What is a CNC Gantry Grinding Machine?

Need to machine huge, heavy parts with extreme precision? Standard machines flex and fail under the load, leading to costly inaccuracies that can scrap an entire project.

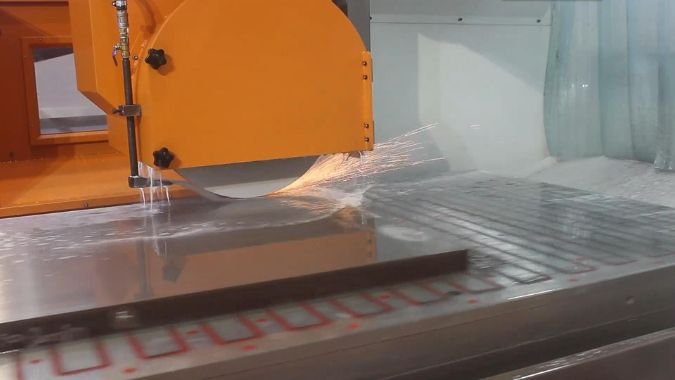

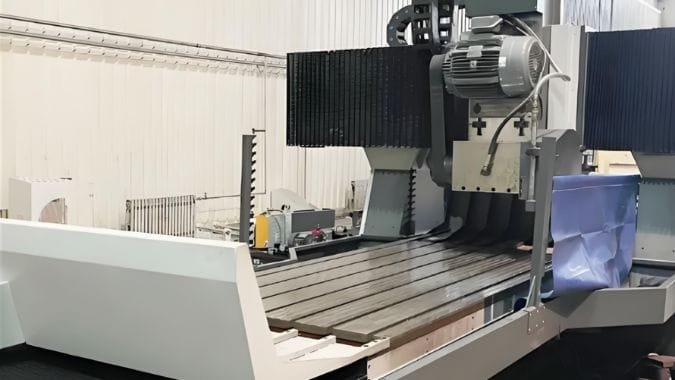

A CNC gantry grinding machine is a massive, high-precision tool built with a rigid overhead frame. It uses computer control to accurately grind flat, angled, and complex surfaces on very large and heavy workpieces, achieving micron-level precision.

When I first saw a gantry grinder in person, I was stunned by its size. It’s built like a bridge for a reason. Its massive frame, with two columns supporting an overhead beam, provides the incredible rigidity needed to grind huge workpieces without any sag or vibration. This robust structure is what makes it so special and allows it to achieve precision that seems impossible for its scale. But what kind of parts actually need a machine this big?

What Types of Workpieces Are Best Suited for CNC Gantry Grinding?

Are you struggling to accurately surface-grind a massive mold or machine tool bed? Standard grinders are too small, and other methods simply lack the required flatness over large distances.

They are best suited for large, heavy workpieces needing extreme flatness, such as machine tool guides, large molds, and aerospace parts. Their rigid frame also makes them ideal for precision guide components and large, complex curved surfaces.

In my experience, the number one reason to use a gantry grinder is sheer size. We’re talking about worktables that can be over 4 meters by 10 meters, designed to hold parts that weigh many tons. This capability opens the door to machining a specific class of components that are fundamental to modern industry.

The most common jobs involve Large and Heavy Workpieces. Think of the base for another machine tool, a massive die for stamping car body panels, or the end face of a wind power main shaft. These parts must be perfectly flat, often with micron-level precision1, and a gantry grinder is the only tool for the job.

Another key area is Precision Guide Components. In our world of machine tools, the accuracy of a machine’s bed and guides determines the quality of every part it makes. Gantry grinders are used to create and recondition these surfaces to near-perfect straightness and flatness. They are also essential for Complex Curved Workpieces, like turbine blades or aerospace structural parts, where the stability of the gantry provides a perfect foundation for multi-axis contouring.

| Workpiece Type | Typical Examples | Key Requirement |

|---|---|---|

| Large & Heavy Parts | Machine tool beds, large mold bases | Extreme size capacity and flatness |

| Precision Components | CNC machine guides, CMM reference planes | Micron-level accuracy (±0.001mm) |

| Complex Surfaces | Turbine blades, aerospace structures | Stability for multi-axis contouring |

| Energy Equipment | Generator casings, wind power shafts | High material removal and stability |

How Does Multi-Axis CNC Control Enable Complex Grinding?

Grinding a complex curve on a turbine blade? A simple three-axis machine can’t keep the wheel perfectly angled as it moves, causing errors and ruining the part’s aerodynamics.

Multi-axis control uses a five-axis system—three linear and two rotary—to continuously adjust the grinding wheel’s angle. This ensures the wheel maintains the optimal cutting posture, allowing for precise grinding of complex surfaces without errors.

This is where gantry machines go from being just big to being incredibly smart. While a basic gantry grinder works in three axes (X, Y, Z) to create flat surfaces, a multi-axis machine adds two rotational axes, typically A (rotation around X) and C (rotation around Z). This five-axis linkage is what lets us tackle truly complex shapes.

The core principle is keeping the grinding wheel in the perfect position at all times. Imagine grinding a curved aero-engine blade. As the wheel moves along the curve, its angle to the surface changes on a 3-axis machine. But with five-axis control, the A and C axes are constantly tilting and rotating the grinding head. This ensures the wheel is always perpendicular to the blade’s surface at the point of contact. This avoids the overcutting or undercutting that would otherwise happen. Behind the scenes, the CNC system performs real-time calculations to ensure path accuracy is less than a micron and dynamically compensates for tool position. It allows us to use advanced superabrasives like diamond and CBN wheels2 effectively. This also reduces setup time, as we can perform multiple operations in a single clamping, which is a huge advantage.

What Flatness and Finish Can CNC Gantry Grinding Machines Achieve?

Do your large parts need to be perfectly flat with a mirror-smooth finish? Other processes can leave subtle waves and tool marks over large surfaces, leading to costly rejections.

A CNC gantry grinder can typically achieve a flatness of ±0.001mm, which is micron-level precision. It also produces a very smooth surface finish, with a roughness average (Ra) of ≤0.4μm, suitable for high-precision components.

These numbers are why customers come to us for CNC Gantry Grinding Machine. Achieving this level of precision on a part the size of a car is an engineering marvel, and it comes down to two things: the machine’s structure and the process control.

Achieving micron-level flatness

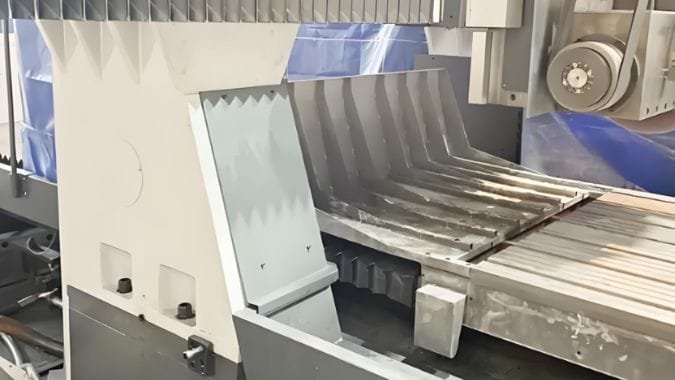

The flatness of ±0.001mm3 is a direct result of the gantry frame’s incredible rigidity. The massive columns and heavy cross-beam eliminate any possibility of the machine sagging or vibrating during the grinding pass. It’s like trying to draw a perfectly straight line using a flimsy ruler versus a heavy, solid steel straight edge. The rigid structure, combined with precision guideways, guarantees a true plane across the entire work surface, which is absolutely critical for machine tool guides and large mold templates.

Creating a perfect surface finish

The surface finish, or Ra value, tells you how smooth the surface is. Getting down to Ra ≤0.4μm is about more than just rigidity; it’s about the entire process. The CNC system precisely controls the speed of the grinding wheel (typically 1000-3000rpm) and the feed rate of the worktable. By optimizing these parameters and choosing the right grinding wheel, we can produce a surface that is not only perfectly flat but also incredibly smooth, which is essential for sealing surfaces and high-precision mating parts.

What Industries Benefit Most from CNC Gantry Grinding Machines?

Working in an industry where large-part precision is absolutely critical? The cost of an error on a massive part can be enormous, making process reliability a top priority.

The industries that benefit most are aerospace, automotive (for large molds), energy generation, medical, and rail transit. These sectors require extreme precision and perfect finishes on very large components, making gantry grinders essential.

The unique capabilities of gantry grinders make them indispensable in several key industries where "big and precise" is the standard.

First and foremost is aerospace and defense. The requirements for aircraft engine blades, intake guide vanes, and even satellite brackets are incredibly high. These parts need perfect contours and flawless surfaces to ensure flight safety and performance.

Next is the automotive industry4. Every car body panel is stamped from a massive mold. The precision and finish of that mold’s surface directly translate to the quality of the final car. Gantry grinders provide the accuracy needed to produce these tools.

The energy sector also relies heavily on these machines. The giant blades for nuclear or wind turbines need to be perfectly shaped and smooth to be efficient. Gantry grinders are used to create the forming grinds on these critical components.

Also, the rail transit industry uses them for planar processing of high-speed rail bogies and track plates, while the medical field requires them for high-precision grinding of fine curved parts like implants.

Conclusion

A CNC gantry grinder’s rigid frame and multi-axis control5 are essential for machining large, heavy parts. It provides the micron-level precision that critical industries like aerospace and energy demand.

-

Find out why micron-level precision is crucial for high-quality manufacturing and how it’s achieved. ↩

-

Find out how superabrasives enhance machining processes and their specific applications. ↩

-

Discover the implications of achieving such flatness in manufacturing and its importance. ↩

-

Understand the role of CNC machining in the automotive industry and its impact on production. ↩

-

Explore the concept of multi-axis control and its advantages in achieving complex shapes. ↩

Chris Lu

Leveraging over a decade of hands-on experience in the machine tool industry, particularly with CNC machines, I'm here to help. Whether you have questions sparked by this post, need guidance on selecting the right equipment (CNC or conventional), are exploring custom machine solutions, or are ready to discuss a purchase, don't hesitate to CONTACT Me. Let's find the perfect machine tool for your needs.