Why is Selecting the Right Tool Crucial for Accuracy and Stability in Profile Machining?

Struggling with inconsistent profile machining results, poor surface finishes, or excessive vibration? Using the wrong cutting tool, especially with materials like aluminum, can quickly ruin expensive stock, cause tool breakage, slow down production, and fundamentally compromise the accuracy and stability of your parts.

Selecting the right tool is crucial because its material, geometry, coating, and condition directly dictate cutting forces, heat generation, chip control, and vibration. These factors fundamentally determine the final dimensional accuracy, surface finish quality, and overall stability of the profile machining process, especially with easily marked or vibrated materials like aluminum.

It might sound straightforward, but choosing that "right tool" involves considering several interconnected factors. Properly securing the workpiece is vital, but the tool itself must be suited to the material’s properties (like aluminum’s softness and tendency to stick) to maintain precision. Let’s break down what types of tools work best, explore critical elements like coatings and geometry, and discuss how to balance cost with performance.

What kind of tools should be chosen for aluminum profile machining?

Machining aluminum seems easy, but are you getting gummy chips, built-up edges, or poor finishes? Using general-purpose tools not designed for aluminum often leads to these problems, resulting in inaccurate cuts and wasted time. Specific tool types are recommended for efficient and clean processing.

For cutting aluminum profiles, carbide saw blades with specific tooth geometry are ideal. For milling, CNC tools like 3-flute chipbreaker end mills or tools made from solid carbide or HSS, specifically designed for aluminum with sharp edges and polished flutes, are key.

Choosing the right tool type and material is the first step. Your combined insights highlight several options:

- Carbide Saw Blades1: Excellent for straight cuts on aluminum extrusions. Look for blades with tooth geometries specifically designed for non-ferrous metals to ensure clean cuts and minimize deformation. Positive or negative tooth designs might be chosen based on the specific application.

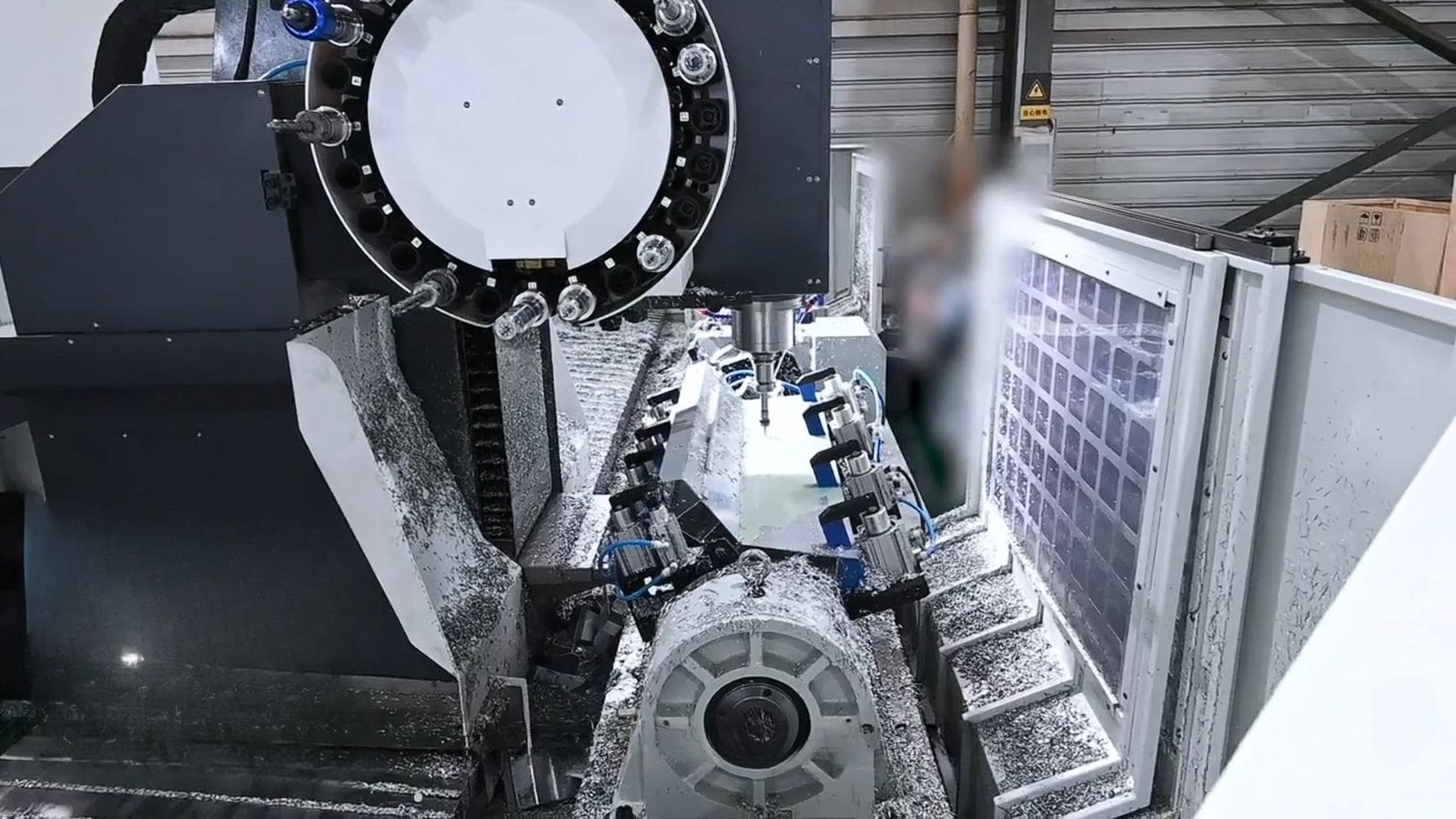

- Carbide End Mills2 (especially for CNC): Significantly harder and more wear-resistant than HSS, allowing higher speeds and feeds. For aluminum, designs often feature:

- Fewer Flutes (e.g., 2 or 3): Provides more room for chip evacuation, critical for preventing chips from packing in aluminum.

- Chipbreaker Geometry: Some designs incorporate features to break chips into smaller, more manageable pieces, further aiding evacuation, especially in milling operations. 3-flute chipbreaker designs are often recommended.

- Sharp Edges & Polished Flutes: Minimizes cutting force and prevents aluminum from sticking (built-up edge).

- High-Speed Steel (HSS): Still viable for lower-speed operations, drilling, tapping, or simpler profiles where cost is a primary concern. Offers good toughness but wears faster than carbide.

- PCD (Polycrystalline Diamond)3: The premium choice for high-volume, high-speed machining of aluminum, especially abrasive alloys. Offers the best wear resistance and finish but comes at a higher initial cost.

The best choice depends heavily on the specific operation (cutting, milling, drilling), the required precision, production volume, and the capabilities of your machine.

What Role Do Tool Coatings Play in Optimizing Performance in Profiles Machining?

Are your tools wearing out faster than expected, or are you struggling with aluminum sticking to the cutting edge? Uncoated tools might get the job done initially, but coatings provide specific enhancements crucial for tackling the challenges of machining materials like aluminum, especially at higher speeds.

Coatings significantly boost tool performance by increasing surface hardness, reducing friction and adhesion (lubricity), enhancing wear resistance, and providing a thermal barrier. This combats issues like built-up edge in aluminum, leading to longer tool life, better finishes, and higher speeds.

Coatings are thin, specialized layers applied to the tool surface. Your research highlights their importance, especially for aluminum:

- Reduced Adhesion & Friction: This is critical for aluminum, which has a tendency to stick to the cutting edge (built-up edge or BUE). Coatings like Titanium Nitride (TiN)4, TiCN, AlTiN, or specialized low-friction coatings (like DLC) create a slicker surface. This prevents material buildup, improves chip flow, and results in cleaner cuts and better surface finishes.

- Increased Hardness & Wear Resistance5: The coating acts as a protective shield, making the tool surface much harder and more resistant to the abrasive wear encountered during cutting. This directly translates to longer tool life.

- Thermal Barrier: Coatings help insulate the tool substrate (e.g., carbide) from the intense heat generated during cutting. This prevents the tool material from softening or degrading, allowing for higher cutting speeds without premature failure, which is particularly relevant in high-speed machining scenarios.

While adding cost, coatings like TiN offer a versatile balance of hardness and low friction suitable for many aluminum applications. The extended life, potential for faster cycle times, and improved part quality often justify the investment, contributing to a lower overall cost per part.

What Tool Geometries are Best Suited for Specific Profile Machining?

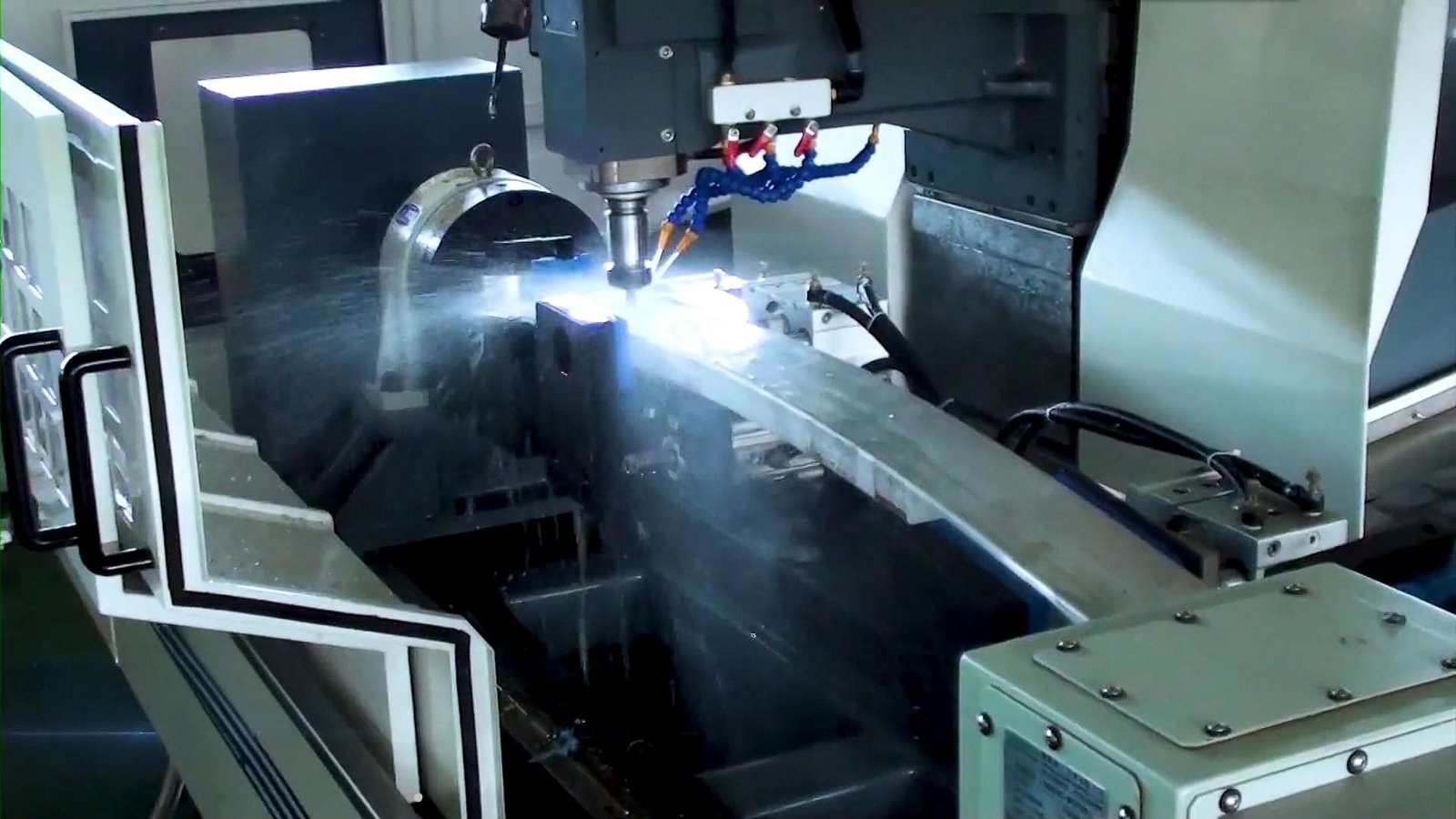

Experiencing issues like vibration, poor chip evacuation, or rough surface finishes even with the right tool material and coating? The specific shape of the cutting edges and the tool’s body—its geometry—is critical for how effectively it cuts the material, controls chips, and maintains stability.

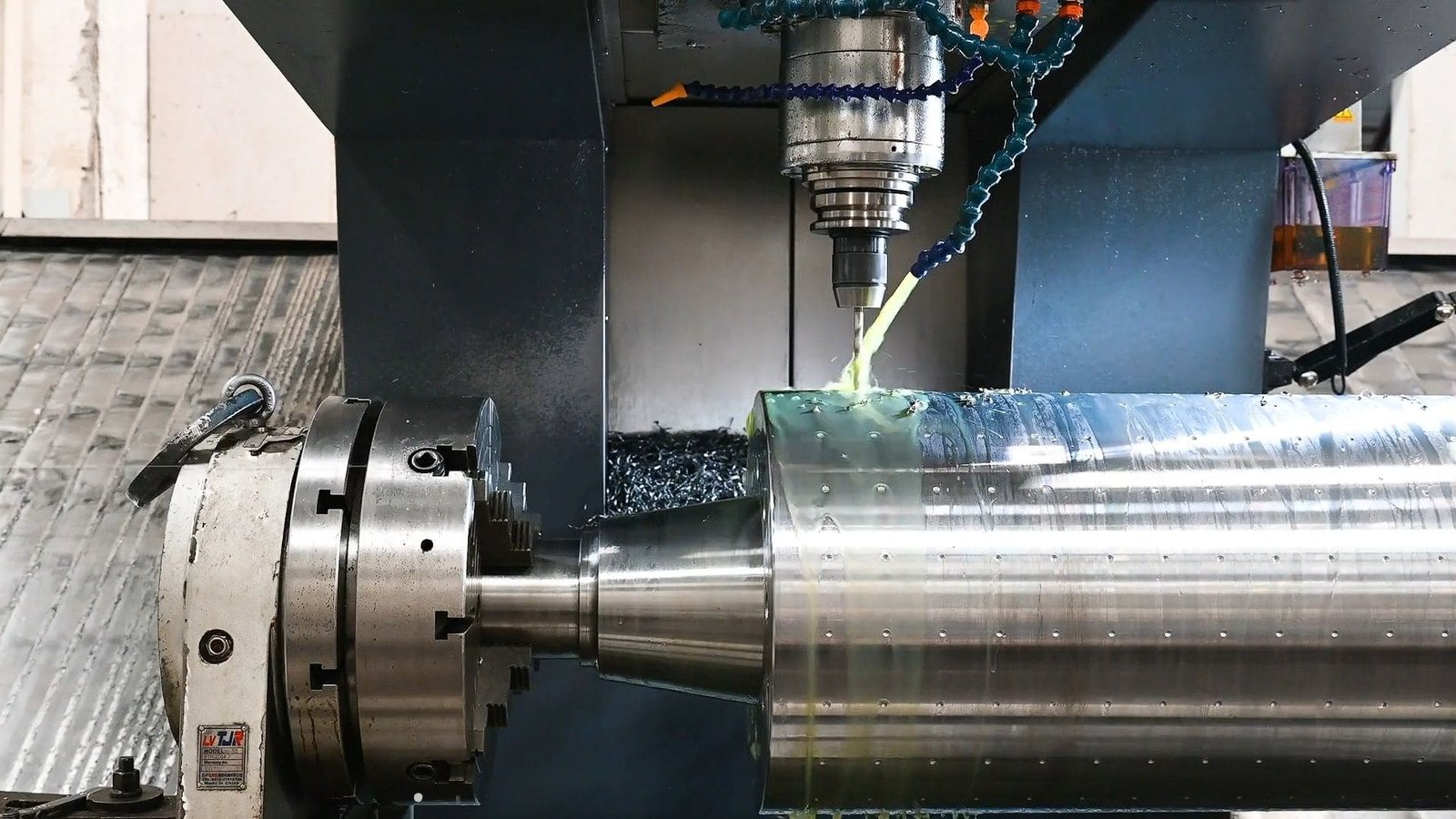

For aluminum profiles, geometries featuring sharp cutting edges, high helix angles (35-45° for end mills) for efficient chip evacuation, and polished flutes are key. Specific designs like chipbreakers on end mills or optimized tooth patterns on saw blades further enhance performance for particular tasks.

Effective geometry goes beyond basic tool type. Key features highlighted by your research include:

- Sharp Cutting Edges6: Essential for cleanly shearing soft materials like aluminum, reducing cutting forces and minimizing material deformation.

- High Helix Angles (End Mills)7: Promote efficient lifting and removal of chips from the cutting zone, crucial for preventing packing in aluminum.

- Polished Flutes: Reduce friction, further aiding chip evacuation and preventing aluminum from welding to the tool surface.

- Rake & Clearance Angles: Optimized positive rake angles reduce cutting forces, while appropriate clearance prevents rubbing.

- Number of Flutes (End Mills): Typically 2 or 3 flutes are preferred for roughing or general-purpose milling in aluminum to maximize chip space.

- Chipbreaker Geometry (End Mills)8: Specialized grooves on the cutting edge break long, stringy chips into smaller, manageable segments, significantly improving chip control and evacuation, especially during aggressive milling.

- Saw Blade Tooth Geometry: For cutting profiles, carbide saw blades need specific tooth shapes (e.g., positive/negative angles, specific grinds) designed to handle aluminum without grabbing or causing excessive burrs.

Matching the geometry—like using a chipbreaker end mill for milling or a correctly designed saw blade for cutting—to the specific material and operation is vital for achieving clean cuts, good finishes, and efficient production.

How Can You Strategically Balance Tool Cost Against Performance and Longevity?

Worried about the high cost of premium cutting tools? It’s tempting to choose the cheapest option, but this often leads to frequent replacements, slow speeds, scrapped parts, and increased machine downtime, ultimately driving up overall manufacturing costs significantly.

Strategically balance tool cost by focusing on the total cost of ownership or cost per part. Evaluate the tool’s lifespan, the cycle time it enables (performance), its impact on part quality, and reduced downtime. Often, a higher initial investment in a quality tool yields greater long-term economy.

Finding the sweet spot between cost and performance requires looking beyond the initial price tag. Your insights suggest these strategies:

- Prioritize Total Cost of Ownership (TCO)9: Don’t just look at the sticker price. Calculate how many good parts a tool produces over its life. Factor in machine time saved due to higher speeds/feeds allowed by better tools. Include the cost of downtime for tool changes. A durable, high-performance tool often wins on TCO.

- Choose High-Quality, Appropriate Tools: Invest in tools made from suitable materials (like carbide for aluminum) and with beneficial coatings (like TiN or application-specific ones). While costing more upfront, their extended life and better performance reduce costs per part.

- Optimize Machining Parameters10: Don’t just use the tool; use it correctly. Work with manufacturer recommendations for speeds, feeds, and depth of cut. Fine-tune these parameters for your specific machine and setup to maximize material removal while preserving tool life.

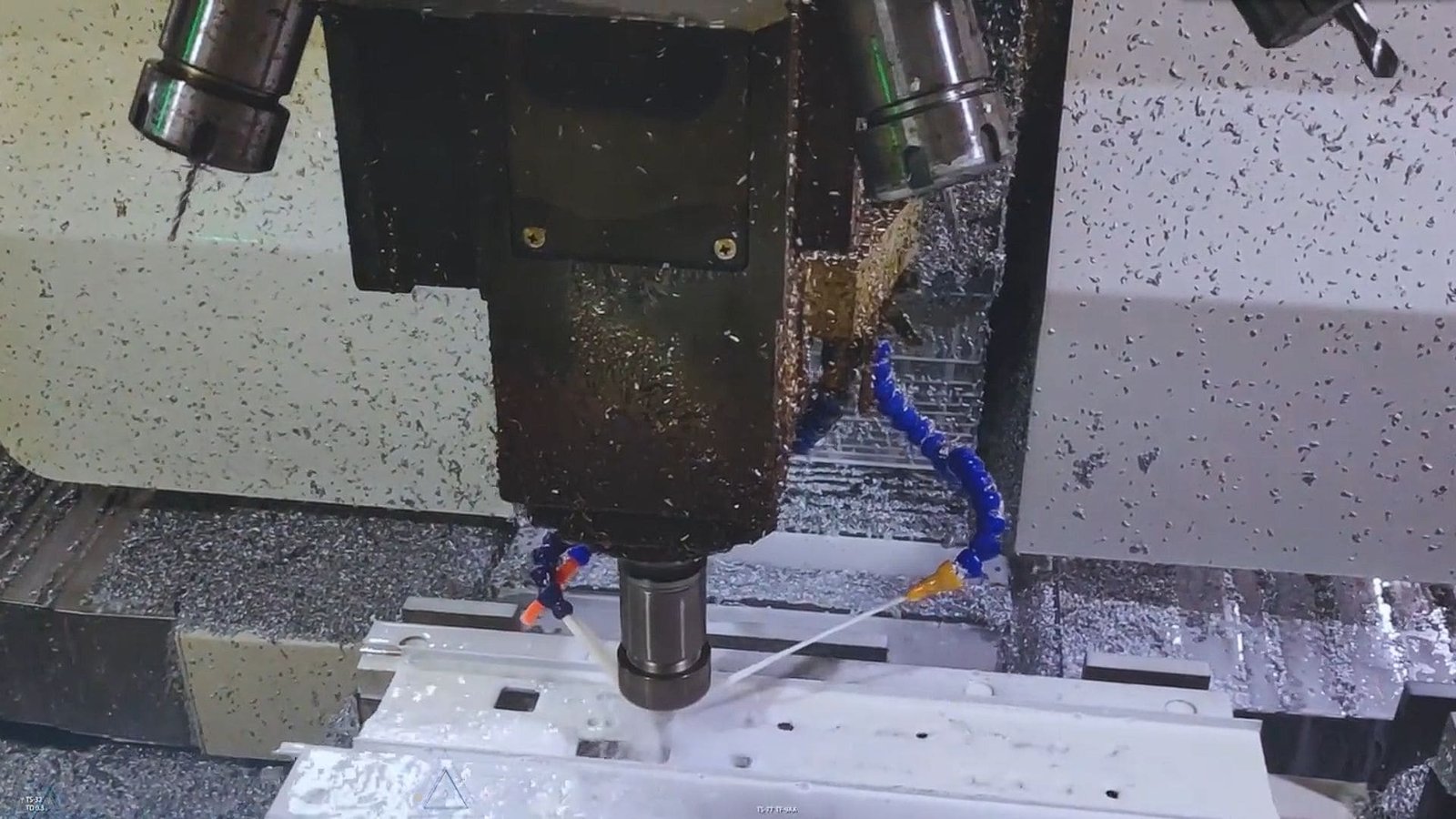

- Ensure Effective Cooling/Lubrication11: Proper coolant application is non-negotiable, especially for aluminum. It reduces heat, minimizes friction and BUE, flushes chips, and significantly extends tool life, allowing you to get the most out of your tool investment.

- Implement Good Tool Management: Regularly inspect tools for wear. Replace them proactively based on performance or predetermined life limits, not just after failure. Keep holders clean and maintain equipment properly.

By adopting this holistic view, focusing on TCO and optimizing the entire process, you can make strategically sound tooling investments that enhance both performance and profitability.

Conclusion

Selecting the right tool for profile machining—considering material, coating, geometry, and balancing cost with TCO—is essential for achieving accuracy, stability, extended tool life, and overall production efficiency, particularly when working with challenging materials like aluminum.

-

Explore the advantages of Carbide Saw Blades for aluminum cutting to ensure precision and efficiency in your projects. ↩

-

Learn how Carbide End Mills enhance CNC machining processes, ensuring better performance and longevity in aluminum applications. ↩

-

Discover the benefits of PCD tools for aluminum machining, especially for high-volume production, to achieve superior results. ↩

-

Explore the advantages of TiN coatings, including improved tool life and performance in aluminum machining. ↩

-

Learn how coatings enhance tool durability and performance, leading to cost-effective machining solutions. ↩

-

Explore how sharp cutting edges enhance machining efficiency and reduce material deformation, crucial for aluminum work. ↩

-

Discover the importance of high helix angles in enhancing chip evacuation and preventing packing, vital for effective aluminum milling. ↩

-

Learn about the advantages of chipbreaker geometry in managing chip size and improving milling performance, especially in aluminum. ↩

-

Understanding TCO helps in making informed decisions about tool investments, ensuring long-term savings and efficiency. ↩

-

Optimizing machining parameters can significantly enhance tool life and performance, leading to cost savings and efficiency. ↩

-

Proper cooling and lubrication are crucial for tool longevity and performance, making it essential to explore best practices. ↩

Chris Lu

Leveraging over a decade of hands-on experience in the machine tool industry, particularly with CNC machines, I'm here to help. Whether you have questions sparked by this post, need guidance on selecting the right equipment (CNC or conventional), are exploring custom machine solutions, or are ready to discuss a purchase, don't hesitate to CONTACT Me. Let's find the perfect machine tool for your needs

Chris Lu

Leveraging over a decade of hands-on experience in the machine tool industry, particularly with CNC machines, I'm here to help. Whether you have questions sparked by this post, need guidance on selecting the right equipment (CNC or conventional), are exploring custom machine solutions, or are ready to discuss a purchase, don't hesitate to CONTACT Me. Let's find the perfect machine tool for your needs