What is a Whirling Machine?

Need to create precise external threads quickly and efficiently? Tired of slow traditional turning or complex milling setups that just don’t cut it for volume production or tricky materials? A whirling machine might be the specialized, high-speed solution you’re looking for.

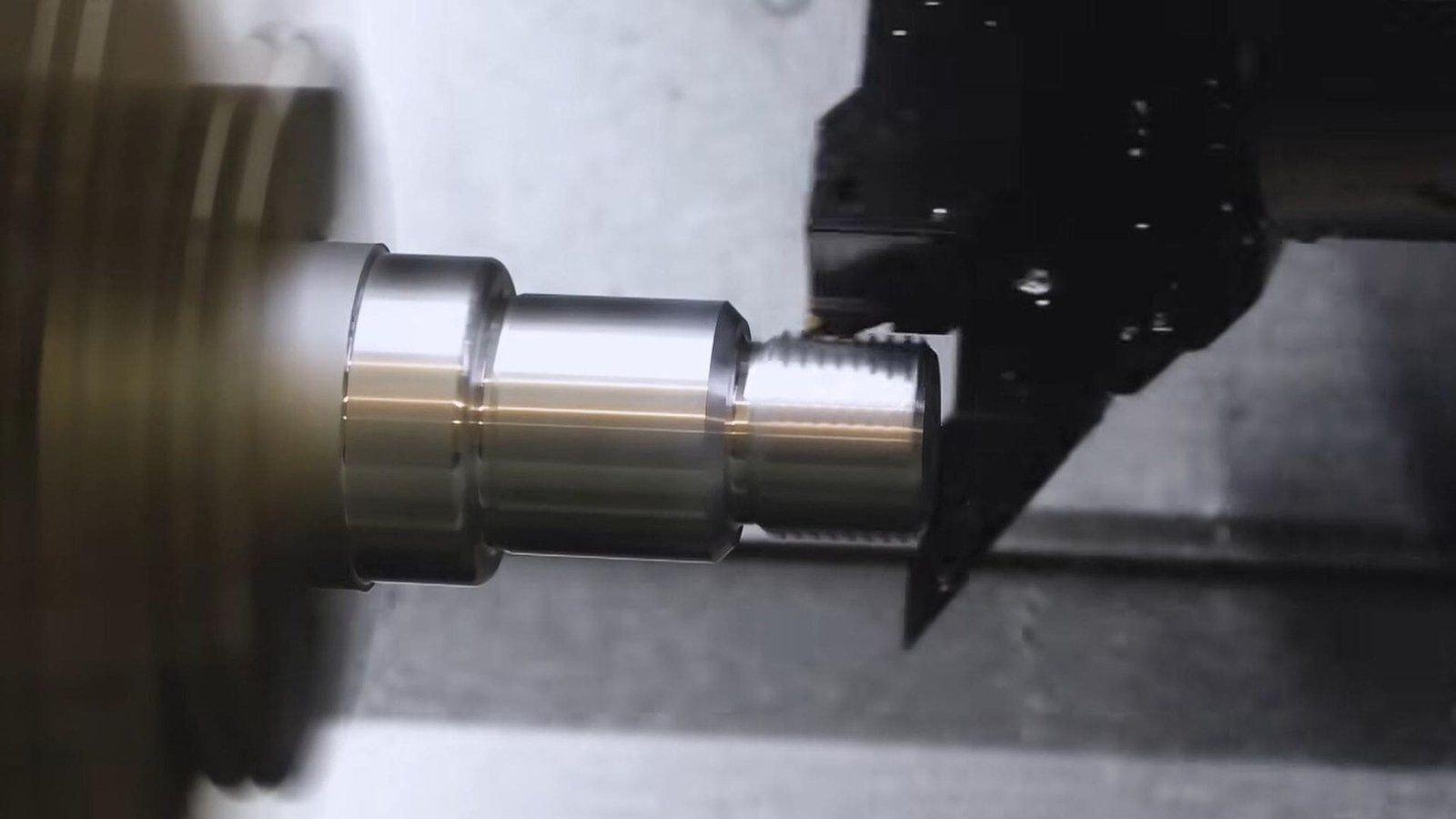

A whirling machine is a specialized piece of equipment, often an attachment for lathes (especially Swiss-type) or a dedicated machine, used to create precise external threads. It employs carbide or other advanced inserts mounted on a high-speed rotating cutter ring to mill threads onto a workpiece, offering exceptional speed, accuracy, and efficiency.

It’s an advanced thread processing method, particularly valuable for complex profiles or high-volume production. While often focused on threads, its precision makes it a significant asset in modern manufacturing. Let’s explore how this impressive technology works and why it stands out.

How does a whirling machine work?

Seen a whirling machine run but unsure how it cuts threads so accurately and fast? It involves high-speed rotation and precise axis control, essentially a highly optimized milling process specifically for threads.

The whirling unit’s cutter ring, holding multiple inserts (often carbide, CBN, or ceramic) shaped to the thread profile, spins at very high speeds. Simultaneously, the workpiece (controlled by the lathe’s C-axis) rotates much slower. The tool head moves linearly along the Z-axis to create the pitch, while the A-axis adjusts the cutting angle for the helix, and the X-axis controls the thread’s minor diameter. This coordinated motion mills the thread, often completing it in a single pass and producing distinctive comma-shaped chips.

Let’s break down those axes and motions:

- High-Speed Cutter Ring: This is the core, spinning rapidly with multiple cutting edges engaged.

- Slow Workpiece Rotation (C-axis): Ensures stability and helps define the thread form.

- Linear Feed (Z-axis): Controls the movement along the workpiece length, determining the thread pitch in coordination with the C-axis rotation. Changing the Z-axis travel direction allows for cutting both right-hand and left-hand threads.

- Angle Adjustment (A-axis): Tilts the whirling head to match the required helix angle of the thread.

- Diameter Control (X-axis): Sets the depth of cut, controlling the minor diameter of the thread.

This process is an interrupted cut1, yet it achieves remarkable precision and surface finish. The smooth chip formation also allows it to effectively machine even hardened materials (up to 65 HRc) and brittle materials, which can be challenging for other methods.

- Cutting Forms (recap): Can be designed for internal or external thread cutting, with external being more common and often featuring helix angle adjustment (e.g., ±40°).

- Cutting Methods (recap): Can use Forward (Climb) Milling or Reverse (Conventional) Milling, depending on material hardness and machine rigidity.

This precise control over multiple axes enables the high efficiency and quality whirling is known for.

What are the advantages of whirling machine compared to lathe in thread machining?

Still relying solely on single-point turning for all your threads? Frustrated by multiple passes, tool wear on tough materials, long cycle times, or the need for messy coolant? Whirling offers compelling advantages, making it a modern, economical threading solution.

Whirling machines are significantly faster (up to 3 times quicker cycle times than lathes), deliver surface finishes often comparable to grinding, handle difficult/hardened materials (up to 65 HRc) effectively, enable cost-saving dry machining, and excel at deep threads or parts with long length-to-diameter ratios.

From my experience at J&M Machine Tools, the switch to whirling can dramatically improve thread production metrics. Here’s a more detailed comparison:

| Feature | Whirling Advantage | Why it Matters |

|---|---|---|

| Cycle Time | Up to 3x faster than traditional turning. Single-pass capability reduces steps (>60%) & time (>50%). | Huge boost in productivity, lower cost per part, faster delivery. |

| Surface Finish | Excellent finish, often comparable to grinding (Ra 0.8μm or better). Fewer polyhedral peaks due to cutting action. | Reduces/eliminates secondary finishing operations. |

| Cost-Effectiveness | Enables dry machining (no coolant costs/management). Reduced setup time (no rough/finish insert matching). | Lower operating costs, simpler setup, cleaner environment. |

| Difficult Materials | Effectively machines hardened steels (up to 65 HRc), titanium alloys, superalloys, stainless steels. | Expands capability, reliable processing for tough jobs. |

| Deep/Long Threads | Excels with deep thread profiles and parts with high length-to-diameter ratios (provides better support/rigidity). | Handles complex geometries where turning might struggle. |

| Accuracy | High dimensional accuracy and thread profile precision, improved by grades compared to some methods. | Ensures high-quality parts, reliable fit and function. |

| Tool Life | Distributed cutting load across multiple inserts can improve tool longevity compared to single-point turning. | Less downtime for tool changes, consistent performance. |

| Lathe Integration | Attachments available for existing lathes (esp. Swiss-type), or available as dedicated machines. | Flexible implementation options based on need. |

These benefits make whirling a superior choice for many demanding thread machining applications, moving beyond the limitations of traditional turning.

Is whirling machine suitable for large-scale manufacturing or only small-scale production?

Wondering if this specialized technology fits high-volume needs or if it’s just for niche, low-volume parts? Can it scale up if your production demands increase? The answer is yes – whirling is versatile enough for both ends of the spectrum.

Whirling machines are suitable for both small-scale, high-precision work and large-scale manufacturing. Dedicated whirling machines are ideal for high-volume production, while whirling attachments on Swiss-type lathes offer flexibility for smaller batches or shops with varied needs.

Here’s how it fits different scales:

- Large-Scale Manufacturing: Dedicated whirling machines2 (like some series from manufacturers such as Leistritz) are optimized for high throughput. Their speed, reliability, potential for automation, and efficiency make them perfect for industries needing thousands or millions of identical threaded parts (e.g., automotive, medical). The significant reduction in cycle time compared to other methods is a major driver here.

- Small-Scale / Flexible Production: For job shops or manufacturers producing smaller batches or a wider variety of parts, adding a whirling attachment3 to a capable CNC Swiss-type lathe4 is a great option. This provides the benefits of whirling (speed, quality on difficult threads) without investing in a fully dedicated machine, maintaining the lathe’s versatility for other operations.

So, whether you’re making a handful of complex prototypes or running continuous production lines, there’s likely a whirling solution that fits your scale and requirements.

What products can whirling machine process, and in which fields are these products used?

Thinking about specific parts like precision screws, worm gears, or maybe even medical implants? Wondering exactly where whirling technology makes its mark? Its capability extends to a wide range of critical components across many key industries.

Whirling machines excel at producing external threaded parts like screws and bolts, worm gears/shafts, lead screws (including ball screws), pump rotors, and critical medical components such as bone screws. These high-precision parts are vital in manufacturing, aerospace, automotive, medical, and energy sectors.

The precision, speed, and material handling capabilities of whirling make it ideal for:

-

Products:

- Lead Screws & Ball Screws: For precise linear motion in machine tools, automation, robotics, and aerospace actuators.

- Worm Shafts & Gears: Used in gearboxes for automotive steering, industrial drives, and lifting mechanisms.

- Medical Screws: High-precision bone screws, spinal fixation screws, and dental implants often made from titanium or PEEK, requiring specific thread forms and biocompatibility. This is a key, perhaps unexpected, application area.

- Pump Rotors: Certain types of pump rotors with helical profiles.

- Aerospace Fasteners & Actuators: Complex, high-strength threaded components for aircraft structures and control systems.

- Automotive Components: Threaded parts for transmissions, steering systems, and engines.

- General Fasteners: High-volume production of specialized or standard screws and bolts where efficiency is key.

-

Fields of Use:

- Manufacturing: General mechanical assemblies requiring precision threads.

- Aerospace & Defense: Critical components needing high reliability and accuracy.

- Automotive: High-volume production of transmission and steering parts.

- Medical Device Industry: Surgical implants, instruments, and dental components.

- Energy Sector: Components for power generation, oil & gas equipment.

- Machine Tool Industry: Building precise motion control components for other machines.

The ability to create complex, accurate threads efficiently in challenging materials makes whirling indispensable in these demanding fields.

Conclusion

In summary, whirling machines offer a specialized, highly efficient method for producing external threads. They deliver significant advantages in speed, surface quality, cost-effectiveness, and material capability compared to traditional turning, making them suitable for both small-scale precision work and high-volume manufacturing across critical industries.

-

Learn about interrupted cuts and their advantages in achieving precision and surface finish in machining processes. ↩

-

Explore this link to understand how dedicated whirling machines enhance manufacturing efficiency and throughput. ↩

-

Discover the advantages of using a whirling attachment for CNC machining to enhance speed and quality in production. ↩

-

Learn about CNC Swiss-type lathes to see how they can improve production flexibility and quality in manufacturing. ↩

Chris Lu

Leveraging over a decade of hands-on experience in the machine tool industry, particularly with CNC machines, I'm here to help. Whether you have questions sparked by this post, need guidance on selecting the right equipment (CNC or conventional), are exploring custom machine solutions, or are ready to discuss a purchase, don't hesitate to CONTACT Me. Let's find the perfect machine tool for your needs

Chris Lu

Leveraging over a decade of hands-on experience in the machine tool industry, particularly with CNC machines, I'm here to help. Whether you have questions sparked by this post, need guidance on selecting the right equipment (CNC or conventional), are exploring custom machine solutions, or are ready to discuss a purchase, don't hesitate to CONTACT Me. Let's find the perfect machine tool for your needs