What to Know About Lathe Accuracy, Speed, and Controls Before Your Lathe Investment?

Investing in a CNC lathe is a big decision. Making the wrong choice can mean wasted money, poor part quality, and endless frustration. Understanding a few key things upfront makes all the difference.

Before investing in a CNC lathe, you need to carefully consider your required part accuracy (surface finish), optimal machining speeds (feed rates), necessary tool turret capabilities, and the most suitable CNC control system. These elements directly impact your productivity and profitability.

You see, these elements – accuracy, speed, the turret, and the controls – are the heart and soul of any CNC lathe. Get them right, and your machine will be a productive workhorse. Get them wrong, and you might be facing an uphill battle from day one. It’s not just about the brand name or the price tag; it’s about matching the machine’s capabilities to the work you actually do. I’ve learned over the years that a little extra homework before buying saves a lot of headaches later. So, let’s break down what you really need to think about.

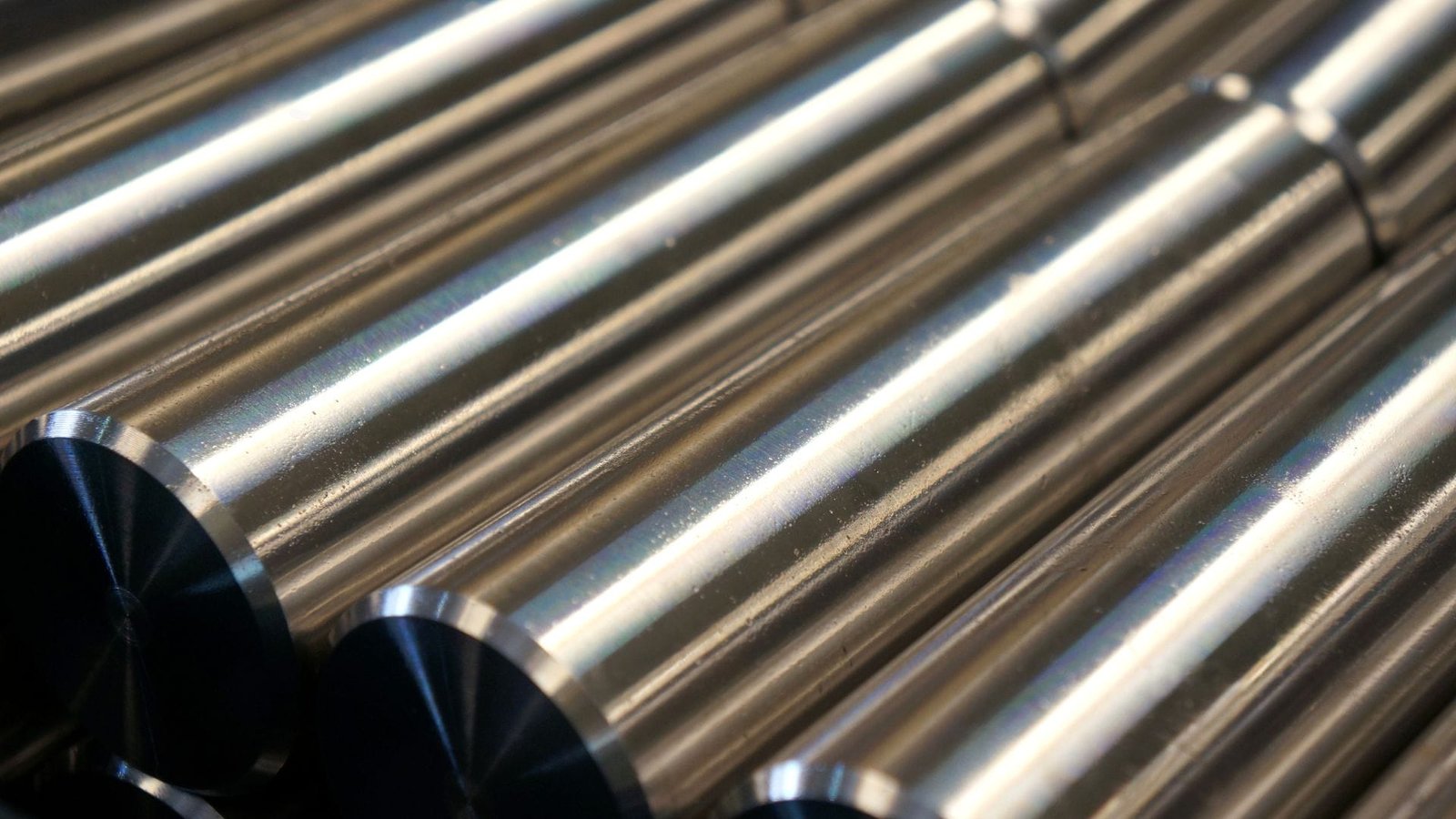

What Specific Surface Finish (Ra) Do Your Workpieces Require?

Are you constantly battling inconsistent surface finishes on your parts? This can lead to rejected work, wasted materials, and unhappy customers if you’re not careful. Knowing your exact surface finish needs is the first step to solving this.

To achieve your required surface finish (Ra), you must select the right cutting tools, optimize machining parameters like cutting speed and feed rate, and ensure your CNC lathe itself is accurate and well-maintained. Typically, CNC lathes can achieve Rz0.4~0.8um.

The surface finish, often measured in Ra (Roughness average)1 or Rz (average maximum height of the profile), is critical. For general turning, a Ra of 1.6 to 3.2 µm might be fine. But for precision components, you might need Ra 0.8 µm or even Rz 0.4-0.8µm, which is a very fine finish.

Achieving this involves several things:

- Tool Selection2: The tool material (carbide, ceramic, CBN), its geometry (especially the nose radius – a larger radius generally gives a better finish at a given feed), and the coating all play a huge role. High-quality, sharp tools are a must.

- Machining Parameters3:

- Cutting Speed: Too slow can lead to built-up edge; too fast can cause premature tool wear and chatter.

- Feed Rate: This is a big one. Lower feed rates generally result in a smoother finish.

- Depth of Cut: Finishing passes should be light to minimize tool pressure and deflection.

- Machine Condition: A rigid machine with minimal spindle runout and good vibration damping is essential. Regular maintenance keeps it performing at its best.

- Coolant: Proper coolant application helps with chip evacuation and temperature control, which impacts finish.

Thinking about these factors helps you choose a lathe that can meet your quality standards.

What Feed Rates Best Suit Your Specific CNC Turning Requirements?

Are your cycle times dragging, or are you burning through cutting tools too quickly? Incorrect feed rates can be a major drain on efficiency and your budget. Finding the right balance is key to productive turning.

The best feed rates for your CNC turning balance machining speed with your desired surface finish, dimensional accuracy, and acceptable tool life. Higher feed rates increase material removal but can degrade finish and shorten tool life.

I learned the hard way that just cranking up the feed rate4 to finish jobs faster isn’t always the best strategy. I ended up with a pile of scrapped parts and a broken tool. The feed rate – how fast the tool moves through the material – is a critical balancing act.

Here’s how it breaks down:

- Surface Finish5: Generally, a lower feed rate results in a smoother surface. This is because the tool marks (cusps) left behind are smaller and closer together.

- Dimensional Accuracy: Very high feed rates can increase cutting forces, potentially leading to tool deflection or vibration, which can affect the accuracy of your parts.

- Tool Life: Pushing tools with excessively high feed rates generates more heat and stress, leading to faster wear and a shorter lifespan for your expensive inserts.

- Production Efficiency: This is where the balance comes in. You want to remove material as quickly as possible, but not at the expense of quality or tool life.

- For roughing passes, where the goal is to remove a lot of material quickly, you’ll use higher feed rates.

- For finishing passes, where accuracy and surface quality are paramount, you’ll use lower feed rates.

The material you’re cutting also plays a big role. Softer materials like aluminum can often handle higher feed rates than tough alloys.

| Factor | Higher Feed Rate Impact | Lower Feed Rate Impact |

|---|---|---|

| Surface Finish | Rougher | Smoother |

| Dimensional Accuracy | Potential for lower accuracy | Higher potential for accuracy |

| Tool Life | Shorter | Longer |

| Material Removal | Faster | Slower |

| Machine Load | Higher | Lower |

Understanding this interplay helps you program your jobs for optimal results, not just speed.

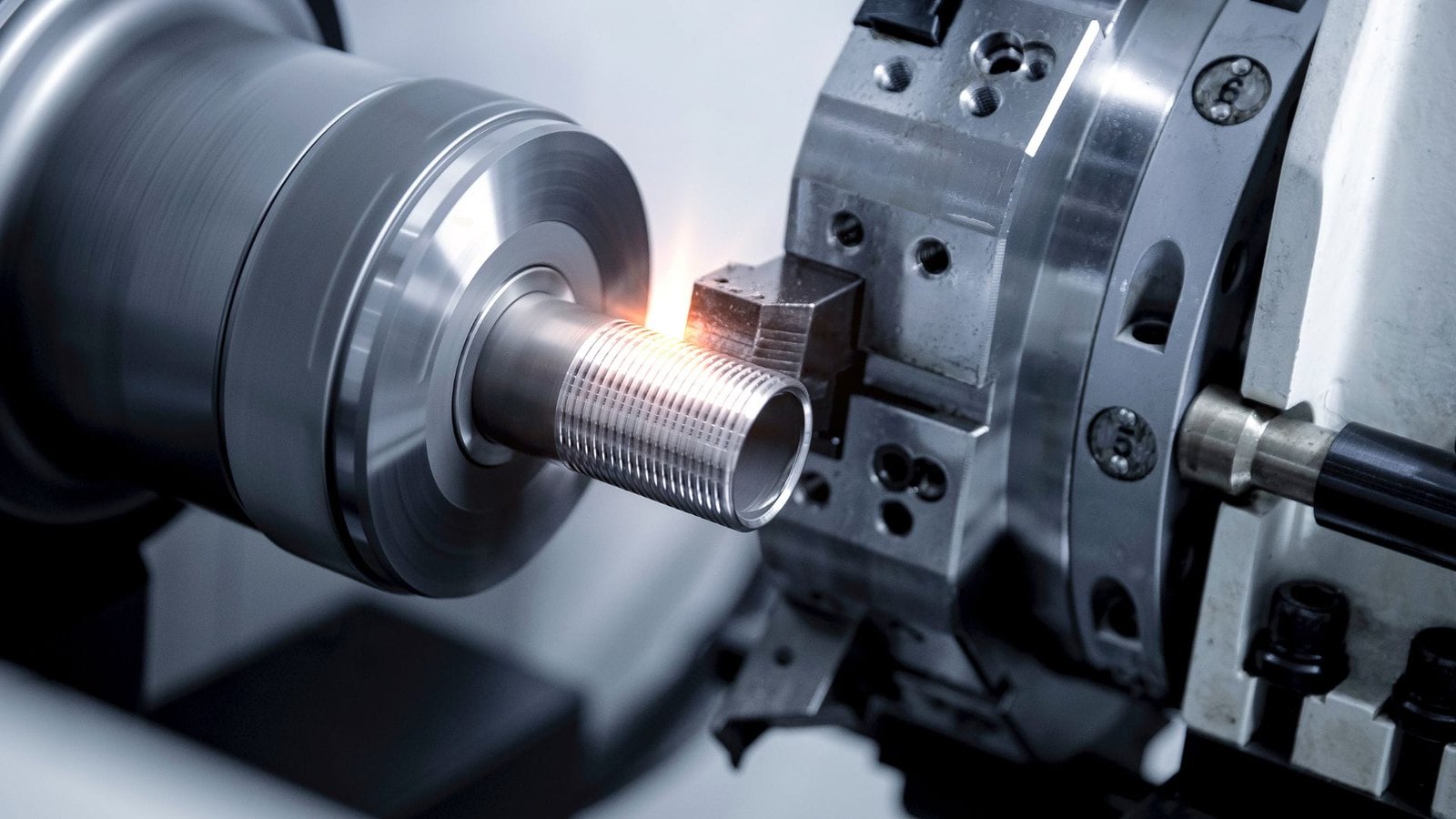

What Specific Turret Capabilities Do Your Typical Parts Require?

Are you constantly swapping tools manually or struggling to machine complex features on your parts? The capabilities of your lathe’s turret can make a huge difference in your shop’s efficiency and the kind of work you can take on.

Your typical parts dictate your turret needs. Consider the number of tool stations, tool change speed, if you need driven tools (live tooling) for milling or drilling, and the overall rigidity of the turret for your operations.

I remember when my shop primarily did simple turned parts, a basic 8-station turret was fine. But as we started taking on jobs with milled flats, cross-drilled holes, and more complex geometries, upgrading to a lathe with live tooling and a Y-axis was a complete game-changer.

When looking at turrets, think about:

- Number of Tool Stations: How many different tools do your common jobs require? More stations (e.g., 10, 12, or even 24 on some machines) mean fewer setups and more "done-in-one" capability.

- Tool Change Time: The time it takes for the turret to index from one tool to the next ("chip-to-chip" time) can add up significantly in high-volume production. Faster is generally better.

- Live Tooling (Driven Tools)6: This is a big one. Live tools allow you to perform milling, drilling, and tapping operations on the workpiece without moving it to another machine. This dramatically improves accuracy and reduces handling. Look for options like BMT (Bolt-Mounted Turret) or VDI (a German standard) for live tool holders, as they offer different benefits in terms of rigidity and setup speed.

- Y-Axis Capability7: A Y-axis adds another dimension of movement to your live tools, allowing for off-centerline machining. This opens up a whole new world of part complexity you can handle.

- Rigidity and Clamping: The turret needs to be robust and clamp tools securely to withstand cutting forces, especially during heavy roughing or when using long boring bars.

If you’re doing simple pins and bushings, a basic turret might suffice. But if your future involves more complex parts, investing in a more capable turret upfront can save you a lot of money and headaches in the long run.

How to Choose a Suitable CNC System for Your New CNC Lathe?

Feeling overwhelmed by the different CNC system options available for lathes? Choosing the wrong control can lead to a steep learning curve, limited machine capabilities, and operational headaches. It’s about finding the right fit for your team and your work.

To choose a suitable CNC system, evaluate its ease of use (conversational programming, graphical interface), the precision it offers, multi-axis control capabilities, any specific industry standards you must meet, and, of course, your budget.

Key Control System Features

- Ease of Use:

- Graphical Interface & Simulation: A clear display and the ability to simulate the toolpath graphically can save a lot of time and prevent costly crashes. I always look for good simulation.

- Precision and Performance8: The control’s processing speed and features like "look-ahead" (which reads upcoming blocks of code to optimize motion) can impact both speed and the quality of the finish on complex contours.

- Multi-Axis Control9: Standard lathes are 2-axis (X and Z). But if you have live tooling, you’ll need C-axis control for spindle positioning. A Y-axis adds another layer. Ensure the control can handle the number of axes your machine has and potentially any future upgrades.

- Compatibility and Support: How well does it integrate with your CAD/CAM software? Is there good local support and training available for that control system? This is often overlooked but crucial.

Common CNC System Brands

You’ll often see a few major players, and also some very capable regional brands. My insights below are based on general industry perception and my own experiences:

- Chinese Brands (e.g., GSK, KND, HNC): I’ve seen these frequently on machines that offer a strong price-to-performance ratio. They are quite popular in many markets and are perfectly capable for a wide range of turning applications, especially for small to medium enterprises. They often feature straightforward operation and can be a good starting point.

- International Brands (e.g., FANUC, Siemens, Heidenhain):

- FANUC: Known for its robustness and reliability. It’s probably the most common control I’ve encountered worldwide. Once you learn it, you can run many machines.

- Siemens: Offers a very integrated system, often praised for its user interface and capabilities in more complex multi-axis machining and automation. Their ShopTurn conversational programming is quite powerful.

- Heidenhain: While perhaps more dominant in milling, their TNC controls are also excellent for lathes, especially where very high precision and advanced programming features are needed.

Here’s a general comparison based on what I’ve gathered:

| Feature | GSK | KND | HNC | Siemens | FANUC | Heidenhain |

|---|---|---|---|---|---|---|

| Origin | China | China | China | Germany | Japan | Germany |

| Typical User Focus | Cost-effective | Broad domestic use | Various industries in China | High-end, Automation | Ubiquitous, Reliability | High-Precision, Complex |

| Conversational Programming | Basic | Basic | Basic | Advanced (ShopTurn) | Moderate (Manual Guide i) | Advanced (Klartext) |

| Graphical Support | Improving | Improving | Improving | Excellent | Good | Excellent |

| Precision Focus | Good | Good | Good | Very High | Very High | Top-Tier |

| Primary Market | China, Export | China | China | Global | Global | Global (esp. Europe) |

| Price Point (General) | Mid-Low | Mid-Low | Mid-Low | High | High | High |

Ultimately, if your operators are familiar with a particular system, that’s a big plus. For very complex work or specific industry requirements (like aerospace), you might lean towards one of the established international brands. For general turning where budget is a key driver, other systems offer excellent value.

Conclusion

Choosing the right CNC lathe involves carefully thinking about its accuracy, speed, turret, and control system. Match these to your work, and you’ll make a sound investment.

-

Understanding Ra is essential for achieving the desired surface finish in machining processes. Explore this link to deepen your knowledge. ↩

-

Selecting the right tool is crucial for achieving optimal surface finishes. This resource will guide you through the selection process. ↩

-

Machining parameters significantly affect the surface finish quality. Learn more about optimizing these parameters for better results. ↩

-

Understanding feed rate is crucial for optimizing machining processes and achieving the best results in production. ↩

-

Exploring surface finish can help you understand its impact on product quality and customer satisfaction. ↩

-

Explore the advantages of live tooling to enhance your machining capabilities and improve production efficiency. ↩

-

Learn how Y-axis capability can expand your machining options and allow for more complex part designs. ↩

-

Learning about Precision and Performance can significantly improve the quality of your machining results and efficiency. ↩

-

Exploring Multi-Axis Control can help you optimize your machining processes and expand your capabilities. ↩

Chris Lu

Leveraging over a decade of hands-on experience in the machine tool industry, particularly with CNC machines, I'm here to help. Whether you have questions sparked by this post, need guidance on selecting the right equipment (CNC or conventional), are exploring custom machine solutions, or are ready to discuss a purchase, don't hesitate to CONTACT Me. Let's find the perfect machine tool for your needs.