Why Is Staged Infeed Often Used on CNC Lathes?

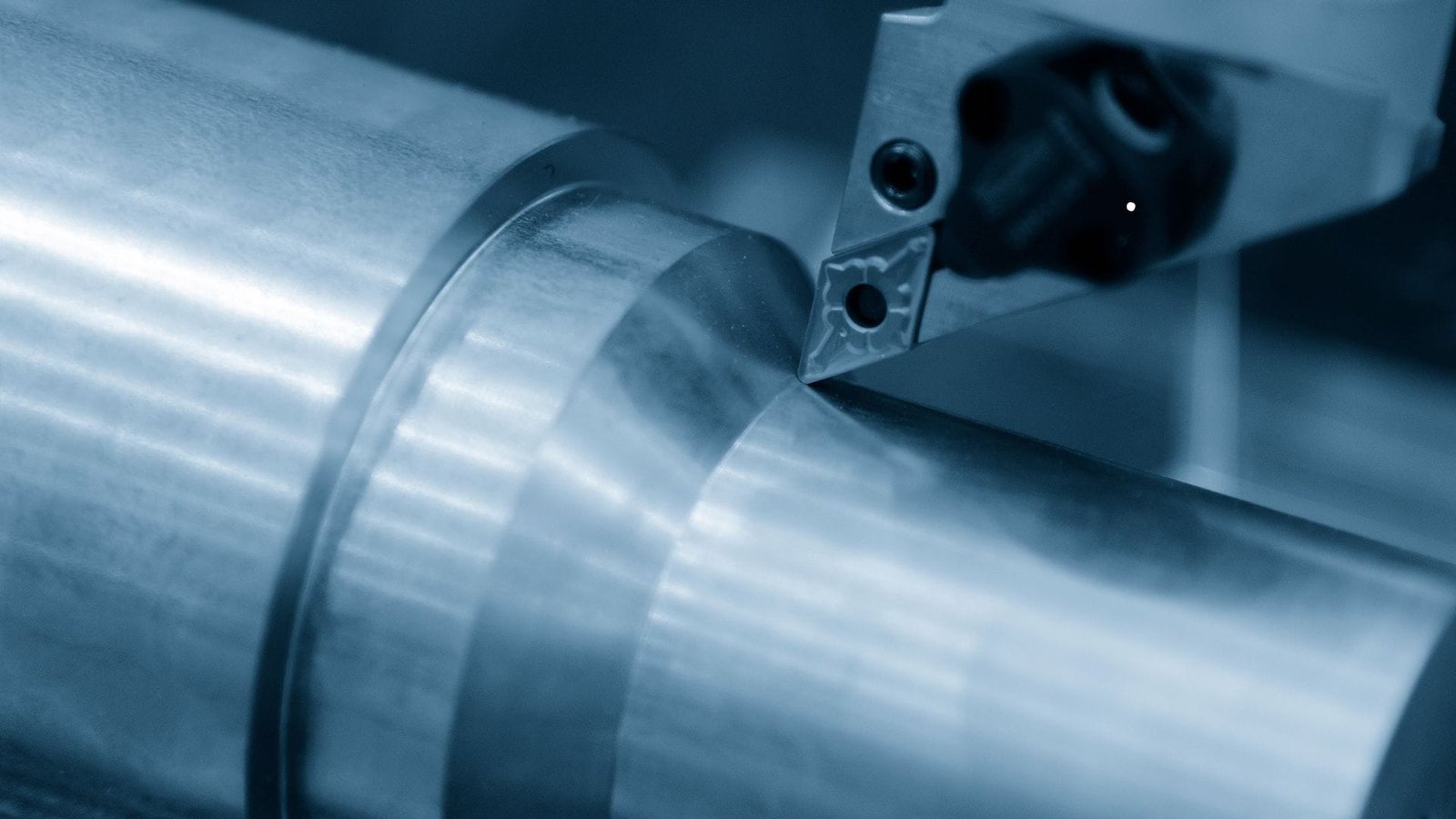

Turning parts in one big cut seems fast. But this can quickly damage your tools, your machine, and the part itself. Staged infeed, sometimes called incremental infeed, offers a much smarter, safer way.

CNC lathes use staged infeed to lower cutting forces. This protects tools and the machine. It also ensures parts are accurate with good finish, especially for larger thread profiles or tough materials, and aids chip removal.

You might be thinking, why not just take one big cut and save some time? It’s a fair question. But there are very solid reasons we almost always use staged infeed, or step feeding, in CNC lathing. It’s not just about taking small steps; it’s about machining intelligently. Let’s look into why this method is so important for getting good results. I think you’ll see that it’s about working smarter, not just harder, especially when precision is key.

Why Does Staged Infeed Become Crucial for Maintaining Tight Tolerances on Difficult-to-Machine Parts in CNC Lathing?

Machining tough materials can feel like a constant fight. These materials push back hard against the cutting tool. This makes it incredibly difficult to hold the very precise dimensions, or tight tolerances, that many jobs demand. Staged infeed provides a method to gain better control.

Staged infeed is vital for tight tolerances on tough parts. It manages high, sudden cutting forces, controls heat, reduces tool wear, and counters work hardening. This allows for predictable, consistent material removal for accuracy.

When I work with difficult-to-machine materials like superalloys, titanium, or hardened steels, holding tight tolerances is always the biggest challenge. These materials present unique problems that staged infeed helps us systematically overcome.

First, let’s consider Cutting Forces and Deflection1. These tough materials generate huge, often sudden, cutting forces. A single deep pass would exert enormous force. This can bend the tool, push the workpiece, or even flex machine components. Staged infeed addresses this.

- Roughing Passes: These take larger depths of cut to remove bulk material. The primary goal isn’t the final tolerance yet.

- Finishing Passes: Subsequent passes use significantly smaller depths. This dramatically reduces cutting forces, leading to less tool, workpiece, and machine deflection. This is key for accurate dimensions.

Next is Heat Control and Thermal Effects2. Machining these materials creates excessive heat. Many also have poor thermal conductivity, concentrating heat. This can cause thermal expansion, leading to inaccuracies. Staged infeed, with smaller cuts, generates less heat per pass and allows better cooling. This thermal stability is essential. I’ve seen parts ruined by heat; staged infeed prevents that.

Then there’s Tool Wear and Cutting Edge Integrity3. Rapid tool wear is common with these abrasive or hard materials. A worn tool cannot produce accurate dimensions. Staged infeed often involves using a dedicated finishing tool or a fresh edge, which has seen minimal wear. This helps maintain a sharp cutting edge.

Finally, we must account for Work Hardening. Many difficult materials harden as they are cut. Staged infeed allows the depth of cut in finishing passes to be carefully chosen to get under any previously work-hardened layer. This predictable and consistent material removal reduces the risk of tool breakage and ensures the part stays true. The smoother surface finish achieved also directly contributes to holding tight tolerances.

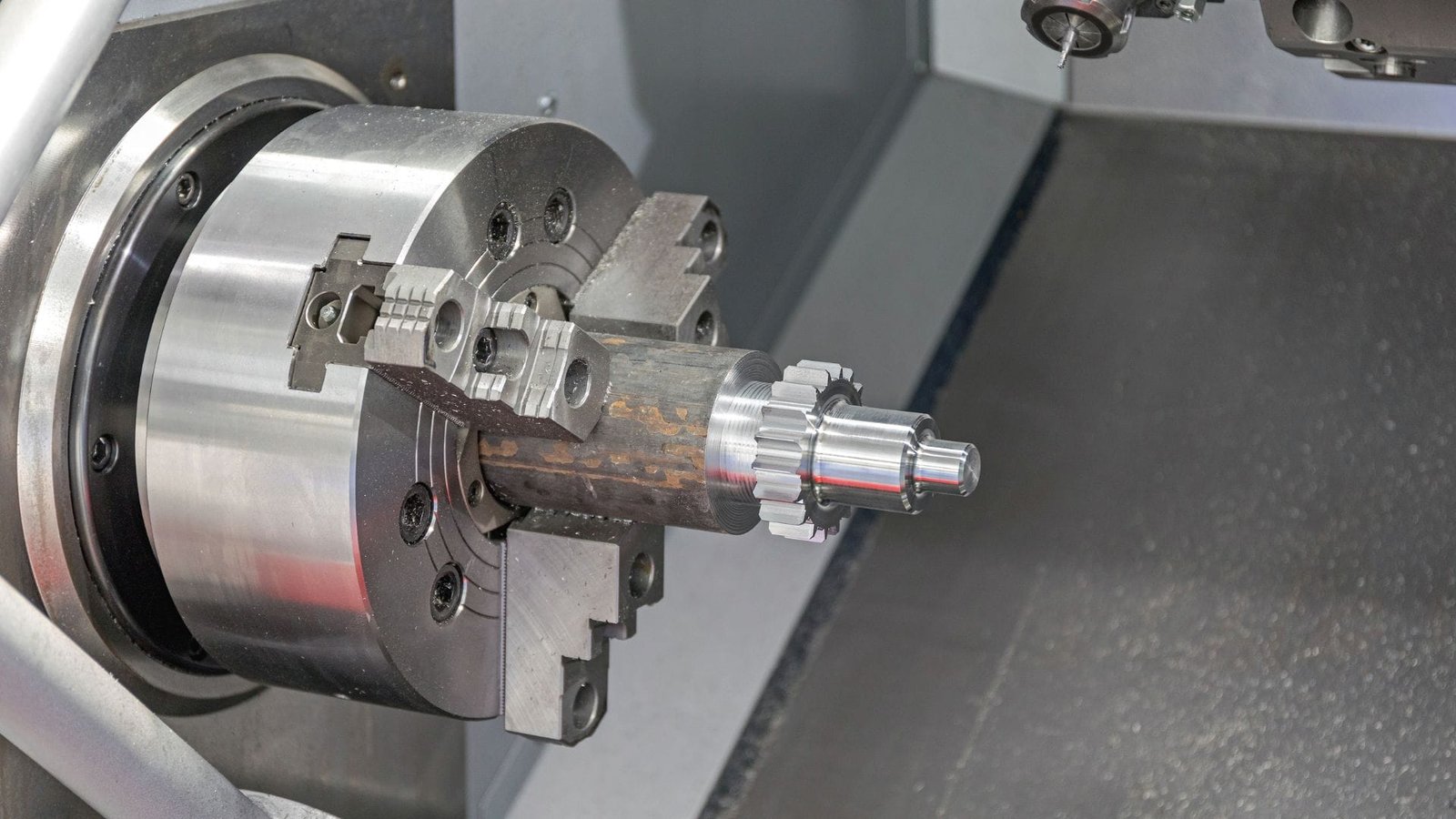

How Can Staged Infeed on a CNC Lathe Contribute to Extended Spindle Bearing and Turret Component Life by Reducing Machining Stresses?

Our CNC lathes are significant investments. We want them to last and remain accurate. Aggressive, continuous cutting can quickly wear out vital parts like spindle bearings and turrets. Staged infeed is a very effective way to protect these valuable components.

Staged infeed extends machine part life by breaking heavy cuts into smaller, manageable ones. This greatly lowers peak stresses, shock loading, and vibrations on spindle bearings and turret components, preserving their accuracy and lifespan.

I always emphasize that a machine tool needs care to perform well long-term, and staged infeed is a core part of that care. The primary benefit comes from how it manages machining stresses.

Reduced Peak Loads and Shock Loading: Instead of one massive impact, staged infeed4 divides the total cutting load into several smaller, gentler passes. When we use a single heavy cut, the spindle bearings and turret face huge axial and radial loads—this is shock loading. Over time, these high peak stresses lead to accelerated wear. Bearings can lose precision, and turret indexing might become less accurate. With staged infeed, the peak force during each pass is much lower. This significantly reduces the wear and tear, helping to extend the operational life of these critical systems.

Minimized Vibrations: Heavy cuts often induce significant vibration. This isn’t just bad for the part’s surface finish; it’s also very harsh on the machine’s components. Think of it like constantly driving a car on a rough, bumpy road—things naturally loosen and wear out faster. Staged infeed, with its smoother, lighter cuts, results in far less vibration. This gentler action helps preserve the fine tolerances built into the machine’s components and reduces stress concentrations.

Lower Thermal Stress: By controlling heat generation through smaller, incremental cuts, staged infeed also reduces thermal stress5 on the machine components themselves. This helps maintain critical machine alignments and further contributes to the longevity and sustained accuracy of the lathe. I’ve seen firsthand how shops that adopt staged infeed strategies experience fewer unexpected breakdowns and lower maintenance costs for their spindles and turrets.

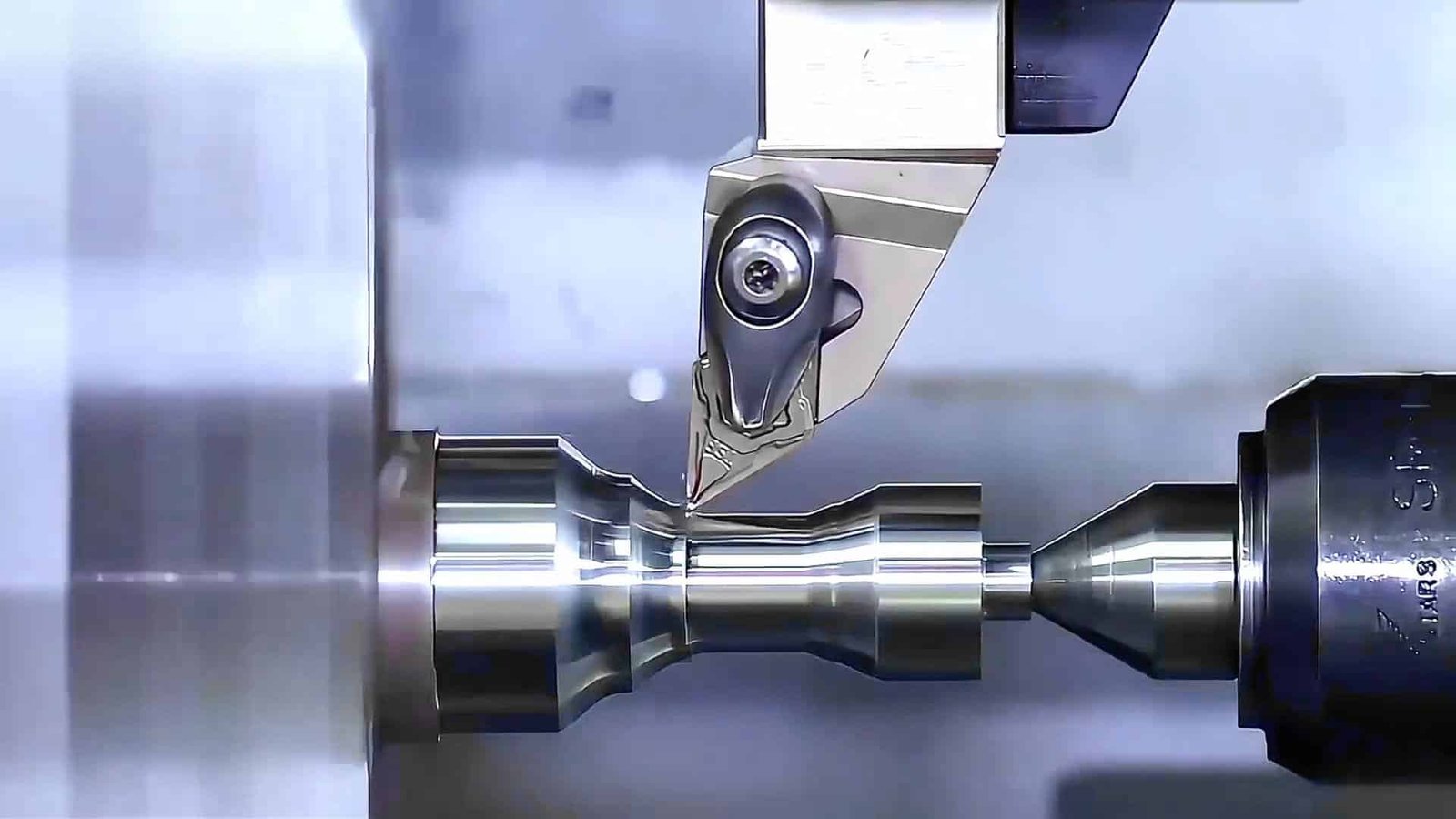

Are There Specific Types of CNC Lathe Tooling or Insert Geometries That Perform Optimally with Staged Infeed Strategies?

Choosing the right cutting tool is always critical for successful machining. And yes, it’s true. Even with a good staged infeed strategy, the wrong tool can still lead to problems or inefficiency. To get the best results, we need to select tooling suited for each stage of the process.

Yes, specific tools and insert shapes enhance staged infeed. Tough roughing inserts handle initial heavy cuts. For precise final staged cuts, finishing inserts with sharp edges, positive rake angles, and effective chip-breaking geometries are best.

In my experience supplying machine tools and advising on processes, tool selection is paramount, especially with staged infeed. You can’t use a one-size-fits-all tool. We must consider what each cutting stage aims to achieve.

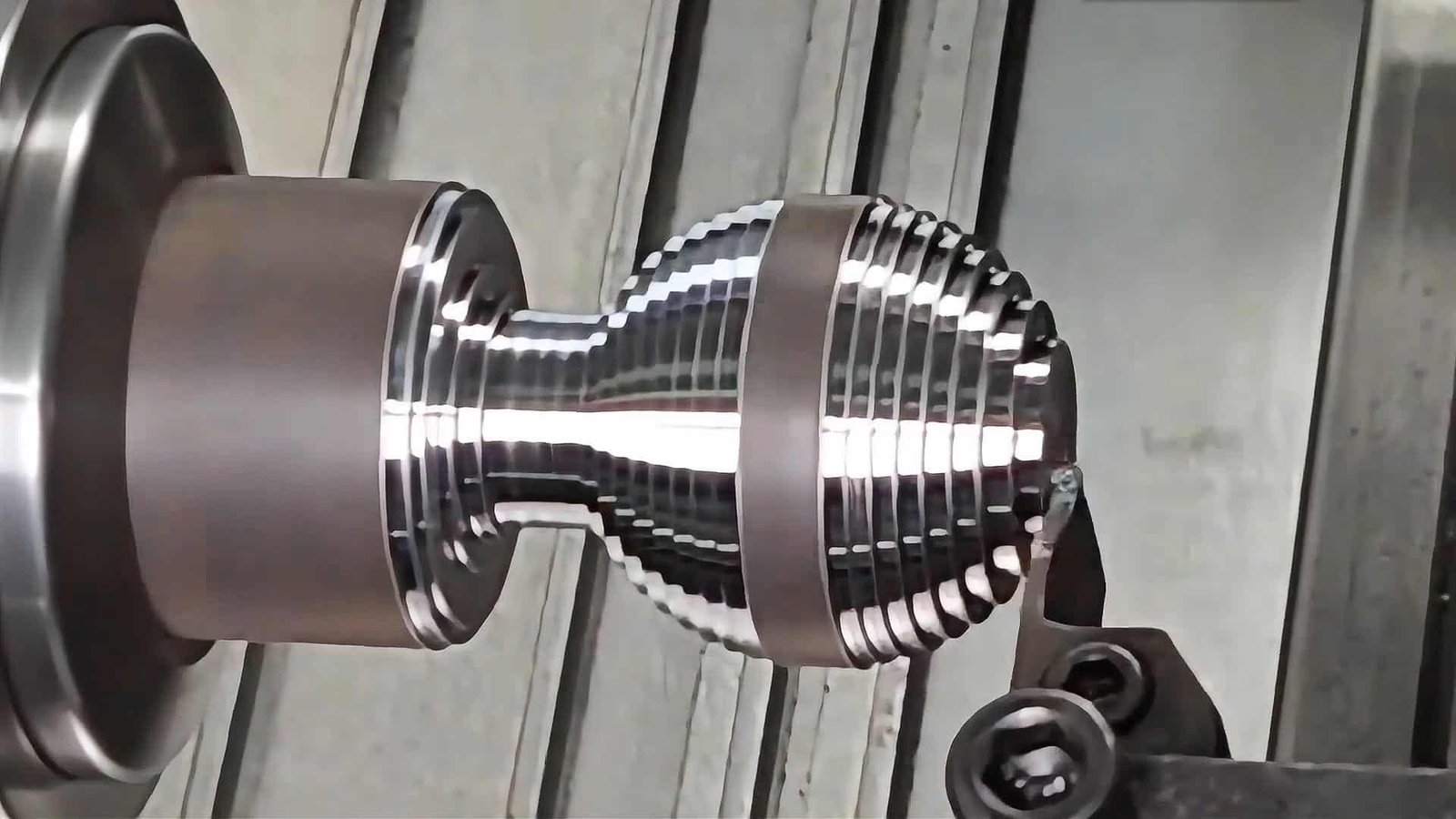

For the initial roughing passes, where the goal is rapid material removal, the tool must be robust.

- Stronger Edge Inserts6: This might involve negative rake angles or honed (slightly rounded) cutting edges for greater strength.

- Tougher Carbide Grades: These are less prone to chipping under higher roughing forces.

- Chipbreakers for Larger Chips: Roughing creates larger chips, so the insert needs geometry to manage them.

When moving to semi-finishing and finishing passes, the focus shifts to accuracy and surface finish. The depth of cut is much smaller.

- Sharper Cutting Edges7: Positive rake angles and very sharp edges cut cleanly with less force, vital for good finish and tight tolerances. Ground periphery inserts are often chosen.

- Effective Chip-Breaking Geometries8: Even with lighter cuts, good chip control is important. Inserts with geometries designed for the smaller chips produced during finishing help maintain a clean cutting zone.

- Wiper Inserts: For the final pass, wiper inserts can produce excellent surface finishes.

- Specialized Coatings: Coatings designed for wear resistance or reduced friction are beneficial.

- Multi-Point Inserts: For some applications like very coarse threads, multi-point inserts can distribute wear effectively during staged cuts.

The tool holder’s rigidity is also crucial to prevent vibration, especially for finishing. I tell people to think of roughing tools as heavy-duty equipment and finishing tools as precision instruments. While the best choice always depends on the specific material and job, matching the tool to the stage of the infeed strategy is key. At J&M Machine Tools, guiding clients to these smart tooling choices is a priority.

Why Should Staged Infeed Be Considered a Primary Machining Strategy?

Some might view staged infeed as overly cautious or slow. They might question its necessity for every job. But ignoring staged infeed can lead to costly issues: broken tools, damaged machines, or subpar parts. That’s why it’s a foundational strategy for reliable, high-quality machining.

Staged infeed is a primary strategy because it effectively manages cutting forces, optimizes heat control, improves accuracy, and enhances surface quality. It’s adaptable across materials and complex geometries, leverages CNC precision, and aids chip control.

When I plan a new machining job or advise someone, thinking in stages is my starting point. It’s not just for tricky situations; it’s a fundamental approach. Here’s why I believe it’s a primary strategy:

Fundamental Control:

- Manages Cutting Forces1: Breaking down material removal into smaller steps keeps forces on the tool and machine low. This is the most basic, vital reason. It protects everything.

- Optimizes Heat Control: Excess heat is detrimental to accuracy. Staged cutting means less heat generation per pass, allowing coolant to work better. This is crucial for finishing.

- Improves Accuracy and Surface Quality: Large forces cause vibration and deflection. Lighter finishing cuts minimize these, leading to higher precision and better finishes. This phased approach is key.

Enhanced Efficiency and Adaptability:

- Better Chip Management2: Staged infeed, especially with appropriate tooling, helps create manageable chips. This is particularly important for operations like turning larger thread profiles (e.g., pitches over 5 mm), where chip control is essential. It often results in more even insert wear too, especially with coarse threads.

- Adaptability: Staged infeed offers flexibility for irregular surfaces (like castings) or interrupted cuts. It allows a cautious initial pass before normal machining. Its versatility means it works well across diverse materials and complex geometries.

- Leverages CNC Capabilities3: Modern CNC systems excel at precisely controlling multiple passes and cutting parameters. Staged infeed is perfectly suited for this, making it highly effective in automated environments and for executing complex toolpaths efficiently. This leads to enhanced machining stability overall.

It’s not about making every job overly complex. For simple parts, a rough and a finish pass (which is basic staging) might be enough. But for complex parts, tough materials, or high precision, a detailed multi-stage approach is essential. It’s about planning to control the process from start to finish.

Conclusion

Staged infeed is a smart, vital method in CNC lathing. It protects tools and machines, ensures quality parts, and helps reliably tackle even the toughest jobs, making it a cornerstone of efficient machining.

-

Understanding cutting forces and deflection is crucial for improving machining accuracy and tool longevity. Explore this link for in-depth insights. ↩ ↩

-

Heat control is vital in machining to prevent inaccuracies and tool damage. Discover effective strategies for managing thermal effects in machining. ↩ ↩

-

Managing tool wear is essential for maintaining precision in machining. Learn about best practices to enhance tool life and performance. ↩ ↩

-

Exploring this resource will provide insights into how staged infeed enhances machining efficiency and reduces wear. ↩

-

Understanding thermal stress is crucial for maintaining machine performance and longevity; this link will deepen your knowledge. ↩

-

Explore how stronger edge inserts enhance durability and performance in machining processes, especially during roughing. ↩

-

Learn about the significance of sharp cutting edges for achieving high-quality finishes and tight tolerances in machining. ↩

-

Discover how chip-breaking geometries can enhance chip control and overall machining efficiency, especially in finishing operations. ↩

Chris Lu

Leveraging over a decade of hands-on experience in the machine tool industry, particularly with CNC machines, I'm here to help. Whether you have questions sparked by this post, need guidance on selecting the right equipment (CNC or conventional), are exploring custom machine solutions, or are ready to discuss a purchase, don't hesitate to CONTACT Me. Let's find the perfect machine tool for your needs

Chris Lu

Leveraging over a decade of hands-on experience in the machine tool industry, particularly with CNC machines, I'm here to help. Whether you have questions sparked by this post, need guidance on selecting the right equipment (CNC or conventional), are exploring custom machine solutions, or are ready to discuss a purchase, don't hesitate to CONTACT Me. Let's find the perfect machine tool for your needs