What is High Speed Electrical Discharge Machining?

Chris Lu

Leveraging over a decade of hands-on experience in the machine tool industry, particularly with CNC machines, I'm here to help. Whether you have questions sparked by this post, need guidance on selecting the right equipment (CNC or conventional), are exploring custom machine solutions, or are ready to discuss a purchase, don't hesitate to CONTACT Me. Let's find the perfect machine tool for your needs.

Chris Lu

Leveraging over a decade of hands-on experience in the machine tool industry, particularly with CNC machines, I'm here to help. Whether you have questions sparked by this post, need guidance on selecting the right equipment (CNC or conventional), are exploring custom machine solutions, or are ready to discuss a purchase, don't hesitate to CONTACT Me. Let's find the perfect machine tool for your needs

You need to cut metal parts using wire EDM, but terms like "High Speed" sound vague. What does it really mean in practice?Without specifics, you might choose HS-WEDM expecting one thing and get results (speed, accuracy, finish) that don’t match your needs, wasting time and money.Let’s define High-Speed Wire EDM (HS-WEDM) clearly, covering its typical parameters and common uses.

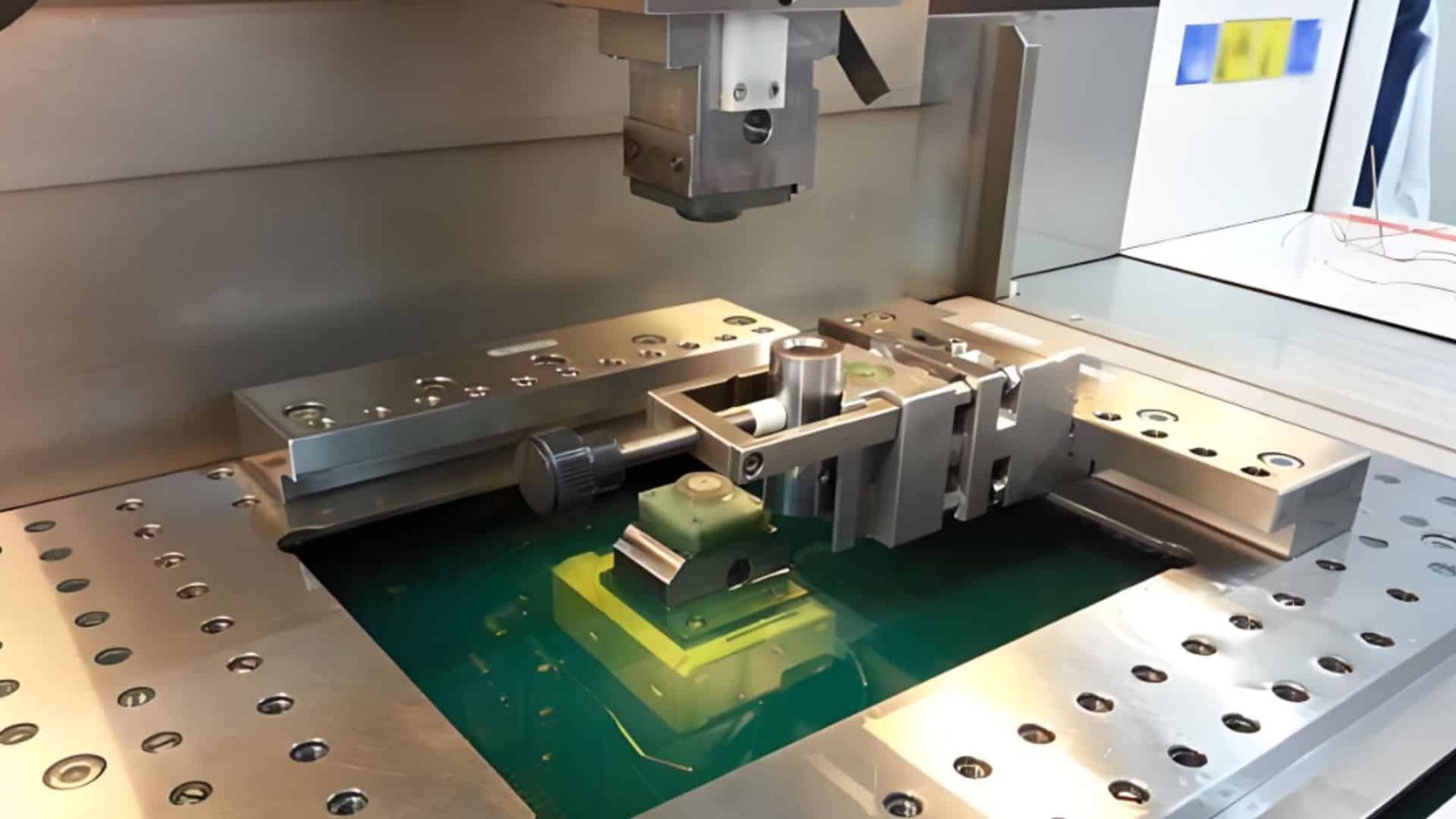

High-Speed Wire EDM (HS-WEDM) is a wire electrical discharge machining process, largely developed in China, characterized by very fast wire travel speeds (around 300-700 meters per minute). It typically uses a reusable molybdenum or tungsten-molybdenum alloy wire and an emulsion working fluid. It’s known for high cutting efficiency and low cost, but offers lower accuracy (around ±0.015–0.02 mm) and rougher finishes.

This method has its place, especially for cost-sensitive or less precise work. But how does it compare to other wire EDM types? Let’s explore.

What is Middle Speed Electrical Discharge Machining?

HS-WEDM is fast but maybe too rough, while the highest precision options seem overly expensive. Is there an effective middle ground?You feel caught between needing better quality than basic HS-WEDM offers but not being able to justify the investment in top-tier LS-WEDM.Middle-Speed Wire EDM (MS-WEDM) was developed to bridge this exact gap, enhancing quality while controlling costs.

Middle-Speed Wire EDM (MS-WEDM) is an enhanced version of HS-WEDM. It also typically uses reusable molybdenum wire but incorporates multiple cutting passes (roughing and finishing) to significantly improve accuracy and surface finish compared to HS-WEDM. It aims for a balance between speed and quality, approaching LS-WEDM results at a moderate cost.

MS-WEDM1 evolved directly from HS-WEDM, aiming to overcome its limitations in precision and finish. It often retains the core mechanics, like using reusable molybdenum wire (similar diameters to HS-WEDM) and likely an emulsion working fluid. The key innovation lies in the control strategy, specifically the use of multiple cutting passes. Think of it as combining a fast high-speed roughing cut with one or more slower, more precise finishing cuts. While the maximum wire speed might still be relatively high (some sources suggest a wide range, maybe 1-12 m/s, reflecting its hybrid nature), the crucial finishing passes are done slower to achieve better results. This multi-cut approach allows MS-WEDM to achieve much higher accuracy, potentially nearing ±0.002 mm, and significantly better surface roughness2 (Ra down to 0.8 μm is possible). It’s designed not just for raw speed but for optimal average efficiency, delivering quality closer to LS-WEDM but with machine and operational costs remaining nearer the HS-WEDM level. It’s a practical solution for molds or parts needing good quality without the extreme precision (and cost) of LS-WEDM.

What is Low Speed Electrical Discharge Machining?

Your project demands the absolute best: maximum precision, flawless surface finish, and tight tolerances achievable with wire EDM.You worry that anything less than the best process will lead to rejected parts, costly rework, or failure in critical applications like aerospace or medical devices.Low-Speed Wire EDM (LS-WEDM) is the established standard for achieving the highest levels of precision and surface quality in wire cutting.

Low-Speed Wire EDM (LS-WEDM) operates with much slower wire speeds (typically 3-15 meters per minute). It uses a disposable copper, brass, or specially coated wire that passes through the workpiece only once. It requires filtered deionized water or kerosene as a working fluid and achieves exceptional accuracy (often ±0.002 mm or better) and outstanding surface finishes (Ra ≤ 0.8μm). Machine costs are significantly higher.

LS-WEDM3 prioritizes quality above all else. Its defining feature is the slow, single-pass wire movement (0.05-0.25 m/s). This uses a brand new, uncontaminated wire surface for every part of the cut, usually copper or brass (often 0.15-0.3 mm diameter, commonly 0.25mm), sometimes with special coatings to boost performance. Because the wire isn’t reused, there’s no degradation affecting the cut. This precision requires a highly controlled environment, using meticulously filtered deionized water or kerosene as the dielectric fluid4 to flush debris effectively and maintain stable electrical conditions. The result is incredibly tight tolerances5 (±0.002 mm is achievable) and surface finishes comparable to grinding. This makes LS-WEDM essential for high-stakes industries making molds, dies, medical implants, and aerospace components. However, this precision demands complex, expensive machinery (often with features like automatic wire threading and anti-electrolysis power supplies) and higher operational costs due to the disposable wire and fluid filtration systems. It’s not ideal for very thick workpieces, but unbeatable for complex, precise small parts.

What Kinds of Wire are Used for Each of These Wire EDM Machining?

You know the machines differ, but does the specific wire material—molybdenum, tungsten, copper, brass—really make a difference?Choosing or using the wrong wire type could hurt cutting speed, compromise accuracy, worsen surface finish, or even lead to frequent wire breaks and downtime.Let’s specify the typical wire materials and diameters used for HS-WEDM, MS-WEDM, and LS-WEDM and explain why they are chosen for each process.

High-Speed (HS) and Middle-Speed (MS) WEDM typically use reusable Molybdenum or Tungsten-Molybdenum alloy wire (often 0.12-0.2 mm diameter) for durability at high speeds. Low-Speed (LS) WEDM uses disposable Copper(commonly 0.25 mm diameter) for optimal conductivity and single-pass precision.

The wire is critical, and the material choice directly supports each machine’s strategy. For HS-WEDM and MS-WEDM, the wire must endure high tension and the stress of rapid back-and-forth movement (reciprocation). Molybdenum6, sometimes alloyed with tungsten, has excellent tensile strength and a very high melting point, making it durable enough to be reused. Common diameters range from 0.03 mm up to 0.25 mm, but 0.12 mm to 0.2 mm are frequently used. Reusability keeps consumable costs down.

For LS-WEDM, the priority shifts to electrical conductivity and the pristine condition needed for a single, precise pass. Copper is highly conductive, enabling efficient sparks. Brass7 (copper-zinc alloy) offers a good balance of conductivity and tensile strength. Diameters are often in the 0.15 mm to 0.3 mm range, with 0.25 mm being very common.Since the wire is used only once (not recycled during the process), its consistent diameter and clean surface guarantee the highest accuracy, justifying the higher consumable cost for demanding applications.

What are the Differences Among HS-WEDM, MS-WEDM and LS-WEDM?

You’ve learned about each type individually, but seeing them compared side-by-side would really clarify the key trade-offs.Without a direct comparison, it’s tough to weigh the pros and cons (speed vs. accuracy, cost vs. quality) and confidently decide which technology best fits your job.Let’s summarize the main distinctions between High-Speed, Middle-Speed, and Low-Speed Wire EDM across several critical parameters.

The core differences involve wire speed, wire type/usage, working fluid, achievable accuracy, surface finish, machine cost, and typical applications. HS is fast/cheap/low-quality, LS is slow/precise/high-quality/expensive, and MS offers a practical balance.

Let’s consolidate the differences. HS-WEDM8 runs fast (300-700 m/min or 5-11.67 m/s) using reusable molybdenum wire and basic emulsion fluid. It’s the cheapest option but yields lower accuracy (±0.015–0.02 mm) and rougher finishes, prone to wire jitter issues. It’s good for general, non-critical work. LS-WEDM operates slowly (3-15 m/min or 0.05-0.25 m/s) with disposable copper/brass wire and highly filtered deionized water/kerosene. It delivers the best accuracy (±0.002 mm) and finish but comes with high machine costs and complexity. It’s essential for precision industries. MS-WEDM sits between them. It uses reusable molybdenum wire like HS-WEDM but employs multiple cuts (fast roughing, slow finishing) to boost quality significantly, approaching LS-WEDM’s accuracy and finish potential. Its overall speed is moderate, and costs are higher than HS but lower than LS. It’s versatile for applications needing better-than-basic quality without the top-tier investment.

| Feature | HS-WEDM (High Speed) | MS-WEDM (Middle Speed) | LS-WEDM (Low Speed) |

|---|---|---|---|

| Wire Speed | Very Fast (300-700 m/min) | Moderate (Hybrid Speed/Multi-cut) | Slow (3-15 m/min) |

| Wire Material | Molybdenum / Tungsten-Moly | Molybdenum | Copper / Brass / Coated |

| Wire Usage | Reusable (Reciprocating) | Reusable (Reciprocating) | Disposable (Single Pass) |

| Wire Diameter | 0.12-0.2 mm common | Likely similar to HS-WEDM | 0.25 mm common |

| Working Fluid | Emulsion | Likely Emulsion | Deionized Water / Kerosene (Filtered) |

| Accuracy | Lower (±0.015–0.02 mm) | Moderate-High (towards ±0.002 mm) | Highest (±0.002 mm or better) |

| Surface Finish | Rougher | Good (Ra ~0.8μm possible) | Excellent (Ra ≤ 0.8μm common) |

| Machine Cost | Lowest | Moderate | Highest |

| Applications | General, low-cost, low precision | Balanced quality/cost, molds | High precision, medical, aerospace |

Understanding these direct comparisons helps match the right technology to your budget and quality needs.

Conclusion

HS-WEDM, MS-WEDM, and LS-WEDM offer distinct capabilities. HS prioritizes speed and low cost, LS delivers maximum precision and finish at high cost, while MS provides a versatile balance. Choose based on your specific part accuracy, finish, and budget requirements.

-

Explore the benefits of MS-WEDM, including its precision and efficiency, to understand its role in modern machining. ↩

-

Understanding surface roughness is crucial for evaluating machining quality and performance in manufacturing processes. ↩

-

Explore this link to understand the innovative technology behind LS-WEDM and its applications in precision engineering. ↩

-

Discover the crucial role of dielectric fluid in wire EDM processes and how it enhances cutting precision and efficiency. ↩

-

Learn about the significance of tight tolerances in manufacturing processes and how they impact product quality and performance. ↩

-

Explore the unique properties of Molybdenum that make it essential for high-performance applications in manufacturing. ↩

-

Discover how Brass combines conductivity and strength, making it a versatile choice for various manufacturing needs. ↩

-

Explore this link to understand the benefits and limitations of HS-WEDM, especially for general machining tasks. ↩