What Features Does a CNC Drilling Machine Need for Tapping?

Need to create internal threads after drilling holes on your CNC drilling machine? You might be wondering if your drilling machine is actually capable of tapping, or if you need specialized features like rigid tapping. Trying to tap without the right machine setup can quickly lead to broken taps stuck in expensive parts, costing you significant time and money.

A CNC drilling machine needs precise spindle speed and feed synchronization (rigid tapping capability), variable spindle speed control, a robust coolant system, the ability to hold tapping tools securely (often with an ATC), and programmable control over depth and cycles to perform tapping effectively.

Simply having a spindle that turns isn’t enough for reliable, accurate tapping. The process demands specific hardware and software capabilities working together. Let’s dive into the different tapping methods and why certain aspects like rigid tapping and coolant are so important for getting good threads every time.

What is Flex Tapping?

Have an older CNC machine, or one where the spindle rotation and Z-axis feed can’t be perfectly synchronized? Trying to tap rigidly in such a situation almost guarantees a broken tap because the feed won’t perfectly match the thread pitch. Flex tapping provides a mechanical solution for these scenarios.

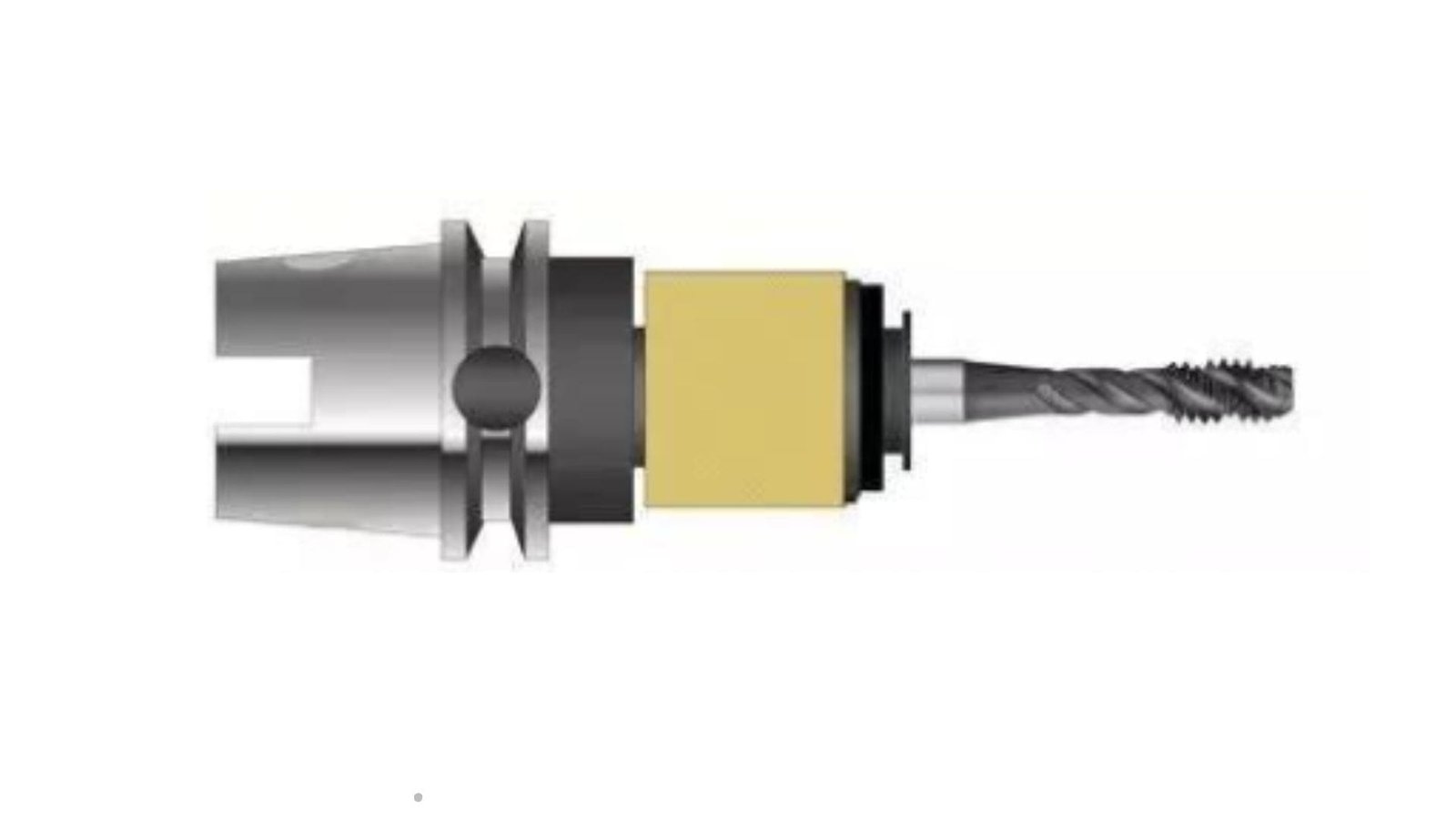

Flex tapping uses a special "floating" tool holder with built-in axial compensation (tension/compression) that allows the tap to follow its own pitch even if the machine’s feed rate isn’t perfectly synchronized with the spindle speed.

This method builds forgiveness into the system using the tool holder itself. Your research highlights its characteristics:

- Adaptability: Because it doesn’t demand perfect electronic synchronization, flex tapping can work on machines with less precise control or handle minor programming errors in feed rate. It’s more forgiving.

- Floating Holder1: The key component. It allows the tap to move slightly axially, compensating for mismatches between the machine’s linear movement and the tap’s natural pitch-driven movement.

- Safety: The built-in float reduces the chance of tap breakage caused by synchronization errors, making it a safer option on less capable machines or in challenging materials where binding might occur.

- Versatility: Can be used on a wider range of machines, including older models without dedicated rigid tapping cycles.

However, the mechanical compensation means the exact depth control might be less precise than rigid tapping, cycles are generally slower, and the specialized holders can be more complex and expensive.

What is Rigid Tapping?

Need to produce highly accurate threads consistently, especially in demanding materials or for high-volume production runs? Relying on compensating holders like in flex tapping might not provide the necessary precision, speed, or process reliability. Rigid Tapping is the modern standard for high-performance CNC thread cutting.

Rigid tapping is a CNC function where the machine’s control system precisely synchronizes the spindle’s rotation speed and the Z-axis feed rate electronically to exactly match the pitch of the tap being used, eliminating the need for compensating holders.

This means the machine actively drives the tap along the correct helical path using precise servo control. Key features include:

- Electronic Synchronization: The heart of the system. The CNC controller continuously monitors spindle position (often via an encoder) and adjusts the Z-axis feed motor’s velocity to maintain perfect sync with the programmed thread pitch.

- Solid Tool Holding: Uses standard, non-floating tool holders like ER collet chucks or dedicated rigid tapping collets. This simplifies tooling and increases rigidity.

- High Precision & Speed2: Because movement is perfectly controlled, rigid tapping produces threads with very high pitch accuracy and allows for significantly faster tapping speeds and feed rates compared to flex tapping.

- Machine Capability Required: This is not just a tooling choice; the CNC machine must have the hardware (servo motors, encoders) and software (rigid tapping cycle options in the control) to perform this synchronization. It’s standard on most modern machines but might be an option on others.

Rigid tapping provides superior control, making it ideal for applications demanding accuracy and efficiency, like in the automotive, aerospace, and medical industries.

Why is Rigid Tapping Crucial for Effective Tapping on a CNC Drilling Machine?

You understand rigid tapping synchronizes the machine’s motion, but why is it considered so essential for modern, effective CNC tapping? Isn’t flex tapping adequate? While flex tapping works, rigid tapping offers fundamental advantages that directly translate to better quality, higher efficiency, and lower costs when the machine supports it.

Rigid tapping is crucial because its precise electronic synchronization guarantees thread accuracy and quality, significantly extends tap life by eliminating axial push/pull forces, enables much higher cutting speeds for improved efficiency, and uses simpler, less expensive, more rigid tool holders.

Let’s unpack why these benefits make rigid tapping the preferred method on capable CNC drilling machines, drawing from your insights:

- Unmatched Accuracy (Synchronized Feed)3: The direct, electronically controlled link between rotation and feed ensures the tap cuts the thread precisely according to its specified pitch, revolution after revolution. This eliminates pitch errors and results in consistently accurate, high-quality threads critical for demanding fits.

- Longer Tap Life (Minimized Axial Force)4: By perfectly matching the feed to the pitch, the machine avoids exerting unwanted axial pressure (pushing or pulling) on the tap. This dramatically reduces stress on the cutting edges and prevents premature wear or breakage, leading to significantly longer tool life.

- Boosted Efficiency (Higher Speeds)5: The precise control and elimination of mechanical lag allow tapping at much higher spindle speeds and feed rates than typically feasible or safe with flex tapping. This drastically shortens cycle times, increasing machine throughput and reducing manufacturing costs, especially noticeable in high-volume production.

- Simplified & Cost-Effective Tooling: Rigid tapping utilizes standard, solid tool holders (like ER collets). These are inherently more rigid, simpler in design, and generally less expensive than the complex tension/compression holders needed for flex tapping.

Essentially, for any modern CNC drilling machine equipped for it, rigid tapping offers superior process control, leading directly to better outcomes: higher quality threads, longer-lasting tools, faster production, and reduced tooling expenses.

Does a CNC Drilling Machine Need Coolant During Tapping?

Setting up a tapping operation on your CNC drilling machine and debating whether to use coolant? Tapping generates substantial friction and heat, particularly in tougher materials like stainless steel or when running at higher speeds. Skipping coolant might seem cleaner or simpler initially, but it frequently leads to problems that cost more in the long run.

Yes, using coolant during CNC tapping is almost always necessary and highly recommended. Coolant provides essential lubrication, cooling, and chip flushing, which directly improves thread quality, prevents tap breakage, and significantly extends the life of the tapping tool.

Tapping is a high-friction cutting process, and managing the heat and chips generated is critical for success. Your research details why coolant6 is vital and the types commonly used:

- Why Coolant is Crucial:

- Lubrication: Reduces the friction between the tap’s cutting edges and the workpiece material. This lowers the required torque, makes the cutting action smoother, prevents material welding to the tap (especially in aluminum), and improves surface finish.

- Cooling: Dissipates the intense heat generated at the cutting zone. This prevents the tap from softening (losing hardness) and wearing out quickly, and avoids thermal expansion issues that can affect thread accuracy.

- Chip Flushing: Helps wash away the small, often tightly curled chips produced during tapping. This prevents chips from packing into the tap’s flutes, which can cause the tap to jam, break, or cut oversized or damaged threads. Effective flushing is especially critical in blind holes.

- Common Coolant Types & Delivery:

- Water-Soluble Fluids (Emulsions, Semi-Synthetics): Offer a good balance of cooling and lubrication. Widely used, cost-effective. Running richer concentrations (e.g., 8-10%) can enhance lubrication for tapping.

- Synthetic Fluids: Primarily water-based, offer excellent cooling and cleanliness. Lubricity varies.

- Cutting Oils (Neat Oils): Provide superior lubrication, often preferred for tough materials (stainless steels, alloys) or form tapping. Less cooling capacity than water-based fluids.

- Delivery: Flood coolant is common. Through-spindle coolant (coolant delivered through channels in the spindle and tool) is highly effective for flushing chips, especially in deep or blind holes.

The ideal coolant choice depends on the material (e.g., neat oil for steels, specific emulsions for aluminum), tap type (cutting vs. forming), and shop practices. However, neglecting coolant altogether during tapping is a recipe for premature tool failure, poor thread quality, and potential workpiece scrap.

Conclusion

For effective tapping, a CNC drilling machine needs precise control like rigid tapping synchronization, variable speed, proper tool holding, and coolant delivery, ensuring accurate threads, good tool life, and efficient production.

-

Exploring the role of floating holders can help you optimize your tapping operations and reduce errors. ↩

-

Exploring the impact of High Precision & Speed can enhance your knowledge of machining efficiency and thread accuracy. ↩

-

Explore how synchronized feed enhances accuracy in CNC machining, ensuring high-quality threads and precision in production. ↩

-

Learn about the importance of minimizing axial force in CNC machining and how it contributes to longer tool life and efficiency. ↩

-

Discover the advantages of higher spindle speeds in CNC tapping, including increased efficiency and reduced manufacturing costs. ↩

-

Understanding the role of coolant can significantly enhance your tapping efficiency and tool longevity. Explore this resource for in-depth insights. ↩

Chris Lu

Leveraging over a decade of hands-on experience in the machine tool industry, particularly with CNC machines, I'm here to help. Whether you have questions sparked by this post, need guidance on selecting the right equipment (CNC or conventional), are exploring custom machine solutions, or are ready to discuss a purchase, don't hesitate to CONTACT Me. Let's find the perfect machine tool for your needs.