What is a centerless grinding machine?

Struggling with precision on parts without center points? Standard grinding often needs centers, but what if your parts simply don’t have them, or high volume makes centering impractical?

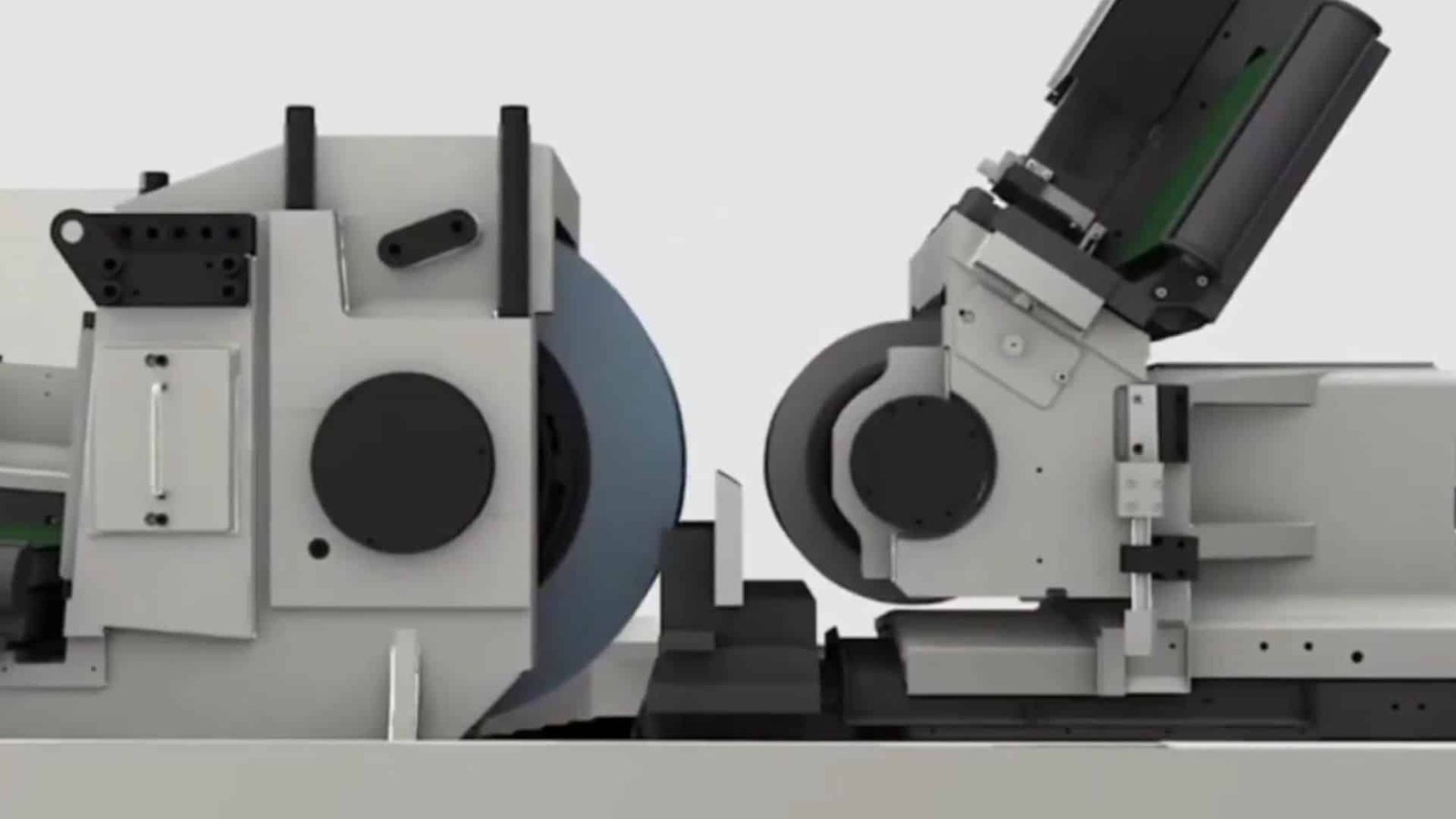

A centerless grinding machine finishes the outside of cylindrical parts using two wheels—a grinding wheel and a regulating wheel—plus a support blade. It doesn’t need center holes, allowing high precision and efficient mass production of components.

Understanding how these machines manage this feat is the first step to seeing their value. We’ve worked with many clients who found centerless grinding solved production bottlenecks conventional methods couldn’t touch. Let’s look closer at how they operate and why they are so effective for certain jobs.

How does a centerless grinding machine work?

How can you grind accurately without holding the part’s center? It sounds tricky, but the clever interaction of key components makes it a very controlled and efficient process.

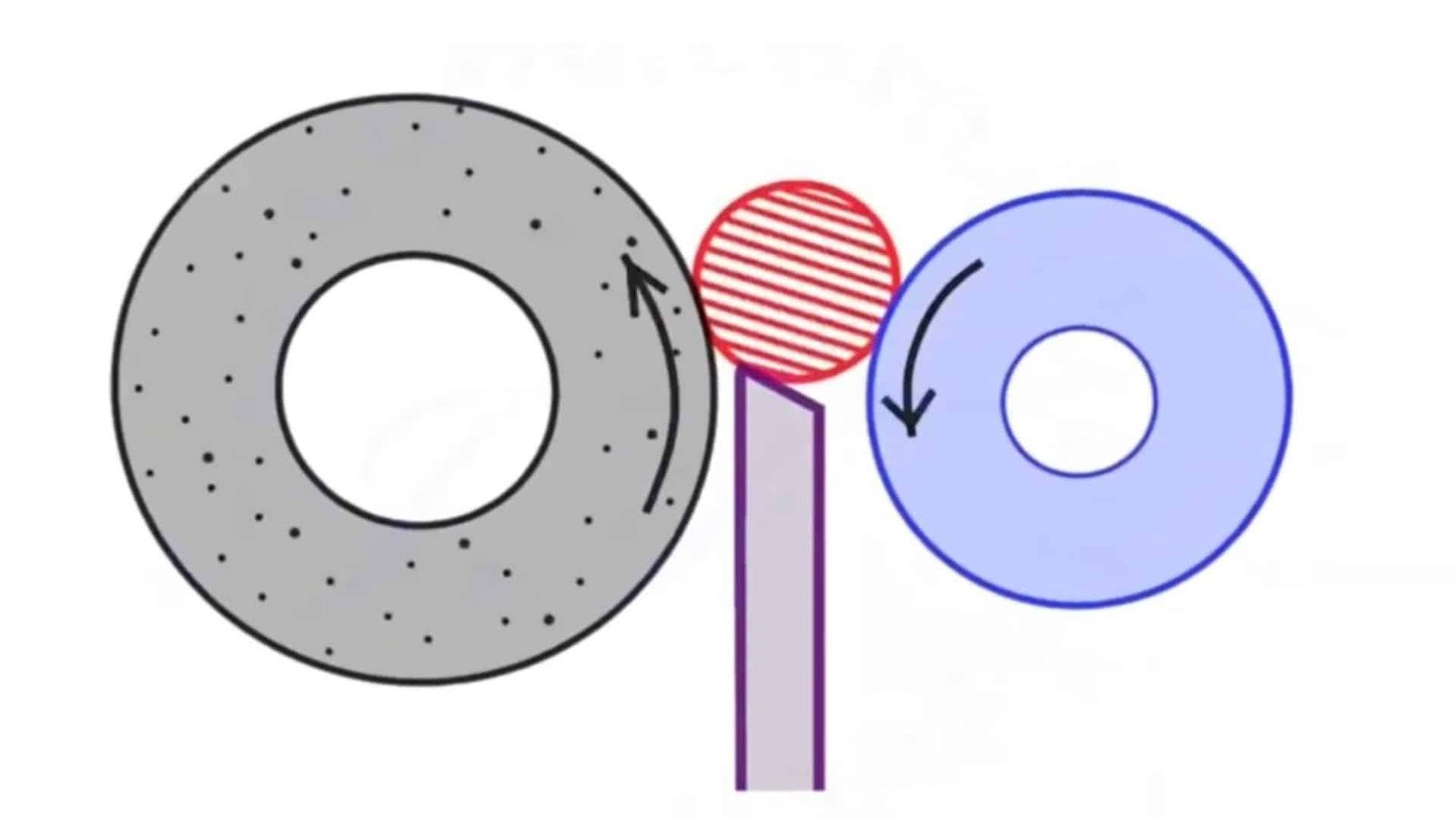

It uses a fast grinding wheel for cutting, a slower regulating wheel for control, and a work rest blade for support. The workpiece sits between them, rotated and precisely fed by the regulating wheel’s action.

Let’s dive deeper into the mechanics. Getting the setup right is crucial, and I’ve spent countless hours helping teams fine-tune these interactions for optimal results.

The Core Components Explained

The magic happens through the coordination of four main parts:

- Grinding Wheel: This is the powerhouse. Made from hard abrasives like aluminum oxide or silicon carbide, it spins at high speed (thousands of surface feet per minute) to remove material accurately. Its specification depends entirely on the job – the material being ground, the stock removal needed, and the target finish.

- Regulating Wheel: This wheel is key to control. Often made of a rubber-bonded abrasive for good friction, it rotates much slower. Its main jobs are to spin the workpiece (through friction) at a consistent speed and, crucially, to control the feed rate. In through-feed grinding, this wheel is slightly tilted or canted, which creates an axial force pushing the workpiece steadily through the grinding zone.

- Work Rest Blade1: This stationary blade sits beneath the workpiece, supporting it between the two wheels. Its height relative to the wheel centers and its top angle are critical adjustments. Proper positioning ensures stability and helps achieve the desired roundness and size. I always say, if you have roundness issues, check the blade height first!

- Machine Base: Provides the rigid foundation for all components, ensuring stability and alignment which are critical for precision grinding.

Three Main Types of Centerless Grinding

Depending on the part shape, we use different modes:

- Through-feed: This is the most common for simple, straight cylinders like pins or rods. Parts are fed continuously, one after another, right through the gap between the wheels. The canted regulating wheel provides the axial push. We set this up often for high-volume jobs where speed is key.

- In-feed (or Plunge)2: Used for parts with heads, shoulders, tapers, or multiple diameters like bolts or valve stems. The workpiece rests on the blade, and either the blade/workpiece or the wheels move radially (plunge) to grind the profile. The grinding wheel is often dressed to the negative shape of the part feature. This needs careful wheel dressing and setup.

- End-feed: Best for tapered parts where the workpiece is fed axially against a stop, ground, and then retracted. Think of grinding the taper on needles or plungers. It’s less common in our shop but essential for specific tapered part requirements.

What are the advantages of centerless grinders compared to external circular grinders?

Is centerless always better than standard grinding? Not always, but knowing the specific benefits helps you choose the right process for your production needs and avoid costly mismatches.

Key advantages include not needing center holes (improving accuracy potential), high throughput via continuous feeding, superior roundness/finish possibilities, and better support that minimizes deflection on long, thin parts.

Let’s unpack these benefits. We’ve seen dramatic productivity gains when clients switch suitable parts to centerless grinding.

Key Benefits Explored

- Eliminates Center Hole Issues: This is fundamental. Preparing center holes takes time and introduces potential errors. If centers are inaccurate or damaged, conventional grinding suffers. Centerless grinding completely bypasses this. I recall a client producing small pins where eliminating centering drastically cut their reject rate.

- High Production Rates: Especially with through-feed grinding, parts can be processed continuously, end-to-end. Loading and unloading are minimized or automated easily. This makes it incredibly fast for mass production. Think thousands of parts per hour.

- Improved Accuracy & Roundness3: The workpiece essentially generates its own center axis between the three contact points (two wheels, one blade). This self-correcting action can produce exceptional roundness, often better than achievable with centers, especially if the initial part isn’t perfectly round.

- Excellent Support Reduces Deflection: Long, thin parts are supported directly under the grinding point by the blade and laterally by the regulating wheel. This minimizes the bending or deflection that can happen when holding such parts between centers, leading to better straightness and consistent diameter. We rely on this for producing long, slender shafts.

- Good Surface Finish4: The stable setup and continuous grinding action typically result in very smooth surface finishes.

Here’s a quick comparison:

| Feature | Centerless Grinding | External Cylindrical Grinding |

|---|---|---|

| Work Holding | Regulating Wheel & Blade | Centers / Chuck |

| Center Holes | Not Required | Required (usually) |

| Typical Use | High volume, simple cylinders | Lower volume, complex shapes |

| Loading Time | Very low (through-feed) | Higher (part mounting/centering) |

| Roundness | Potentially Very High | Dependent on center hole accuracy |

| Slender Parts | Excellent Support, Low Deflection | Prone to deflection |

External grinders still win for complex profiles needing precise indexing or parts where centers are unavoidable. It’s about using the right tool for the job.

What is the role of the rubber wheel in the centerless grinder?

That often rubbery-looking wheel seems less aggressive than the main grinding wheel. Is it just for spinning the part? Its role is actually complex and absolutely vital for the whole process to work correctly.

The rubber (regulating) wheel controls the workpiece’s rotation speed and axial feed (in through-feed). Its essential grip guides the part, ensures stable contact, and dampens vibrations for better precision.

Understanding everything this wheel does is crucial for troubleshooting and setup. I often find that regulating wheel issues are behind many common grinding problems.

Functions of the Regulating Wheel

Let’s break down its critical jobs:

- Rotation Control: Made from materials like rubber-bonded abrasive5 to provide high friction, it grips the workpiece. By rotating much slower than the grinding wheel, it forces the workpiece to spin at its own surface speed. This speed difference is fundamental to the grinding action. Adjusting this speed directly impacts material removal and finish. Too much slippage here, and you lose control.

- Feed Control (Through-feed): As mentioned, tilting the regulating wheel’s axis provides the driving force to push the workpiece axially through the machine in through-feed mode. The angle controls the speed of this feed.

- Positioning and Stability: Working with the work rest blade, it provides the lateral force holding the workpiece securely against the blade and ensuring consistent contact with the grinding wheel. This stable three-point contact is key to accuracy.

- Vibration Damping: The relatively softer nature of the rubber-bonded wheel helps absorb vibrations generated during grinding. This damping effect significantly contributes to achieving fine surface finishes and roundness. A hard regulating wheel would transfer far more vibration.

- Maintaining Grip: The friction is essential. If the wheel surface becomes glazed or loaded with swarf, it can slip against the workpiece, leading to inconsistent rotation, poor finish, and potential inaccuracies. Regular dressing (cleaning and restoring the surface) is vital. We schedule this religiously in our shop.

It’s the regulating wheel that dictates the pace and precision of the workpiece’s journey through the grinding process.

What kind of workpieces are suitable for centerless grinding?

Wondering if this method is right for your specific parts? While extremely capable, centerless grinding isn’t a universal fix. Knowing its sweet spot helps you leverage its strengths effectively.

It’s ideal for high-volume production of cylindrical parts like pins, rods, tubes, shafts, bearing rings/races, rollers, valve stems, injector needles, and fasteners. Tapered or simple profiled parts (using in-feed) are also very suitable.

Let’s explore the characteristics that make a part a prime candidate. Guiding clients on this involves looking at geometry, volume, material, and precision needs.

Ideal Workpiece Characteristics

- Geometry:

- Simple Cylinders: Through-feed shines here. Perfect for parts needing their entire outer diameter ground, like motor shafts, piston pins, drill bit blanks, and precision rods.

- Complex Profiles (In-feed/End-feed): Parts with heads (bolts), grooves, multiple diameters (hydraulic spools), or tapers (valve stems, needles) are handled using in-feed or end-feed techniques.

- Production Volume: Centerless grinding offers the biggest cost advantages in medium to high-volume runs6 due to its speed and automation potential. Setup takes time, so it’s less ideal for one-offs unless the specific benefits (like extreme roundness) are critical. We often see it used for automotive components like axles, bushings, and camshafts produced in the millions.

- Precision Requirements: It excels where tight tolerances7 on diameter, roundness, straightness, and surface finish are paramount. Achieving tolerances below 1 micrometer (< 0.00004 inches) is possible with well-maintained machines and skilled setup, crucial for applications like bearing components or fuel injector parts.

- Material: Most grindable materials work – various steels (hardened, stainless), aluminum, brass, titanium, even ceramics and some plastics can be centerless ground. The key is matching the grinding wheel, regulating wheel, and coolant to the material.

- Difficult-to-Hold Parts: Long, thin parts that would deflect easily in a chuck or between centers are often perfect candidates.

If your parts fall into these categories, centerless grinding could significantly improve your quality and efficiency.

Does centerless grinding require coolant?

Thinking about the practical setup? A common question arises: is coolant, or cutting fluid, absolutely necessary? Can you get away without it to simplify things?

Yes, coolant is almost always essential in centerless grinding. It manages the intense heat generated, lubricates the grinding zone, flushes away damaging debris (swarf), and prevents workpiece thermal damage like burns or distortion.

Let’s look closely at why coolant is non-negotiable for quality results. In my experience troubleshooting grinding floors, nine times out of ten, if there’s a sudden quality drop, checking the coolant supply and condition is the first step.

Why Coolant is Necessary

The high-speed friction involved in grinding creates a lot of heat right at the grinding zone. Coolant performs several vital functions:

- Heat Control (Cooling)8: This is paramount. Coolant carries heat away, preventing:

- Thermal Damage: Burns, discoloration, or unwanted metallurgical changes on the workpiece surface.

- Dimensional Instability: Heat causes parts to expand. Grinding a hot part to size means it will be undersize when it cools. Consistent temperature is key for tolerance control.

- Wheel Damage: Overheating can break down the bond in the grinding wheel or cause glazing.

- Lubrication9: Coolant reduces friction between the grinding wheel/workpiece, workpiece/regulating wheel, and workpiece/blade. Benefits include:

- Better Surface Finish: Less friction means a smoother cutting action.

- Longer Wheel Life: Reduces wear on both the grinding and regulating wheels.

- Reduced Power Draw: Less friction means less energy needed.

- Flushing: The flow washes away metal chips (swarf) and abrasive particles. This prevents:

- Wheel Loading: Swarf getting clogged in the wheel pores, reducing cutting efficiency.

- Surface Scratching: Loose debris being dragged across the finished surface.

- Process Stability: Proper cooling prevents overheating that can cause the regulating wheel to lose its grip (slip) on the workpiece, leading to loss of control and accuracy.

- Corrosion Prevention: Most coolants include rust inhibitors to protect the machine and the parts.

Effective delivery is also key – often requiring a high volume or even high pressure to penetrate the air barrier created by the fast-spinning grinding wheel and reach the cutting zone. Skipping or skimping on coolant is asking for trouble in any precision grinding operation.

Conclusion

Centerless grinding offers high precision for cylindrical parts without needing centers, making it ideal for volume production. Its unique wheel-and-blade system, combined with essential coolant use, delivers efficiency, accuracy, and excellent surface finishes.

-

Discover the significance of the Work Rest Blade in achieving stability and precision in grinding, a key factor in quality outcomes. ↩

-

Discover the intricacies of In-feed grinding, especially for complex parts, and its importance in precision machining. ↩

-

Discover the mechanisms behind improved accuracy and roundness in centerless grinding, crucial for precision engineering. ↩

-

Learn about the factors that lead to superior surface finishes in centerless grinding, essential for quality assurance in production. ↩

-

Explore this link to understand how rubber-bonded abrasives enhance grinding efficiency and precision, crucial for quality finishes. ↩

-

Discover the most efficient manufacturing processes for medium to high-volume production, optimizing cost and speed for your projects. ↩

-

Learn about techniques to achieve tight tolerances, crucial for precision parts like bearings and fuel injectors, ensuring high-quality output. ↩

-

Understanding heat control is crucial for maintaining precision and preventing damage during grinding operations. Explore this link for in-depth insights. ↩

-

Lubrication plays a vital role in enhancing grinding efficiency and prolonging tool life. Discover more about its impact on performance. ↩

Chris Lu

Leveraging over a decade of hands-on experience in the machine tool industry, particularly with CNC machines, I'm here to help. Whether you have questions sparked by this post, need guidance on selecting the right equipment (CNC or conventional), are exploring custom machine solutions, or are ready to discuss a purchase, don't hesitate to CONTACT Me. Let's find the perfect machine tool for your needs

Chris Lu

Leveraging over a decade of hands-on experience in the machine tool industry, particularly with CNC machines, I'm here to help. Whether you have questions sparked by this post, need guidance on selecting the right equipment (CNC or conventional), are exploring custom machine solutions, or are ready to discuss a purchase, don't hesitate to CONTACT Me. Let's find the perfect machine tool for your needs