What is a CNC Surface Grinding Machine?

You need parts with perfectly flat, smooth surfaces, often with very tight tolerances for flatness and parallelism. How do you achieve this reliably and automatically?Trying to get precise flat surfaces with milling alone is tough, and hand finishing is slow, skill-dependent, and inconsistent, especially for high-volume or critical parts.A CNC Surface Grinding Machine is the specialized, automated tool designed specifically for creating highly accurate flat surfaces.

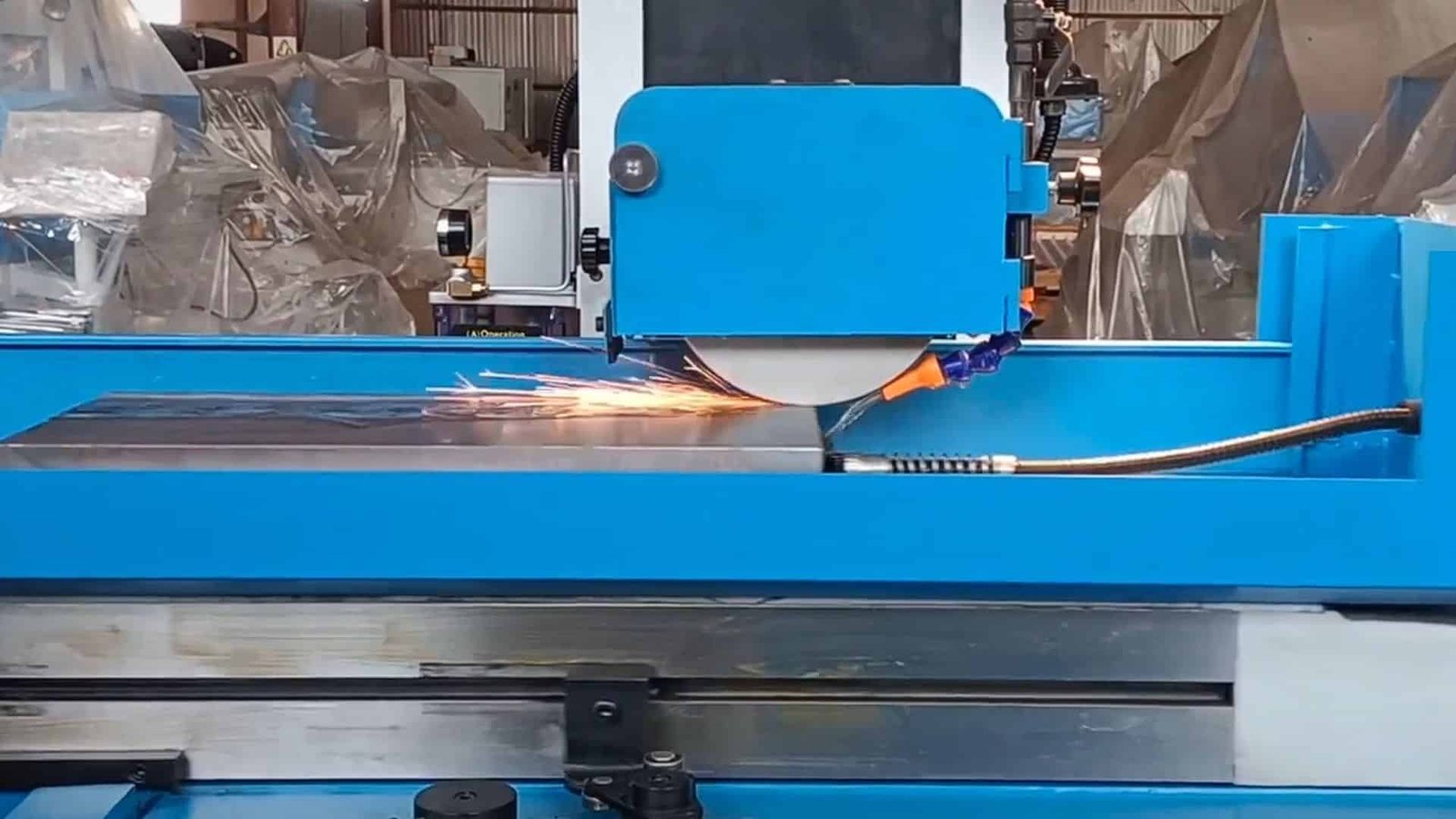

A CNC Surface Grinding Machine uses computer numerical control (CNC) to automate the precise guiding of a rotating abrasive wheel over a workpiece. This removes material to produce extremely flat, parallel, and smooth surfaces, crucial for finishing parts in industries like aerospace and automotive.

These machines are fundamental in tool rooms, mold making, and production environments where precision flat surfaces are critical. They represent advanced hard-fine machining, often used as a finishing step. Now that we know what it is, let’s explore how it achieves such accuracy through automation.

How do CNC Surface Grinding Machines Work?

You see the table moving, the wheel spinning under computer control, but how does that automated dance result in a perfectly flat surface across the entire part?Without understanding the coordinated movements programmed into the CNC, it’s hard to grasp how the machine achieves such high precision and repeatability consistently.Let’s break down the controlled, automated movements that define CNC surface grinding.

The machine securely holds the workpiece on a table that moves (e.g., back and forth). The spinning grinding wheel, precisely controlled by the CNC system via pre-programmed instructions (like G-code), moves across the workpiece and incrementally feeds downward, removing material accurately.

The process involves highly coordinated motion in multiple axes, all managed by the CNC controller1. The workpiece rests on a table (often moving along the X-axis). The grinding wheel assembly typically handles the cross-feed (Y-axis) and the critical downfeed (Z-axis). The CNC program dictates the speeds, feeds, and exact path. For instance, the table reciprocates under the wheel, the wheel steps over a precise amount, and then feeds down by a few microns for the next pass. This automation ensures every movement is exact and repeatable, reducing human error and significantly cutting down production time, especially for complex shapes or high-volume runs. The result is consistent high tolerance work2, essential for modern manufacturing. This level of control allows for continuous operation and efficient production grinding3, not just slow finishing.

What Kinds of Grinding Wheels do Surface Grinding Machines Use?

The variety of grinding wheels is huge – different materials, sizes, shapes, grits. How do you pick the right one for your specific surface grinding job?Using the wrong wheel leads to poor finish, slow work, burning the part, rapid wheel wear, or even safety issues. Choosing correctly is vital for success.Selecting the correct wheel type (abrasive material, bond), shape, size, and grit depends heavily on the workpiece material and the finish requirements.

Surface grinders use wheels made of abrasive particles like Aluminum Oxide (for steels) or Silicon Carbide (for cast iron, non-metals), often in vitrified bonds. Diamond or CBN wheels tackle very hard materials. Grit size (e.g., 80-120 for general work) balances speed and finish.

Choosing the wheel starts with the material. Aluminum Oxide4 is great for most steels. Silicon Carbide works well on cast iron, non-ferrous metals (aluminum, brass), and non-metals like ceramics or glass. For extremely hard materials like hardened tool steels or carbides, superabrasives like CBN (Cubic Boron Nitride5) or Diamond are needed. Wheels come in various shapes too (straight, cup, dish) to suit different jobs like flat grinding, sharpening, or form grinding. Grit size affects finish and speed: lower numbers (e.g., 46) cut faster but rougher; higher numbers (e.g., 120+) give a smoother finish but cut slower. A common range like 80-120 offers a good balance. Modern wheels are also very efficient, enabling higher material removal rates, making CNC surface grinders suitable for production grinding tasks, not just final finishing touches on parts like crankshafts or molds.

| Wheel Abrasive | Typical Materials Ground | Common Grit Range | Notes |

|---|---|---|---|

| Aluminum Oxide | Steels (carbon, alloy, tool steels) | 46 – 120+ | Most common general-purpose wheel |

| Silicon Carbide | Cast Iron, Aluminum, Brass, Ceramics | 60 – 120+ | Good for brittle or non-ferrous materials |

| Ceramic Al. Oxide | Hardened Steels, Difficult Alloys | 60 – 120 | Tougher, longer lasting than standard AlOx |

| CBN / Diamond | Very Hard Steels, Carbides, Ceramics | 100+ (Mesh Size) | Superabrasives for extreme hardness |

How are Workpieces Held Down on the CNC Surface Grinder?

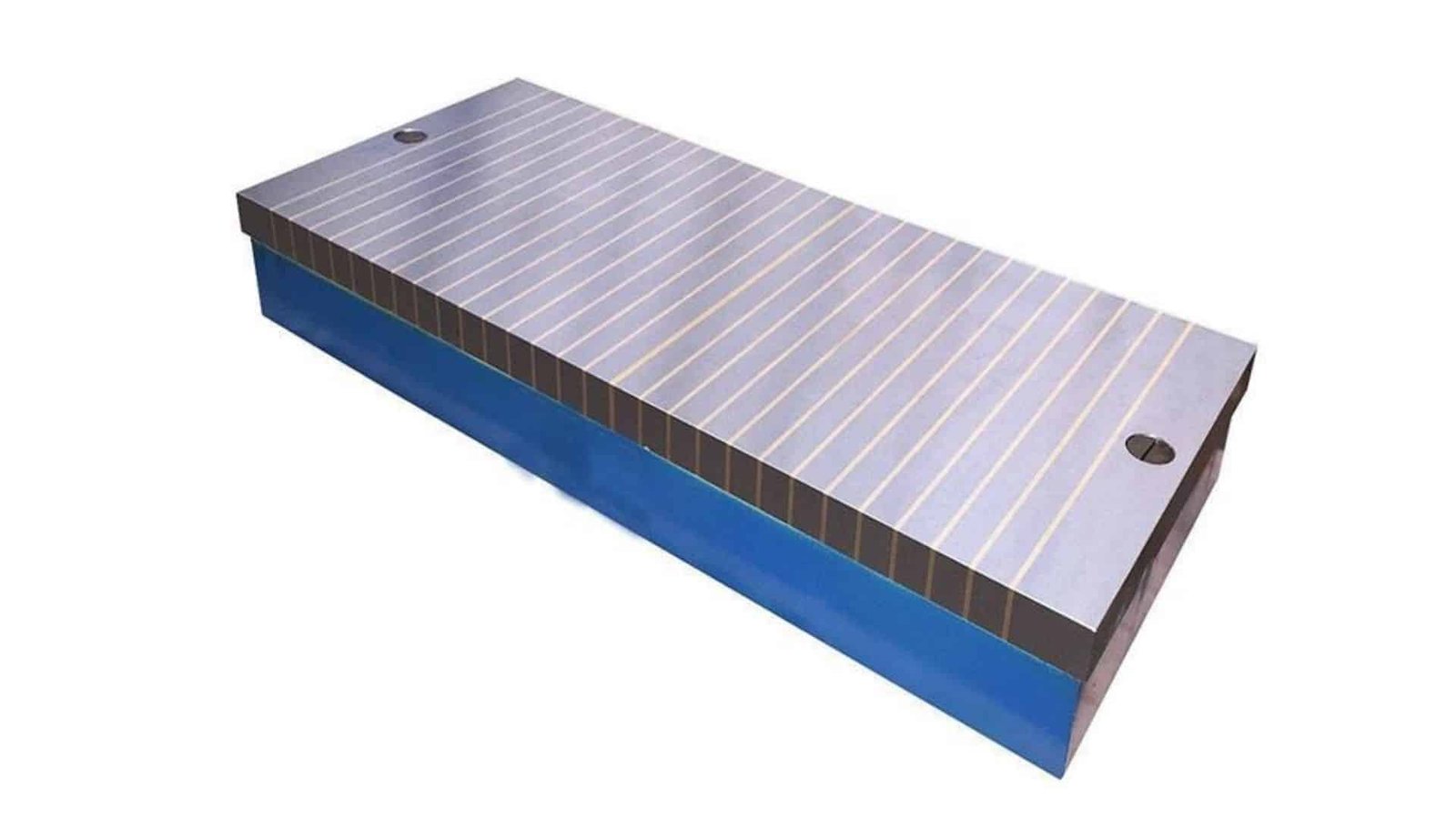

Grinding applies force. How do you make absolutely sure the workpiece stays perfectly flat and doesn’t budge during the grinding cycle?Even the tiniest movement or lift will destroy the flatness and accuracy you need, wasting time and material. Secure workholding is non-negotiable.Reliable workholding is essential, with electromagnetic chucks being very common, supported by a rigid machine structure for overall stability.

Ferrous workpieces are typically held very securely by powerful electromagnetic chucks built into the machine table. Non-ferrous parts require mechanical clamping, precision vises, or other fixtures to ensure stability during grinding.

Electromagnetic chucks6 are the standard for steel and iron parts. They use strong magnetism, switched on/off easily, to pull the workpiece flat against the chuck surface, providing excellent, evenly distributed holding force. This prevents movement and helps achieve flatness. However, magnetism doesn’t work on materials like aluminum, brass, plastics, or many stainless steels. For these, other methods are needed, such as precision machine vises7 bolted to the table, dedicated clamping fixtures, or sometimes vacuum chucks. Underlying all this is the machine’s own construction. A heavy, rigid machine bed (often made from vibration-damping cast iron8 like Meehanite) and precise, smooth guideways for table movement are critical. This robust structure ensures that the workholding method, whatever it is, has a stable platform, enabling the machine to achieve micro-feed accuracy and maintain close tolerances consistently.

Do CNC Surface Grinders Use Working Fluid or Coolant?

Grinding looks hot and sparky! Do these machines need liquid to cool things down, or do they run dry?Running dry incorrectly can lead to burnt parts, warped surfaces, or damaged wheels. Using fluid when not needed is messy. Knowing when to use coolant is important.Yes, CNC surface grinders frequently use coolant (wet grinding) for several key benefits, although dry grinding is occasionally used for specific situations.

Coolant (like oils, water-based emulsions, or synthetics) is typically essential in CNC surface grinding to manage heat, flush away debris, improve surface finish, and prevent rust. Dry grinding is reserved for specific materials or process needs.

Wet grinding is the norm because the benefits are significant. Coolant types9 vary – oils, oil-water emulsions, synthetic fluids, pastes, even gels – chosen for the application.

Key Reasons for Using Coolant (Wet Grinding):

- Cooling: It removes the intense heat generated at the grinding point. This stops the workpiece from burning, warping, or losing its desired hardness, and helps the grinding wheel last longer.

- Flushing10: The fluid flow washes away tiny metal chips (swarf) and abrasive particles. This prevents surface scratches and keeps the wheel cutting cleanly, crucial for a good finish and accuracy.

- Lubrication: Some fluids reduce friction, allowing for smoother grinding and potentially better efficiency.

- Rust Prevention11: Many coolants contain rust inhibitors to protect the machine and the workpiece.

When Dry Grinding Might Be Used: - Material Reactivity: Some materials (like magnesium) react poorly with water-based coolants.

- Contamination Concerns: In ultra-clean environments (like some electronics), coolant residue might be unacceptable.

- Specific Processes: Certain setups with specific superabrasive wheels might call for dry grinding, although coolant is often still preferred if possible due to heat.

Generally, for quality surface grinding on metals, coolant is vital for managing heat, ensuring a good finish, and protecting the equipment.

| Condition | Reason | Coolant Use | Coolant Types Often Used |

|---|---|---|---|

| General Steel Grinding | Heat generation, chip flushing, finish quality | Yes (Wet) | Emulsions, Synthetics, Oils |

| Hardened Steel Grinding | Prevent thermal damage, maintain hardness | Yes (Wet) | Synthetics, Oils |

| High Precision Work | Flush fine chips, maintain accuracy | Yes (Wet) | Filtered Synthetics/Oils |

| Magnesium Alloy Grinding | Material reacts with water | No (Dry) | N/A |

| Ultra-Clean Applications | Avoid coolant residue contamination | Possibly No (Dry) | N/A |

| Cast Iron Grinding | Chip flushing, cooling | Yes (Wet) | Synthetics, Emulsions |

Conclusion

CNC surface grinders use computer control for automated, high-precision flat surface finishing. Proper wheel selection, secure workholding (often magnetic chucks), and generally, the use of coolant are all critical factors for achieving accurate, smooth results on various materials.

-

Understanding CNC controllers is crucial for grasping modern manufacturing processes and automation. ↩

-

Learning about high tolerance work can enhance your knowledge of quality standards in manufacturing processes. ↩

-

Exploring production grinding can reveal its advantages in efficiency and precision for high-volume manufacturing. ↩

-

Explore the advantages of Aluminum Oxide in grinding applications, especially for steel, to enhance your material selection process. ↩

-

Learn about Cubic Boron Nitride’s unique properties and its effectiveness in grinding hard materials, crucial for advanced machining. ↩

-

Explore the advantages of Electromagnetic chucks for efficient workholding and precision in machining processes. ↩

-

Discover how precision machine vises contribute to accuracy and efficiency in machining operations. ↩

-

Learn about vibration-damping cast iron and how it enhances machine stability and performance. ↩

-

Understanding coolant types can enhance your grinding process and improve efficiency. Explore this resource for detailed insights. ↩

-

Discover the importance of flushing in maintaining surface quality and accuracy in grinding operations. ↩

-

Learn how rust prevention in coolants can protect your machinery and workpieces, ensuring longevity and performance. ↩

Chris Lu

Leveraging over a decade of hands-on experience in the machine tool industry, particularly with CNC machines, I'm here to help. Whether you have questions sparked by this post, need guidance on selecting the right equipment (CNC or conventional), are exploring custom machine solutions, or are ready to discuss a purchase, don't hesitate to CONTACT Me. Let's find the perfect machine tool for your needs

Chris Lu

Leveraging over a decade of hands-on experience in the machine tool industry, particularly with CNC machines, I'm here to help. Whether you have questions sparked by this post, need guidance on selecting the right equipment (CNC or conventional), are exploring custom machine solutions, or are ready to discuss a purchase, don't hesitate to CONTACT Me. Let's find the perfect machine tool for your needs