What is a CNC External Cylindrical Grinding Machine?

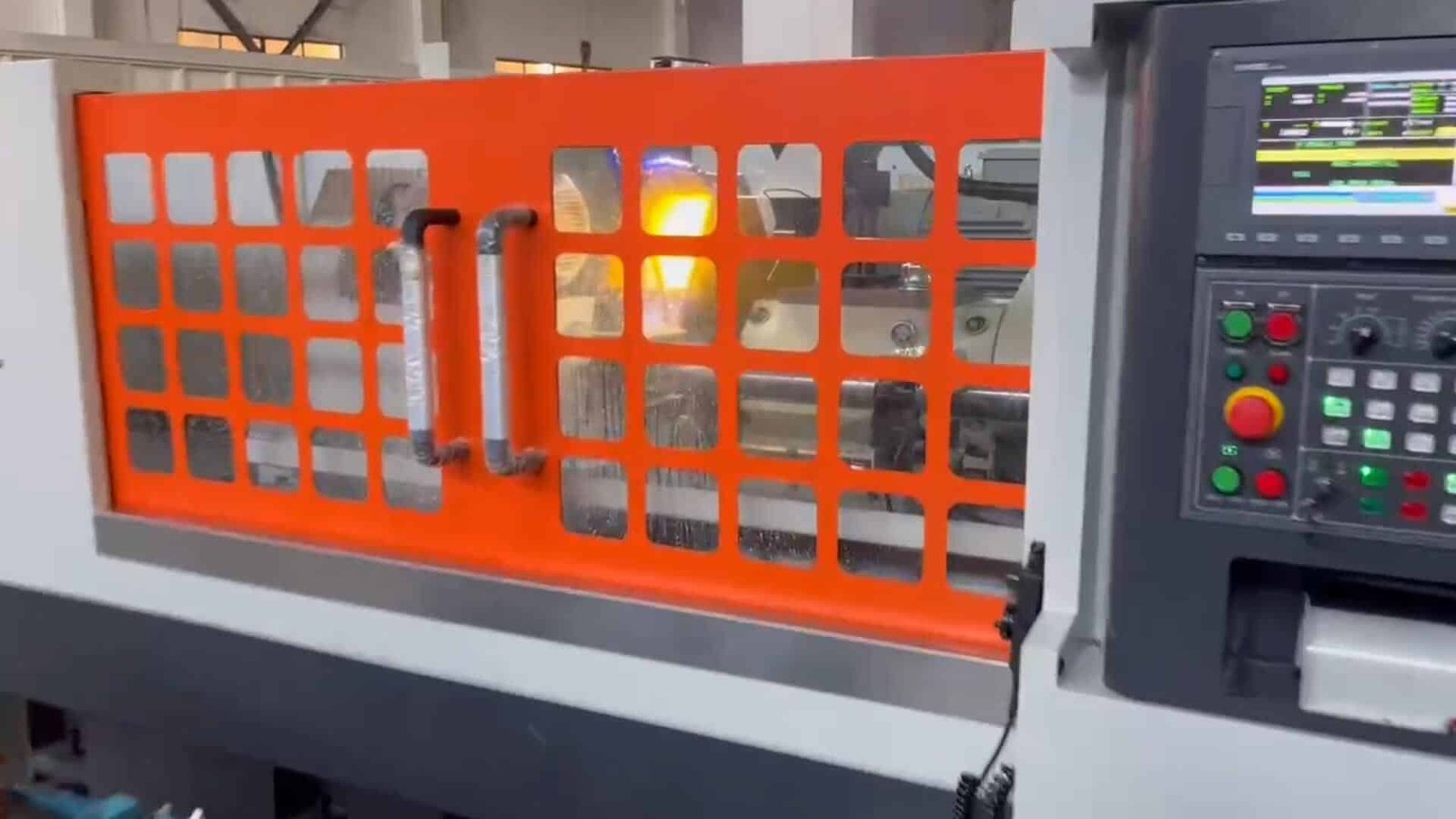

You need perfectly round and smooth outer surfaces on metal parts, but how do you achieve that high level of precision consistently, especially for demanding industries?Manual methods are too slow and inconsistent, while basic turning might not give the required finish or micron-level accuracy needed for automotive or aerospace components, particularly on hard materials.A CNC External Cylindrical Grinding Machine is a specialized, computer-controlled tool designed precisely for this high-precision task on outside diameters.

A CNC External Cylindrical Grinding Machine is a machine tool that uses computer numerical control (CNC) to precisely grind the outside diameter of cylindrical workpieces. It employs a rotating abrasive wheel to remove small amounts of material, achieving very tight tolerances (often in the micron range) and fine surface finishes essential in critical industries.

This type of machine is vital where accuracy is non-negotiable. Surprisingly versatile, they can often handle a wide range of workpiece sizes, from small pins to large shafts weighing hundreds of kilograms. But knowing what it is is just the first step; let’s look at how it actually works.

How do CNC External Cylindrical Grinding Machines Work?

You see the machine in action, you see the perfectly finished part, but what exactly is happening during the grinding cycle? How does it control the process so accurately?Not understanding the core process makes it difficult to appreciate the technology’s sophistication or effectively manage production if issues arise. Let’s break down the fundamental operating principle and the role of CNC in these precise grinding machines.

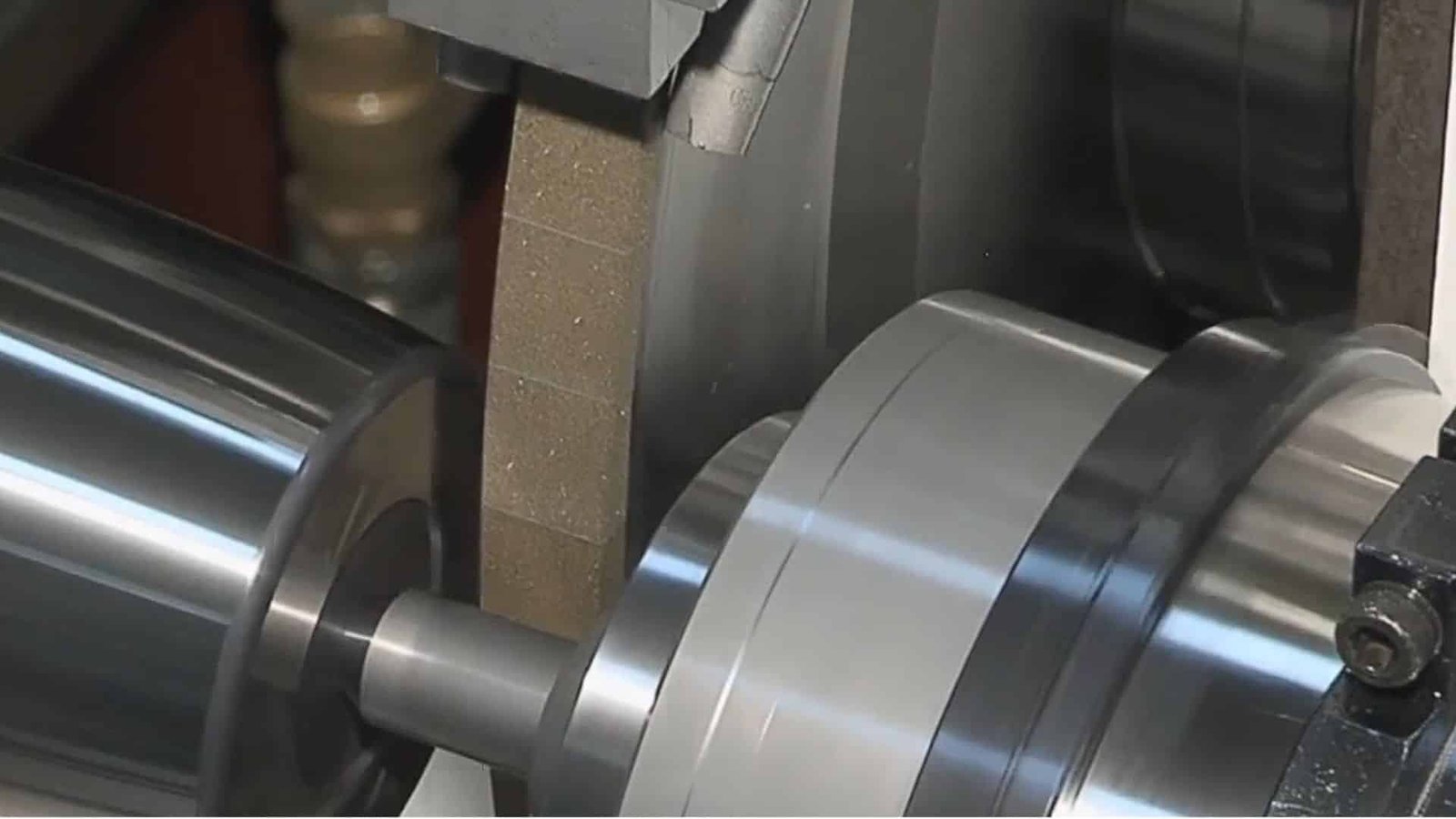

The machine securely holds the workpiece (often between centers or in a chuck) and rotates it. A separate, rapidly spinning grinding wheel (made of materials like Aluminum Oxide or CBN) is guided by the CNC system to contact the workpiece’s outer surface, removing material through controlled abrasion until the exact dimensions and finish are achieved.

The operation is a highly controlled interaction between the workpiece and the grinding wheel. The workpiece rotates steadily, while the abrasive grinding wheel1 spins at high speed on its own spindle. The CNC controller2, often programmed using CAD data, orchestrates the critical movements: it precisely manages the wheel’s feed rate into the workpiece (infeed), its movement along the workpiece axis (traverse speed for traverse grinding), or its direct plunge into the part (plunge grinding). It also controls the workpiece rotation speed and the final position to ensure dimensional accuracy. This automated control allows for complex shapes and consistent results. Coolant is constantly applied to manage heat, flush away grinding swarf, and improve surface quality. It’s not just spinning and touching; it’s a precise, computer-managed process removing material micron by micron, significantly reducing human error and boosting production efficiency compared to manual methods.

What are the Advantages of an External Cylindrical Grinding Machine?

Lathes can also make parts round. So why add the complexity and expense of a dedicated grinding machine? What specific benefits justify its use?Overlooking the unique advantages of grinding might lead to lower quality parts, struggles with hard materials, or inconsistencies that are unacceptable in high-stakes applications.External cylindrical grinding offers distinct capabilities that make it indispensable for achieving top-tier quality and performance in manufactured components.

Key advantages include achieving exceptionally high dimensional accuracy (micron tolerances) and geometric precision (roundness, cylindricity), producing very fine and smooth surface finishes critical for function and appearance, the ability to effectively machine hardened materials (like steel or exotic alloys) unsuitable for turning, and highly consistent, repeatable results thanks to CNC automation.

Let’s look closer at these benefits. Precision: We’re talking tolerances measured in microns, essential for components like bearings or fuel injectors. Surface Finish3: Grinding delivers exceptionally smooth surfaces, vital for seals, low-friction movement, or applications like medical devices and hydraulic systems where finish impacts performance. Hard Materials: Post heat-treatment, many parts become too hard for effective turning. Grinding excels here, easily handling hardened steels, carbides, and other tough materials. Consistency & Automation: The CNC ensures every part matches the program specifications, crucial for mass production in sectors like automotive. This automation reduces errors, increases throughput, allows for continuous operation, enhances safety, and enables the grinding of complex profiles, tapers, and shoulders efficiently. These combined advantages make external cylindrical grinding the go-to process for final, high-precision finishing of critical rotating or cylindrical components.

Can an External Cylindrical Grinding Machine Do Internal Cylindrical Grinding?

The name is pretty specific – "External." But what if your shop also needs to grind the inside diameter of a bore with high precision?Investing in a completely separate internal grinding machine seems inefficient if the need isn’t constant, raising questions about machine flexibility.While a standard external grinder cannot typically do internal work, the answer becomes nuanced when considering "Universal" cylindrical grinders.

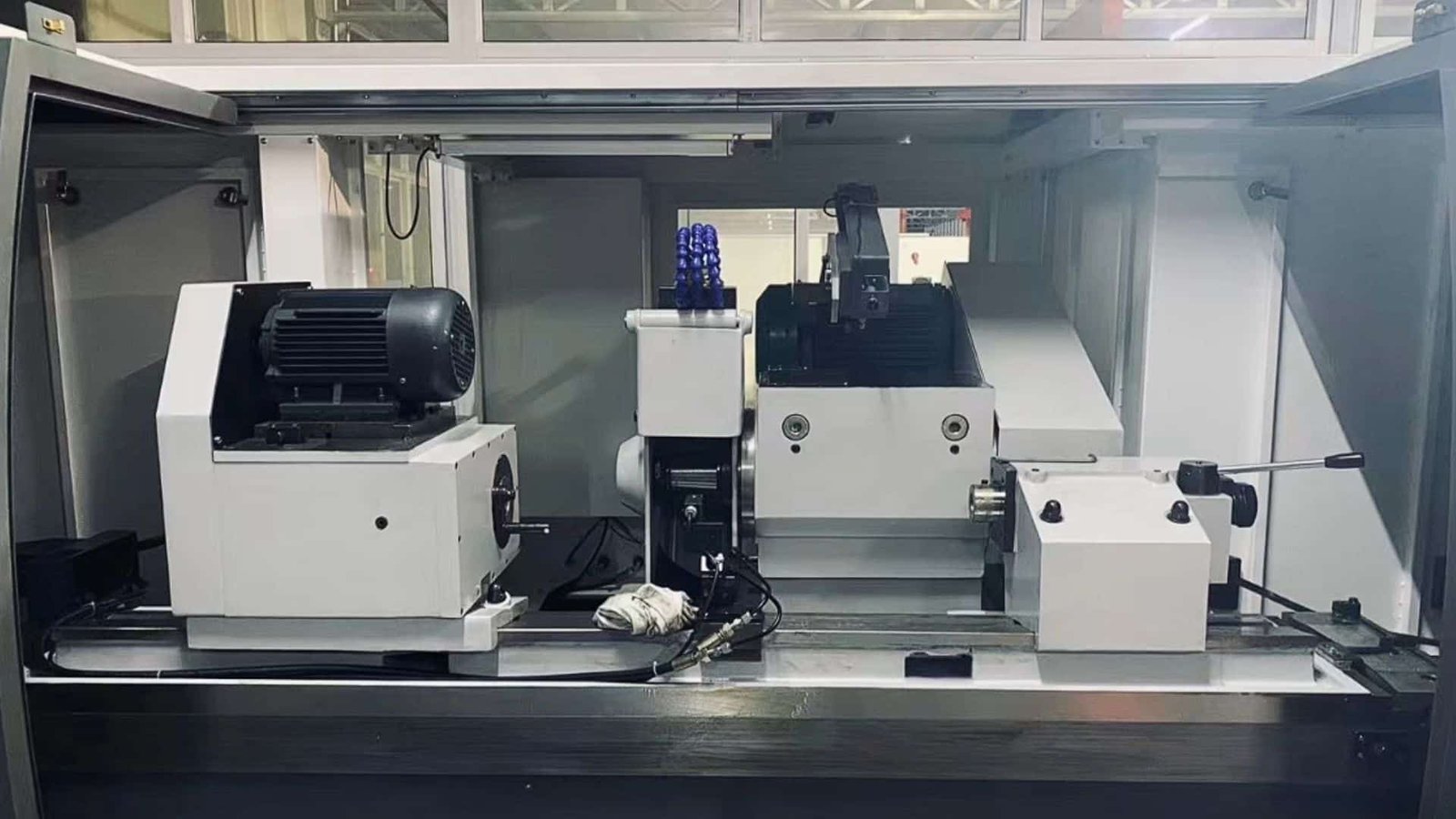

A dedicated external cylindrical grinder is designed exclusively for outside diameters. However, a Universal Cylindrical Grinding Machine, despite its name sometimes including "external," is specifically built for flexibility and often can perform internal grinding, usually via special attachments or configurations. It’s crucial to check the specific machine’s capabilities.

This is a common point of confusion. Your standard external grinder holds the work between centers or in a chuck, focusing the grinding wheel on the OD. Internal grinding requires accessing the inner bore. A Universal grinder, however, is designed for versatility. It often features a swiveling wheelhead that can mount a separate, smaller, high-speed internal grinding spindle. This allows the machine, with the proper setup (changing wheel, adjusting parameters, possibly rotating the head), to grind internal diameters, faces, and tapers in addition to external surfaces4, sometimes even in a single clamping (like some STUDER models). So, while most machines labeled purely "external" can’t do ID work, the "universal" variants often bridge that gap. But it’s not automatic – you must verify the specific model’s features and attachments. Internal grinding is often considered a more complex process, demanding specific setups even on universal machines.

Is a Universal External Cylindrical Grinding Machine the Right Choice for All Grinding Machining?

Hearing "universal" sounds like the perfect solution – one machine handles external, internal, tapers, maybe more! Should every shop just aim for a universal model?Opting for a universal machine might mean compromising on the absolute peak performance or rigidity needed for the most demanding, specialized grinding tasks.While incredibly versatile, a universal grinder is not the optimal solution for every grinding need; its strength in flexibility must be weighed against the demands of the specific application.

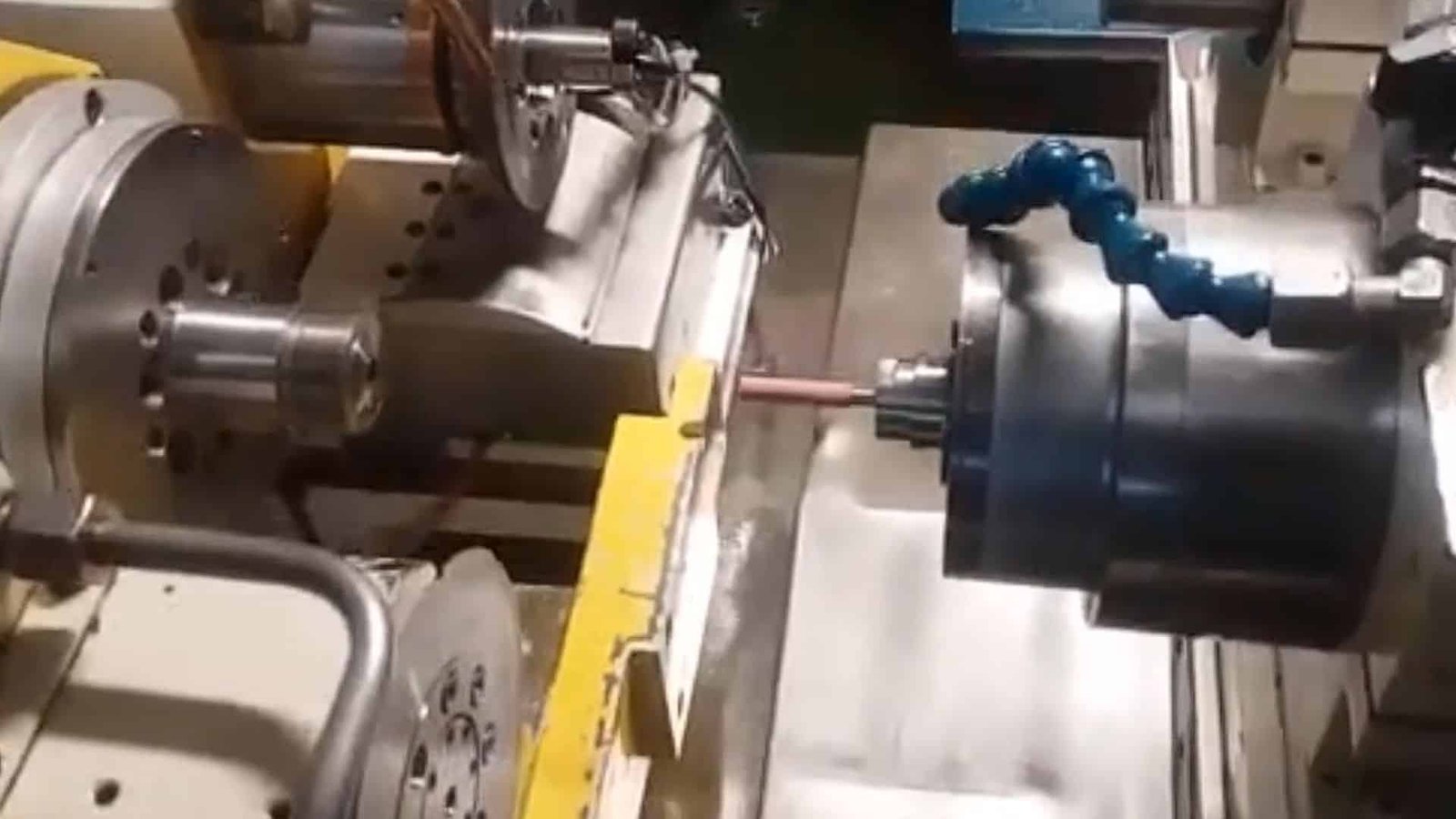

No, a universal grinder isn’t universally the best. It excels at handling a variety of cylindrical grinding tasks (OD, ID, faces, tapers) on one machine, but it’s not suited for non-cylindrical grinding like surface grinding (flat parts) or centerless grinding (high-volume rods/pins). Furthermore, for the absolute highest precision in purely external or internal work, a dedicated machine might offer slight advantages.

A universal cylindrical grinder5 is a powerhouse of flexibility, ideal for job shops or departments needing to process diverse parts with various cylindrical features (external, internal, tapers, even complex shapes like polygons or flats on some models, like those from EMAG Weiss). It minimizes the need for multiple specialized machines. However, this versatility can involve some trade-offs in ultimate rigidity compared to a machine built only for external or only for internal grinding. For applications demanding the absolute pinnacle of micron-level precision6 and surface finish (e.g., high-end aerospace, optics, ultra-precision tooling), a dedicated high-precision machine7, optimized structurally for only one type of grinding, might provide that final increment of performance. And crucially, universal grinders are still cylindrical grinders – they aren’t designed for grinding large flat surfaces (that’s a surface grinder) or for high-volume grinding of parts without centers (that’s centerless grinding). The choice depends on balancing the need for versatility against the specific type of grinding and the absolute level of precision required.

Conclusion

CNC external cylindrical grinders deliver precision OD finishing. Universal models add valuable internal grinding flexibility but aren’t suited for non-cylindrical work like surface grinding. For ultimate single-task precision, dedicated machines excel. Choose based on the mix of tasks, required accuracy, and operational efficiency needed.

-

Learning about abrasive grinding wheels can help you choose the right one for specific grinding tasks, enhancing efficiency. ↩

-

Understanding CNC controllers is crucial for grasping how precision and automation enhance grinding processes. ↩

-

Exploring surface finish can provide insights into its critical role in the functionality and longevity of mechanical parts. ↩

-

Discover the methods used for grinding external surfaces, crucial for precision in machining applications. ↩

-

Explore the advantages of universal cylindrical grinders for diverse machining needs and their flexibility in job shops. ↩

-

Learn about the techniques and technologies that enable micron-level precision in high-end machining applications. ↩

-

Discover the benefits of dedicated high-precision machines for achieving superior performance in specific grinding tasks. ↩

Chris Lu

Leveraging over a decade of hands-on experience in the machine tool industry, particularly with CNC machines, I'm here to help. Whether you have questions sparked by this post, need guidance on selecting the right equipment (CNC or conventional), are exploring custom machine solutions, or are ready to discuss a purchase, don't hesitate to CONTACT Me. Let's find the perfect machine tool for your needs

Chris Lu

Leveraging over a decade of hands-on experience in the machine tool industry, particularly with CNC machines, I'm here to help. Whether you have questions sparked by this post, need guidance on selecting the right equipment (CNC or conventional), are exploring custom machine solutions, or are ready to discuss a purchase, don't hesitate to CONTACT Me. Let's find the perfect machine tool for your needs