What Workpiece Dimensions and Weight Must Your Ideal CNC Drilling Machine Accommodate?

Choosing a CNC drilling machine feels like a big step. If you pick one that’s too small or not sturdy enough for your parts, you’ll face constant problems. Getting this right from the start is key.

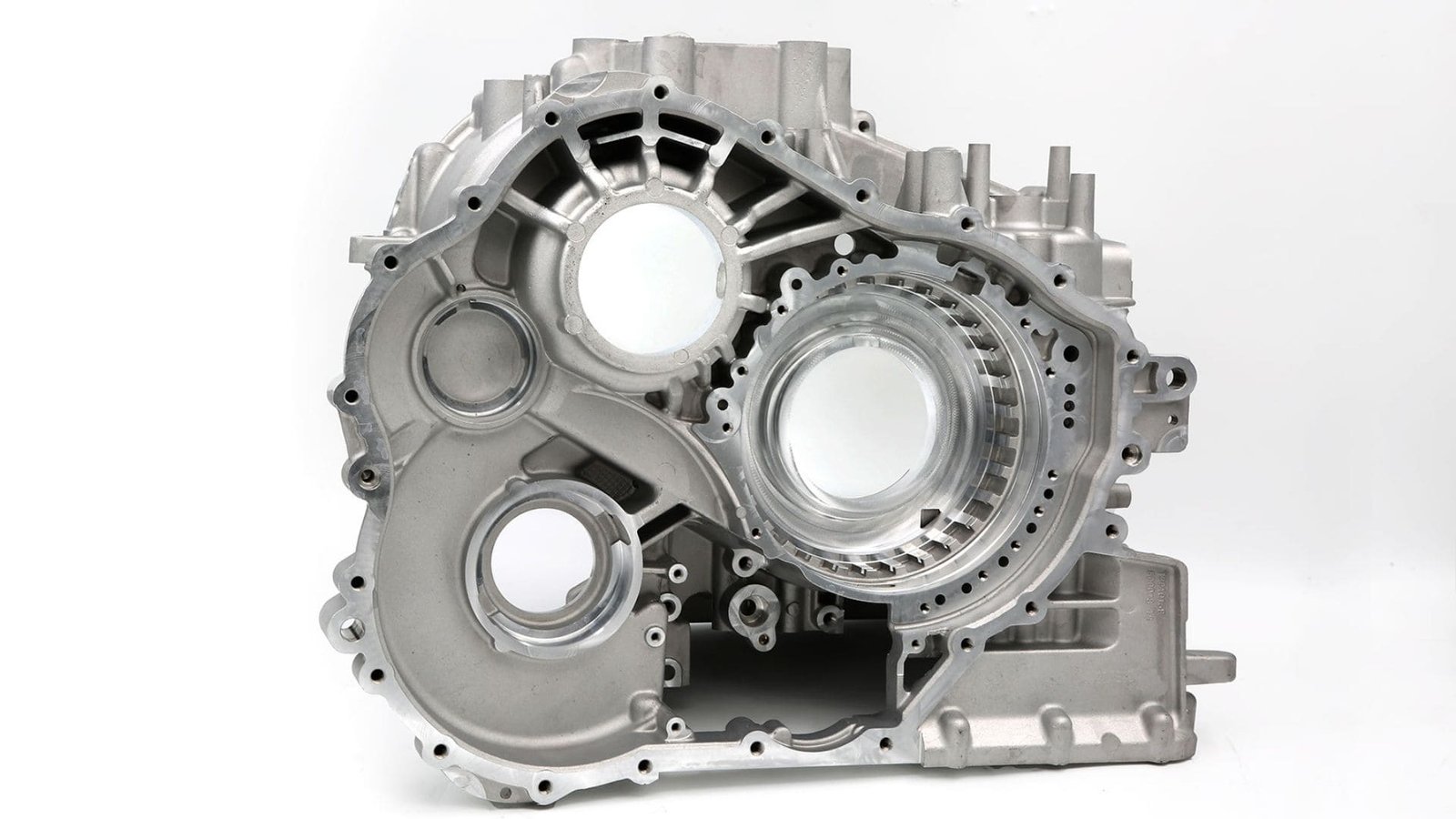

Your ideal CNC drilling machine must feature a worktable and travel range appropriate for your largest workpieces and possess the structural integrity and load capacity to support your heaviest items securely, ensuring precision and safety.

You see, it’s pretty straightforward: the machine has to fit your work. I’ve seen folks get excited by fancy features, only to find out their common jobs are too big or too heavy for their new purchase. The first thing I always check is the basic physical capacity. Can it hold the part? Is the worktable big enough? Can it handle the weight without flexing or vibrating? These basic questions have to be answered before anything else. If the part doesn’t fit, or if the machine can’t hold it steady, all the other bells and whistles don’t mean a thing. So, let’s dig into why these physical aspects are so fundamental to your success and what you should consider before looking at speeds or special features.

How Do the Materials You Plan to Drill Influence Spindle and Power Requirements?

Are your drills wearing out too fast, or is the machine struggling with harder materials? This could mean your spindle and motor aren’t up to the task. Matching power to the material is crucial.

The materials you drill dictate your spindle and power needs. Harder or tougher materials, like alloy steels, demand more spindle torque and horsepower, often with adjusted speeds, to drill effectively without excessive tool wear or machine strain.

So, what should you think about?

- Material Hardness and Toughness:

- For softer materials1 like wood, plastics, or even some softer aluminums, you can often get away with higher spindle speeds and might not need a huge amount of power. The cutting forces are lower. Some spindles designed for these can reach very high RPMs.

- When you move to harder or tougher materials2—think carbon steels, alloy steels, stainless steels, or titanium alloys—the game changes. These materials resist the drill bit much more. You’ll need a machine with:

- Sufficient Spindle Power (Horsepower): Enough power to keep the drill turning consistently, even when it’s deep in the material.

- Adequate Spindle Torque: Torque is the twisting force. For tough materials, especially with larger drills, you need good torque, often at lower RPMs, to make the drill cut effectively rather than just rub and heat up.

- Processing Parameters:

- Cutting Speed: This needs to be adjusted based on the material. Harder materials usually mean lower cutting speeds.

- Feed Rate: This also changes. For very hard materials, a slower feed rate might be needed to prevent tool breakage.

- Cutting Depth: The depth you drill in one go also affects the load on the spindle.

Essentially, a machine that excels at drilling aluminum quickly might struggle with steel. And a machine built for steel needs the robustness and power to handle those tougher jobs. It’s about having the right tool for the material.

What Types of Holes and Their Diameters/Depths Define Machine Capability Needs?

Are you limited by the kinds of holes your current setup can produce? Maybe you can’t go deep enough, or achieve the right quality. The holes themselves tell you what machine capabilities you need.

The types of holes (e.g., through-holes, blind holes, tapped pre-holes), their diameters, and especially their depths dictate the necessary Z-axis travel, spindle power, tool holding, and potentially specialized drilling cycles and coolant systems.

The hole itself tells you a lot about the machine you need.

Consider:

- Hole Diameter3: Small holes (e.g., a few millimeters) don’t need massive power but do need precision and good spindle speed control. Larger holes (e.g., 50mm or more) demand significant power, torque, and a very rigid machine and tool holding. The maximum drilling diameter is a key spec.

- Hole Depth: This is a big one.

- Shallow holes are straightforward.

- Deep holes4 (often defined as more than 5-10 times the diameter) present challenges like chip evacuation, tool wander, and heat buildup. Your machine needs sufficient Z-axis travel. You might also need features like peck drilling (where the drill retracts periodically to clear chips) or, ideally, through-spindle coolant (coolant forced through the drill itself) to flush chips and cool the cutting edge. The machine’s structural strength is also key to maintaining straightness in deep holes.

- Hole Type:

- Drilling: This is the basic hole-making operation. Usually for holes up to 80mm, often for less critical applications like bolt holes or pre-holes for tapping.

- Reaming: Used after drilling to improve the hole’s diameter accuracy and surface finish. The machine needs to guide the reamer accurately.

- Boring: For larger diameters and high precision, often when a standard drill/reamer isn’t available or accurate enough. This requires a very rigid machine and spindle.

- Honing: A finishing process for very smooth surfaces and tight tolerances in small holes. This is more specialized.

- Counterboring/Countersinking: These create specific features at the hole opening. The machine needs to handle the intermittent cutting forces.

Here’s a simple breakdown:

| Hole Process | Typical Use | Key Machine Needs |

|---|---|---|

| Drilling | General purpose holes, pre-holes | Adequate power, Z-axis travel, good chip evacuation |

| Reaming | Improved size and finish | Good spindle accuracy, smooth feed |

| Boring | Large diameter, high precision | High rigidity, power, precise tool adjustment |

| Deep Hole | Holes >5-10x diameter | Long Z-travel, peck drilling, through-spindle coolant |

Thinking about the biggest, deepest, and most complex holes you’ll regularly produce will guide you to the right machine specs.

How Do Accuracy & Finish Impact Your CNC Drilling Machine Selection?

Are you constantly battling to meet tight tolerances on hole positions, or is the surface finish inside your drilled holes not up to par? This can lead to a lot of frustration and rejected parts. The right machine makes all the difference.

Higher accuracy and finer surface finish requirements in drilled holes demand a CNC drilling machine with superior structural rigidity, precision motion components like ballscrews and linear guides, a high-quality spindle with minimal runout, and stable workpiece clamping.

If your parts need to be spot-on, the machine itself must be capable.

What contributes to accuracy and finish in drilling?

- Machine Structure and Rigidity: A heavy, well-damped machine base and a rigid column are vital. Any flex or vibration during the drilling process will translate directly into errors in the hole’s position, straightness, or roundness. The overall robustness of the machine is a big factor.

- Precision Motion System5:

- Ballscrews and Linear Guides: High-quality, preloaded ballscrews for moving the X, Y, and Z axes ensure precise positioning with minimal backlash. Smooth, rigid linear guideways support these movements accurately.

- Feedback Systems: For top-tier accuracy, some machines use precision feedback systems, like optical rulers or high-resolution encoders, to achieve micron-level positioning.

- Spindle Quality: The spindle must hold and rotate the drill bit true, with very little runout (wobble). Excessive runout leads to oversized holes and a poor surface finish. Quality bearings and a well-balanced spindle are essential.

- Workpiece Clamping: The part must be held absolutely securely. If it shifts even slightly during drilling, all accuracy is lost. A good fixturing strategy is key.

- Your Drilling Process:

- Lubrication/Coolant: Proper coolant application is crucial. It reduces heat, lubricates the cut, and helps evacuate chips, all of which contribute to better accuracy and surface finish.

It’s also worth noting that factors like ambient temperature, humidity, and even dust in the workshop can have a subtle impact on very high-precision work. Keeping the equipment clean is important. Generally, deeper holes and smaller diameter holes are more challenging when it comes to maintaining high accuracy.

What Production Volume and Desired Cycle Times Should Your Chosen CNC Drilling Machine Be Able to Achieve?

Are your drilling operations creating a bottleneck in your workflow, slowing down overall production? If you need to increase output and get parts completed faster, the speed and efficiency of your CNC drilling machine are critical.

To meet high production volumes and achieve short cycle times, your CNC drilling machine needs capabilities like fast rapid traverse rates, quick spindle acceleration and deceleration, efficient chip management systems, and potentially automation features such as automatic tool changers or integration with loading/unloading systems.

A slow machine will be directly costing you money and opportunities. Cycle time—the total time it takes to complete all drilling operations on one part—became a huge focus.

Several machine characteristics influence this:

- Rapid Traverse Rates6: This is how fast the machine can move its axes (X and Y primarily for hole-to-hole movement, and Z for retracts) when it’s not cutting. Faster rapid traverse rates significantly reduce non-cutting time, which can be a large portion of the cycle on parts with many holes. Machines with servo motors often offer higher feed rates, which can boost production significantly.

- Spindle Performance7: Quick acceleration to the programmed RPM and quick deceleration for retracts also trim seconds off the cycle.

- Efficient Drilling Cycles: As mentioned before, using optimized CNC drilling cycles (like

G81,G83,G73) appropriate for the hole depth and material helps. The control system’s processing speed also plays a part in executing these cycles efficiently. - Chip and Dust Management: If chips aren’t cleared effectively, you might have to slow down, or even stop the machine to clear them manually. This kills productivity. An effective coolant system is one part of this. For some materials or dry drilling operations, a robust vacuum system is essential to remove dust and chips continuously. I’ve learned that having a vacuum with a bit more power than you think you need, and a large capacity collection, helps avoid production delays due to clogged filters or full bags.

- Automation Features8 (for higher volumes):

- Automatic Tool Changers (ATC): If a part requires multiple drill sizes, or subsequent operations like reaming or tapping that can be done on the same machine, an ATC drastically reduces manual intervention and setup time between tools.

- Automatic Loading/Unloading Systems: For very high-volume, repetitive tasks, integrating robotic or pallet-based loading/unloading systems can allow the machine to run almost continuously.

When evaluating for production volume, I consider the number of holes per part, the complexity, and the number of parts I need per shift or per day. This helps me decide whether I need a high-speed, potentially automated machine, or if a simpler, more standard CNC drilling machine will suffice.

Conclusion

Selecting the right CNC drilling machine really boils down to understanding your specific work: the typical dimensions and weight of your parts, the materials you’ll be drilling, the types and depths of holes required, your accuracy and finish standards, and your production volume targets.

-

Understanding softer materials can help you optimize machining processes and select the right tools for efficiency. ↩

-

Exploring this topic will provide insights into the challenges and solutions for machining tough materials effectively. ↩

-

Understanding hole diameter is crucial for selecting the right machine and ensuring precision in your projects. ↩

-

Exploring the challenges of deep holes can help you choose the right tools and techniques for effective machining. ↩

-

Understanding Precision Motion Systems can enhance your knowledge of accuracy in machining, leading to better results in your projects. ↩

-

Understanding rapid traverse rates can help you optimize your machining processes and reduce cycle times, leading to increased productivity. ↩

-

Exploring spindle performance can reveal ways to enhance your machining efficiency and reduce production costs. ↩

-

Learning about automation features can help you make informed decisions about investing in technology that boosts production efficiency. ↩

Chris Lu

Leveraging over a decade of hands-on experience in the machine tool industry, particularly with CNC machines, I'm here to help. Whether you have questions sparked by this post, need guidance on selecting the right equipment (CNC or conventional), are exploring custom machine solutions, or are ready to discuss a purchase, don't hesitate to CONTACT Me. Let's find the perfect machine tool for your needs.