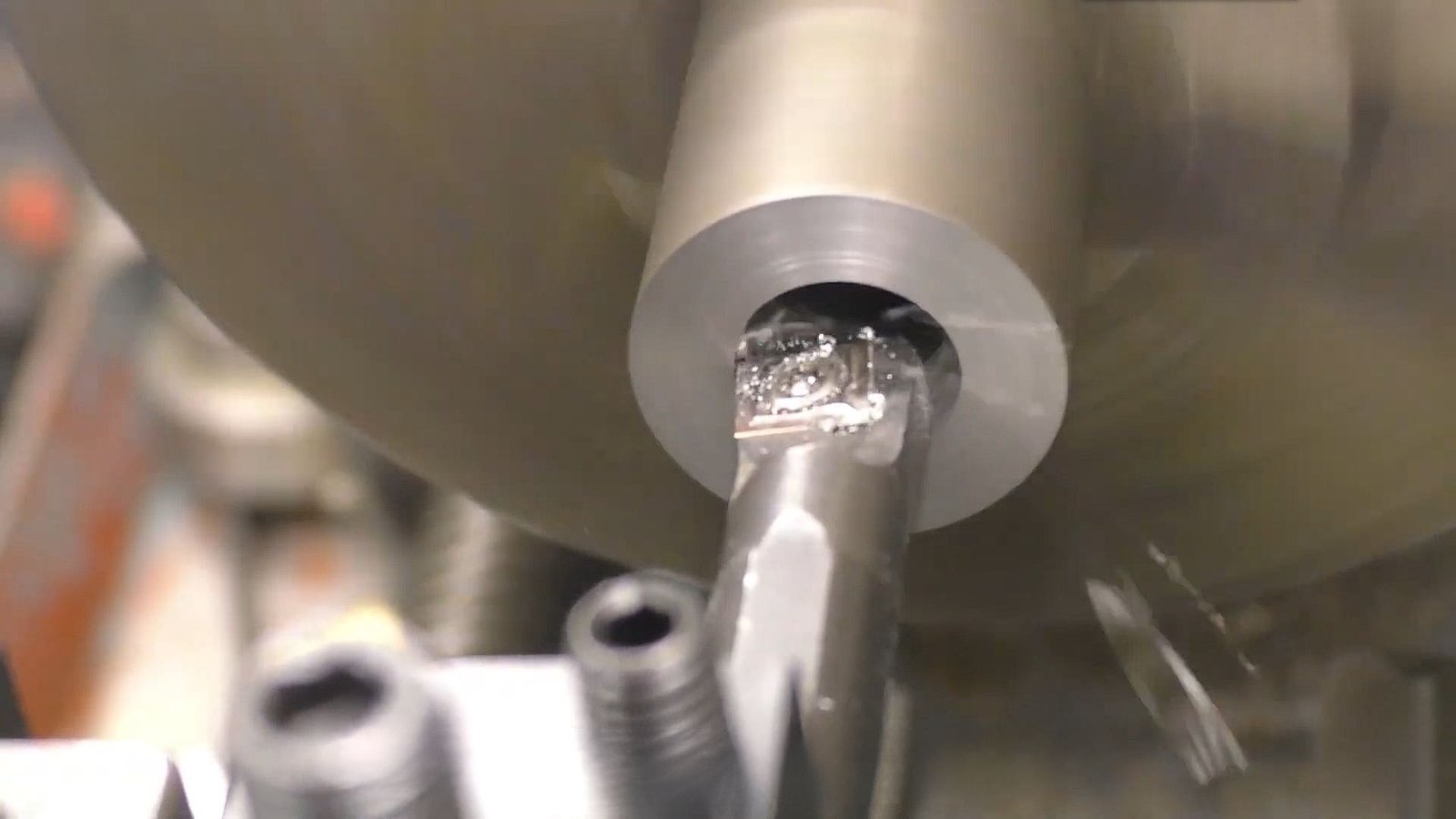

Need to create precise internal holes in a workpiece, maybe deep ones, large ones, or with critical tolerances? You might wonder if your trusty lathe is up to the task, or if you really need a dedicated boring machine. Trying to push a lathe beyond its limits for complex boring can lead to inaccuracies, chatter, tool deflection, and difficulty handling large or awkwardly shaped parts.

A boring machine is generally preferred because it’s specifically designed for high-precision boring of large, deep, or complex holes. It offers greater rigidity, handles larger/more complex workpieces (like engine blocks), and features specialized capabilities like extendable spindles, making it more accurate and efficient for demanding boring tasks than a standard lathe.

While CNC lathes can perform some boring, they are primarily designed for external turning with the workpiece rotating. Boring machines, conversely, are built specifically for enlarging and finishing internal diameters with high precision, often on stationary or controllably rotated workpieces. This fundamental design difference, along with features tailored for accuracy, makes them the superior choice for most serious boring work, especially when dealing with challenging geometries or tight tolerances.

What Level of Precision and Accuracy Can Be Expected from a CNC Boring Machine for Critical Hole Tolerances?

Dealing with parts for aerospace or medical devices that demand extremely tight tolerances on hole diameters, positions, and geometry? You might worry if any machine can reliably deliver the necessary precision for such critical components. Relying on less capable methods is often not an option and can lead to costly failures.

CNC boring machines are capable of achieving very high levels of precision, typically reaching IT7 to IT6 tolerance grades (translating to roughly ±0.0005 inches or better) for precision boring in steel, with excellent surface finishes often ranging from Ra 0.63 down to 0.08 micrometers.

Achieving this requires a high-quality machine, precise setup, and optimized processes. Here’s what contributes to that accuracy:

- Understanding Tolerances: IT (International Tolerance) grades quantify precision, with lower numbers meaning tighter tolerances. While IT9-IT7 might be standard, precision boring often targets IT7-IT61. Achieving tolerances like ±0.0005 inches (around 13 micrometers) or even tighter (down to 5 microns mentioned in some contexts) is feasible with careful setup. This ensures holes are round, straight, and precisely located.

- Surface Finish (Ra)2: Low Ra values (0.63-0.08 μm) mean a very smooth surface, crucial for sealing, bearing fits, or reducing friction.

- Key Factors: High machine rigidity minimizes vibration. Quality tooling (sharp, balanced, minimal spindle runout, correct holders) is essential. Optimized cutting parameters (speed, feed) and proper coolant application are critical. Secure workpiece clamping prevents movement. The CNC control itself ensures consistent, programmed execution, reducing human error compared to manual methods.

Precision boring machines are therefore ideal for critical fits like bearing seats3, engine cylinder bores4, and components where mating part accuracy is paramount.

| Tolerance Level | Typical IT Grade (Steel) | Approx. Inch Tolerance | Typical Surface Roughness (Ra) | Application Example |

|---|---|---|---|---|

| General Boring | IT9 – IT7 | > ±0.001" | > 0.8 μm | Clearance holes, basic fits |

| Precision Boring5 | IT7 – IT6 | ±0.0005" or better | 0.63 – 0.08 μm | Bearing seats, engine bores, fits |

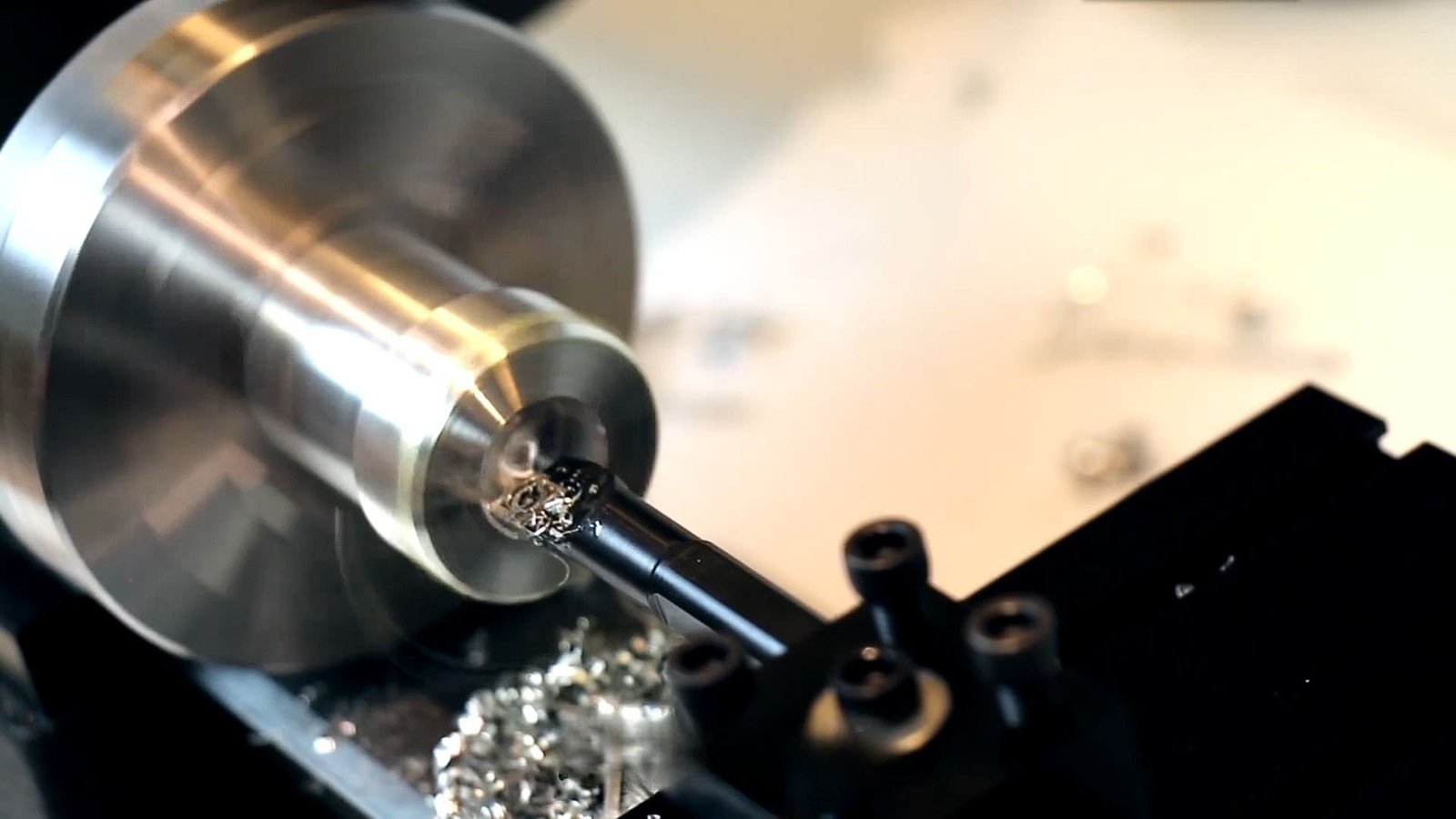

How Does the Extendable Spindle Enhance the Capabilities of CNC Boring Machines?

Need to bore deep inside a heavy casting or reach internal features blocked by other parts of the workpiece? Using standard-length tooling might be impossible or require extremely long, flexible tools that compromise accuracy. This is where the extendable spindle, a key feature of many boring machines, shines.

The extendable spindle (often called a W-axis or boring quill) allows the cutting tool to automatically extend or retract axially, independent of the main machine axes. This dramatically increases machining reach for deep holes and internal features while often maintaining better rigidity than using very long tool extensions.

This feature significantly boosts versatility and addresses common machining challenges:

- Mechanism: It involves an inner spindle (holding the tool) that slides axially within the main rotating headstock assembly. Power is transmitted for rotation, but this inner spindle can move in and out based on the CNC program. Ingenious designs involving intermediate shafts and flanges allow this movement without problematic friction between the moving and stationary parts.

- Deep Hole Capability6: The most obvious benefit is reaching deep inside parts to bore holes or machine features that would be inaccessible with fixed spindles or standard tooling lengths.

- Improved Rigidity for Reach7: Compared to using excessively long, custom boring bars (which are prone to deflection and vibration), extending the machine’s own robust spindle often provides a more stable cutting condition deep inside the part, leading to better accuracy and surface finish.

- Flexibility & Reduced Setups8: It allows machining of various features at different depths (e.g., bores, counterbores, internal faces, spotfacing) within a single workpiece clamping. This saves considerable setup time, reduces handling, and improves the positional accuracy between machined features.

The extendable W-axis makes CNC boring machines exceptionally adaptable for complex internal machining tasks common in industries dealing with large or intricate components.

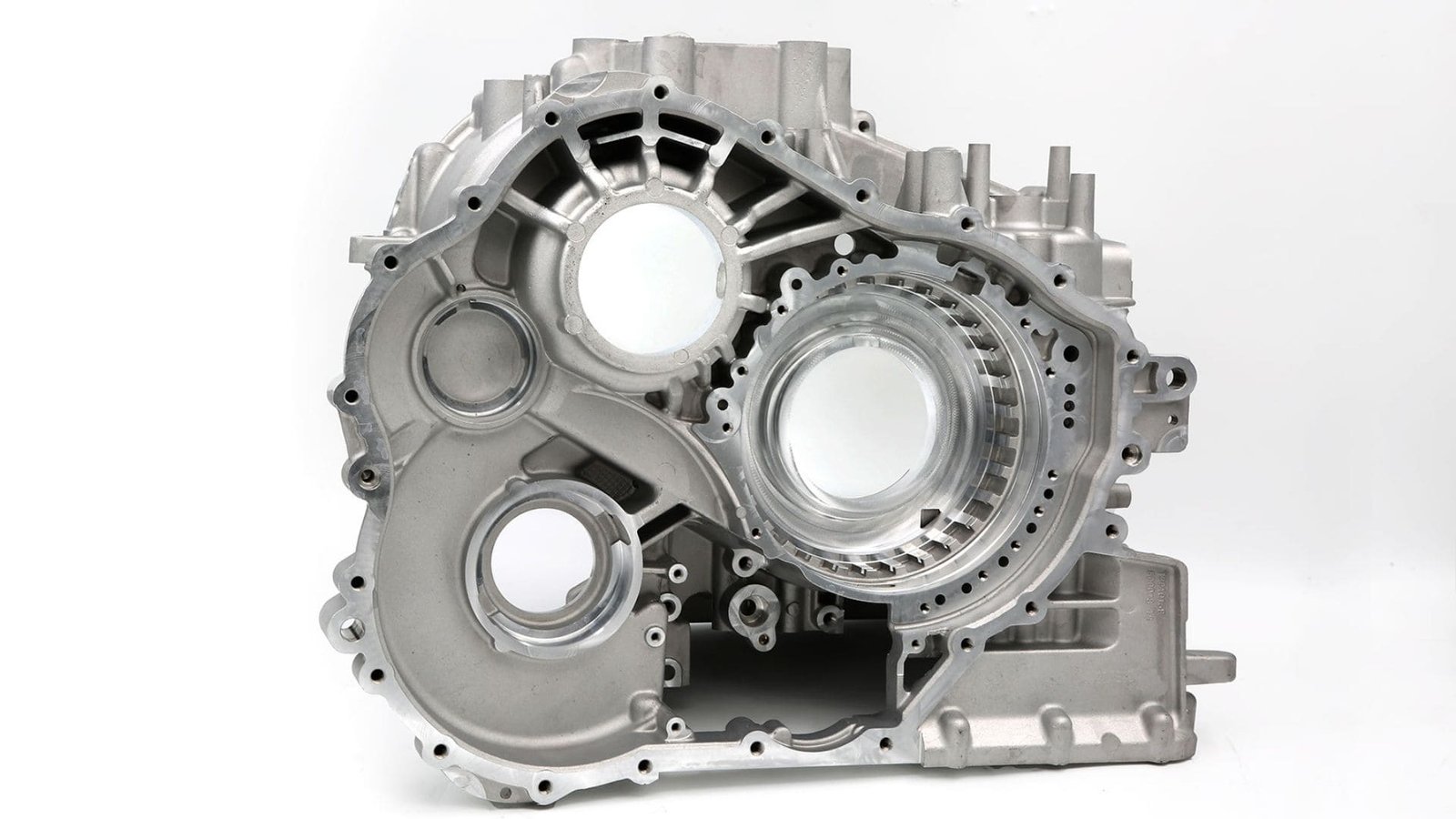

What Kinds of Workpieces are Best Suited for Machining on a CNC Boring Machine?

Wondering if your parts justify using a dedicated boring machine? While versatile, these machines truly excel with certain types of components where their size capacity, rigidity, and precision boring capabilities offer significant advantages over standard mills or lathes.

CNC boring machines are ideal for large, heavy, or awkwardly shaped parts, particularly box-type components (like gearboxes, engine blocks) and any workpiece requiring high-precision machining of complex internal hole systems, often involving features on multiple faces or deep within the part.

Here’s why these parts are a perfect match:

- Box-Type Parts: Components like transmission housings, pump bodies, machine tool structures, and engine blocks often have:

- Machining on Multiple Sides: Horizontal boring machines with rotary tables allow easy access to multiple faces in fewer setups, critical for maintaining relationships between features.

- Complex Hole Systems9: They usually require multiple bores (for shafts, bearings, cylinders) needing precise diameters, locations, parallelism, and perpendicularity. Boring machines provide the necessary accuracy and control.

- Size and Weight: These parts often exceed the capacity of typical lathes or milling machines. Boring machines are built to handle substantial size and weight.

- Parts with Critical Internal Features: Any component demanding high accuracy for its bores (diameter, roundness, straightness, position) is a prime candidate, especially if boring is the finishing step for tight tolerances.

- Deep or Long Bores: The extendable spindle capability makes boring machines highly suitable for parts where the hole depth is significant relative to the diameter.

- Secure Fastening: The need for high precision means workpieces must be rigidly fixtured using clamps, vises, or specialized fixtures to ensure stability during the machining process.

If your workpiece is large, intricate, and the accuracy of its internal bores is non-negotiable, a CNC boring machine is often the most effective solution.

What major industries rely on CNC boring machines as essential machine tools?

Curious where these powerful and precise machines make the biggest impact? Understanding the key sectors that depend heavily on CNC boring highlights their crucial role in manufacturing high-value, critical components where failure is not an option. Their capabilities are often indispensable.

Major industries including Aerospace, Automotive, Heavy Machinery, Energy (Oil & Gas, Power Generation), Mold & Die Making, Defense, and Medical Device manufacturing rely heavily on CNC boring machines for producing essential components demanding large, deep, or highly accurate internal features.

The precision, power, and capacity of CNC boring machines make them vital across these demanding sectors:

- Aerospace: Machining engine components (turbine casings10, shafts), landing gear parts, and structural frames requiring tight tolerances and reliability.

- Automotive: Essential for engine blocks (cylinder bores, crankshaft/camshaft bores), transmission housings, differential housings, ensuring performance and longevity.

- Heavy Machinery / Industrial Equipment: Manufacturing components for construction/mining equipment, large gearboxes, pumps, and presses involving large, robust parts with critical bores.

- Energy & Power Generation: Producing turbine casings, generator housings, valve bodies, and components for oil & gas extraction (e.g., drill pipes, wellhead equipment) operating under extreme conditions.

- Mold & Die Making: Creating precise cavities, cores, guide pin holes, and other features in large injection molds, forging dies, and stamping dies.

- Defense: Manufacturing components for military vehicles, artillery systems, and other equipment requiring high precision and durability.

- Medical Devices: Although often smaller scale, precision boring is used for creating components for surgical instruments, diagnostic equipment, and implants where accuracy is paramount.

In these industries, the ability to accurately machine large, complex internal features makes CNC boring machines a cornerstone of advanced manufacturing.

Conclusion

While lathes serve basic boring needs, dedicated CNC boring machines are overwhelmingly preferred for most complex or high-precision tasks. Their superior rigidity, accuracy potential (often reaching IT6 tolerance), capacity for large parts, and features like extendable spindles make them indispensable across critical manufacturing industries.

-

Understanding IT7-IT6 tolerances is crucial for achieving high precision in engineering. Explore this link to deepen your knowledge. ↩

-

Surface Finish (Ra) is vital for performance in engineering applications. Learn more about its significance and measurement techniques. ↩

-

Learn about the manufacturing process of bearing seats and why precision is crucial for performance. ↩

-

Discover the significance of precision in engine cylinder bores for optimal engine performance and longevity. ↩

-

Explore this link to understand how Precision Boring enhances accuracy and efficiency in manufacturing processes. ↩

-

Explore how deep hole capability enhances machining efficiency and precision, especially for complex components. ↩

-

Learn about the importance of rigidity in CNC machining and how it leads to better accuracy and surface finish. ↩

-

Discover how flexibility and reduced setups can save time and improve accuracy in machining processes. ↩

-

Learn about the challenges and solutions in machining complex hole systems, crucial for high-precision components. ↩

-

Learn about turbine casings to see their importance in aerospace and energy, ensuring efficiency and reliability in operations. ↩

Chris Lu

Leveraging over a decade of hands-on experience in the machine tool industry, particularly with CNC machines, I'm here to help. Whether you have questions sparked by this post, need guidance on selecting the right equipment (CNC or conventional), are exploring custom machine solutions, or are ready to discuss a purchase, don't hesitate to CONTACT Me. Let's find the perfect machine tool for your needs.