What Makes CNC Turn-Mill Machines More Capable Than Standard CNC Lathes?

Tired of shuffling parts between a lathe and a mill? Standard lathes excel at turning round shapes, but complex parts often need flats, slots, or off-center holes. This usually means extra setups, wasted time, increased handling, and a higher risk of errors that can scrap expensive components.

CNC turn-mill machines, essentially hybrid machines combining turning and milling, outperform standard lathes by using ‘live’ rotating tools and often a Y-axis. This lets them complete complex parts with both cylindrical and non-cylindrical features entirely in one setup, boosting efficiency and accuracy.

Think of it this way: a standard CNC lathe rotates the workpiece against stationary tools. A turn-mill can do that and rotate cutting tools against a positioned workpiece, like a milling machine. This integration is key. By eliminating the need to transfer parts, these machines save floor space, reduce overall processing time, and are increasingly vital in industries like aerospace, automotive, and medical device manufacturing where complex, high-precision parts are the norm. Let’s dive into the features that make this possible.

Why is ‘Live Tooling’ the Defining Feature of a CNC Turn-Mill Center?

Is your lathe limited to only using static turning, boring, or facing tools? This restricts you mainly to rotationally symmetrical shapes. Adding milled features like flats, cross-holes, or keyways typically requires moving the part to a separate milling machine, introducing delays and potential inaccuracies.

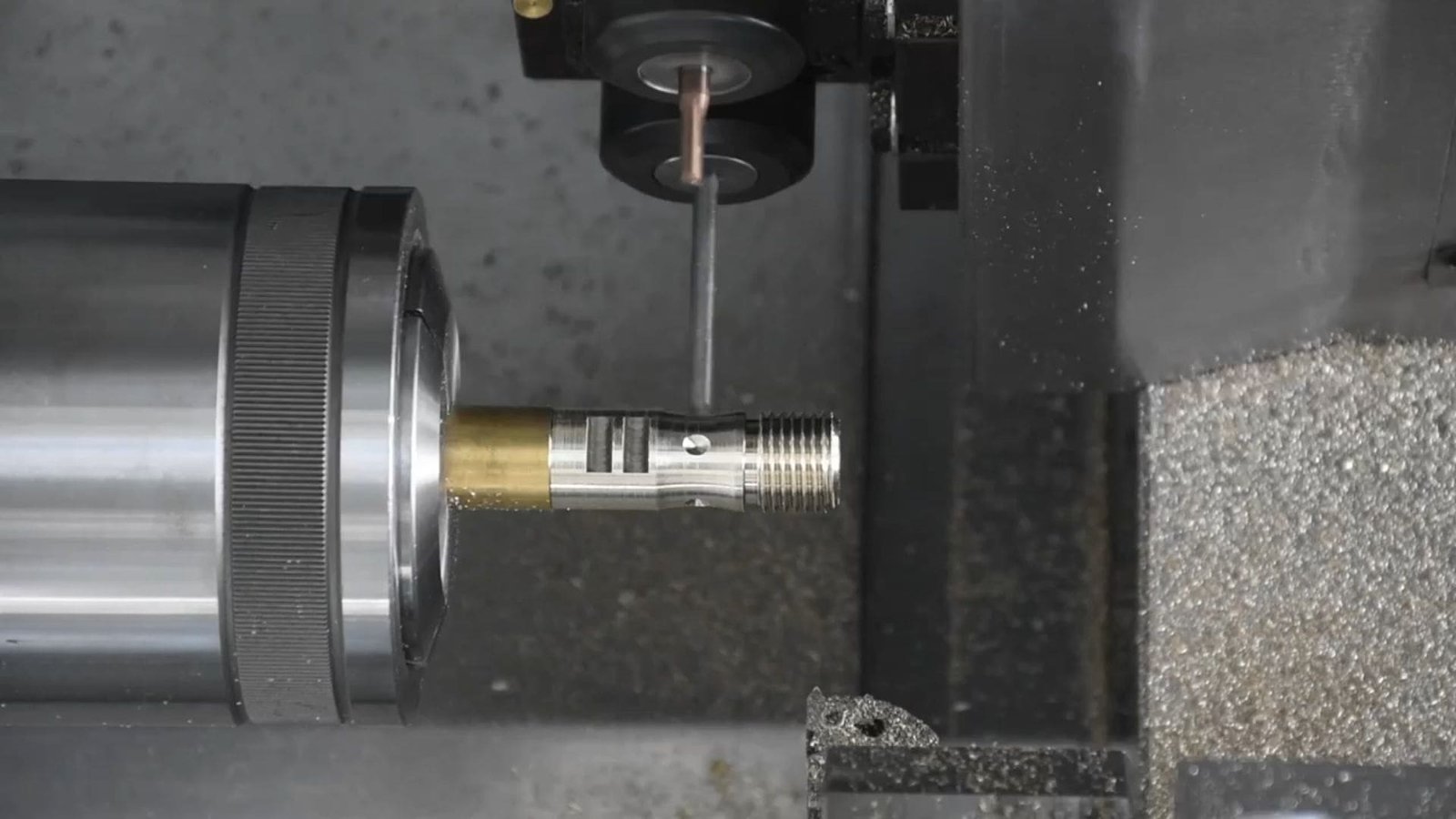

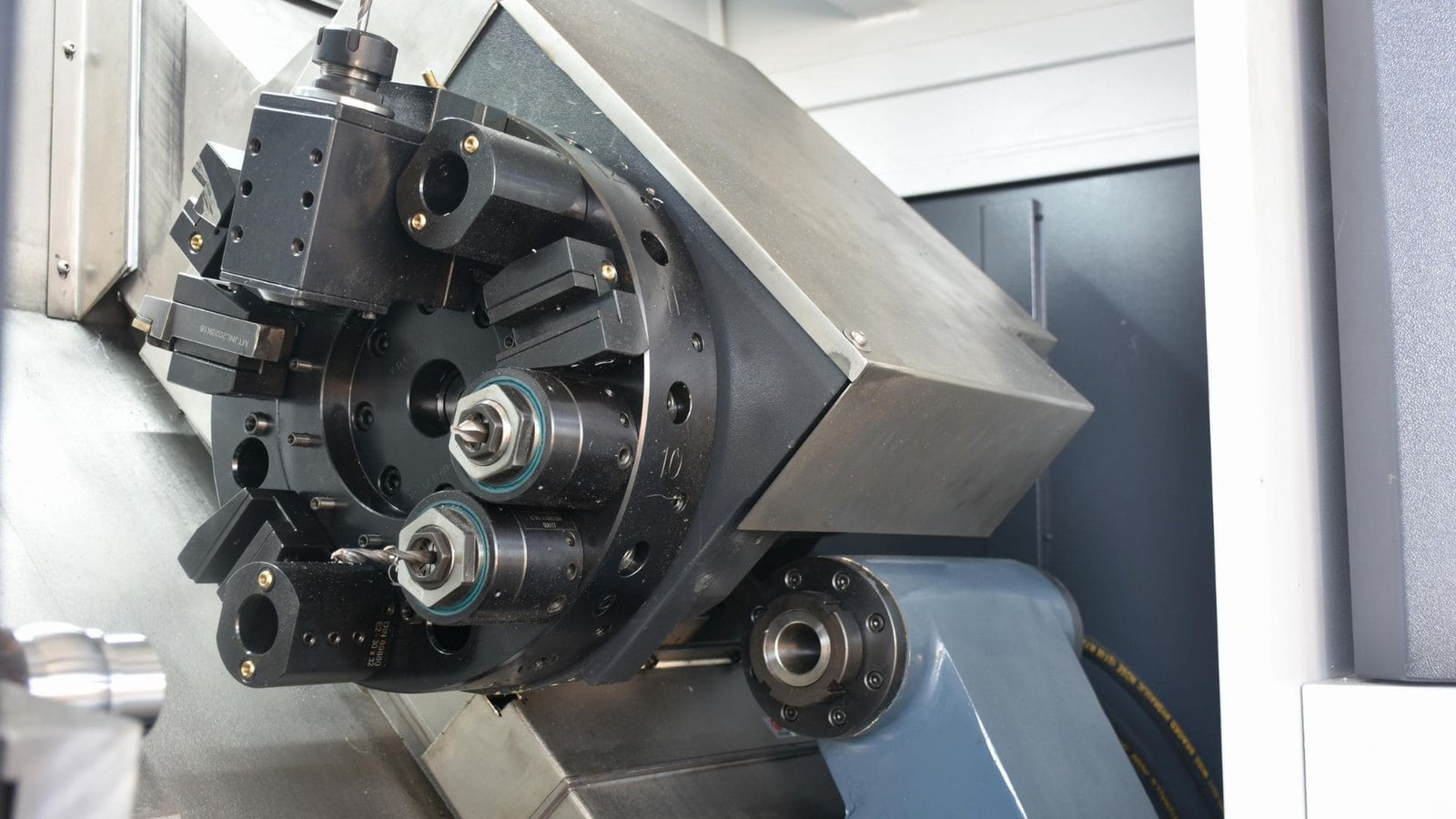

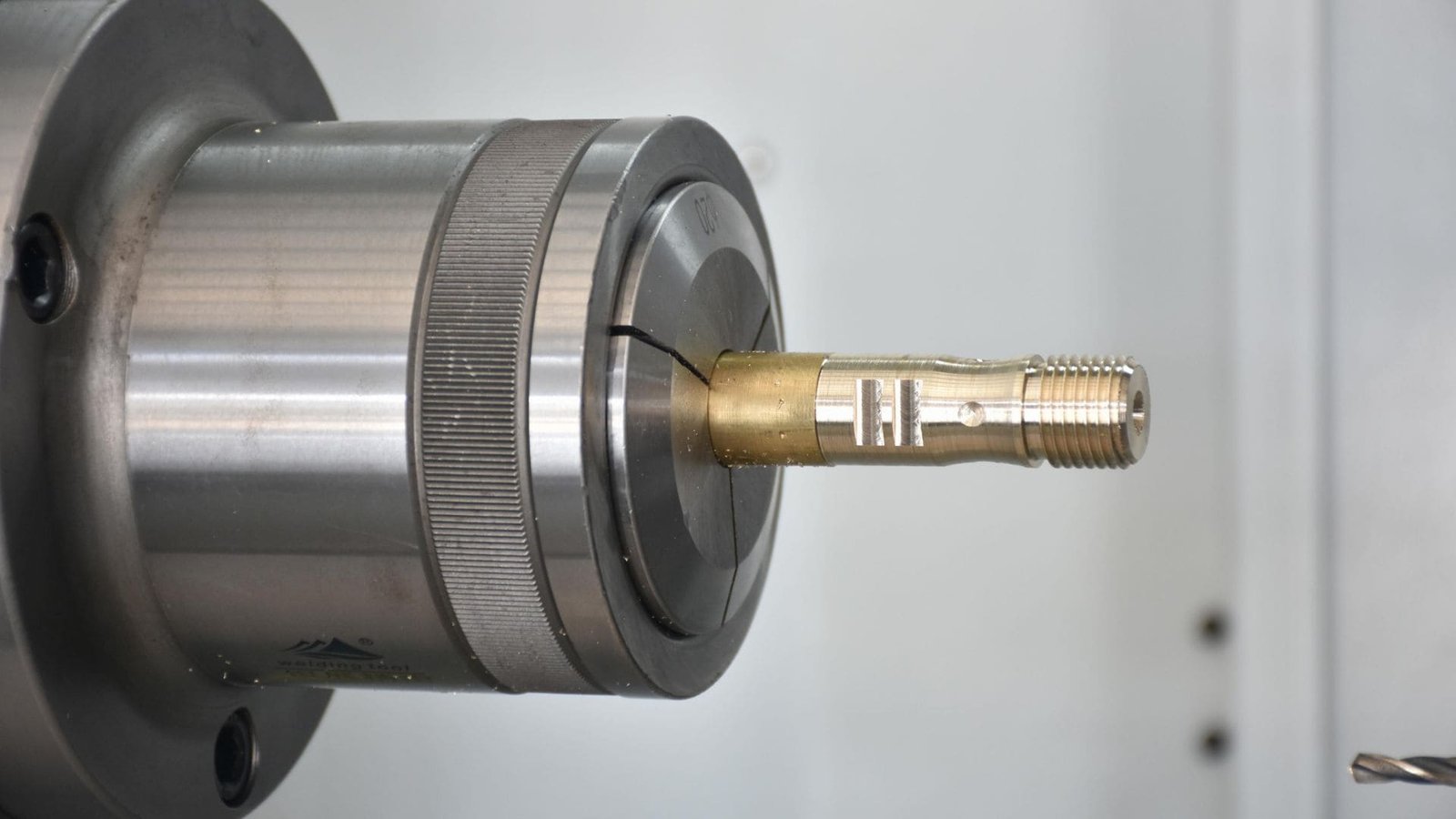

Live tooling is the game-changer. It refers to powered tool stations on the turn-mill’s turret that hold rotating cutting tools (like end mills, drills, taps). This enables milling, drilling, and tapping operations directly on the workpiece while it’s held in the main turning spindle.

Unlike a standard lathe turret holding only stationary tools, a turn-mill turret integrates powered stations.

- How it Works: Specific turret stations have dedicated motors that spin the cutting tool held within a specialized live tool holder. While this tool is cutting, the machine’s main spindle can precisely index the workpiece (using the C-axis) or hold it stationary.

- Milling & Drilling on a Lathe Platform: This allows operations perpendicular or parallel to the part’s centerline – think milling flats onto a shaft, drilling cross-holes for pins, tapping threads into the side, or even etching designs.

- Versatility Boost: It dramatically expands the geometric complexity possible on a single machine. As your insights noted, it enhances flexibility, allowing various tools to be used effectively.

- Efficiency: By performing these operations without needing a secondary machine setup, live tooling1 significantly cuts down on total production time, reduces handling, and streamlines the workflow.

This fundamental ability to use rotating cutting tools on a lathe-style platform is what truly defines a turn-mill center2 and gives it a massive advantage for producing multi-featured parts.

How Can Machining Complex Parts in One Clamping on a Turn-Mill Improve Overall Accuracy Compared to Multiple Setups?

Moving parts between machines seems routine, but every time you unclamp, move, and re-clamp a workpiece, tiny errors are introduced. For complex components needing precise relationships between turned diameters, milled faces, and drilled holes, these small errors accumulate, potentially compromising the final part’s accuracy.

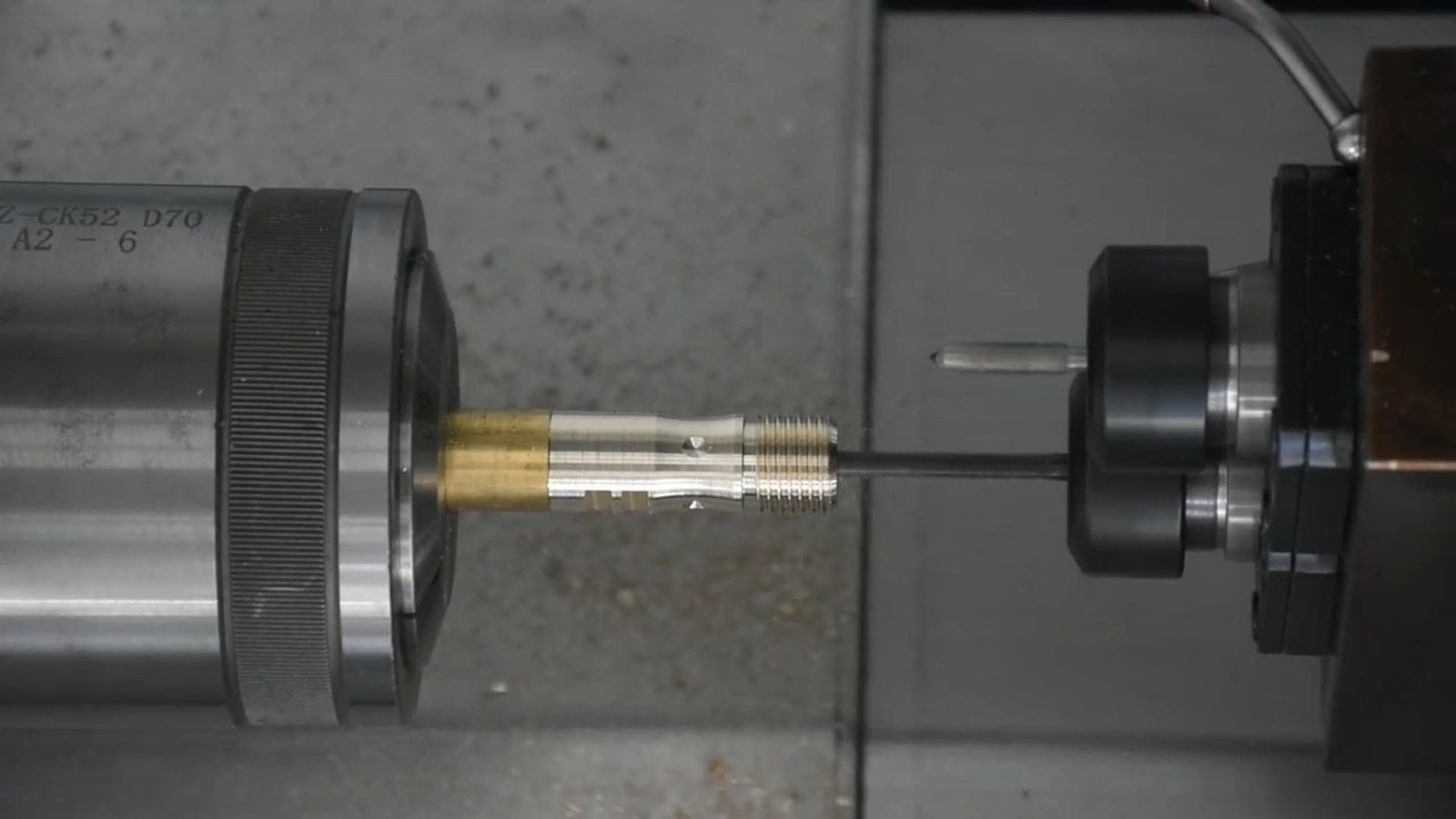

Machining ‘done-in-one’ on a turn-mill significantly improves overall accuracy. It avoids the stack-up of errors from re-clamping and eliminates inconsistencies caused by re-establishing reference points (datums) on different machines.

The benefits of single clamping for precision are substantial, as highlighted in your research:

- Eliminates Re-Clamping Errors: Each time a part is fixtured, its position can vary slightly. Multiple setups multiply this potential error source. One clamping means this variation occurs only once.

- Consistent Datum Reference3: All features machined in a single setup are referenced from the same origin point (datum). Moving the part requires establishing a new datum on the next machine, inevitably introducing small discrepancies (datum shift) that affect the positional accuracy between features machined across different setups.

- Maintains Geometric Relationships4: Critical relationships like concentricity, perpendicularity, and parallelism between turned and milled features are much easier to hold accurately when machined sequentially without removal. Re-clamping makes maintaining these relationships extremely challenging.

- Reduces Distortion & Stress: Handling and re-fixturing can induce small stresses or even slight distortions in the part, especially with less rigid materials, affecting dimensional stability. One clamping minimizes this risk.

- Consistent Surface Finish: Machining all surfaces on one machine under consistent conditions can lead to more uniform surface finishes compared to using multiple machines with potentially different tooling or coolant conditions.

For components like aerospace turbine blades or medical implants where precision is paramount, the accuracy gained by eliminating multiple setups often makes turn-mill machining the preferred method.

What is the Significance of the Y-axis Capability Commonly Found on Turn-Mill Machines?

Are you struggling to machine features that aren’t right on the centerline of your turned part? Using just C-axis interpolation on a lathe for milling can be limiting and less accurate for true off-center features like keyways, pockets, or accurately placed hole patterns. The Y-axis provides the missing dimension for true milling capability.

The Y-axis adds a crucial linear axis of movement for the tool, typically perpendicular to the X-axis (diameter) and Z-axis (length). This allows the live tool to move up/down or forward/backward relative to the spindle centerline, enabling precise off-center milling and drilling.

While combining X, Z, and C axes allows some interpolated milling, a dedicated Y-axis5 offers true, programmable linear travel across the workpiece face or diameter.

- Functionality: As your insights detail, the Y-axis allows transverse feed6, moving the live tool (mill or drill) vertically or horizontally relative to the part’s center.

- Enabling Off-Center Machining: This is fundamental for accurately milling features that don’t lie on the axis of rotation – think milling precise keyways, flats on shafts offset from center, complex pockets, or drilling accurate bolt hole patterns.

- Complex Geometries: Working in coordination with X, Z, and C axes (and potentially a B-axis for tool tilt), the Y-axis allows for much more complex surface contouring and feature generation, essential in industries like automotive and medical.

- Types (as you noted): Can be a true orthogonal slide (‘real’ Y-axis) offering direct movement, or a ‘virtual/interpolated’ Y-axis achieved through coordinated motion of other axes, often providing rigidity in a compact design.

Essentially, the Y-axis elevates a turn-mill from a lathe with added milling to a genuine multi-tasking machine capable of tackling significantly more complex geometries7 in one go.

What Complex Machining Operations Can a Turn-Mill Perform beyond Basic Turning and Milling?

Think turn-mills just do simple turning plus basic flats and cross-holes? You might be underestimating the sheer range of sophisticated operations these powerful machines can integrate, often performing tasks that would otherwise require multiple specialized machines.

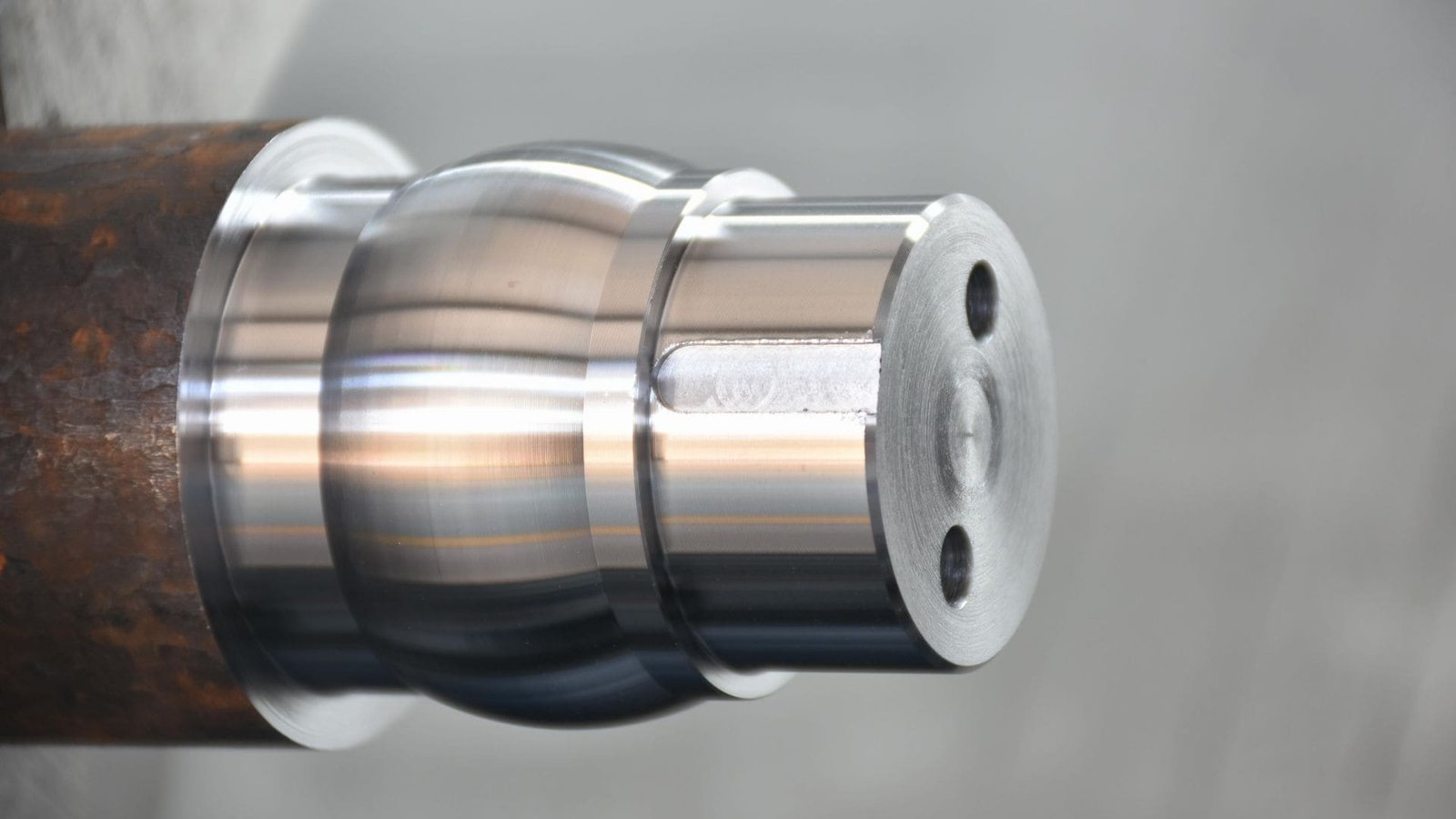

Modern turn-mills execute highly complex operations including multi-axis contouring, angled drilling/milling (with B-axis), gear cutting, deep hole drilling, precision boring, and various secondary operations like knurling or grooving – all within a single clamping.

By leveraging live tooling, the Y-axis, often a tilting B-axis for the tool spindle, and advanced CNC controls, turn-mills can perform a surprising variety of tasks:

- Advanced Drilling & Tapping8: Beyond simple holes, they can create complex bolt patterns, angled holes (using B-axis), counterbores, and tap threads accurately aligned with turned features, even along the length while the part rotates.

- Precision Boring9: Finish internal diameters to tight tolerances after turning or rough drilling, maintaining concentricity and positional accuracy.

- Complex Contouring (3, 4, or 5-axis)10: Interpolating X, Y, Z, C, and potentially a B-axis allows machining of intricate shapes, sculpted surfaces, tapered features, and complex profiles found in aerospace parts or medical implants.

- Gear Cutting: Some turn-mills can be equipped for gear hobbing or shaping, enabling the production of certain types of gears directly on the machine.

- Secondary Operations: Integrate tasks like knurling (for grip), grooving, or threading using live tools, adding further value within the single setup.

- Simultaneous Machining: Some advanced machines can even perform turning operations with one tool while simultaneously milling or drilling with another live tool, drastically reducing cycle times.

This ability to consolidate such a wide range of operations makes turn-mills incredibly productive and cost-effective for complex, high-value components.

Conclusion

CNC turn-mill machines offer clear advantages over standard lathes for complex parts. By integrating live tooling and often a Y-axis, they perform turning, milling, drilling, and other advanced operations in a single clamping, drastically improving accuracy, reducing setup time, and boosting overall efficiency for modern manufacturing demands.

-

Explore this link to understand how live tooling enhances machining efficiency and versatility, making it a game-changer in manufacturing. ↩

-

Discover the benefits of turn-mill centers, which combine turning and milling operations for improved production efficiency and part complexity. ↩

-

Understanding consistent datum reference is crucial for achieving precision in machining processes, especially in complex components. ↩

-

Exploring geometric relationships in machining can enhance your knowledge of precision engineering and its applications. ↩

-

Understanding the Y-axis’s role in machining can enhance your knowledge of multi-tasking machines and their capabilities. ↩

-

Exploring transverse feed will provide insights into how tools move relative to workpieces, crucial for precision machining. ↩

-

Learning about complex geometries can help you appreciate the advanced capabilities of modern machining techniques in various industries. ↩

-

Explore this link to understand how Advanced Drilling & Tapping enhances precision and efficiency in CNC machining processes. ↩

-

Discover the significance of Precision Boring in achieving tight tolerances and maintaining accuracy in machining operations. ↩

-

Learn about Complex Contouring and its role in creating intricate designs and profiles in advanced machining applications. ↩

Chris Lu

Leveraging over a decade of hands-on experience in the machine tool industry, particularly with CNC machines, I'm here to help. Whether you have questions sparked by this post, need guidance on selecting the right equipment (CNC or conventional), are exploring custom machine solutions, or are ready to discuss a purchase, don't hesitate to CONTACT Me. Let's find the perfect machine tool for your needs

Chris Lu

Leveraging over a decade of hands-on experience in the machine tool industry, particularly with CNC machines, I'm here to help. Whether you have questions sparked by this post, need guidance on selecting the right equipment (CNC or conventional), are exploring custom machine solutions, or are ready to discuss a purchase, don't hesitate to CONTACT Me. Let's find the perfect machine tool for your needs