Why Are Profile Machining Centers Essential for Window, Door, and Facade Production?

Chris Lu

Leveraging over a decade of hands-on experience in the machine tool industry, particularly with CNC machines, I'm here to help. Whether you have questions sparked by this post, need guidance on selecting the right equipment (CNC or conventional), are exploring custom machine solutions, or are ready to discuss a purchase, don't hesitate to CONTACT Me. Let's find the perfect machine tool for your needs.

Chris Lu

Leveraging over a decade of hands-on experience in the machine tool industry, particularly with CNC machines, I'm here to help. Whether you have questions sparked by this post, need guidance on selecting the right equipment (CNC or conventional), are exploring custom machine solutions, or are ready to discuss a purchase, don't hesitate to CONTACT Me. Let's find the perfect machine tool for your needs

Struggling with slow, error-prone manual processing of long aluminum, PVC, or even steel profiles? These bottlenecks hurt delivery times, compromise quality, and make it hard to compete in the demanding window, door, and facade market.

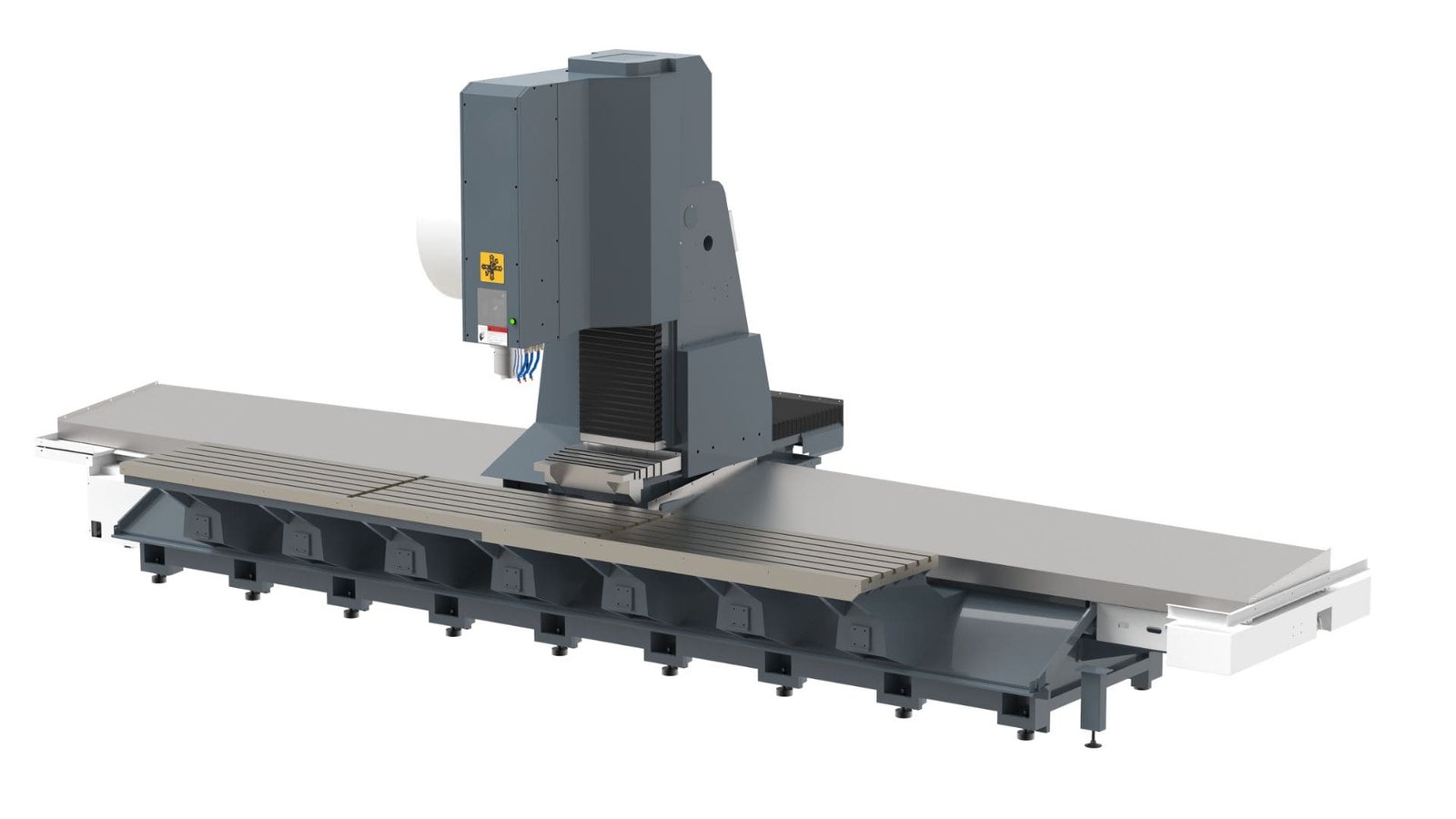

Profile machining centers are essential because they offer high precision and automated efficiency, consolidating multiple operations like cutting, milling, drilling, and tapping on long profiles (aluminum, PVC, steel, etc.) in a single setup, drastically boosting productivity and quality.

These specialized CNC machines aren’t just bigger versions of standard machining centers. They are specifically engineered for the unique challenges of processing the long, often complex extrusions used in building envelopes. Understanding their specific advantages makes their indispensability clear.

What Are the Core Advantages of a Profile Machining Center?

Considering a profile center but unsure if the investment truly pays off? Justifying the cost requires a clear understanding of the specific, powerful advantages it brings over traditional methods or standard machines.

Core advantages include high automation for efficiency, exceptional precision for quality, consolidating many processes to cut costs and save space, high flexibility for diverse jobs, and intelligent features for easier operation and maintenance.

At J&M Machine Tools, we consistently see these benefits transform workshops. Your detailed research confirms these strengths:

- Multi-functionality & Process Consolidation1: They combine numerous tasks (cutting, drilling, milling, tapping, even screwing) onto one platform. This eliminates the need for multiple separate machines, streamlining workflow dramatically. Think of it as turning several production steps into one efficient pass.

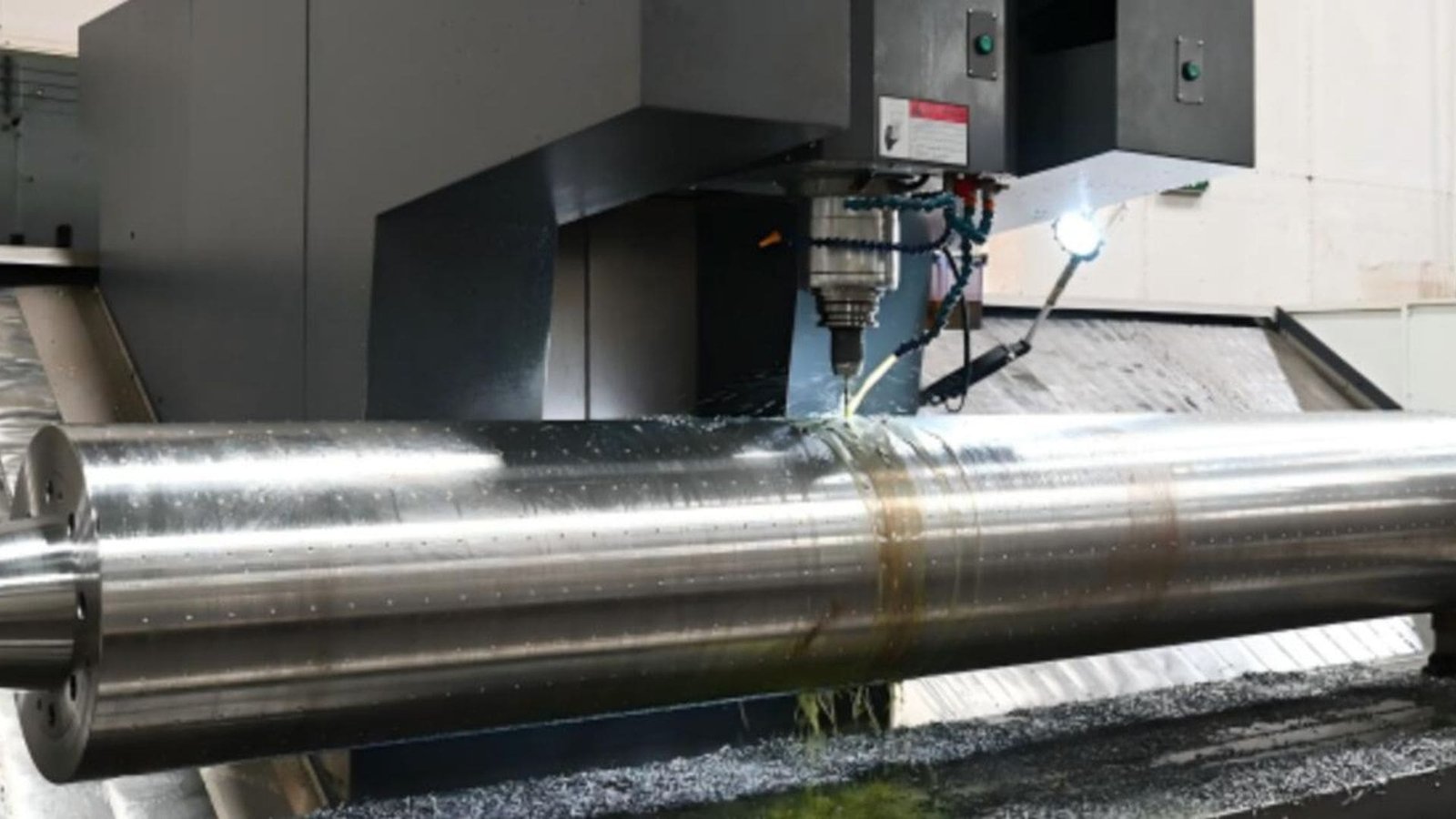

- High Automation & Efficiency2: Advanced CNC systems enable automated cycles, often 24/7 operation with minimal supervision. Features like automatic tool changers (with up to 16 tools changing in seconds) and automated loading/unloading systems significantly reduce labor, shorten cycles, and boost throughput (often by over 30%).

- Exceptional Precision & Quality3: CNC control delivers micron-level accuracy (e.g., ±0.01mm) and high repeatability. This is critical for window and door components needing tight tolerances for sealing and assembly. Automation minimizes human error, ensuring consistent quality.

- High Flexibility & Versatility: These centers handle various materials (aluminum, PVC, steel, brass) and complex profile shapes. Easy program updates allow quick adaptation to design changes without costly retooling, making them ideal for both small batches and large-scale production.

- Space and Cost Savings: By consolidating operations, they require less floor space than multiple traditional machines. Reduced handling, less scrap, lower labor needs, and optimized energy use contribute to significant cost savings. Their modular design can also simplify maintenance.

How Does the Extended X-Axis Travel Typically Found on Profile Centers Benefit Production?

Dealing with long 6-meter or even longer extrusions on standard machines is awkward, slow, and error-prone? Multiple setups increase handling time, risk damage, introduce potential inaccuracies, and cripple production flow for large windows, doors, or facade elements.

The extended X-axis travel (often 6.5m, but up to 74 feet+ on some models!) allows complete machining of very long profiles in a single clamping, drastically reducing handling, improving accuracy, speeding up throughput, and enabling larger product designs.

This feature is fundamental to their design, addressing a core industry need. Your research highlights how crucial this is:

- Handling Standard & Oversize Lengths: Extrusions often come in 6-meter lengths, but architectural designs may require even longer sections. Profile centers are built with X-axis travels (from around 2.5m to over 22m) to accommodate these without repositioning. This avoids cutting long pieces down and rejoining them later.

- Single Setup Efficiency4: Machining the entire length in one setup is a massive time saver. It eliminates the labor and machine downtime associated with unclamping, moving, precisely realigning, and re-clamping long, potentially flexible parts.

- Maximized Productivity (Pendulum Processing)5: Some machines with very long beds offer "pendulum processing." While the spindle works on a part at one end, the operator can safely load or unload another part at the opposite end. This keeps the spindle running almost continuously, maximizing output.

- Improved Accuracy & Reduced Waste: Every re-clamping introduces potential error. Machining in one go ensures all features are perfectly aligned along the full length. It also reduces the risk of damage during handling and minimizes waste from multiple setups.

- Optimized Worktable Design: The long, narrow worktable efficiently supports these profiles, often with specialized clamping systems designed for various shapes.

Can Profile Centers Reduce Setup Times by Machining Multiple Faces in a Single Clamping?

Spending far too much time flipping, rotating, and re-clamping profiles just to machine different sides or angles? Each setup takes valuable operator and machine time, introduces potential positioning errors, and significantly slows the completion of complex window, door, or facade components.

Absolutely. Profile centers dramatically slash setup times by using multiple CNC-controlled axes (X, Y, Z) combined with rotating spindle heads (A/C axes) or tables to access and machine multiple faces (often 3, 4, or even 5 sides) of the profile in just one clamping.

This multi-sided access is a cornerstone of their efficiency. Your insights confirm this capability:

- Advanced Axis Configuration6: Beyond the standard X, Y, and Z, many profile centers incorporate rotary axes. An A-axis might tilt the spindle around the X-axis, a C-axis might rotate the spindle around the Z-axis, or specialized fixtures might rotate the part itself.

- Access Without Re-clamping: This combination allows the cutting tool to reach the top, sides, ends, and even angled surfaces of the profile while it remains securely clamped in its original position. Machines capable of 5-sided machining7 are common.

- Streamlined Workflow: Imagine all the milling, drilling, and tapping needed on three or more sides of a window frame profile being completed sequentially without the operator intervening to reposition the part. This transforms the workflow, turning multiple operations into one continuous process. Models like the Thorwesten PBZ are designed specifically for this kind of "one pass" efficiency.

- Huge Time Savings: Eliminating multiple setups directly translates to less machine downtime and less operator labor per part.

- Enhanced Accuracy: Keeping the part in a single, fixed clamping ensures much higher positional accuracy between features on different faces compared to methods involving manual repositioning.

What Range of Operations Can Be Consolidated onto a Single Profile Machining Center?

Still using separate machines for sawing, milling, drilling, and tapping profiles, leading to workflow chaos? Moving parts between stations eats up time, increases the risk of handling damage, demands excessive floor space, and makes production scheduling a nightmare.

Profile machining centers are incredibly versatile, consolidating a vast range of operations including cutting, sawing, milling (pockets, faces, contours, slots, end-milling), drilling, tapping, reaming, countersinking, routing, engraving, marking, flow drilling, and even screwing/assembly tasks.

The goal is "done-in-one8" machining. These machines function as complete processing stations for profiles, equipped for nearly every task needed for window, door, and facade fabrication9:

| Operation | Description | Benefit of Consolidation |

|---|---|---|

| Cutting/Sawing | Cutting profiles accurately to final length. | Eliminates separate saw station. |

| Milling | Pockets, face milling, contouring, slots, end milling, notching. | Handles complex shaping/joinery. |

| Drilling | Fastener holes, weep holes, hardware mounts, drainage holes. | Precise hole location and size. |

| Tapping | Creating internal threads for screws. | Ready for fastener assembly. |

| Reaming | Enlarging/finishing drilled holes to precise diameters. | Ensures accurate fits for pins/dowels. |

| Countersinking | Conical recesses for flat-head screws. | Provides flush fastener mounting. |

| Routing/Engraving | Complex shapes for locks, handles, hinges; adding markings. | Handles specific hardware/identification. |

| Marking | Adding part numbers, alignment marks, or identifiers. | Aids assembly and traceability. |

| Flow Drilling | Creates extruded holes in thin materials for stronger threads. | Specialized fastening technique. |

| Scraping/Cluttering | Specific cleaning or preparation operations. | Improves finish or assembly fit. |

| Screwing | Some advanced centers can automatically insert screws. | Integrates assembly steps. |

| Special Ops | Lock case milling, handle slot opening, circle/oblong hole milling. | Caters to specific component needs. |

By integrating this wide array of operations, profile centers drastically reduce the need for multiple machines, minimize part movement and associated risks, simplify production flow, and significantly cut overall costs while boosting quality and speed.

Conclusion

Profile machining centers are indispensable for modern window, door, and facade manufacturers. Their ability to precisely, efficiently, and flexibly handle long parts, perform numerous operations, and machine multiple faces in one setup drives productivity and quality essential for competitiveness.

-

Explore how multi-functionality can streamline your workshop operations and enhance productivity. ↩

-

Discover the impact of automation on efficiency and labor reduction in CNC machining processes. ↩

-

Learn why precision is crucial for manufacturing quality components and how it affects overall production. ↩

-

Exploring this resource will provide insights into how single setup efficiency can significantly enhance productivity and reduce costs in machining processes. ↩

-

This link will help you understand the innovative pendulum processing technique and its impact on machining efficiency and output. ↩

-

Explore this link to understand how advanced axis configurations enhance machining efficiency and precision. ↩

-

Discover the advantages of 5-sided machining and how it can streamline your manufacturing processes. ↩

-

Explore this link to understand how done-in-one machining can streamline your manufacturing process and enhance efficiency. ↩

-

Discover the latest innovations in window, door, and facade fabrication to stay ahead in the industry. ↩