Struggling to machine long, slender parts accurately? They vibrate and flex under pressure, causing scrap parts and killing your production efficiency. This is a common and costly problem.

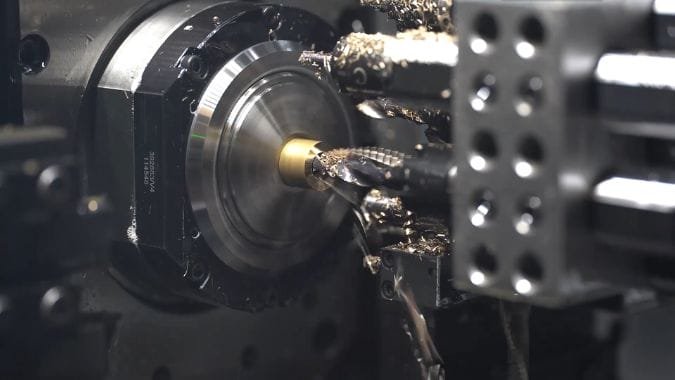

A Swiss-type lathe is a precision CNC machine where the workpiece moves through a guide bushing past the tools. This design provides rigid support right at the cutting point, making it perfect for mass-producing long, slender, and complex parts in a single operation.

On a regular lathe, the part spins in one place while the tools move back and forth. But here, the bar stock itself was sliding out of the machine past a row of tools. This fundamental difference is the secret to its incredible precision, especially on parts that seem impossible to make otherwise.

How Does a Swiss-type Lathe Differ from a Conventional CNC lathe?

Conventional lathes struggle with long, thin parts, causing chatter and poor accuracy. The workpiece’s own length becomes its biggest enemy as it whips and flexes under cutting forces.

A Swiss-type lathe moves the workpiece through a guide bushing to the tools. On a conventional lathe, the workpiece is clamped and stationary while the tools travel along its length, creating vibration.

The core difference between these two machines changes everything. In a Swiss-type, the headstock slides along the Z-axis, pushing the material out. In a conventional lathe1, the headstock is fixed. This single design change leads to several key advantages for specific jobs. With 7 to 13 axes compared to a conventional lathe’s 3 or 4, a Swiss-type can perform multiple operations like turning, milling, and drilling at the same time. They also typically use oil-based coolant for better lubricity and heat reduction, which results in such a fine finish that often no secondary processing is needed.

| Feature | Swiss-type Lathe | Conventional Lathe |

|---|---|---|

| Workpiece Motion | Material slides through a guide bushing | Material is fixed, spins in a chuck |

| Tool Motion | Tools are mostly stationary (X/Y axes) | Tools travel along the length (Z-axis) |

| Number of Axes | High (7-13), simultaneous operations | Low (3-4), sequential operations |

| Ideal Parts | Long, slender, complex, small parts | Shorter, larger diameter parts |

| Coolant | Typically oil-based for high lubricity | Typically water-based |

| Post-Processing | Often minimal to none required | Often requires secondary finishing |

How Does the Sliding Headstock Change the Swiss-type Machining process?

The "sliding headstock" sounds technical and confusing. If you don’t grasp how this single component works, the machine’s true advantage for precision machining remains a mystery.

The sliding headstock grips the raw material and precisely pushes it through the guide bushing past the tools. This means the machine’s Z-axis motion comes from the material moving forward, not from the tools traveling.

The sliding headstock is the heart of the Swiss-type lathe2. It is essentially a very precise, movable collet chuck that grips the bar stock. Its only job is to push and pull the material forward and backward along the Z-axis with extreme accuracy. This changes the process to what we call "segmented machining3."

Instead of machining the whole part at once, the headstock advances a small segment of the bar stock through the guide bushing. The tools machine just that section. Then, the headstock advances the next segment, and the process repeats. Because the tools are waiting right outside the guide bushing, the machine is always cutting on a piece of material that is rigidly supported. It doesn’t matter if the part is 100mm long; the distance from support to tool never changes. This eliminates vibration and allows for incredible precision.

Why is the Guide Bushing Critical for Machining long, Slender Parts Precisely?

Imagine trying to write by pressing down hard in the middle of a long, thin pencil. It bends. The same thing happens to slender parts during machining, making precision impossible.

The guide bushing acts as a solid, ultra-precise support right at the point of the cut. It prevents the long, slender workpiece from bending or vibrating under tool pressure, ensuring extreme accuracy.

If the sliding headstock is the heart, the guide bushing4 is its soul. This small but mighty component is the key to defeating vibration, especially on parts with a high length-to-diameter (L:D) ratio5, often anything over 4:1. Its role is threefold.

Positioning and Support

The guide bushing is a super-hard, highly precise sleeve that the bar stock slides through. Its internal diameter is matched perfectly to the stock, with clearances as tight as 0.003mm. This ensures the workpiece is perfectly centered and cannot bend when the tools apply pressure.

Synchronous Rotation

To prevent friction, the guide bushing rotates at the exact same speed as the main spindle, driven by a synchronous belt. This ensures the material feeds through smoothly without any twisting or binding.

Allows Deeper, Faster Cuts

Because of this rigid support, we can make deeper, more aggressive cuts in a single pass without fear of the part deflecting. On a conventional lathe, we would have to take multiple shallow passes, which is slow and inefficient. The guide bushing lets us be both fast and incredibly precise.

What Industries Benefit Most from Swiss-type Machining Capabilities?

Need to produce millions of tiny, complex parts with flawless precision? Conventional machining methods are often too slow, too inconsistent, and too expensive for this demanding challenge.

The medical, electronics, aerospace, and watchmaking industries benefit most. They rely on Swiss-type lathes for mass-producing small, complex, high-precision components like bone screws, 5G connectors, and tiny shafts.

The unique strengths of Swiss-type machining—"high precision," "miniaturization," and "automated production6"—make it the core technology for several key industries.

Medical Devices: This industry demands perfection. For parts like orthopedic implants and miniature needles, you need micron-level precision. A Swiss lathe can machine these complex parts from tough materials in a single clamping, dramatically improving the yield rate.

Electronics and Communications: The world runs on tiny connectors. Components for 5G communication need to be mass-produced with perfect dimensional consistency. The high speed and rigidity of Swiss-type lathes ensure the millionth part is identical to the first.

Aerospace and Military: These industries require parts made from difficult materials like titanium. For components in navigation systems or fuel nozzles, Swiss-type machines can perform complex, multi-process machining while controlling error accumulation, guaranteeing reliability.

Other industries like watchmaking, automotive, firearms, and even musical instruments also rely heavily on Swiss-type lathes for producing their small, complex, and high-volume components.

Conclusion

Swiss-type lathes use a guide bushing to machine long, complex parts with incredible precision. This makes them essential for industries like medical and aerospace that demand miniature, perfect components.

-

Learn about the drawbacks of conventional lathes and how they compare to modern machining technologies. ↩

-

Explore this link to understand the unique features and advantages of Swiss-type lathes in precision machining. ↩

-

Learn about segmented machining to discover how it enhances efficiency and precision in manufacturing processes. ↩

-

Understanding the guide bushing’s role can enhance your machining efficiency and precision, making it a must-read. ↩

-

Exploring the impact of L:D ratio on machining can help optimize your processes and improve part quality. ↩

-

This resource will help you understand the advantages of automated production, including cost savings and increased output in manufacturing. ↩

Chris Lu

Leveraging over a decade of hands-on experience in the machine tool industry, particularly with CNC machines, I'm here to help. Whether you have questions sparked by this post, need guidance on selecting the right equipment (CNC or conventional), are exploring custom machine solutions, or are ready to discuss a purchase, don't hesitate to CONTACT Me. Let's find the perfect machine tool for your needs.