Why is Through-Spindle Coolant Critical for CNC Deep Hole Drilling?

Drilling deep holes destroys tools when heat builds up and chips get stuck. If you rely on external nozzles, you will ruin your expensive workpieces and waste production time.

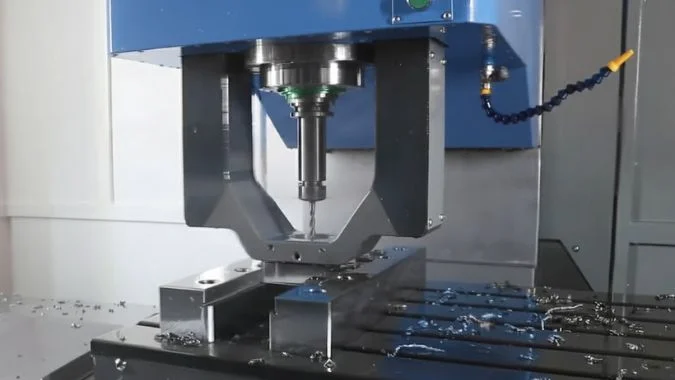

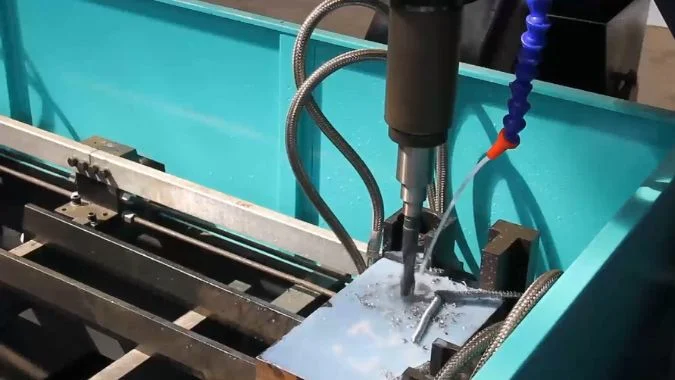

Through-spindle coolant delivers high-pressure fluid directly through the tool’s internal channels to the cutting edge. It breaks the vapor barrier to reduce heat, flushes chips out of deep holes to prevent jamming, and lubricates the contact zone. This ensures extended tool life and superior precision where external flood cooling fails, especially in holes deeper than three times the diameter.

Many operators struggle with broken drills because they trust standard flood cooling. The liquid never reaches the bottom of the hole. You need to understand the mechanics of internal flow to save your tools.

Why Traditional Flood Cooling Falls Short in Deep Holes?

You aim your external nozzles perfectly, but the coolant just splashes off the surface.

External flood cooling cannot penetrate deep holes effectively. As the drill advances beyond three times its diameter, coolant efficiency drops by up to 66% because the tool body blocks the fluid. This leads to heat buildup, chip impaction, and the need for slow "pecking" cycles to prevent failure.

Many people think that "more water" equals "better cooling." This is false.

The Application Point Problem

Conventional water cooling covers the workpiece surface. It looks impressive. But inside a hole that is deep, the tool tip is bone dry. The physical body of the drill blocks the liquid. The spinning tool acts like a fan, blowing the coolant away. This leads to a delayed cooling effect. The heat builds up faster than the water can enter. Research shows that once you go deeper than 3x the diameter, the cooling efficiency drops drastically, often by more than 60%.

The Stability Issue and Pecking

Deep hole machining is unstable with flood cooling. The heat does not dissipate through the workpiece effectively. External nozzles cannot remove this heat quickly. The tool expands due to thermal expansion. The workpiece deforms. To fight this, operators use "pecking cycles1"—drilling a little, pulling out, and drilling again. This destroys machining continuity and slows down production massively. Internal cooling fixes this by delivering the fluid through internal channels inside the tool. It hits the "hot spot" immediately. It controls the temperature at the exact moment of the cut, eliminating the need for slow pecking processes.

How Does High-Pressure Internal Flow Facilitate Continuous Chip Evacuation?

Chips are the silent killers of deep hole drilling, causing jams and snapped tools.

High-pressure coolant acts like a hydraulic ram, breaking chips and pushing them up and out of the hole. This prevents packing, keeps the flutes clean, and stops secondary cutting that damages the surface, allowing for continuous drilling without interruptions.

When you drill deep, the chips have a long way to travel. Gravity does not help you here. You need force.

The Mechanism of Evacuation

In conventional setups, the external spray force scatters. It does not form a "directional flushing force." Chips accumulate at the bottom. They get recut by the tool. This is called "secondary cutting." It increases wear and ruins the hole quality. Internal cooling changes the physics. We pump fluid at 20 to 70 bar (roughly 300 to 1,000 psi) through the center of the spindle.

Preventing Clogging and Breakage

This high-pressure stream2 hits the bottom of the hole and reverses direction. It carries the chips out along the flutes. It acts like a conveyor belt of fluid. This is critical for materials that create long, stringy chips. The pressure breaks the chips into smaller pieces. A clean hole means the tool does not bind. It prevents the catastrophic "snap" that happens when a deep drill gets clogged. Without this internal pressure, the chips pile up in pockets, leading to friction and inevitable tool breakage.

| Feature | External Cooling | Through-Spindle Cooling |

|---|---|---|

| Flow Direction | Random/Surface | Directional/Internal |

| Chip Removal | Weak/Dispersed | Strong/Hydraulic Flush |

| Clogging Risk | High | Low |

| Pressure Impact | Minimal at depth | High at cutting edge |

Why Does Focused Cooling Directly Correlate with Extended Tool Life?

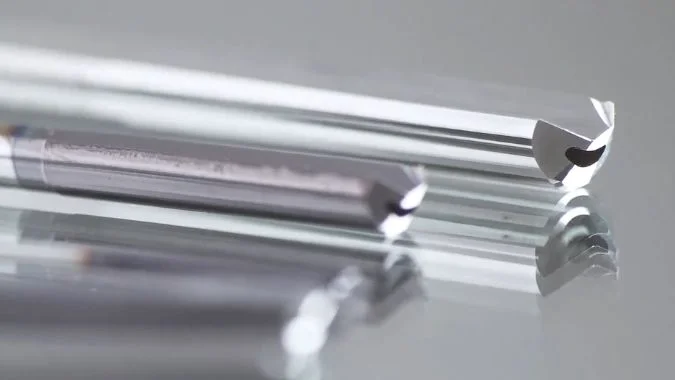

Heat softens your cutting edges, making them dull and prone to catastrophic failure.

Internal cooling attacks the heat source directly, penetrating the vapor barrier to prevent thermal softening. By maintaining a stable temperature, it reduces diffusion wear and prevents microcracks, potentially increasing tool longevity by over 200% compared to external cooling methods.

Heat is the enemy of tool life. In a deep hole, the cutting zone is an oven. The heat has nowhere to go.

The Vapor Barrier Challenge

When the temperature gets high enough, the coolant boils instantly. It forms a "vapor barrier3." This is a layer of steam that traps heat. It prevents liquid from touching the metal. Standard cooling cannot break this barrier. High-pressure internal coolant (20-70 bar) penetrates this steam layer. It reaches the tool tip directly.

Slowing Down Wear

This direct contact lowers the temperature immediately. It stops "thermal wear4." It reduces diffusion wear, where atoms from the tool migrate to the chip. It prevents adhesive wear, where the metal welds to the tool. Studies have shown that this focused cooling can extend tool life by more than 200%. It prevents "thermal shock," which causes microcracks in the carbide.

System Integration

This requires smart technology. The CNC system monitors the pressure. It ensures flow during critical stages, like drilling in and drilling out. This thermal management keeps the edge hard. It prevents plastic deformation. It allows you to run at higher speeds, making the tool last longer even under aggressive cutting parameters. You save money not just on speed, but on buying fewer replacement drills.

How Does Through-Spindle Coolant Guarantee Superior Surface Finish and Precision?

Rough finishes and oversized holes are often caused by unstable temperatures and vibration.

The system lubricates the cutting interface to reduce friction and suppress vibration. By preventing the "built-up edge" and stabilizing temperatures, it avoids thermal expansion of the workpiece, ensuring tight tolerances and a smooth, mirror-like finish.

You cannot get a precision hole if the tool is vibrating or rubbing. Internal cooling5 acts as a stabilizer for the entire process.

Lubrication in Narrow Spaces

Conventional water has difficulty forming a lubricating film deep in a hole. It is too tight. Internal cooling forces lubricant directly between the tool edge and the wall. This reduces friction. It prevents the "Built-Up Edge" (BUE), where material sticks to the cutter and acts like a rough file. A clean edge cuts cleanly. It leaves a smooth surface without scratches.

Vibration Suppression

Vibration leaves "chatter marks" or ripples. This often happens when cutting forces fluctuate due to heat or chip packing. Internal cooling creates a steady thermal state. It reduces "thermomechanical coupling." The high-pressure fluid also adds a damping effect. It increases the rigidity of the cutting action.

Dimensional Accuracy6

Heat makes things grow. If the workpiece gets hot, it expands. You drill the hole, the part cools down, and the hole shrinks. It becomes undersized. By removing heat instantly, the part stays at room temperature. The dimensions you program are the dimensions you get. This consistency is why internal cooling is a requirement for any high-precision aerospace or automotive component where tolerances are measured in microns.

Conclusion

Through-spindle coolant is not a luxury; it is a necessity for deep hole drilling. It manages heat, evacuates chips, and guarantees precision. To protect your tools and quality, you must cool from the inside out.

-

Learn about pecking cycles and their impact on machining efficiency, crucial for optimizing production processes. ↩

-

Exploring the benefits of a high-pressure stream can help you optimize your drilling processes and maintain hole quality. ↩

-

Understanding vapor barriers can help you optimize cooling strategies and enhance tool longevity in machining. ↩

-

Exploring thermal wear prevention techniques can significantly improve your machining efficiency and tool lifespan. ↩

-

Explore how internal cooling enhances precision and reduces defects in machining processes. ↩

-

Learn about the critical role of temperature control in maintaining dimensional accuracy during machining. ↩

Chris Lu

Leveraging over a decade of hands-on experience in the machine tool industry, particularly with CNC machines, I'm here to help. Whether you have questions sparked by this post, need guidance on selecting the right equipment (CNC or conventional), are exploring custom machine solutions, or are ready to discuss a purchase, don't hesitate to CONTACT Me. Let's find the perfect machine tool for your needs.