What is a Deep Hole Drilling Machine?

Chris Lu

Leveraging over a decade of hands-on experience in the machine tool industry, particularly with CNC machines, I'm here to help. Whether you have questions sparked by this post, need guidance on selecting the right equipment (CNC or conventional), are exploring custom machine solutions, or are ready to discuss a purchase, don't hesitate to CONTACT Me. Let's find the perfect machine tool for your needs.

Chris Lu

Leveraging over a decade of hands-on experience in the machine tool industry, particularly with CNC machines, I'm here to help. Whether you have questions sparked by this post, need guidance on selecting the right equipment (CNC or conventional), are exploring custom machine solutions, or are ready to discuss a purchase, don't hesitate to CONTACT Me. Let's find the perfect machine tool for your needs

Drilling a truly deep, straight hole with a standard drill bit is often a recipe for disaster. The drill wanders off-center, chips clog the flutes causing the tool to jam and break, and a lack of proper cooling can ruin both the tool and the expensive workpiece. This leads to scrapped parts, broken tools, and costly downtime.

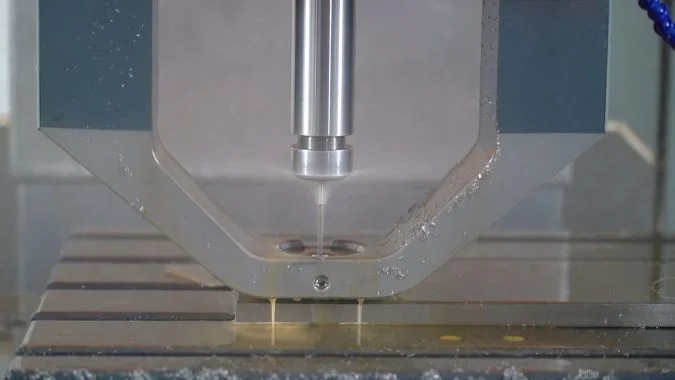

A deep hole drilling machine is a specialized machine tool designed specifically for drilling holes with a high length-to-diameter (L/D) ratio, typically greater than 10:1 and sometimes reaching up to 300:1. It uses advanced methods, combined with high-pressure coolant systems, to produce exceptionally straight, accurate holes with excellent surface finishes in a single, efficient pass.

Deep Hole Drilling Machine takes what is normally a difficult, high-risk process and turns it into a reliable and precise operation. Let’s explore what makes these machines so uniquely capable.

What are the Methods of Drilling Used on Deep Hole Drilling Machine?

When drilling a deep hole, you can’t just use a longer twist drill and hope for the best. The fundamental problems of chip evacuation and coolant delivery become impossible to solve, leading to certain failure. To succeed, specialized techniques are essential.

Deep hole drilling machines predominantly use two distinct methods: Gun Drilling for smaller diameter holes, and BTA Drilling for larger ones. Both methods rely on uniquely designed tools and high-pressure coolant systems to forcefully flush chips out of the hole and keep the cutting zone perfectly lubricated and cool.

Knowing which method to apply is an essential first step. The decision is primarily based on the diameter of the hole you need to create. Both are brilliant engineering solutions to the same core challenge, just applied at different scales.

Gun Drilling1

This is the preferred method for smaller diameter holes, a range where extreme precision is often the main goal.

- Ideal Diameter Range2: Typically used for holes from 1 mm up to about 40 mm.

- How it Works: The gun drill tool has a single cutting edge and a long, straight flute (often a V-shaped groove). High-pressure coolant is pumped through a small channel running down the center of the tool. This powerful jet of coolant sprays directly at the cutting face, where it both cools the cut and forcefully blasts the tiny chips back out of the hole along the external V-groove.

- Key Advantages: It produces exceptionally straight holes with a fantastic surface finish, making it perfect for applications like medical surgical instruments, automotive fuel injectors, and aerospace components where precision is absolutely critical.

BTA Drilling3

When you need to create larger deep holes with maximum efficiency, BTA (Boring and Trepanning Association) drilling is the superior method.

- Ideal Diameter Range: Generally used for holes with diameters above 20 mm.

- How it Works: The process is essentially the reverse of gun drilling. High-pressure coolant is pumped into the hole around the outside of the drill tube. The chips created at the cutting head are then flushed back through the hollow center of the drill tube and away from the workpiece.

- Key Advantages: This internal chip evacuation allows for much faster feed rates and higher material removal rates. It is the most efficient choice for larger, deeper holes found in industries like energy exploration and heavy equipment manufacturing. A variation of this method called Ejector Drilling uses a dual-tube system and can be adapted for some machines without a full high-pressure setup.

Why Choose Deep Hole Drilling Machine Over Standard Drilling Machine?

Imagine you need to drill a hole through a part that is ten times deeper than it is wide. On a standard drill press or CNC mill, the tool starts to struggle almost immediately; the hole veers off-center, and you can hear the tool straining. You quickly realize this job requires a different class of machine altogether.

You should choose a deep hole drilling machine because it is purpose-built to conquer the three critical challenges of deep hole drilling: achieving precision straightness, ensuring forced chip evacuation, and delivering direct cutting-edge cooling. Standard drilling machines simply lack the necessary rigidity, high-pressure coolant systems, and specialized tool guidance to perform these demanding tasks reliably.

The difference isn’t just about using a longer tool; it’s about a complete re-engineering of the drilling process. I’ve seen many attempts to "make it work" with standard equipment, and they almost always end in broken tools and scrapped parts. Here’s a clear breakdown of why a specialized machine is the only real solution.

Precision, Straightness, and Depth

Deep hole drilling machines4 are designed for high aspect ratios. They maintain minimal deviation even at extreme depths. In contrast, standard drills deflect easily, and this error compounds as the hole gets deeper. The ability to achieve a single, continuous, and straight hole saves immense time over less reliable methods.

Uninterrupted Chip Evacuation5

This is the single biggest hurdle that specialized machines overcome.

- Deep Hole Machine: Uses a high-pressure coolant system to continuously and forcibly blast chips out of the hole. The process never needs to stop to clear chips.

- Standard Drilling Machine: Relies on a slow "peck drilling" cycle (drilling a little, retracting to clear chips, drilling a little more), which is extremely time-consuming and still risks chips packing in the flutes.

Superior Cooling and Lubrication

Getting coolant to the cutting edge is vital.

- Deep Hole Machine: Delivers a high-volume jet of coolant directly through or around the tool to the cutting zone. This provides maximum cooling, extending tool life and resulting in an excellent surface finish that often eliminates the need for secondary operations.

- Standard Drilling Machine: Uses external flood coolant that cannot penetrate a deep hole, leaving the cutting edge to run hot and dry.

How Do Deep Hole Drilling Machines Maintain Tight Tolerances Over Extreme Hole Depths?

You have a critical task: drill a hole through a long, expensive component, and it must be perfectly straight and precisely on-size from one end to the other. How can a machine maintain such high accuracy when the cutting edge is working deep inside the part, completely out of sight?

Deep hole drilling machines maintain tight tolerances by creating a synergistic system of specialized self-guiding tools, precision start-up bushings, a high-pressure coolant system that ensures perfect chip evacuation and thermal stability, and an extremely rigid, purpose-built machine structure that minimizes deflection and vibration.

From my own experience, this remarkable precision doesn’t come from a single magic bullet. It’s the result of the tool, the process, and the machine architecture all working together in perfect harmony. Let’s break down how these elements contribute.

Specialized Tooling and Guidance System

The tools themselves are engineered to be self-guiding.

- Tool Design: Gun drills and BTA tools are designed with specific pads and cutting angles that create a balance of forces. As the tool cuts, these forces press the tool head against the walls of the hole it’s creating, effectively burnishing the surface and forcing the tool to follow an incredibly straight path.

- Guide Bushing6: To guarantee the hole begins perfectly on-center, the process starts with the tool passing through a hardened, precision-ground guide bushing. This bushing provides rigid support at the entry point until the tool is deep enough in the cut to guide itself.

The Role of the High-Pressure Coolant System7

The coolant system is as crucial for accuracy as it is for chip removal.

- Perfect Chip Evacuation: By instantly flushing chips away, the system prevents any build-up that could deflect the tool and ruin the hole’s straightness or surface finish.

- Thermal Stability: The constant flow of temperature-controlled coolant prevents the tool and workpiece from heating up. This eliminates thermal expansion, which would otherwise cause the hole’s diameter to change as it is being drilled.

The Ultra-Rigid Machine Platform8

The machine itself is the foundation of precision. It is built with features designed to resist deflection and vibration, including:

- Precision Components9: Using high-quality ball linear guides and precision lead screws ensures smooth, accurate, and repeatable movement of the tool.

- Spindle Cooling: Many machines incorporate an automatic oil cooling system for the spindle to maintain thermal stability during long drilling cycles.

This combination of technologies allows these machines to achieve impressive tolerances, with dimensional accuracy up to IT7-IT11 and straightness deviations as low as 0.5 mm per 1000 mm of depth.

What Industries are Deep Hole Drilling Machines Most Commonly Used?

When you look at a complex injection mold with perfectly straight cooling channels, or the long, precise bore in an aircraft landing gear strut, you are seeing the work of a deep hole drilling machine. These critical features are often impossible to create with standard machining, making this technology indispensable for many high-tech and heavy-duty industries.

Deep hole drilling machines are most commonly found in Mold Manufacturing, Aerospace, the Automotive Industry, Energy/Oil & Gas, and Medical Device manufacturing. These sectors depend on this technology to create critical internal features that require extreme depth-to-diameter ratios and exceptionally high precision.

The demand for this technology is fueled by the engineering need for components that are stronger, lighter, more efficient, and more complex. I’ve been involved in projects across most of these sectors, and the common denominator is always the requirement for an internal feature that simply cannot be made any other way.

| Industry | Common Applications |

|---|---|

| Mold Manufacturing | Long cooling/heating channels in injection molds and die-cast dies, ejector pin holes, guide pillar and bush holes. |

| Aerospace & Defense | Hydraulic lines in landing gear, actuator components, turbine shafts, missile components, and firearm barrels. |

| Automotive | Deep oil galleries in engine blocks and crankshafts, transmission shafts, fuel system components, and steering parts. |

| Energy / Oil & Gas | Bores in drill collars, extraction tools, nuclear power plant components, and pipelines. |

| Medical | Cannulated surgical instruments (like drills and screwdrivers), orthopedic implants, and prosthetic devices. |

| Heavy Equipment | Hydraulic cylinders, rock drilling tools, and other components for construction and mining machinery. |

Essentially, any industry that needs to precisely move fluids through a solid component or requires a long, straight bore for a mechanical function is a primary user of deep hole drilling technology.

Conclusion

Deep hole drilling machines are highly specialized and essential tools in modern manufacturing. By using advanced methods like gun drilling and BTA drilling, they deliver a level of precision, straightness, and efficiency for deep holes that standard machines simply cannot match. They are the enabling technology behind many critical industrial components.

-

Explore the benefits of Gun Drilling for precision applications, especially in medical and aerospace industries. ↩

-

Understanding the ideal diameter ranges can help you choose the right drilling method for your project. ↩

-

Learn how BTA Drilling enhances efficiency and speed in manufacturing larger, deeper holes. ↩

-

Explore the benefits of deep hole drilling machines to understand their efficiency and precision in specialized applications. ↩

-

Learn how uninterrupted chip evacuation enhances drilling processes, leading to faster and more reliable results. ↩

-

Learning about Guide Bushings can provide insights into achieving better hole accuracy and alignment. ↩

-

Understanding the role of a High-Pressure Coolant System can enhance your machining accuracy and efficiency. ↩

-

Discovering the advantages of an Ultra-Rigid Machine Platform can lead to enhanced precision and reduced vibration in your operations. ↩

-

Exploring the impact of Precision Components can help you improve your machining processes and outcomes. ↩