What is a Dual Spindle CNC Lathe?

Struggling with slow production times on complex turned parts? Constantly moving parts from one machine to another adds labor, introduces errors, and kills your profit margins.

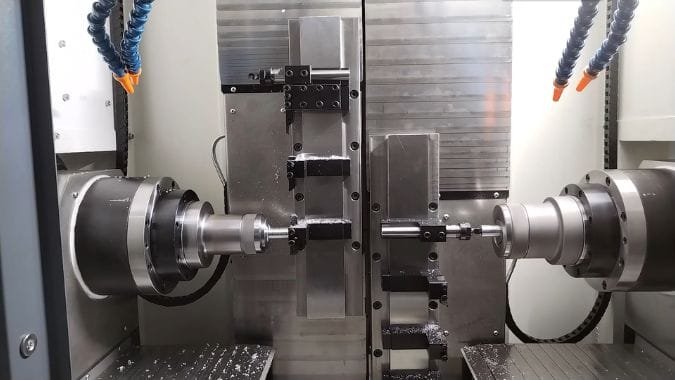

A dual spindle CNC lathe is a machine with two opposing spindles: a main spindle and a sub-spindle. This setup enables "Done-in-One" manufacturing, machining both ends of a part in a single, uninterrupted operation.

When I first saw a dual spindle lathe in action, it was a game-changer. The ability to complete a complex part without an operator ever touching it is the key to true "lights-out" manufacturing. This technology isn’t just an upgrade; it’s a complete shift in how you approach production turning. It’s about eliminating waste and combining multiple processes into one seamless flow.

How Does a Sub-spindle Differ From a Main Spindle In Function?

You see two spindles on the machine, but are they just mirror images of each other? Using them incorrectly can lead to poor performance and even damage the machine.

The main spindle is the powerhouse with higher torque for heavy cutting. The sub-spindle is the versatile finisher, used for secondary operations and even to provide support like a live tailstock.

Think of it as having two specialists. The main spindle1 is the primary workhorse, while the sub-spindle2 is the expert helper who completes the job, but its capabilities have grown over the years.

The Powerhouse: Main Spindle

The main spindle always handles the first operation (OP10). It’s engineered for maximum rigidity and power to take the heaviest cuts from raw bar stock. Its job is to establish the part’s primary features and datums with extreme accuracy.

The Finisher & Supporter: Sub-spindle

The sub-spindle’s most basic job is to pick the part off and machine the back side (OP20). However, on more advanced machines, sometimes called "twin spindle" lathes, the sub-spindle is just as powerful as the main, allowing for heavy, aggressive machining on both sides. An often-overlooked function is its ability to act as a fully synchronized "live tailstock." For long, thin shafts, we can program the sub-spindle to grip the free end of the part, providing rigid support that dampens vibration, improves surface finish, and allows for much faster cutting.

What Are The Productivity Advantages of a Dual Spindle lathe over Standard CNC Lathes?

A standard CNC lathe is a workhorse, but it has a big weakness: it creates work-in-process (WIP) inventory that clogs up your shop floor and ties up capital.

A dual spindle lathe eliminates WIP by completing the part in one cycle. It performs OP10 and OP20 simultaneously, turning a multi-step process into one seamless, automated operation.

The productivity leap is massive because it attacks all the "non-value-added" time in your process. On a standard lathe, you run OP10, then an operator unloads the parts. Those parts then sit in a bin, waiting. They get moved to another machine, re-fixtured, and re-qualified before OP20 can even begin. All that handling, transport, and storage time is waste.

A dual spindle lathe3 eradicates this waste. Even better, it enables overlapped machining4. While the sub-spindle is busy performing OP20 on the first part, the main spindle has already started machining OP10 on the next part from the bar stock. The total cycle time is no longer OP10 + OP20; it’s simply the time of whichever operation is longer. This parallel processing is a fundamental force multiplier that single-spindle machines can never match, turning two operations into one.

How Can a Dual Spindle Lathe Reduce Cycle Time and Cost-per-part in Production?

Your quote is competitive, but long cycle times and high labor costs are eating your profits. You need to make parts faster and cheaper without sacrificing quality.

A dual spindle lathe attacks cost from every angle: it slashes cycle times through parallel machining, eliminates manual labor for part handling, and improves quality by removing re-clamping errors.

The financial justification for a dual spindle machine is overwhelming when you look at the total cost-per-part. In some real-world cases, moving a complex part from a multi-machine process to a single dual spindle setup has resulted in a 10-fold reduction in cycle time5.

This is achieved by attacking every source of waste. The "Done-in-One" process, especially when paired with a bar feeder and parts catcher, allows for true "lights-out" manufacturing. We can load it with material, hit cycle start, and let it run unattended overnight, producing hundreds of finished parts. This drastically reduces direct labor costs and maximizes the return on our investment. Furthermore, by machining all features in a single clamping, the concentricity and alignment between front-and-back features are nearly perfect. This boosts the yield of good parts from 80% to over 95% in some cases, slashing scrap and rework costs.

What Industries and Applications Benefit Most from Dual Spindle CNC Lathe Capabilities?

Your shop makes a wide variety of parts. How do you know if a dual spindle machine is the right investment for your specific type of work?

Industries needing complex parts with features on both ends benefit most. This includes automotive for drivetrain components, medical for surgical implants, and aerospace for high-strength fittings.

While many shops can benefit, this technology is a true game-changer for specific applications where the advantages are most pronounced.

High-Volume, High-Precision6

- Automotive: The relentless demand for millions of identical engine, transmission, and drivetrain parts at low cost makes this technology essential.

- Medical: Perfect for producing complex orthopedic implants like bone screws and surgical instruments from tough materials like titanium, where the "Done-in-One" process guarantees the required precision.

- Aerospace & Defense: Ideal for high-strength fasteners, hydraulic fittings, and guidance system components where feature alignment and reliability are non-negotiable.

Ideal Part Geometries7

Think of any part that requires work on both ends:

- Shafts and Axles: These parts almost always have features like threads, grooves, or cross-holes on both ends.

- Valves and Fittings: Perfect candidates that require turning, threading, and internal porting on multiple faces, where the relationship between features is critical.

Conclusion

A dual spindle CNC lathe is a production strategy. By embracing "Done-in-One" manufacturing, it eliminates waste, boosts productivity, and delivers a lower cost-per-part, providing a decisive competitive advantage for any modern shop.

-

Understanding the main spindle’s role can enhance your machining efficiency and accuracy. ↩

-

Exploring the benefits of a sub-spindle can help you optimize your machining operations and achieve better results. ↩

-

Exploring the advantages of dual spindle lathes can enhance your production efficiency and reduce cycle times significantly. ↩

-

Understanding overlapped machining can help you optimize your manufacturing processes and reduce waste effectively. ↩

-

Explore this link to understand how significant cycle time reductions can enhance efficiency and profitability in manufacturing. ↩

-

Explore this link to understand how High-Volume, High-Precision manufacturing can revolutionize production efficiency and quality. ↩

-

Discover the significance of Ideal Part Geometries in manufacturing processes and how they enhance product functionality. ↩

Chris Lu

Leveraging over a decade of hands-on experience in the machine tool industry, particularly with CNC machines, I'm here to help. Whether you have questions sparked by this post, need guidance on selecting the right equipment (CNC or conventional), are exploring custom machine solutions, or are ready to discuss a purchase, don't hesitate to CONTACT Me. Let's find the perfect machine tool for your needs

Chris Lu

Leveraging over a decade of hands-on experience in the machine tool industry, particularly with CNC machines, I'm here to help. Whether you have questions sparked by this post, need guidance on selecting the right equipment (CNC or conventional), are exploring custom machine solutions, or are ready to discuss a purchase, don't hesitate to CONTACT Me. Let's find the perfect machine tool for your needs