Which Turret Type Generally Offers Higher Indexing Accuracy and Repeatability: Hydraulic or Servo?

Need absolute precision when your CNC lathe changes tools? Ever wonder if tiny inconsistencies stem from the turret itself? Choosing the right turret technology is vital for consistently hitting those tight tolerances part after part.

Servo turrets generally deliver higher indexing accuracy and repeatability. They use precise servo motors with encoder feedback for positioning errors often within hundredths of a millimeter, beating the less precise mechanical positioning of hydraulics.

This superior precision comes from how servo systems track position using closed-loop control. Hydraulic systems, while strong, don’t typically have this level of fine positioning feedback. Understanding how they work mechanically reveals why one excels in accuracy.

How Does the Actuation Mechanism Differ Between Hydraulic and Servo Turrets on a CNC Lathe?

You hear "hydraulic" and "servo," but what’s actually making the turret spin and clamp? Getting the mechanics wrong could mean picking a system unsuited for your needs – sacrificing power, precision, or flexibility.

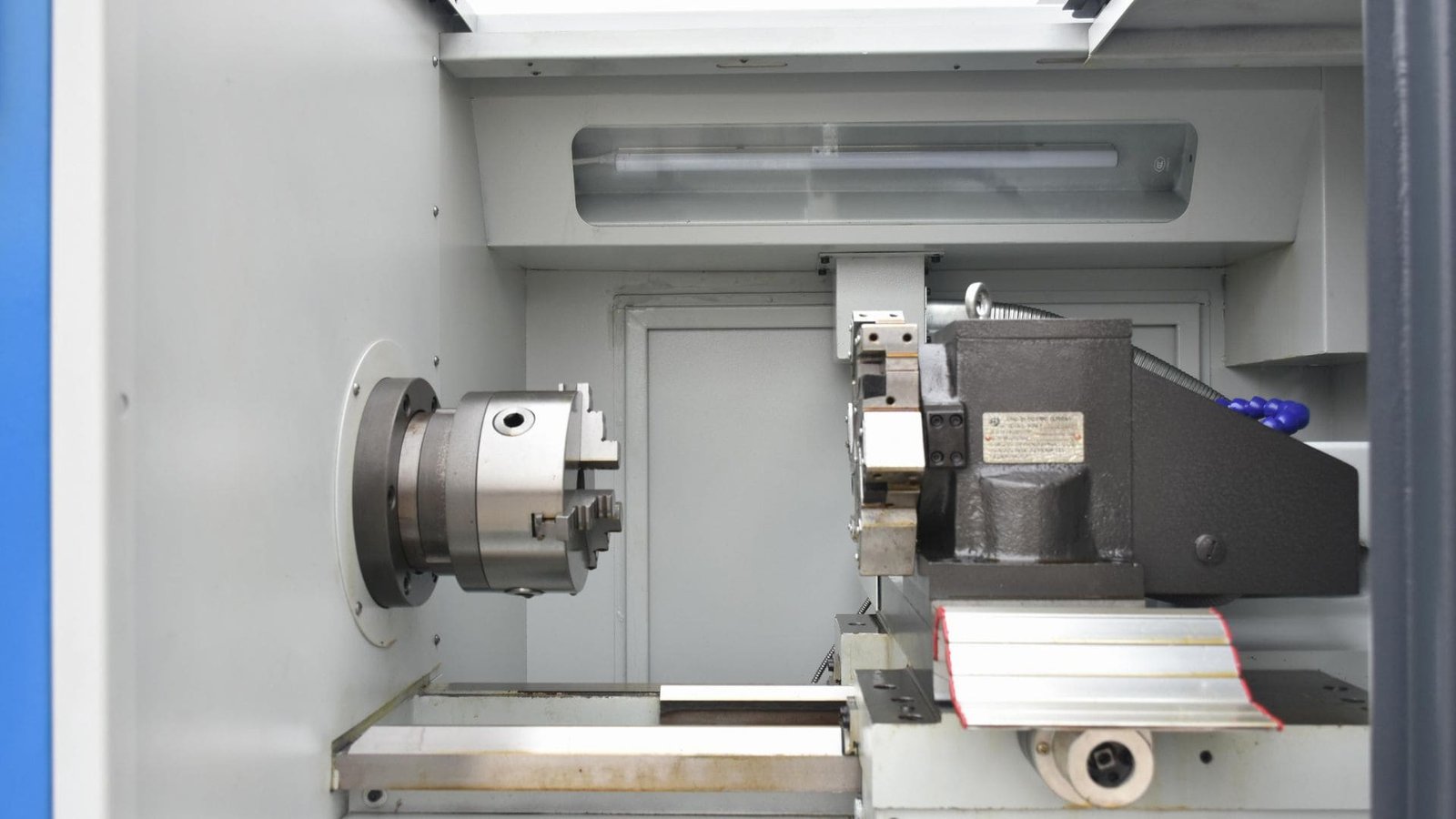

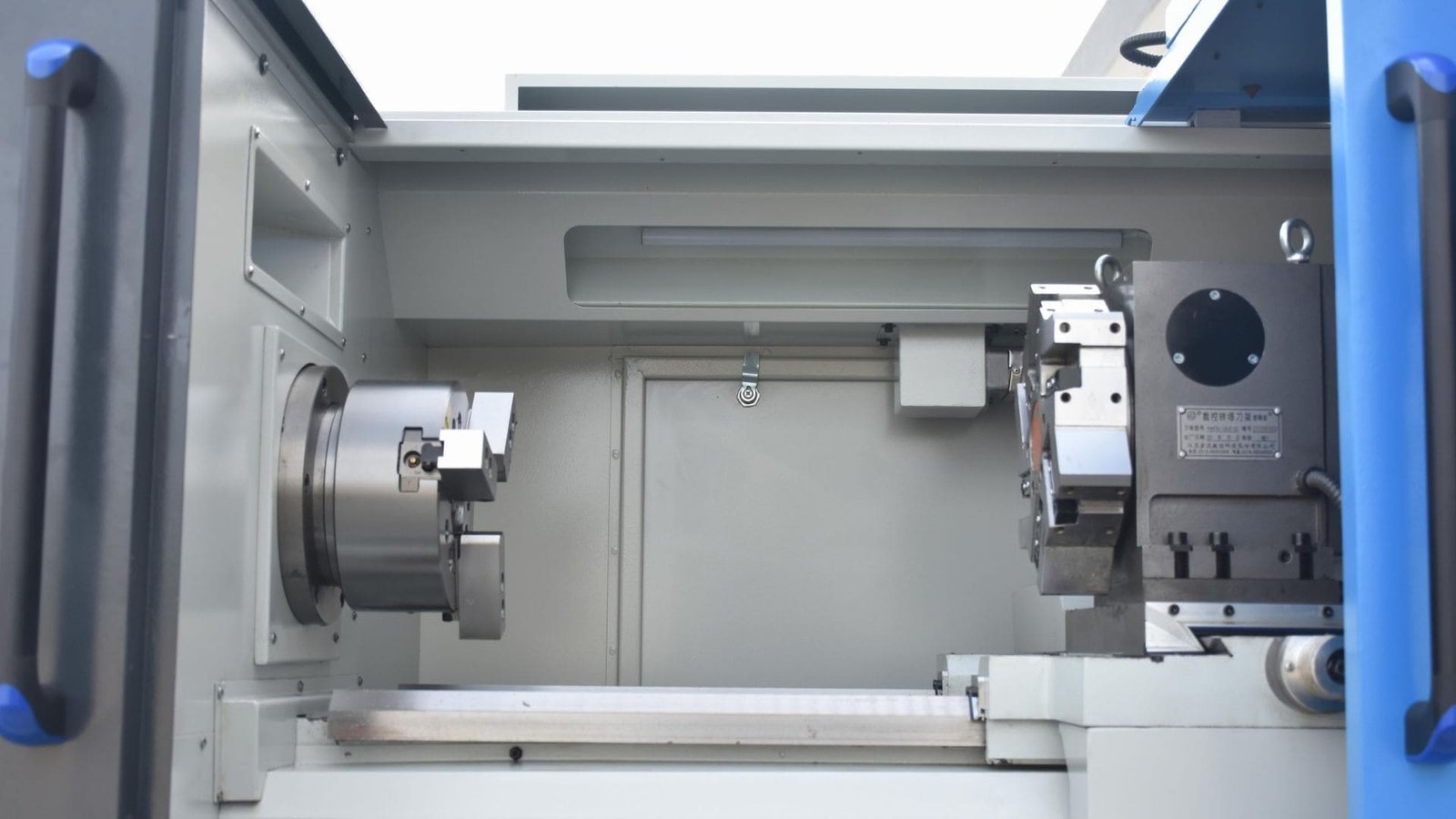

Servo turrets use an electric servo motor for precise rotation, but often rely on hydraulic or pneumatic power for clamping. Hydraulic turrets use hydraulic pressure generated by a pump for both driving rotation and clamping the tools.

Working at J&M Machine Tools, I see how different these approaches are. Your new insights clarify this well:

- Servo Turret: Think of it as a hybrid system. A highly controllable servo motor1 handles the precise indexing motion. But the actual clamping force to lock the tool in place often comes from a separate hydraulic or pneumatic system. This combines electric precision for positioning with fluid power muscle for secure clamping. This setup offers great flexibility, easily handling more tool stations and complex operations.

- Hydraulic Turret: This is a more traditional fluid power setup. An electric motor drives a pump creating oil pressure. Valves direct this pressure to actuators that both rotate the turret and clamp the tools. This all-hydraulic approach delivers significant force, making it excellent for heavy-duty cutting (like large gears or shafts) where high clamping rigidity2 is essential to resist vibration. It’s simpler in concept but less flexible electronically.

What Are the Typical Indexing Speed Differences Between Hydraulic and Servo Turrets?

Tired of watching the turret slowly rotate between cuts? Those precious seconds accumulate, eating into your production output. The turret’s drive system directly dictates how fast you can change tools.

Servo turrets index significantly faster than hydraulic ones. Their quick electronic response minimizes non-machining time, boosting productivity, especially when many tool changes are needed. Hydraulic systems have inherently slower response times.

Speed is a major win for servos. Your research confirms they switch tools faster, directly cutting down on non-productive time in the cycle. The servo motor can accelerate, index, and decelerate very rapidly based on program commands, allowing tool changes often under 0.15 seconds. This ability to freely and quickly switch to any programmed tool position is a big efficiency gain in complex jobs or high-speed machining3. Hydraulic turrets, relying on fluid flow and valve actuation, simply react slower, typically taking 0.15 to 0.25 seconds or more. While reliable, this slower pace makes them less ideal for speed-critical applications or high-volume production where every fraction of a second counts. For pure speed between cuts, servo technology is the clear leader.

Is There a Significant Difference in Energy Consumption Between Hydraulic and Servo Turret Systems?

Is your workshop’s energy bill climbing higher? Machine tool power draw is a significant operating expense. The turret drive technology choice impacts how much electricity your lathe consumes over time.

Yes, there’s a big difference: servo turrets are much more energy-efficient. They mainly draw power only when indexing ("on-demand"), whereas hydraulic pumps often run continuously, wasting energy even when the turret is idle.

This is a key operational advantage, especially with rising energy costs. As your research reinforces, the servo motor only spins (and draws significant power) during the brief moment it’s indexing the turret. When stationary, its power consumption is minimal. This "on-demand" usage drastically cuts down energy waste. In stark contrast, many hydraulic systems4 keep the pump running continuously whenever the machine is on, just to maintain pressure and be ready. This constant power draw, regardless of whether a tool change is happening, adds up to significant energy consumption over shifts and weeks. Choosing a servo turret aligns better with sustainable practices and can lead to noticeable savings on the electricity bill compared to a constantly running hydraulic system.

How Do Hydraulic and Servo Turrets Compare in Terms of Initial Cost and Long-Term Operating Expenses?

Balancing the upfront budget against future running costs? The sticker price is just the start. Maintenance needs, energy use, and performance all contribute to the total cost of owning and operating a turret.

Hydraulic turrets have a lower initial purchase price due to simpler tech. Servo turrets cost more upfront but often have lower long-term costs thanks to energy savings, less maintenance (no hydraulic fluid care), and higher productivity.

This is where you weigh the immediate budget against future value. Your insights paint a clear picture:

- Initial Cost: Hydraulic turrets5 are generally cheaper to buy. Their established, less complex technology makes them appealing for businesses focused on minimizing upfront investment, especially for general machining like automotive parts.

- Long-Term Operating Expenses: Here,servo turrets6 often pull ahead.

- Energy Savings: As noted, they use less electricity.

- Maintenance: Servo systems avoid the routine maintenance of hydraulics – no oil changes, filter replacements, or concerns about seal leaks degrading performance over time. While servos have complex electronics, they typically require less regular upkeep than hydraulic fluid systems.

- Productivity & Precision: The higher speed and accuracy of servos mean faster cycles, fewer rejected parts due to tolerance issues, and the ability to tackle more demanding jobs (like aerospace or medical parts). This performance boost adds significant value over the machine’s life.

So, the higher initial investment for a servo turret can be justified by its lower running costs and superior performance, offering better long-term value, especially in precision-critical or high-volume environments.

Conclusion

Servo turrets win on accuracy, speed, and energy use, justifying higher initial cost for precision work. Hydraulic turrets are cheaper upfront and powerful, better for heavy-duty tasks with looser tolerances. Choose based on job needs and budget.

-

Understanding servo motors is crucial for grasping their role in precision applications like turret systems. ↩

-

Learning about clamping rigidity will help you understand its significance in achieving precision and stability in machining processes. ↩

-

Discover the benefits of high-speed machining and how it can improve production efficiency and reduce cycle times in manufacturing. ↩

-

Learn about the drawbacks of hydraulic systems and why alternatives like servo motors may be more efficient. ↩

-

Explore the benefits of Hydraulic turrets to understand their cost-effectiveness and suitability for general machining tasks. ↩

-

Learn how servo turrets enhance productivity and precision, making them ideal for demanding machining applications. ↩

Chris Lu

Leveraging over a decade of hands-on experience in the machine tool industry, particularly with CNC machines, I'm here to help. Whether you have questions sparked by this post, need guidance on selecting the right equipment (CNC or conventional), are exploring custom machine solutions, or are ready to discuss a purchase, don't hesitate to CONTACT Me. Let's find the perfect machine tool for your needs.