You struggle with slow thread milling speeds and overheating parts during long production runs. Traditional turning methods often wear out tools too quickly and distort precision components.

Internal whirling is a high-speed threading process where cutters mounted on the inner side of a rotating ring remove material from a workpiece passing through it. It cuts full thread depths in one pass, reduces heat transfer to the part, and handles hardened steels up to 65 HRC with ease.

I often see customers struggling to produce long screws efficiently. They use standard lathes or grinding and get poor results. Internal whirling is a specialized technique, but it changes everything for screw production. Let me explain how it works and why you might need it for your shop.

How Does Internal Whirling Work?

You watch the machine run, but the mechanics look confusing because the axes do not line up. You need to understand the movement to optimize the process.

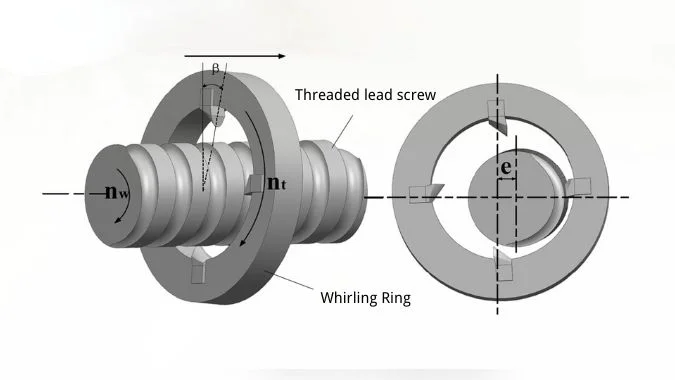

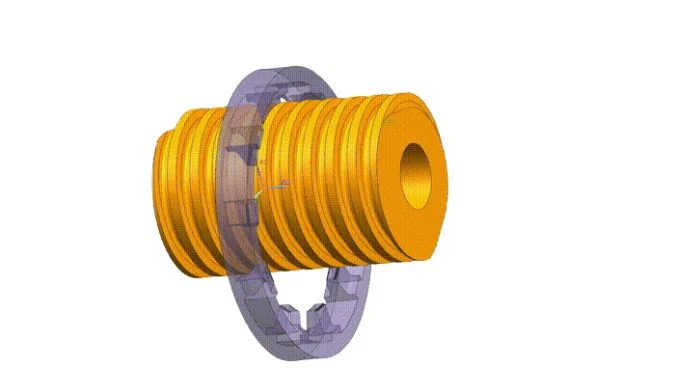

The workpiece passes through the center of a rotating cutter ring. The ring is tilted to the thread’s helix angle. As the ring spins at high speed (up to 400m/min), the workpiece rotates slowly in the same direction, allowing the inner cutters to form the complete thread profile in one pass.

The mechanics of this process are unique and highly efficient. In internal whirling, the milling cutters sit evenly distributed on the inner side of a milling cutter disk. The axis of this cutter disk does not coincide with the axis of the workpiece. Instead, we tilt it to a specific angle. This angle matches the helix angle, usually labeled as γ, of the thread we want to make.

During the operation, the milling cutter disk drives the cutters at a very high speed. The linear speed1 can often reach 400 meters per minute. While this happens, the workpiece rotates at a low speed (often 20 to 50 rpm) in the same direction as the cutter disk. This speed difference is key. For every single rotation of the workpiece, the cutter disk feeds forward by one thread pitch2 in the axial direction.

This movement allows the machine to process and form the thread groove in a single pass. Because the cutter disk is eccentric to the workpiece, only one milling cutter engages the metal at any given moment. The position of the processing area remains almost unchanged. This creates short, comma-shaped chips. The cutting thickness changes periodically from small to large and back to small. This intermittent cutting action3 gives each tool time to cool down in the air between cuts. The chips carry away most of the heat, so the workpiece temperature stays low. This prevents thermal deformation, which is a common headache in standard turning.

What Are the Precision and Efficiency of Internal Whirling?

You want faster production, but you fear that pushing the speed will ruin your accuracy. You need to find the balance between high material removal and geometric limits.

Internal whirling offers higher efficiency than external whirling due to its large cutting envelope. However, precision relies on maintaining a helix angle below 14°. Exceeding this angle causes tooth profile overcutting, meaning you must work within specific geometric limitations to ensure accuracy.

Efficiency is the main selling point here. Internal whirling has a long envelope travel. It removes a massive volume of material quickly. In my experience, it has a much higher relative efficiency than external whirling because the cutting forces are substantial and directed effectively. You can finish a part much faster, often replacing slow thread grinding processes even on materials hardened to 65 HRC.

However, precision has physical limits that you must respect. Because the workpiece passes through the inner hole of the main shaft, we cannot tilt the cutter head too much. The processing helix angle4 is generally limited to between 12° and 14°. You might think, "Why not just make the inner hole bigger to tilt it more?" You cannot do that. If you increase the hole size to get a steeper angle, you lose control of the profile. It causes overcutting of the tooth shape. The geometry fails. You cannot guarantee the accuracy of the tooth profile if you push past these structural limits. You must work within this specific angular range.

| Feature | Advantage | Limitation |

|---|---|---|

| Cutting Volume | Large, high efficiency | Requires robust machine |

| Helix Angle | Standard threads ok | Max 12°-14° |

| Profile Accuracy | High in one pass | Overcuts if angle is too steep |

What Are the Tool Requirements for Internal Whirling?

You see rough tool marks on your finished screws and the measurements vary between parts. Your current tooling setup is likely causing these quality issues.

Using conventional welded carbide heads leads to setup errors and rough finishes because typically only one tool cuts effectively. You must use machine-clamped whirling cutters that allow multi-tool form milling. This guarantees consistent datums and smooth surface quality using inserts like CBN or ceramic.

The tool determines the finish. Many shops try to save money by using conventional welded carbide tool heads. This is a mistake. It is extremely difficult to set these tools perfectly. Even if you install multiple cutters, you cannot guarantee they are all on the exact same centerline. In practice, usually only one forming tool actually does the cutting. The others just spin air.

This leads to two problems. First, the efficiency drops because you are not using all the edges. Second, you get rough tool marks on the surface. The accuracy suffers because the installation datum is not consistent. To fix this, you must solve the tool problem. You need to use machine-clamped whirling milling cutters5. These allow for true multi-tool form milling. When every insert sits in a precise pocket, they all cut together. This ensures the tooth profile is accurate. It smoothes out the surface quality.

For hard materials, we use advanced inserts like CBN (cubic boron nitride)6 or ceramics. These materials withstand the heat and abrasion of cutting 65 HRC steel at high speeds. The intermittent cutting action further extends tool life by allowing heat to dissipate during the non-cutting part of the rotation.

What Are the Common Workpieces Processed by Internal Whirling?

You wonder if this machine fits your product line or if it is too specialized. You need to know exactly which parts benefit from this technology to justify the investment.

Internal whirling is ideal for long, threaded components like ball screws, feed screws, and automotive EPS worms. It excels at producing extrusion screws and helical gears. However, it is not suitable for large-lead threads due to cutter disk structural limitations.

This technology is specific. It is not for every bolt and nut. It is for high-value, complex threaded parts where the workpiece is a long shaft or screw. We see it used most often for extrusion screws7 and PC rotor pumps. These require long, consistent threads that would warp under the heat of standard turning. In the automotive industry, it is standard for steering gear EPS worms. It is also perfect for diamond rollers and creating precise oil grooves.

Ball screws and feed screws are the bread and butter of internal whirling. We also see it used for helical gears. However, there are limits. You cannot process workpieces with very large leads. The structural size of the cutter disk restricts this. Also, chip evacuation is tight. You must plan for chip flow. If the lead is too large, the chips can clog the cutter ring. But for the parts listed above, especially long slender shafts, it is the most efficient method available.

| Category | Specific Parts |

|---|---|

| Motion Control | Ball screw, Feed screw |

| Automotive | EPS worm, Steering gear |

| Industrial | Extrusion screw, PC rotor pump |

| Specialized | Diamond roller, Oil groove, Helical gear |

Conclusion

Internal whirling offers high-speed, single-pass threading for screws and worms. By using precise machine-clamped tools and managing helix angles, you achieve superior efficiency and finish compared to traditional milling.

-

Explore how linear speed affects milling efficiency and quality, crucial for optimizing machining processes. ↩

-

Learn about the precise feed mechanism of the cutter disk that enables single-pass thread groove formation with high accuracy. ↩

-

Learn why intermittent cutting action helps in tool cooling and prevents thermal deformation during milling. ↩

-

Learn why maintaining the processing helix angle between 12° and 14° is crucial for precision and avoiding overcutting in machining. ↩

-

Explore this to understand how machine-clamped whirling milling cutters improve accuracy and surface quality by ensuring all inserts cut together precisely. ↩

-

Learn why CBN inserts are ideal for high-speed cutting of hard materials due to their heat resistance and durability, enhancing tool life and performance. ↩

-

Learn about extrusion screws and why internal whirling is ideal for creating their precise, long threads without warping. ↩

Chris Lu

Leveraging over a decade of hands-on experience in the machine tool industry, particularly with CNC machines, I'm here to help. Whether you have questions sparked by this post, need guidance on selecting the right equipment (CNC or conventional), are exploring custom machine solutions, or are ready to discuss a purchase, don't hesitate to CONTACT Me. Let's find the perfect machine tool for your needs.