Why Almost All CNC Whirling Machines Are Customized?

You want to produce high-precision threads in seconds, but your standard machine setup keeps producing rejects. You tweak settings for hours, but the thread profile is still off.

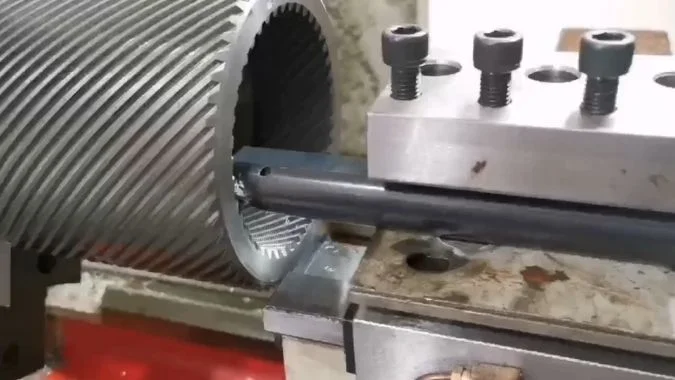

CNC whirling machines are almost always customized because the process relies on a "one-pass" forming method where the tool geometry must perfectly match the workpiece. Unlike standard turning, there is no room for error. Customization ensures the cutter angle, insert shape, and coolant systems align exactly with the thread profile and material properties.

Many shop owners try to use a "one-size-fits-all" whirling attachment. They end up with vibration marks and broken inserts. To get the speed and quality this technology promises, you have to tailor the machine to the part.

Why Do Complex Geometries Require Customized CNC Whirling Machines?

You cannot force a square peg into a round hole, yet many shops try to cut complex screw profiles with generic inserts. This leads to immediate failure.

Complex geometries, such as multi-start threads and asymmetrical worms, require customization because standard machines lack the flexibility for simultaneous multi-axis movements. A customized setup adjusts the cutter head helix angle and may utilize extended spindles or specialized tool holders to prevent collisions and ensure the insert matches the cross-sectional profile perfectly.

The core of CNC whirling1 is not just spinning a cutter; it is the precise coordination of motion. The cutter head spins at high speed while the workpiece moves slowly. This creates a "generative" cutting action. Because whirling finishes the thread in a single pass, the tool effectively acts as a negative mold of the final part.

If you are making a standard bolt, maybe a standard tool works. We see demands for multi-start worms, free-form surfaces, and complex medical bone screws.

Standard machines often struggle with these irregular shapes. They lack the necessary clearance or the ability to control tool orientation across multiple axes.

If the tool geometry does not match the workpiece exactly, two things happen:

- Collision and Interference: Standard holders might hit the workpiece when cutting steep angles or deep threads.

- Profile Error: The thread walls are not straight because the "swing" of the cutter does not match the pitch.

Customized tools solve this. We adjust the helix angle of the cutter ring to match the pitch of the screw. We might even engineer specific tool holders or modify the spindle design to handle tight curvatures. This ensures the insert enters and exits the cut cleanly. Without this customization, the tool rubs against the side of the thread, ruining the surface finish.

How Does Standardizing CNC Whirling Limit Precision and Tolerance?

Buying "off-the-shelf" tooling sounds cheaper, but it costs you more in the long run. Standard tools force you to accept "good enough" tolerances.

Standardization limits precision because generic tools often default to broader tolerances (around ±0.127mm) to accommodate various tasks, whereas whirling requires ±0.025mm or better. Customization accounts for specific variables like material expansion and vibration, preventing the inconsistencies in surface finish that occur when using fixed parameters for unique jobs.

When you use a standardized whirling setup, you are compromising. You are hoping that a general-purpose angle will work for a specific job. In my experience, hope is not a strategy.

The main enemy of precision in whirling is vibration and thermal drift. Standard machines impose fixed parameters on speeds and tooling. They do not account for the specific way your workpiece might expand when hot or vibrate under load.

The Tolerance Gap

General CNC machining might accept tolerances around ±0.005 inches (approx. 0.127mm). However, high-end whirling2 often demands tolerances as tight as ±0.001 inches (approx. 0.025mm). A standard machine simply cannot hold this because it lacks the rigidity or the fine-tuned calibration for that specific diameter.

The Consequence

If the tool does not match the profile, it creates unstable cutting forces. The machine starts to shake at a microscopic level. This vibration transfers to the workpiece.

The result? You fail to meet the "7-8 grade" thread accuracy standards. You get "chatter marks" on the thread flanks. Customization improves the surface roughness (Ra)3. By designing the cutter specifically for the job, we can achieve Ra values of 1.6 to 3.2μm. This is critical for parts like lead screws where friction must be minimized.

Why Do Advanced Materials Require Custom CNC Whirling Configurations?

Cutting soft aluminum is easy; cutting medical-grade titanium or Inconel is a war against heat and friction. You cannot use the same tactics for both.

Advanced materials like titanium alloys and Inconel require custom configurations because they have low thermal conductivity and high hardness. Customization allows for high-pressure coolant integration and specific insert coatings to manage heat buildup. Without these tailored adjustments, standard setups lead to rapid tool wear, work hardening, and part deformation.

Material properties dictate the machine setup. This is non-negotiable.

We categorize materials by their "personality."

- Hard Materials (Hardened Steel HRC35-45): These eat tools. We need to customize the insert with high wear resistance and reinforced coatings.

- Heat-Sensitive Materials (Titanium, Inconel)4: These materials do not conduct heat well. The heat stays in the cutting edge and the part, causing warping. Standard flood coolant is often not enough. We often need to customize the machine with high-pressure coolant systems that target the cutting zone directly to evacuate chips and heat.

- Sticky Materials (Aluminum, Soft Steel): These want to stick to the cutter. If chips accumulate, they clog the whirling ring. We must customize the chip evacuation path.

Here is a real example. We had a customer making orthopedic implants from titanium. With a standard setup, the heat was warping the screws.

We customized the process. We changed the cutting parameters and the insert geometry to reduce the cutting force.

The Result: The cycle time dropped from 2 minutes to 35 seconds. The defect rate fell to near zero. We also use "layered milling" tools. These have separate roughing and finishing edges on the same insert. This extends tool life significantly.

| Material | Challenge | Customization Strategy |

|---|---|---|

| Titanium/Inconel | Heat & Low Conductivity | High-pressure coolant, sharp angles |

| Hardened Steel | Rapid Tool Wear | Reinforced coatings, rigid cutter design |

| Aluminum | Chip Clogging | Polished flutes, optimized evacuation path |

How Does Customization Improve Efficiency in CNC Whirling Operations?

Slow cycle times kill profit margins. You need a machine that thinks faster than the operator and cuts without hesitation.

Customization improves efficiency by optimizing tool paths and integrating the whirling unit into composite equipment like Swiss-type lathes, which can extend tool life by up to 50%. Custom CNC systems minimize "air cutting" time and streamline debugging, allowing for faster setups and continuous, automated production runs with reduced waste.

Efficiency is not just about the cutter spinning faster. It is about the whole system working together.

When we customize a CNC whirling machine, we look at the software and the workflow.

1. System Optimization5

We modify the CNC algorithms. For a specific thread, we can optimize the acceleration and deceleration ramps. We use "multi-axis linkage" to coordinate the movements perfectly. This cuts out milliseconds from every rotation. Over a run of 10,000 parts, that is huge.

2. Tool Life and Cost6

By tailoring the tool geometry to the exact load, we reduce unnecessary wear. Research and our own experience show that custom tooling can extend tool life by up to 50% compared to using generic inserts that "rub" rather than cut. This lowers the cost per part significantly.

3. Simulation and Verification

We use advanced simulation software to verify the cut before machining. This shortens the "debugging cycle." You do not waste time or material testing on the machine; you test on the computer. This eliminates the risk of collision and ensures that when you press "start," the first part comes out correct. This customization turns a standalone machine into an automated production cell.

Conclusion

CNC whirling is a specialized process that demands customization. By tailoring the tool geometry, material handling, and control software, you transform a standard machine into a high-precision, high-speed production engine that reduces waste and guarantees strict tolerances.

-

Explore this link to understand the intricacies of CNC whirling and its applications in precision machining. ↩

-

Explore this link to understand how high-end whirling can enhance precision and meet stringent tolerances in machining. ↩

-

Discover techniques to improve surface roughness (Ra) for better performance in precision parts like lead screws. ↩

-

Explore this link to learn effective strategies for machining heat-sensitive materials, ensuring better performance and reduced defects. ↩

-

Explore this link to discover effective strategies for optimizing CNC systems, enhancing efficiency and productivity. ↩

-

This resource provides insights on extending tool life and reducing costs, crucial for maximizing manufacturing efficiency. ↩

Chris Lu

Leveraging over a decade of hands-on experience in the machine tool industry, particularly with CNC machines, I'm here to help. Whether you have questions sparked by this post, need guidance on selecting the right equipment (CNC or conventional), are exploring custom machine solutions, or are ready to discuss a purchase, don't hesitate to CONTACT Me. Let's find the perfect machine tool for your needs.