead Center Within the Tailstock?

Confused about whether to use a ‘live’ or ‘dead’ center in your tailstock, and how that choice impacts your CNC machining? Choosing incorrectly might lead to excessive heat, premature wear, or subpar support, ultimately affecting job quality and efficiency.

A live center has internal bearings allowing its tip to rotate with the workpiece, minimizing friction and heat. A dead center is solid; the workpiece rotates against its stationary tip, generating more friction and heat.

Understanding the distinction is key for optimizing your setup, especially in a demanding CNC environment. Your research provides a clear comparison:

| Feature | Live Center | Dead Center (Fixed Center) |

|---|---|---|

| Rotation | Tip rotates with workpiece via internal bearings | Tip is fixed; workpiece rotates against it |

| Friction/Heat | Low friction, less heat generation | High friction, significant heat generation possible |

| Speed Limit | Suitable for higher RPMs common in CNC machining | Lower RPM limits due to friction/heat build-up |

| Accuracy | Very good positioning accuracy, maintains concentricity | Simple, potentially high initial rigidity |

| Wear | Bearing wear over time (requires maintenance) | Tip wears due to friction (needs lubrication) |

| Suitability | Preferred for CNC (speed, long runs, heat-sensitive materials) | Simpler setups, manual lathes, lower speeds |

For most modern CNC lathe applications3 focusing on speed, precision, and efficiency, the live center is the standard choice. Its ability to rotate drastically reduces friction, preventing the workpiece center hole from burning or distorting, and allowing for higher cutting speeds4 without issue. Dead centers, while simpler, require careful lubrication and speed management to avoid wear and heat damage, making them less practical for automated or long-running CNC jobs.

How Does Proper Tailstock Alignment and Pressure Affect Machining Outcomes?

Have you meticulously set up your workpiece with the tailstock, yet still encounter frustrating taper, inconsistent diameters, or poor finishes? Often, the culprit isn’t the workpiece or the tooling, but incorrect tailstock alignment or pressure.

Proper tailstock alignment is crucial; misalignment directly causes taper and roundness errors. Incorrect pressure (too little or too much) leads to vibration, deflection, poor finish, workpiece damage, or even safety risks.

Think of the tailstock and spindle centers needing to form a perfectly straight line, parallel to the lathe bed’s Z-axis. Your research highlights the critical nature of getting this right:

- Alignment Effects5: If the tailstock center isn’t perfectly aligned (horizontally or vertically) with the spindle’s axis, it forces the workpiece to rotate eccentrically. This guarantees a taper along the part’s length and can also introduce roundness errors. Maintaining alignment ensures the workpiece rotates concentrically for accurate cuts.

- Pressure Effects: Applying the right amount of pressure is a balancing act.

- Too Little Pressure: The workpiece isn’t held securely. It can vibrate excessively (chatter), shift slightly during cutting, or deflect under tool pressure, leading to poor surface finish, dimensional inaccuracies6, and potential tool life reduction.

- Too Much Pressure: Especially on slender parts or delicate materials, excessive force can cause the workpiece to bow or deform. It can also damage the center drill hole in the workpiece, overheat the center (especially dead centers), or put undue stress on live center bearings or even the machine’s spindle bearings.

Achieving high-quality results consistently demands both precise geometric alignment and carefully controlled, appropriate clamping pressure tailored to the workpiece and the forces involved in the machining operation.

How Do You Adjust the Tailstock Position Properly?

Need to align your tailstock precisely but unsure of the best procedure? Relying on guesswork or simple visual checks isn’t sufficient for CNC accuracy and will likely result in scrapped parts due to taper or other geometric errors.

Adjust the tailstock by first sliding it close to the workpiece, locking it, then fine-tuning quill extension via the handwheel/leadscrew. Crucially, verify alignment using a dial indicator against a test bar or precision diameter before applying appropriate pressure.

Getting the tailstock perfectly coaxial with the spindle centerline is non-negotiable for precision work. Based on standard practice and your detailed research, here’s a reliable method:

- Loosen Lock: Release the main locking mechanism securing the tailstock body to the lathe bed ways.

- Rough Position: Manually slide the entire tailstock assembly along the ways to the approximate required position for the workpiece length.

- Lock Body: Securely tighten the main lock to fix the tailstock body’s position on the bed.

- Adjust Quill: Use the handwheel or leadscrew to extend the tailstock quill (the part holding the center) towards the workpiece. Install the appropriate center (live or dead).

- Check Alignment (Critical Step):

- Mount a precision test bar between centers or turn a precise diameter on stock held in the chuck.

- Use a sensitive dial test indicator mounted on the carriage/cross slide.

- Check for vertical alignment by running the indicator along the top surface of the test bar/diameter or the tailstock quill itself. Adjust height (often using shims under the tailstock base if needed) until the reading is consistent.

- Check for horizontal alignment by running the indicator along the side facing the operator. Adjust using the tailstock’s side-set screws until the reading is consistent along the length.

- Apply Pressure: Advance the quill carefully to engage the center with the workpiece’s center hole. Apply sufficient pressure to hold the part securely without deforming it – this often requires some feel or reference to machine specifications.

- Verify Stability: Gently try to move the workpiece end near the tailstock to ensure it’s firmly held with no play before starting the cut. For long/critical parts, consider a test cut and measure for taper, making fine adjustments as needed to compensate for any minor way wear.

This methodical process ensures the tailstock provides accurate, stable support.

Conclusion

The tailstock is a vital CNC lathe component for supporting longer workpieces, drastically improving machining accuracy and surface finish. Understanding live vs. dead centers, and meticulously ensuring proper alignment and pressure, are essential for optimal results.

-

Understanding this concept is crucial for improving machining accuracy and preventing defects in workpieces. ↩

-

This knowledge is essential for ensuring precision in manufacturing processes, especially for high-precision components. ↩

-

Stay updated on the latest trends in CNC lathe applications to improve your machining processes. Check out this resource for valuable information. ↩

-

Learn how cutting speeds impact performance to optimize your CNC operations. This link provides essential knowledge for better results. ↩

-

Understanding alignment effects is crucial for achieving precision in lathe operations, ensuring better quality and accuracy in your work. ↩

-

Identifying causes of dimensional inaccuracies can enhance your machining processes, ensuring higher quality and precision in your projects. ↩

Chris Lu

Leveraging over a decade of hands-on experience in the machine tool industry, particularly with CNC machines, I'm here to help. Whether you have questions sparked by this post, need guidance on selecting the right equipment (CNC or conventional), are exploring custom machine solutions, or are ready to discuss a purchase, don't hesitate to CONTACT Me. Let's find the perfect machine tool for your needs.