Why Are Fiber Laser Cutters Preferred Over CO₂ Laser Cutters for Metal Cutting?

You want to cut metal efficiently, but choosing between technologies is confusing. Picking the wrong laser wastes energy and money. Fiber technology is the clear winner for modern metal fabrication.

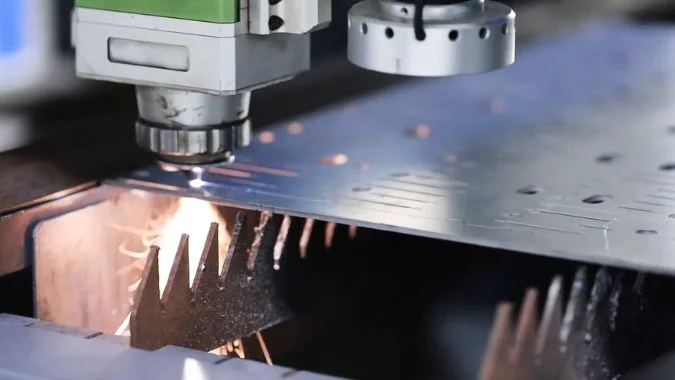

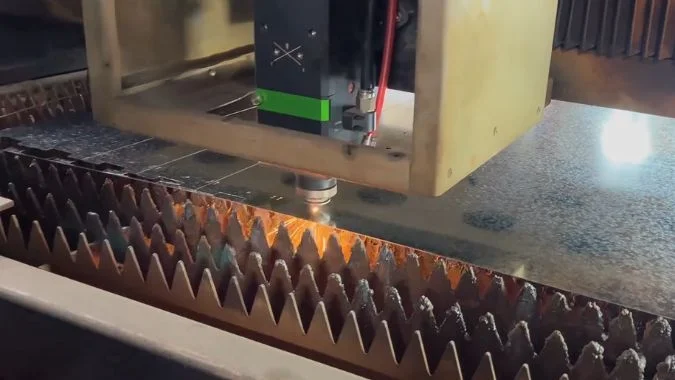

Fiber laser cutters are preferred for metal because their shorter wavelength is absorbed more efficiently by metals, resulting in faster cutting speeds on thin sheets. They offer 25-30% electro-optical efficiency compared to 8-10% for CO₂, drastically reducing energy bills. Additionally, their solid-state design eliminates mirror maintenance and gas consumables.

In the modern metal fabrication industry, the move toward fiber laser technology is a logical progression. While CO₂ lasers remain versatile for non-metals, they are no longer the most effective tool for metalwork. Today’s competitive market demands the high-speed throughput and low operational overhead that only fiber technology can deliver, making it the clear choice for any shop focused on metal processing.

How Does the Wavelength of a Fiber Laser Improve Absorption in Metal Materials?

Reflective metals like aluminum ruin older lenses. Fighting back reflections causes downtime. Science proves shorter wavelengths solve this absorption problem instantly.

Fiber lasers operate at a wavelength of 1.06 μm, ten times shorter than CO₂. This "near-infrared" wavelength couples easily with the free electrons in metals, significantly reducing reflection. This allows for efficient cutting of highly reflective materials like copper and aluminum, which often bounce energy back into CO₂ optics.

I have seen clients struggle with copper. They try to cut it with a CO₂ machine. The beam bounces off the surface like light off a mirror. This is dangerous for the machine optics. The physics is simple but critical.

The Physics of Absorption

A CO₂ laser has a wavelength1 of 10.6 μm. This is considered "far-infrared." Metal surfaces, especially shiny ones like aluminum and silver, act as a shield against this wavelength. They reflect the energy away. A fiber laser uses 1.06 μm. This is "near-infrared." It interacts with the "free electron" system in the metal. The metal cannot reflect it as easily. It absorbs the energy.

Heat Generation and Surface Treatment

Because the metal absorbs the light, it gets hot instantly. The energy transfer is efficient. You do not need to use high power just to break through the surface reflection. You also do not need to apply special coatings or absorption sprays to the metal before cutting. We see this specifically with stainless steel. The short wavelength creates a "micro-level light trapping structure2." It turns the surface black. It melts fast. This is why you can cut conductive metals on a fiber laser without damaging the source through back-reflection3.

| Feature | Fiber Laser | CO₂ Laser |

|---|---|---|

| Wavelength | ~1.06 μm (Near-Infrared) | ~10.6 μm (Far-Infrared) |

| Absorption | High (Couples with electrons) | Low (Reflects off surface) |

| Reflective Metals | Excellent (Cu, Al, Ag) | Poor (Risk of damage) |

What Are the Differences in Cutting Speed Between Fiber and CO₂ Lasers on Thin Sheet Metal?

Slow cutting speed4s kill your production margins5. Waiting for parts creates bottlenecks. Fiber lasers utilize concentrated energy to slash processing times for thin metals.

For metal sheets under 6mm, fiber lasers are significantly faster, often reaching speeds 3 to 5 times higher than CO₂ systems. The beam focuses to a much smaller spot size, creating high power density that melts material instantly. A 1.5kW fiber machine can match the output of a 3kW CO₂ machine.

Speed is money in a production shop. If you are cutting thin gauge sheet metal, fiber is a race car. The difference comes down to focus and density.

Spot Size and Power Density

A fiber laser beam can be focused into a tiny spot. It is much smaller than a CO₂ beam spot. Imagine pressing a needle versus pressing a thumb. The needle goes through easier. The fiber beam concentrates all its energy into that tiny point. This creates incredible power density6. The metal vaporizes instantly. This is why fiber lasers dominate in high-volume production environments like automotive manufacturing7.

The Speed Advantage

I tell my clients to look at their material thickness. If you cut mostly under 6mm, fiber wins. For 1mm to 3mm stainless steel, a fiber laser is typically 2 to 3 times faster than a CO₂ laser of the same power. In some specific scenarios, speeds can reach up to 20 meters per minute, making it up to 5 times faster. A 1.5kW fiber machine cuts as fast as a 3kW CO₂ machine. You get more production with half the power rating.

Edge Quality and Heat Zones

Speed usually means bad quality, but not here. Because the fiber laser melts the metal so fast, the heat does not spread. The "Heat Affected Zone8" is small. The cut is clean. You get fewer burrs. You do not need to grind the edges later. CO₂ is still good for very thick plates (above 8mm) where edge smoothness matters more than speed, but for thin sheets, it is too slow and puts too much heat into the part.

What Are the Energy Efficiency Advantages of Fiber Lasers Over CO₂?

High electricity bills eat into your monthly profits. Inefficient machines turn dollars into useless waste heat. Fiber technology converts power directly into cutting performance.

Fiber lasers achieve an electro-optical conversion efficiency of 25-30% or higher, compared to just 8-10% for CO₂. This means a fiber system uses roughly 70% less electricity to do the same work. The reduced heat generation also lowers the demand on cooling systems9 and eliminates warm-up times.

Look at your electric meter. A CO₂ laser is basically a heater that also cuts metal. It is incredibly inefficient. This is the main reason our customers switch to fiber.

The Conversion Ratio

"Electro-optical conversion efficiency" sounds technical, but it is just a measure of waste. A CO₂ laser is roughly 10% efficient. That means for every $100 of electricity you buy, only $10 turns into a laser beam. The other $90 turns into waste heat. A fiber laser is roughly 30% efficient. You get three times the beam power for the same electricity. This is often called "wall-plug efficiency."

The Chiller and Warm-Up Effect

It is not just the laser source. Because CO₂ lasers10 create so much waste heat, you need a massive water chiller to keep them cool. That chiller uses a lot of power. Fiber lasers run cooler. You can use a smaller chiller. This saves even more electricity. Also, CO₂ lasers often need warm-up time to stabilize the gas. Fiber lasers are instant-on. There is no idle energy waste waiting for the machine to get ready.

Total Operating Cost

When you add it all up, a fiber laser uses 20% to 30% of the power of a CO₂ machine. If you run a machine all day, this is huge. You save on the laser power. You save on the chiller power. You save on the HVAC bill for your factory because the machine is not heating up the room. Over five years, these savings can pay for a large portion of the machine itself.

Why Does a Fiber Laser Cutter Require Significantly Less Maintenance Than a CO₂ System?

Machine downtime for alignment kills your schedule. Fragile mirrors and gas mixes cause constant headaches. Solid-state fiber engines run for thousands of hours without intervention.

Fiber lasers are solid-state devices with no moving parts inside the source. The beam travels through a sealed cable, eliminating the need for mirror alignment, gas mixing, or resonator cleaning. While CO₂ tubes need replacement every 20,000 hours, fiber modules can last over 100,000 hours.

I have seen maintenance crews spend days fixing CO₂ beam paths. It is a nightmare. The machine has to stop. The production stops. You lose money. Fiber lasers solve this by changing the design completely.

No Mirrors, No Alignment

A CO₂ laser uses mirrors to bounce the beam from the back of the machine to the cutting head. These mirrors get dirty. They get hot. If the machine vibrates, they move. You have to align them constantly. Fiber lasers use a glass fiber cable. It is like a garden hose for light. You can shake it, move it, or bend it. The beam always stays inside. You never have to align the beam path.

Solid State Durability

CO₂ lasers use gas mixtures and high-voltage turbines to circulate that gas. These are mechanical parts. They wear out. You have to replace vacuum pumps and glass tubes. Fiber lasers are "solid state." They use semiconductor diodes and doped optical fibers. There are no moving parts inside the laser source. There is nothing to wear out.

Lifespan Differences

A typical CO₂ tube or turbine lasts about 20,000 to 30,000 hours. Then you face a major repair bill. Fiber laser modules last over 100,000 hours. That is over 10 years of normal use. You do not need to buy laser gas bottles. You do not need a clean room environment. Dust does not hurt the fiber source because it is sealed. The only maintenance you do is wiping the cover glass on the cutting head.

Conclusion

Fiber lasers dominate metal cutting through speed, efficiency, and low maintenance. While CO₂ remains useful for non-metals like wood or plastics, fiber is the only logical choice for profitable metal fabrication shops.

-

Explore how the wavelength of fiber lasers enhances their cutting ability on various metals. ↩

-

Understand the innovative micro-level light trapping structure that improves cutting efficiency. ↩

-

Learn about back-reflection and its impact on laser cutting performance, especially with CO₂ lasers. ↩

-

Understand the significant cutting speed advantages of fiber lasers over CO₂ lasers for metal sheets. ↩

-

Discover how efficient laser cutting can enhance production margins and profitability. ↩

-

Explore the concept of power density and its crucial role in achieving fast and efficient laser cutting. ↩

-

Find out how fiber lasers are revolutionizing the automotive manufacturing process. ↩

-

Learn about the Heat Affected Zone and how fiber lasers minimize it for better edge quality. ↩

-

Understand the role of cooling systems in laser cutting machines and how fiber lasers reduce their need. ↩

-

Discover the limitations of CO₂ lasers and why fiber lasers are preferred for metal cutting. ↩

Chris Lu

Leveraging over a decade of hands-on experience in the machine tool industry, particularly with CNC machines, I'm here to help. Whether you have questions sparked by this post, need guidance on selecting the right equipment (CNC or conventional), are exploring custom machine solutions, or are ready to discuss a purchase, don't hesitate to CONTACT Me. Let's find the perfect machine tool for your needs.