Struggling with high-volume production of tiny parts? Traditional methods are often slow, create waste, and require constant operator attention. This inefficiency can eat into your profits and delay critical orders, leaving you behind competitors.

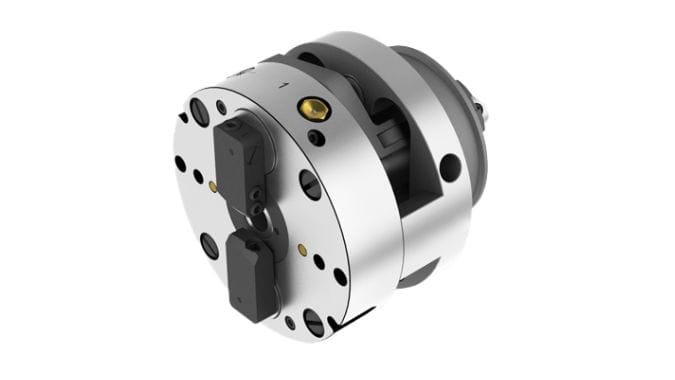

An Escomatic lathe is a specialized Swiss-type machine where the material remains stationary while the cutting tools rotate around it. Fed from a continuous coil, it is designed for extremely fast, high-volume production of small, high-precision parts, effectively reversing the traditional turning process.

The Escomatic is one of those game-changers, but its unique principle is often misunderstood. Its story begins in the Swiss watch industry, where they needed to make millions of perfect, tiny parts fast. This machine was the answer. Now, let’s dig into what makes this technology so unique and powerful for certain jobs.

How Does an Escomatic Lathe Fundamentally Differ from a Swiss-type CNC Lathe?

You think you know Swiss-type lathes. But the Escomatic design flips the entire concept on its head. Assuming they are the same can lead to costly mistakes in process planning and machine selection.

The core difference is what rotates. In a standard Swiss-type lathe, the material bar stock spins and moves through a guide bushing. In an Escomatic lathe, the material from the coil stock stays still while the tool head spins around it.

The Escomatic’s "kinematic inversion1" is the secret to its incredible speed. Because only the small, lightweight tool head is spinning, it can reach very high RPMs without the vibration and "stock whip" you’d get from spinning a long bar of material. This low-inertia system2 is built for pure speed. A Swiss-type, on the other hand, is built for pure rigidity on long, slender parts by supporting the rotating bar right at the cut.

The Kinematic Difference

| Feature | Escomatic Lathe | Conventional Swiss-Type CNC Lathe |

|---|---|---|

| Primary Motion | Tool head rotates around material | Material rotates and feeds past tools |

| Material State | Stationary (axially fed only) | Rotating and axially feeding |

| Core Advantage | Extreme speed, no "stock whip" | Extreme rigidity for long, slender parts |

| Rotating Mass | Small, low-inertia tool head | Entire bar of material |

This fundamental difference in design philosophy dictates what each machine is best at. One chases the ultimate turning speed, while the other chases the ultimate geometric flexibility and support.

When Should a Manufacturer Choose an Escomatic Lathe Over a Swiss-Type CNC Lathe for Small, Precision Parts?

Choosing the wrong machine for a high-volume job is a huge financial misstep. You could end up with a machine that’s too slow for your needs or far too complex and expensive for a simple part.

Choose an Escomatic lathe for extremely high-volume production runs of relatively simple, turned parts. Opt for a Swiss-type CNC lathe for more complex parts with features like milled flats or cross-holes, or for lower-to-medium volume runs.

Making the right call here comes down to a simple trade-off: speed versus complexity. I always ask my clients two questions: "What does the part look like?" and "How many million do you need?" The answer almost always points directly to the right machine.

The Decision Matrix

The choice becomes clear when you map part complexity against production volume3.

- Low Complexity, High Volume: This is the Escomatic’s home turf. Think simple connector pins, rivets, or small shafts needed in the millions. The machine’s speed and the efficiency of coil stock give it the absolute lowest cost-per-part in this quadrant.

- High Complexity, Variable Volume: This is where the Swiss-type shines. For parts like medical bone screws with complex threads and milled features, or jobs with smaller batch sizes, the Swiss-type’s tooling flexibility and quick changeover make it the clear winner.

For jobs in the middle, a deeper analysis is needed. Modern CNC Escomatics4 have gained more capabilities for secondary operations, while Swiss-type makers have focused on reducing cycle times. However, for most applications, sticking to this basic framework will guide you to a sound and profitable decision.

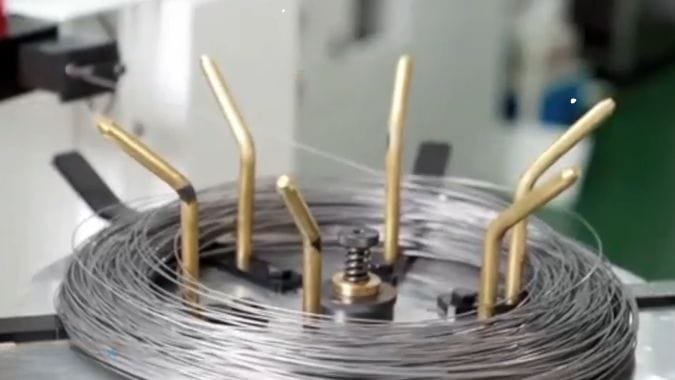

What are the Major Advantages of Using Coil Stock Instead of Bar Stock for High-Volume Production?

Relying on bar stock for mass production introduces hidden costs. Constant bar changes mean machine downtime, wasted material remnants, and more operator attention, all of which chip away at your efficiency.

Using coil stock significantly cuts costs and boosts efficiency. It enables continuous, 24/7 production with almost zero material waste, requires less labor for loading, and takes up less warehouse space compared to heavy bar stock.

I’ve walked through shops where the cost savings from switching to coil were astronomical. The most visible benefit is the remnant pile—or lack thereof. A bar-fed lathe leaves a useless remnant from every single bar. When you run millions of parts, those remnants add up to tons of scrap. Coil stock gets rid of this waste almost entirely.

Achieving "Lights-Out" Manufacturing

The ultimate goal for many shops is unattended, "lights-out" production. Coil stock is the key to achieving this. A single large coil can hold enough material for an entire shift, or even a full day, of non-stop running. The machine just keeps going. A bar feeder, while automated, must stop the machine for one to three minutes every time it loads a new bar. With short cycle times, this downtime adds up quickly, representing a significant loss of production capacity. Coil feeding eliminates this interruption, maximizing uptime and allowing a single operator to oversee a whole cell of machines.

Here’s a quick cost-benefit breakdown:

| Factor | Coil Stock (Escomatic Lathe) | Bar Stock (Swiss-Type Lathe) |

|---|---|---|

| Material Yield | Very High (~99%) | Lower (up to 10% lost in remnants) |

| Machine Uptime | Maximized (Continuous feed) | High (Interrupted by bar loading) |

| Labor Needs | Minimized (Long unattended runs) | Higher (Operator tends bar feeder) |

| Storage Space | Compact | Large footprint for bar bundles |

What Industries Rely on Escomatic Lathes for Manufacturing their Small, Intricate Components?

Many industries are built on the back of tiny, precise parts. But making them profitably at a massive scale is a major challenge. The precision required leaves no room for error, and the volume demands incredible speed.

Escomatic lathes are vital in the electronics, automotive, and medical industries. They are used to manufacture components like connector pins, watch parts, dental posts, and automotive rivets where both high precision and extreme volume are critical.

The reputation of Escomatic machines was born in the Swiss watchmaking industry, but their application has spread to any sector that needs millions of identical, tiny metal parts. If your business depends on making huge quantities of a simple component perfectly every time, you are in the target market for this technology.

High-Volume Application Examples

- Electronics & Connectivity: This is a massive market for Escomatics. Every phone, computer, and 5G tower is filled with tiny connector pins, sockets, and contacts. These parts are relatively simple, but they must be produced by the billions with perfect consistency. The Escomatic lathe is the workhorse that makes this possible, churning out these components from coils of brass or copper alloy at an extremely low cost.

- Automotive & E-Mobility: The automotive industry uses these machines to produce billions of simple shafts, rivets, and pins for things like timing chains and small valves. As the industry moves to electric vehicles, the demand for high-quality electrical terminal pins and connectors has exploded, creating even more work perfectly suited for the Escomatic’s high-speed capabilities5.

- Medical & Dental: While the most complex medical parts like bone screws are made on Swiss-type lathes, there is still huge demand for simpler components. Escomatic lathes are used to produce millions of dental posts, basic pins for surgical instruments, and other high-volume medical disposables where cost and consistency are key.

Conclusion

Escomatic lathes are specialists. They offer unmatched speed for high-volume, small-part production by rotating tools around stationary coil stock. This unique method saves time, eliminates waste, and drives down cost-per-part in the right applications.

-

Understanding kinematic inversion can enhance your knowledge of high-speed machining and its advantages. ↩

-

Exploring low-inertia systems will reveal their impact on speed and precision in modern machining. ↩

-

Understanding production volume is crucial for optimizing manufacturing processes and cost efficiency. ↩

-

Exploring CNC Escomatics can reveal advanced capabilities that enhance production efficiency and reduce costs. ↩

-

Discover the advantages of high-speed capabilities in manufacturing processes and how they enhance efficiency. ↩

Chris Lu

Leveraging over a decade of hands-on experience in the machine tool industry, particularly with CNC machines, I'm here to help. Whether you have questions sparked by this post, need guidance on selecting the right equipment (CNC or conventional), are exploring custom machine solutions, or are ready to discuss a purchase, don't hesitate to CONTACT Me. Let's find the perfect machine tool for your needs.