Why is cutting fluid necessary for wire EDM?

Chris Lu

Leveraging over a decade of hands-on experience in the machine tool industry, particularly with CNC machines, I'm here to help. Whether you have questions sparked by this post, need guidance on selecting the right equipment (CNC or conventional), are exploring custom machine solutions, or are ready to discuss a purchase, don't hesitate to CONTACT Me. Let's find the perfect machine tool for your needs.

Chris Lu

Leveraging over a decade of hands-on experience in the machine tool industry, particularly with CNC machines, I'm here to help. Whether you have questions sparked by this post, need guidance on selecting the right equipment (CNC or conventional), are exploring custom machine solutions, or are ready to discuss a purchase, don't hesitate to CONTACT Me. Let's find the perfect machine tool for your needs

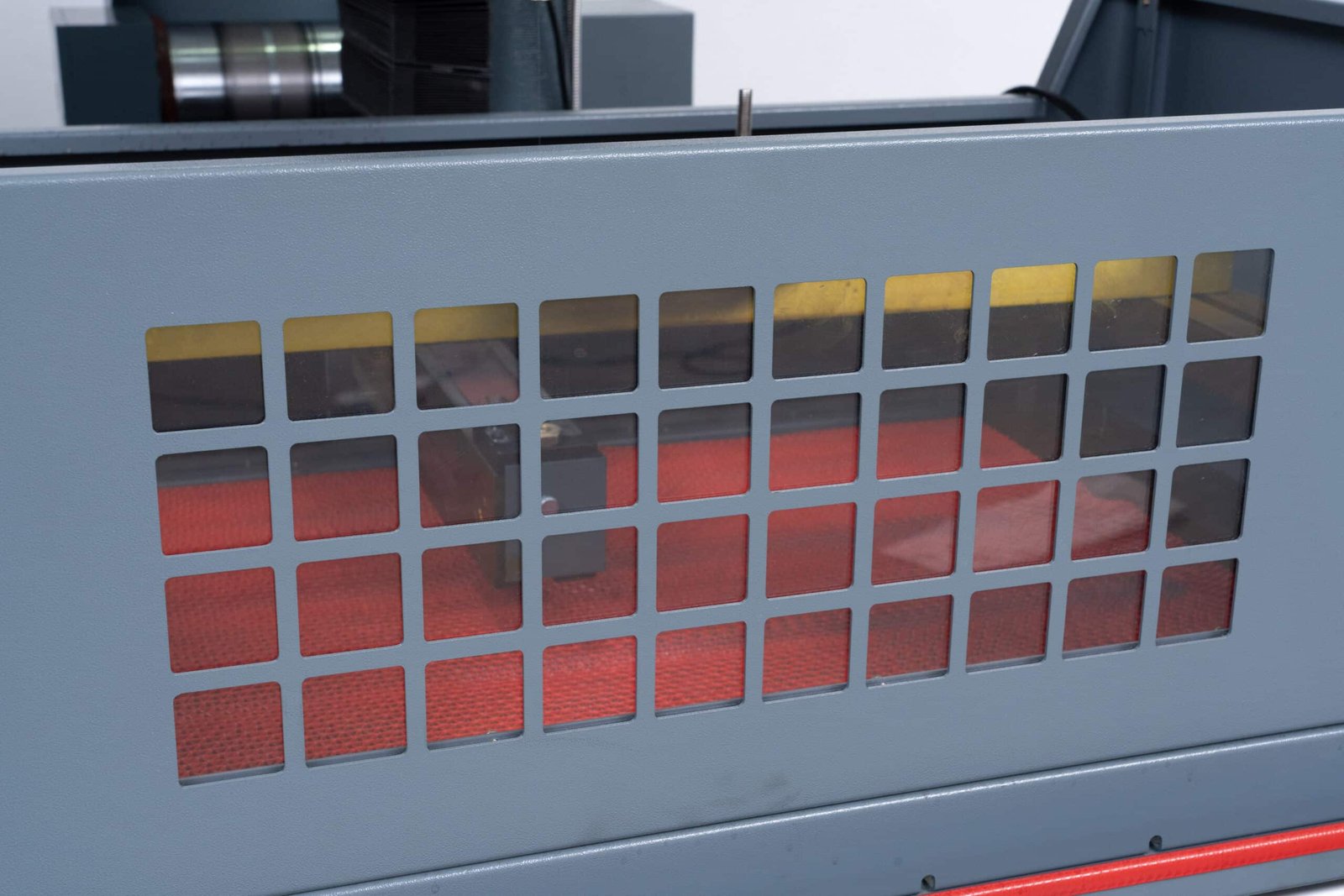

You see wire EDM machines running with liquid spraying everywhere. Is it just messy, or is that fluid actually doing something important for the cut?Skipping the fluid or using dirty fluid might seem simpler or cheaper, but it leads to unstable sparking, terrible cuts, damaged parts, broken wires, and potentially wrecked machinery.Let’s understand why that cutting fluid (properly called dielectric fluid) is absolutely essential for the wire EDM process to function correctly and achieve good results.

Cutting fluid in wire EDM is critical. It acts as a dielectric medium to control electrical discharge stability, insulates between sparks, cools the intense heat generated at the wire and workpiece, and crucially, flushes away tiny eroded metal particles (debris) from the narrow cutting gap.

This fluid performs multiple vital tasks simultaneously; without it, controlled cutting is impossible. Now, let’s explore what kinds of fluids are used and how they impact everything from cut quality to operational maintenance.

What Kinds of Liquid are Used for Wire EDM?

You hear about deionized water, oil, emulsions… it’s confusing. Does it really matter which fluid you use for your machine or specific job?Using the wrong fluid type, or fluid in poor condition, can drastically hurt cutting speed, precision, surface finish, and even cause operational problems or damage.Let’s clarify the common types of working fluids used in wire EDM, their properties, and where each one fits best in the process.

The primary working fluid for most modern wire EDM, especially Low-Speed (LS-WEDM), is highly filtered deionized (DI) water due to its excellent dielectric strength and flushing ability. Oil-based fluids are sometimes used, particularly for achieving very fine surface finishes, while emulsions are common in High-Speed/Middle-Speed (HS/MS-WEDM).

Deionized water1 is the workhorse fluid for wire EDM, particularly in LS-WEDM where precision is paramount. Its high dielectric strength2 allows it to act as an effective insulator until the voltage potential is just right for a spark to jump the gap, enabling fine control over the discharge. Critically, its low viscosity allows it to be pumped effectively through the cutting gap (often via high-pressure nozzles) to flush away the microscopic eroded particles, preventing them from causing short circuits or interfering with the cut. Oil-based dielectric fluids are less common but have a niche; they can sometimes produce smoother surface finishes in specific applications. Emulsified liquids (oil-water mixtures) are frequently found in the less precise, cost-focused HS-WEDM and MS-WEDM machines, offering a balance of cooling and basic flushing. Kerosene, while used in some die-sinking EDM, is generally not typical for wire EDM processes. Regardless of the type, maintaining the fluid’s cleanliness and properties is crucial for performance.

How Often Should the Cutting Fluid Be Replaced?

The cutting fluid clearly gets dirty over time, but changing it involves downtime, cost for new fluid, and disposal. How long can you realistically use it?Pushing the fluid life too long seems economical but inevitably leads to deteriorating performance: slower cuts, worse accuracy, poor surface finish, increased wire breaks, and potential rust or damage to machine components.Fluid replacement isn’t based on a simple timer; it’s condition-based. Let’s discuss the factors determining fluid health and the maintenance needed.

Wire EDM fluid replacement depends on usage intensity, filtration system effectiveness, fluid type, materials cut, and required quality. It should be replaced when its quality degrades beyond the ability of filters and deionizing systems to maintain it, monitored through regular checks rather than a fixed schedule.

Think of the fluid system like your car’s circulatory system – filters clean it, but eventually, the fluid itself breaks down or gets overwhelmed. In wire EDM, the fluid constantly picks up metal particles and discharge byproducts. Paper filter cartridges remove solid debris, and for DI water systems, deionizing resin3 bottles or beds remove conductive ions to maintain low conductivity (high dielectric strength). However, filters clog and need replacement, and resin beds become saturated and need regeneration or replacement. Over time, especially when cutting certain materials like aluminum which quickly increases conductivity, the fluid itself can become too contaminated or chemically degraded for the filters/resin to handle effectively. Running with dirty or high-conductivity fluid leads directly to unstable sparking, slower cutting, poor finish, rust, and wire breaks. Regular monitoring is key.

| Maintenance Task | Typical Frequency | Purpose |

|---|---|---|

| Replace paper-filter cartridges | Periodically, based on pressure/clogging | Remove solid debris, maintain fluid cleanliness |

| Regenerate/Replace deionizing resin | As needed, based on conductivity level | Control fluid conductivity for stable discharge |

| Check/Clean conductivity sensor | Regularly (e.g., every few filter changes) | Ensure accurate fluid monitoring, prevent issues |

| Clean/Inspect fluid tank | Periodically (e.g., during fluid change) | Remove settled sludge and contaminants |

| Replace entire fluid batch | When quality degrades significantly | Restore optimal machining performance |

Follow manufacturer guidelines, but adapt based on conductivity readings (for DI water), visual inspection, filter change frequency, and observed cutting performance. Proactive maintenance prevents costly problems.

Why Can Low-Speed WEDM Only Use Copper Wire and Only Once?

Low-Speed WEDM uses pricey wire (copper, brass, coated) and just discards it after one pass through the material. Why this seemingly wasteful single-use approach?Reusing wire seems like it would save significant cost, making you question why LS-WEDM adheres strictly to the single-pass method.The single-use wire is fundamental to achieving the ultra-high precision that defines LS-WEDM. Let’s explore the reasons.

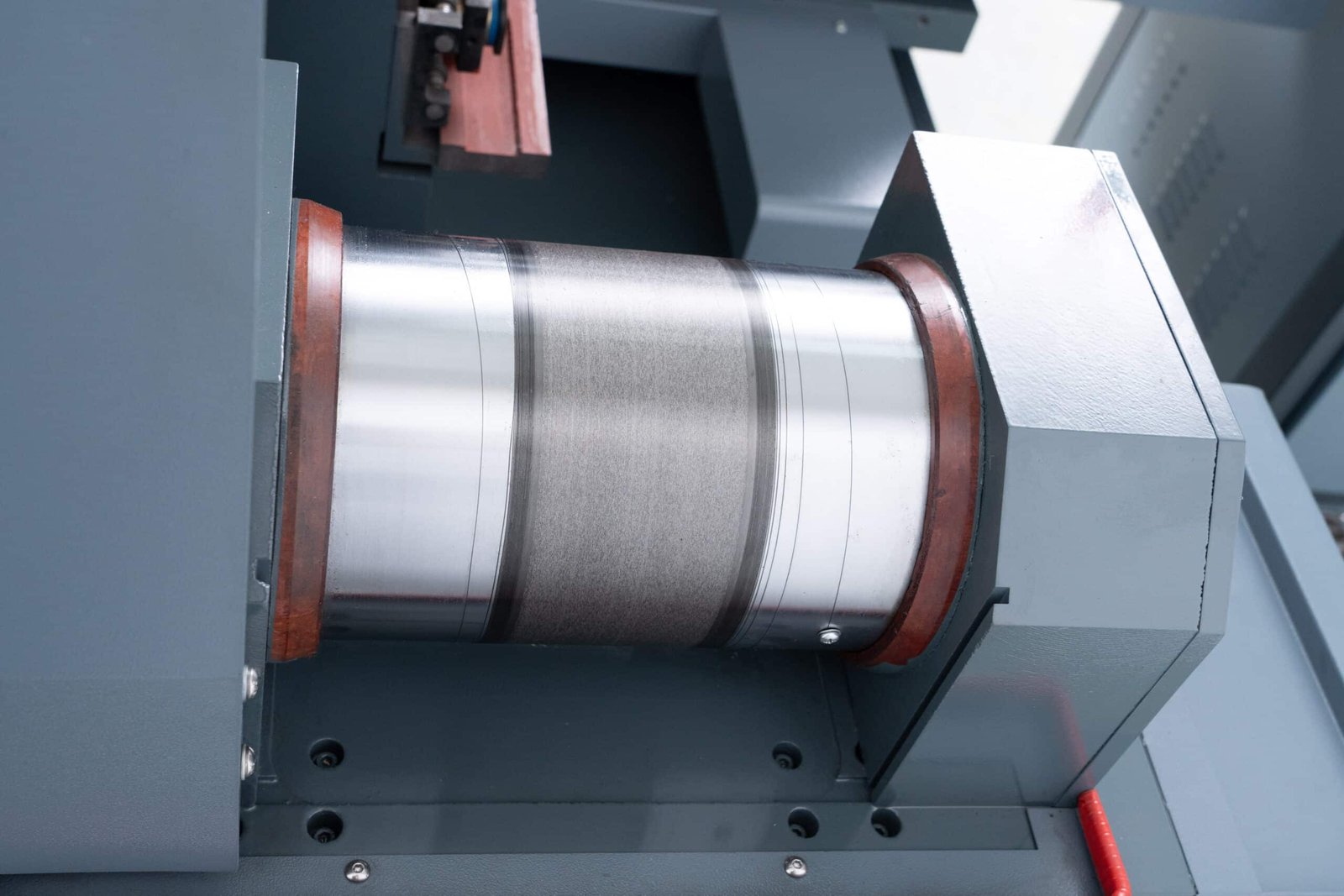

LS-WEDM demands single-use wire (typically copper, brass, or coated types) because the process requires absolute consistency for maximum precision. Any heat-induced changes, physical wear, or deformation from the first pass would compromise the accuracy needed for subsequent cutting. The machine’s continuous feed design also facilitates this.

LS-WEDM operates at slow wire speeds (often below 0.2 mm/s or 12 m/min) with the wire moving continuously in one direction from a supply spool, through the workpiece, and onto a take-up system before being discarded. Copper and brass wires are standard choices due to their excellent electrical conductivity (copper’s is very high, ~5.96 × 10^7 S/m), which is ideal for controlled discharges at these slow speeds. While these materials are relatively inexpensive compared to molybdenum, they lack the extreme tensile strength and heat resistance needed for reuse under EDM conditions. Here’s why reuse is impractical for LS-WEDM’s goals:

- Precision Mandate: LS-WEDM targets micron-level accuracy. Even microscopic wear on the wire surface or slight changes in diameter/straightness after one pass would introduce unacceptable errors.

- Material Properties: Copper/brass wire loses some strength and rigidity due to the heat and tension involved, potentially stretching or deforming slightly.

- Wear: Constant sparking erodes the wire surface, changing its characteristics.

- Continuous Feed Design: The machines are designed for smooth, continuous feeding of fresh wire, ensuring a consistent electrode condition throughout the cut. Trying to rewind and precisely tension used wire would be complex and unreliable.

Therefore, the single-pass approach with fresh wire is essential for the guaranteed precision and surface finish expected from LS-WEDM, justifying the consumable cost.

Why Can High-Speed and Middle-Speed WEDM Use Molybdenum Wire Multiple Times?

If LS-WEDM must use wire once, how do HS-WEDM and MS-WEDM get away with running their molybdenum wire back and forth repeatedly?It seems like the same heat, tension, and wear factors should apply, making wire reuse risky or detrimental to quality.The combination of a much tougher wire material and different process priorities makes wire reuse feasible and economical in HS/MS-WEDM.

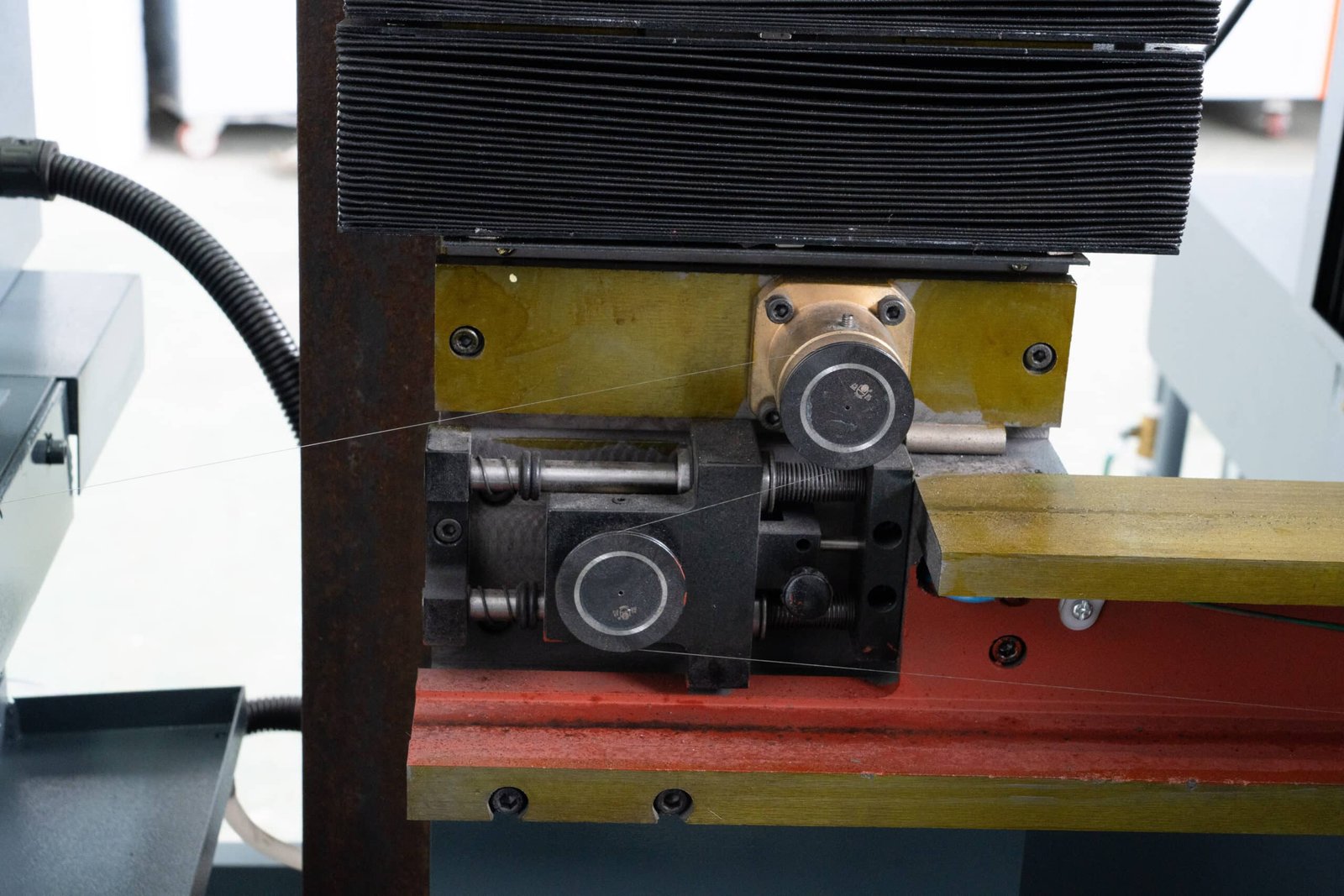

HS-WEDM and MS-WEDM utilize molybdenum wire’s exceptional properties—very high tensile strength and high melting point—allowing it to withstand the intense mechanical and thermal stresses of rapid reciprocating motion (e.g., 8-10 m/s for HS-WEDM). The lower precision demands of these processes tolerate the gradual wire degradation.

The key lies in molybdenum ("Moly"). This refractory metal is significantly stronger and more resistant to heat and wear than copper or brass. Its high tensile strength allows it to handle the constant back-and-forth pulling (reciprocation) at high speeds without easily breaking. Its high melting point helps it resist damage from the electrical sparks. This inherent durability makes it suitable for reuse over many cycles. While the molybdenum4 wire does degrade over time—it wears down, its surface changes, and it eventually needs replacement—this gradual degradation is acceptable within the typical accuracy requirements (often ±0.015 mm or larger) of HS-WEDM and many MS-WEDM applications. These processes prioritize cutting speed and low operational cost. Reusing the durable molybdenum wire fits perfectly with this philosophy, offering substantial savings on consumables compared to the single-pass LS-WEDM method. MS-WEDM might use multiple passes to improve finish, but it still relies on the reusable Moly wire5 for the bulk of the cutting. It’s a pragmatic choice where extreme precision isn’t the absolute top priority.

Conclusion

Cutting fluid is vital in WEDM for dielectric control, cooling, and flushing. DI water dominates precision work (LS-WEDM), while emulsions serve faster, less critical tasks (HS/MS-WEDM). Fluid maintenance is condition-based, crucial for performance. Wire choice reflects process needs: single-use Copper/Brass for LS precision, reusable Molybdenum for HS/MS durability and cost-effectiveness.

-

Explore the advantages of Deionized water in wire EDM processes, including its role in precision and performance. ↩

-

Learn how high dielectric strength contributes to effective insulation and precision in wire EDM applications. ↩

-

Learn about deionizing resin’s role in maintaining fluid quality and its importance in various industrial applications. ↩

-

Explore the unique properties of molybdenum and its applications in various industries, enhancing your understanding of this vital metal. ↩

-

Learn how reusable Moly wire can significantly reduce costs and improve efficiency in machining, making it a smart choice for manufacturers. ↩