Why a 45° Slant Bed CNC Lathe Is Preferred for Heavy-Duty Cutting Operations?

Struggling with heavy cuts on your lathe? Vibration chatter, mountains of chips, and poor accuracy can scrap expensive parts and slow you down. A 45° slant bed design directly targets these heavy-duty machining headaches.

A 45° slant bed is often chosen for heavy cuts because its steeper angle uses gravity to get chips out fast, crucial when you’re removing lots of material. Manufacturers highlight its "best heavy cutting performance," suggesting it handles the heat and stress better.

This rapid chip disposal is key for intense jobs. But it’s not the only factor. The angle choice affects rigidity, workpiece size, and more. Let’s see how the common 30° angle compares, especially for everyday machining tasks.

What are the Advantages of Choosing a 30° Slant Bed CNC Lathe better than 45° for General Machining?

Need a lathe for a mix of jobs, not just non-stop heavy roughing? While a 45° bed is tough, a 30° slant bed often brings better versatility for general-purpose machining, making it a popular choice.

A 30° slant bed typically allows for a larger swing diameter, meaning you can fit bigger workpieces on the machine. This flexibility is key for shops handling diverse jobs, making it more suitable for general machining compared to the often more compact 45° design.

From my time at J&M Machine Tools, versatility is often king in a job shop. The ability to handle a wider range of part sizes is a major plus. Some manufacturers, specifically note their 30° designs allow for "large swing and super heavy cutting," confirming this advantage. The shallower 30° angle physically creates more clearance between the highest point of the bed and the spindle centerline. This doesn’t just mean bigger diameters; sometimes it also offers a bit more room for tool turret setups or longer X-axis travel, as suggested by Yash Machine’s insights on inclined beds1 accommodating more tools. While the 45° excels at intense, focused cutting, the 30° strikes a balance, offering good stability (as we’ll discuss) and the adaptability needed for varied workpiece sizes and setups common in general machining. It’s less specialized for pure chip removal and more geared towards flexibility.

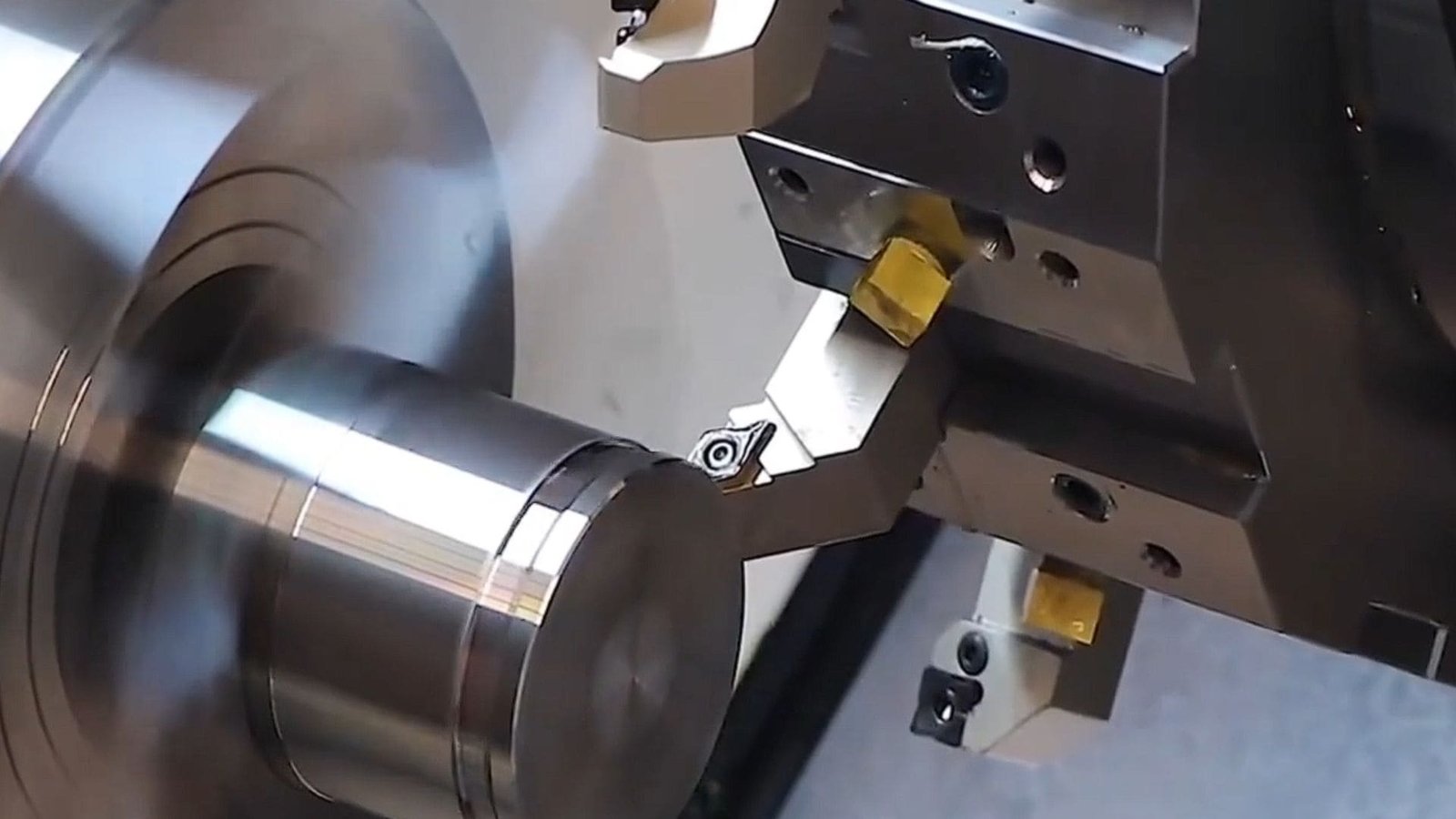

How Does the Slant Angle (30° vs 45°) Influence Chip Evacuation and Coolant Flow?

Fighting chip nests and watching coolant splash everywhere but the cutting edge? Poor chip and coolant management leads to tool breakage, bad finishes, and downtime. The bed’s slant angle is a primary factor in how well these flow.

The steeper 45° angle provides a faster path for chips to slide away due to gravity, improving evacuation, especially with heavy chip loads. Coolant also flows more directly. A 30° angle still offers good flow (way better than flat beds), but chips move slower, and coolant might spread more broadly.

It really boils down to basic physics – gravity pulls things down a steeper slope faster. Think of the 45° bed as a more efficient slide for chips. This rapid clearance is why manufacturers highlight "easy chip disposal2" on their 45° models for heavy cutting environments where chips pile up quickly. This prevents chips from interfering with the cut or getting packed around the tool. While Hurco notes slant beds generally have better chip evacuation3, the 45° angle maximizes this gravitational advantage. Coolant follows a similar path, flowing quickly down the 45° incline, washing chips away and draining efficiently. On a 30° bed, chips still fall away effectively thanks to gravity, but the movement is less rapid. Coolant flow might be less direct, potentially spreading over a wider area, which could be fine for general cooling but less forceful for flushing heavy chip loads compared to the 45° design. Both are vast improvements over flat beds, but 45° optimizes for speed of removal.

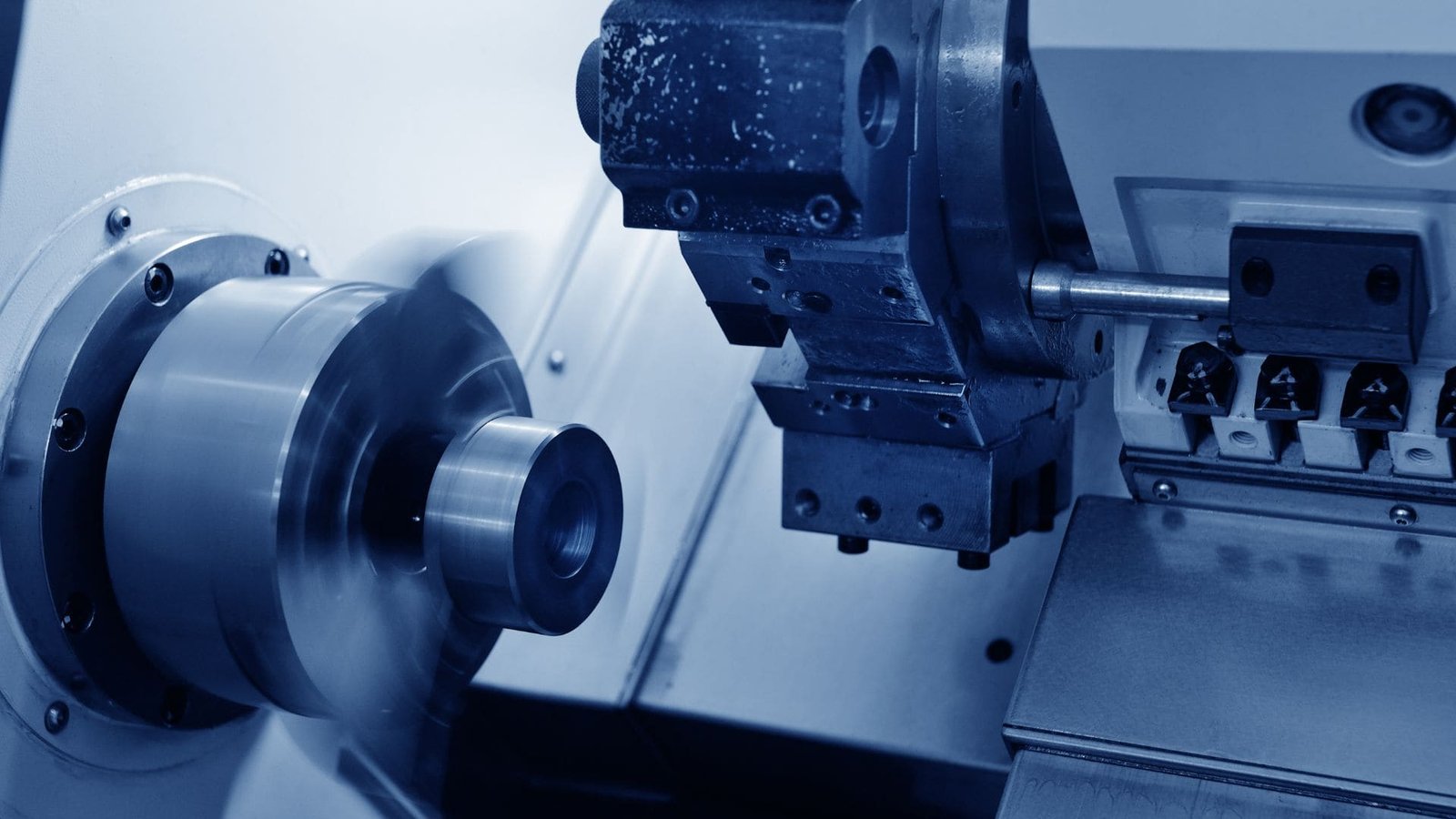

Does the Bed Angle Affect the Overall Rigidity and Vibration Dampening of a Slant Bed Lathe?

Getting chatter marks that ruin your finish or limit cutting speeds? Machine vibration is the enemy of precision and tool life. While both 30° and 45° slant beds boost rigidity, the angle does play a role.

Yes, both 30° and 45° slant beds offer significantly better rigidity and vibration dampening than flat beds due to their structure and gravity assist. While 45° aligns forces well for heavy cuts, the difference in overall rigidity between 30° and 45° might be less critical than the machine’s build quality (casting, guideways).

Slant beds inherently have a structural advantage. Their triangular cross-section is naturally more stable than the rectangular form of a flat bed. This design resists bending and twisting forces better. Furthermore, as Yash Machine points out, the cutting forces on a slant bed tend to align better with gravity, pushing down into the rigid structure rather than trying to lift the tool/carriage like on a flat bed, which reduces vibration. Your earlier insights correctly mentioned the 45° angle leveraging gravity effectively during heavy cuts. However, the new research suggests that while true, the inherent rigidity boost from simply being a slant bed (whether 30° or 45°) might be the more significant factor compared to a flat bed. High-quality construction, like using Meehanite casting4 or robust box guideways (mentioned by Annn Yang), likely contributes as much or more to overall stiffness and vibration control than the specific angle choice between 30° and 45°. So, while 45° is tailored for heavy cutting stability, both angles provide a fundamentally rigid platform compared to older designs.

Beyond 30° and 45°, Are There Other Common Slant Bed Angles and What Are Their Use Cases?

Think 30° and 45° are the only games in town for slant beds? While they are the most common, machine tool builders sometimes use other angles for specific, specialized needs.

Yes, other angles like 60° and even up to 75° exist, though they are less common. These steeper angles are typically used in compact machine designs or for applications requiring extreme chip evacuation, such as high-speed, high-volume production.

Comparative Table: Slant Bed Angles and Key Attributes

To summarize the differences, the following table compares the angles based on the discussed factors:

| Angle | Chip Evacuation | Workpiece Size (Swing) | Coolant Flow | Rigidity/Vibration | Typical Use Case |

|---|---|---|---|---|---|

| 30° | Moderate, slower | Larger, suitable for big workpieces | Slower, broader | High, stable for general use | General machining, varied sizes |

| 45° | Better, faster | Moderate, compact design | Faster, direct | High, stable for heavy cutting | Heavy-duty cutting, high chip output |

| 60° | Excellent, very fast | Smaller, compact machines | Very direct | High, niche applications | Compact designs, high-speed production |

| 75° | Exceptional, rapid | Very limited, specialized | Highly direct | High, custom designs | Extreme chip evacuation, niche uses |

This table encapsulates the trends observed, though specific machine designs may vary.

So, while 30° and 45° cover most general and heavy-duty needs, these other angles cater to niche requirements where space, chip flow, or automation integration are extreme priorities.

Conclusion

Choosing a slant bed angle involves trade-offs. 45° excels at heavy cutting with rapid chip removal, while 30° offers greater versatility and workpiece capacity for general machining. Both provide superior rigidity over flat beds.

-

Learn how inclined beds can enhance machining efficiency and accommodate more tools for versatile setups. ↩

-

Explore how easy chip disposal enhances efficiency in machining processes, especially in heavy cutting environments. ↩

-

Discover the significance of chip evacuation in machining and how it affects tool performance and product quality. ↩

-

Discover the advantages of Meehanite casting in manufacturing, which can significantly enhance the durability and performance of machinery. ↩

Chris Lu

Leveraging over a decade of hands-on experience in the machine tool industry, particularly with CNC machines, I'm here to help. Whether you have questions sparked by this post, need guidance on selecting the right equipment (CNC or conventional), are exploring custom machine solutions, or are ready to discuss a purchase, don't hesitate to CONTACT Me. Let's find the perfect machine tool for your needs.